CN203067350U - Chlorine centrifugal compressor impeller - Google Patents

Chlorine centrifugal compressor impeller Download PDFInfo

- Publication number

- CN203067350U CN203067350U CN 201320073731 CN201320073731U CN203067350U CN 203067350 U CN203067350 U CN 203067350U CN 201320073731 CN201320073731 CN 201320073731 CN 201320073731 U CN201320073731 U CN 201320073731U CN 203067350 U CN203067350 U CN 203067350U

- Authority

- CN

- China

- Prior art keywords

- impeller

- chlorine

- blades

- long

- blade

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Landscapes

- Structures Of Non-Positive Displacement Pumps (AREA)

Abstract

The utility model provides a chlorine centrifugal compressor impeller. An upper impeller cover and a lower impeller cover are arranged on the impeller; a shaft hole is formed in the upper impeller cover; a chlorine inlet is formed in the lower impeller cover; long blades and short blades are alternately arranged between the two impeller covers in a radial manner; and each long blade is formed by connecting a straight line section and an arc line section in a transition manner. The length of the arc line section a of each long blade is twice that of the straight line section b of the long blade. The length of each short blade is equal to that of the straight line section b of each long blade. According to the utility model, the long blades, formed by connecting the straight line sections and the arc line sections, and the short blades are alternately arranged on the impeller, the arc line sections of the long blades facilitate suction of chlorine, and the straight line sections of the long blades and the linear short blades can increase the centrifugal force, so that chlorine compression flow and outlet pressure can be improved. Therefore, the chlorine centrifugal compressor impeller is suitable for being applied to centrifugal compressors for chlorine compression.

Description

Technical field

The utility model provides the chlorine Centrufugal compressor impeller that mechanical field is used for the chlorine compression.

Background technique

Be used for single blade that the chlorine gas compressor impeller is provided with radial arrangement at present, therefore low to the chlorine compression ratio, cause flow little.Therefore when needs improve chlorine flowrate, can not satisfy the demand.

Summary of the invention

In order to improve chlorine compression flow and pressure, the utility model provides the chlorine Centrufugal compressor impeller.This impeller solves the technical problem that increases chlorine centrifugal compressor flow and pressure by alternate linear leaf and the short blade of arranging that distribute at impeller.

The scheme that the utility model technical solution problem adopts is:

Be provided with upper and lower impeller cover at impeller, impeller cover on top is provided with axis hole, impeller cover in the bottom is provided with chlorine inlet, and radial between two impeller covers have linear leaf and short blade alternately, and linear leaf is connected and composed by straightway and arc transition.

The arc a length of described linear leaf is 2 times of straightway b length.

The equal in length of the straightway b of the length of described short blade and linear leaf.

Good effect, because the utility model alternate setting is constituted by straightway and arc on impeller linear leaf and lineal shape short blade, the arc of linear leaf is conducive to draw chlorine, and linear leaf straightway and rectilinear short blade can increase centrifugal force, thereby can improve chlorine compression flow and outlet pressure.Suitable centrifugal compressor applications as the chlorine compression.

Description of drawings

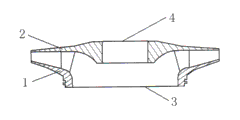

Fig. 1 is the utility model blade wheel structure figure

Fig. 2 arranges schematic representation for the utility model impeller blade

Among the figure, 1. impeller, 2. impeller cover, 3. chlorine inlet, 4. axis hole, 5. linear leaf, 6. short blade.

Embodiment

According to the figure, be provided with upper and lower impeller cover 2 at impeller 1, the impeller cover on top is provided with axis hole 4, and the impeller cover in the bottom is provided with chlorine inlet 3, radial between two impeller covers have linear leaf 5 and short blade 6 alternately, and linear leaf is connected and composed by straightway b and arc a transition.

The arc a length of described linear leaf is 2 times of straightway b length.

The equal in length of the straightway b of the length of described short blade and linear leaf.

The utility model characteristics:

Because the blade of impeller is made up of linear leaf and rectilinear short blade that straightway and arc transition connect and compose, wherein, linear leaf is beneficial to and increases the chlorine intake, and the straightway of linear leaf and rectilinear short blade are beneficial to the centrifugal force that increases impeller and the pressure of dishing out, thereby, the chlorine gas compressor flow of the impeller of employing the utility model structure is big, and the outlet pressure height is particularly suitable for the chlorine transportation art and uses.

