CN203556538U - Automatic sand sieving machine - Google Patents

Automatic sand sieving machine Download PDFInfo

- Publication number

- CN203556538U CN203556538U CN201320633858.2U CN201320633858U CN203556538U CN 203556538 U CN203556538 U CN 203556538U CN 201320633858 U CN201320633858 U CN 201320633858U CN 203556538 U CN203556538 U CN 203556538U

- Authority

- CN

- China

- Prior art keywords

- screen drum

- funnel

- automatic sand

- screen

- motor

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Landscapes

- Combined Means For Separation Of Solids (AREA)

Abstract

The utility model discloses an automatic sand sieving machine which comprises a funnel, wherein an opening in the bottom of the funnel is communicated with a screen drum placed transversely through a bent passage; the tail end of the screen drum adopts an opening end; the body of the screen drum adopts a screen cloth; a conveyor belt device is arranged below the screen cloth; a vibrating motor is mounted on the funnel; the screen drum is driven by the motor and led by a rotary shaft to rotate. The automatic sand sieving machine is reasonable in structure, small in labor intensity and excellent in working performance, and greatly improves the working efficiency.

Description

Technical field

The utility model relates to a kind of sand sieving machine.

Background technology

Existing sieve sand, generally adopts common screen cloth, manual operation, and labour intensity is large, inefficiency.

Summary of the invention

It is a kind of rational in infrastructure that the purpose of this utility model is to provide, the automatic sand screening machine of favorable working performance.

Technical solution of the present utility model is:

An automatic sand screening machine, is characterized in that: comprise funnel, the outlet at bottom of funnel is communicated with the screen drum of laterally placing by bent passage, and the end of screen drum is openend, and the stack shell of screen drum is screen cloth, and screen cloth below is conveyer belt apparatus; On funnel, fill vibrating motor; Screen drum is the form by motor-driven rotating shaft driven rotary.

The screw propulsion mechanism that sand is pushed to screen drum is set on described rotating shaft.

Described transfer gantry, motor-driven left and right conveying roller is equipped with at transfer gantry two ends, and conveyer belt installs around on left and right conveying roller, and transfer gantry is provided with multipair carrying roller; Every pair of carrying roller is comprised of forward and backward two carrying rollers, and forward and backward two carrying rollers are the form to middle declivity.

The utility model is rational in infrastructure, and operating efficiency improves greatly, and labour intensity is little, and service behaviour is excellent.

Accompanying drawing explanation

Below in conjunction with drawings and Examples, the utility model is described in further detail.

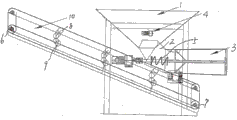

Fig. 1 is the structural representation of an embodiment of the utility model.

The specific embodiment

An automatic sand screening machine, comprises funnel 1, and the outlet at bottom of funnel is communicated with the screen drum 3 of laterally placing by bent passage 2, and the end of screen drum is openend, and the stack shell of screen drum is screen cloth, and screen cloth below is conveyer belt apparatus; On funnel, fill vibrating motor 4; Screen drum is the form by motor-driven rotating shaft driven rotary.

The screw propulsion mechanism 5 that sand is pushed to screen drum is set on described rotating shaft.

Described transfer gantry, motor-driven left and right conveying roller 6,7 is equipped with at transfer gantry two ends, and conveyer belt 10 installs around on left and right conveying roller, and transfer gantry is provided with multipair carrying roller; Every pair of carrying roller is comprised of forward and backward two carrying rollers 8,9, and forward and backward two carrying rollers are the form to middle declivity, the form low in the middle of forming, two ends are high.

During work, sand enters screen drum from funnel through bent passage, screen drum rotation under rotating shaft drives, and fine sand falls into conveyer belt from screen cloth, and coarse sand, under screw promotes, is transported to backward, from the end of screen drum, flows out.

Claims (3)

1. an automatic sand screening machine, is characterized in that: comprise funnel, the outlet at bottom of funnel is communicated with the screen drum of laterally placing by bent passage, and the end of screen drum is openend, and the stack shell of screen drum is screen cloth, and screen cloth below is conveyer belt apparatus; On funnel, fill vibrating motor; Screen drum is the form by motor-driven rotating shaft driven rotary.

2. automatic sand screening machine according to claim 1, is characterized in that: the screw propulsion mechanism that sand is pushed to screen drum is set on described rotating shaft.

3. automatic sand screening machine according to claim 1, is characterized in that: described transfer gantry, and motor-driven left and right conveying roller is equipped with at transfer gantry two ends, and conveyer belt installs around on left and right conveying roller, and transfer gantry is provided with multipair carrying roller; Every pair of carrying roller is comprised of forward and backward two carrying rollers, and forward and backward two carrying rollers are the form to middle declivity.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201320633858.2U CN203556538U (en) | 2013-10-15 | 2013-10-15 | Automatic sand sieving machine |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201320633858.2U CN203556538U (en) | 2013-10-15 | 2013-10-15 | Automatic sand sieving machine |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN203556538U true CN203556538U (en) | 2014-04-23 |

Family

ID=50506290

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201320633858.2U Expired - Fee Related CN203556538U (en) | 2013-10-15 | 2013-10-15 | Automatic sand sieving machine |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN203556538U (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN105414002A (en) * | 2015-11-24 | 2016-03-23 | 洛阳开拓新能源开发有限公司 | Biomass particle raw material impurity removing device |

| CN110404758A (en) * | 2019-08-30 | 2019-11-05 | 杭州富阳飞尚装饰工程有限公司 | A kind of interim sand sieving machine of interior decoration |

-

2013

- 2013-10-15 CN CN201320633858.2U patent/CN203556538U/en not_active Expired - Fee Related

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN105414002A (en) * | 2015-11-24 | 2016-03-23 | 洛阳开拓新能源开发有限公司 | Biomass particle raw material impurity removing device |

| CN110404758A (en) * | 2019-08-30 | 2019-11-05 | 杭州富阳飞尚装饰工程有限公司 | A kind of interim sand sieving machine of interior decoration |

| CN110404758B (en) * | 2019-08-30 | 2021-01-12 | 杭州富阳飞尚装饰工程有限公司 | Interim screening sand machine that interior decoration used |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN204232230U (en) | A kind of Chinese chestnut automatic peeling machine | |

| CN203556538U (en) | Automatic sand sieving machine | |

| CN201613562U (en) | Uniform feeding device for herbal medicine slicing machine | |

| CN102940304A (en) | Garlic clove rubbing machine | |

| CN105964491B (en) | A kind of semi-automatic O-ring assembling oiling device | |

| CN104971878A (en) | Sand screening machine for building | |

| CN204867167U (en) | Angle steel loading attachment | |

| CN203228330U (en) | Height-adjustable plastic conveying roller press | |

| CN203446478U (en) | Rapid peanut kernel peeling machine | |

| CN202722395U (en) | Fish flesh bone removing device | |

| CN108212313A (en) | A kind of broken synchronized model device of sieve feed powder for building gravel | |

| CN103896049A (en) | Conveying devices for bagged spring belts | |

| CN203140282U (en) | Vibrating type lotus seed sorting device | |

| CN108792420A (en) | A kind of ox, which is butchered, uses conveying device | |

| CN202774013U (en) | Cooked-egg shelling device | |

| CN204957717U (en) | Brush hair flattening conveying system | |

| CN203389862U (en) | Camellia seed and shell separating machine | |

| CN208265418U (en) | A kind of coiled plastic material cutting means | |

| CN201813810U (en) | Peanut sheller | |

| CN204297641U (en) | A kind of scraper feeding machine | |

| CN203292054U (en) | Sand screening machine | |

| CN204656717U (en) | A kind of full-automatic powder de-ironing machine | |

| CN204093703U (en) | The husky machine of automatic screening | |

| CN204996553U (en) | Sand magnetic separation device | |

| CN203648855U (en) | Shrimp sieving machine |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| CF01 | Termination of patent right due to non-payment of annual fee | ||

| CF01 | Termination of patent right due to non-payment of annual fee |

Granted publication date: 20140423 Termination date: 20201015 |