Claims (1)

1. chlorine Centrufugal compressor impeller is characterized in that:

Be provided with upper and lower impeller cover (2) at impeller (1), impeller cover on top is provided with axis hole (4), impeller cover in the bottom is provided with chlorine inlet (3), radial between two impeller covers have linear leaf (5) and short blade (6) alternately, and linear leaf is connected and composed by straightway b and arc a transition;

The arc a length of described linear leaf is 2 times of straightway b length;

The equal in length of the straightway b of the length of described short blade and linear leaf.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN 201320073731 CN203067350U (en) | 2013-02-17 | 2013-02-17 | Chlorine centrifugal compressor impeller |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN 201320073731 CN203067350U (en) | 2013-02-17 | 2013-02-17 | Chlorine centrifugal compressor impeller |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN203067350U true CN203067350U (en) | 2013-07-17 |

Family

ID=48766140

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN 201320073731 Expired - Lifetime CN203067350U (en) | 2013-02-17 | 2013-02-17 | Chlorine centrifugal compressor impeller |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN203067350U (en) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN104074798A (en) * | 2014-07-29 | 2014-10-01 | 成都赛乐化新机电有限公司 | Impeller assembly for chlorine gas compressor |

| CN104500426A (en) * | 2014-12-31 | 2015-04-08 | 东莞市锐天机电科技有限公司 | Energy-saving high-speed air blower |

| CN104564812A (en) * | 2013-10-21 | 2015-04-29 | 苏州宝时得电动工具有限公司 | Impeller and fan |

| CN105723094A (en) * | 2013-09-12 | 2016-06-29 | 诺沃皮尼奥内股份有限公司 | Liquid tolerant impeller for centrifugal compressors |

-

2013

- 2013-02-17 CN CN 201320073731 patent/CN203067350U/en not_active Expired - Lifetime

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN105723094A (en) * | 2013-09-12 | 2016-06-29 | 诺沃皮尼奥内股份有限公司 | Liquid tolerant impeller for centrifugal compressors |

| CN105723094B (en) * | 2013-09-12 | 2019-02-26 | 诺沃皮尼奥内股份有限公司 | The impeller of tolerance liquid for centrifugal compressor |

| US10920788B2 (en) | 2013-09-12 | 2021-02-16 | Nuovo Pignone Srl | Liquid tolerant impeller for centrifugal compressors |

| CN104564812A (en) * | 2013-10-21 | 2015-04-29 | 苏州宝时得电动工具有限公司 | Impeller and fan |

| CN104074798A (en) * | 2014-07-29 | 2014-10-01 | 成都赛乐化新机电有限公司 | Impeller assembly for chlorine gas compressor |

| CN104500426A (en) * | 2014-12-31 | 2015-04-08 | 东莞市锐天机电科技有限公司 | Energy-saving high-speed air blower |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN203067350U (en) | Chlorine centrifugal compressor impeller | |

| CN202091251U (en) | Intermediate blade of compressor with hub with diameter of phi 940 | |

| CN203130596U (en) | Serial inducer | |

| CN202646156U (en) | Double-tongue volute-casing centrifugal pump | |

| CN201982359U (en) | Wear ring sealing structure of multistage centrifugal pump | |

| CN204327506U (en) | First stage impeller double-sucking type axial subdivision two end supports multistage centrifugal pump | |

| CN2791302Y (en) | High-performace balancing-type hydraulic vane pump | |

| CN205779755U (en) | The centrifugal water pump that a kind of raising is the most high-lift | |

| CN204677491U (en) | The half-closed cycloid impeller of auto pump | |

| CN202048023U (en) | Primary blade of large-sized high-rotation-speed air compressor | |

| CN204099281U (en) | A kind of large-scale volute pump pump case | |

| CN203130598U (en) | Closed type impeller | |

| CN101881283A (en) | High-efficiency suction chamber structure with double suction pumps | |

| CN201705730U (en) | Volute type structure of tangent pump body | |

| CN202545285U (en) | Impeller three-flow-direction configuration electric submersible pump connecting section with pressure relief holes | |

| CN203756553U (en) | Double-suction forced-drain submerged pump | |

| CN2921376Y (en) | Electric fuel pump | |

| CN203189323U (en) | Low-noise low-pressure-pulsation double-suction split centrifugal pump | |

| CN202545342U (en) | Multi-stage high-lift single-suction submerged motor pump configured for impeller three-flow structure | |

| CN202031882U (en) | Novel single-stage double-suction volute chamber open centrifugal pump | |

| CN203809312U (en) | High-efficiency vertical pipeline pump | |

| CN204511962U (en) | A kind of double shrouded wheel | |

| CN203548200U (en) | Vane of vane pump | |

| CN204003470U (en) | A kind of novel three leaf Roots air blower rotors | |

| CN202165304U (en) | Novel first-stage double suction impeller of pump |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| CX01 | Expiry of patent term |

Granted publication date: 20130717 |

|

| CX01 | Expiry of patent term |