CN202943101U - Cap tightening clamping piece of tube-making machine - Google Patents

Cap tightening clamping piece of tube-making machine Download PDFInfo

- Publication number

- CN202943101U CN202943101U CN 201220706718 CN201220706718U CN202943101U CN 202943101 U CN202943101 U CN 202943101U CN 201220706718 CN201220706718 CN 201220706718 CN 201220706718 U CN201220706718 U CN 201220706718U CN 202943101 U CN202943101 U CN 202943101U

- Authority

- CN

- China

- Prior art keywords

- hole

- clamping piece

- tube

- making machine

- cap tightening

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Landscapes

- Holders For Apparel And Elements Relating To Apparel (AREA)

Abstract

The utility model discloses a cap tightening clamping piece of a tube-making machine. The clamping piece comprises a body, wherein the body is of an arc-shaped structure, is provided with two cylindrical through holes at the left end, namely a first through hole and a second through hole respectively from top to bottom, and is provided with a circular through hole at the right end; and the diameter of the second through hole at the left end of the body is larger than that of the first through hole. The cap tightening clamping piece has the characteristics that structure design is reasonable and use is convenient.

Description

Technical field

The utility model relates to a kind of engineering goods, is the tight cap intermediate plate of a kind of tuber specifically.

Background technology

The tight cap intermediate plate of some tubers on the existing market, structural design is unreasonable, uses inconvenient.

Summary of the invention

The utility model provides a kind of tuber tight cap intermediate plate.

The purpose of this utility model is to solve the more existing tight cap intermediate plate of tubers, and structural design is unreasonable, inconvenient problem with use.

The technical scheme that its technical problem that solves the utility model adopts is: the tight cap intermediate plate of a kind of tuber, comprise body, described body is arcuate structure, its left end is provided with two columniform through holes, be respectively from top to bottom the first through hole and the second through hole, right-hand member is provided with the through hole of a circle, and the diameter of described body left end the second through hole is greater than the diameter of the first through hole.

The utlity model has reasonable in design, characteristics easy to use.

Description of drawings

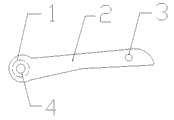

Fig. 1 is structure top view of the present utility model.

Fig. 2 is structure front view of the present utility model.

The specific embodiment

The utility model is described in further detail below in conjunction with drawings and Examples:

As shown in the figure, the utility model comprises body 2, described body 2 is arcuate structure, its left end is provided with two columniform through holes, be respectively from top to bottom the first through hole 4 and the second through hole 1, right-hand member is provided with the through hole 3 of a circle, and the diameter of described body left end the second through hole 1 is greater than the diameter of the first through hole 4.

Claims (2)

1. the tight cap intermediate plate of tuber, comprise body, and it is characterized in that: described body is arcuate structure, and its left end is provided with two columniform through holes, is respectively from top to bottom the first through hole and the second through hole, and right-hand member is provided with the through hole of a circle.

2. the tight cap intermediate plate of a kind of tuber according to claim 1, it is characterized in that: the diameter of described body left end the second through hole is greater than the diameter of the first through hole.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN 201220706718 CN202943101U (en) | 2012-12-20 | 2012-12-20 | Cap tightening clamping piece of tube-making machine |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN 201220706718 CN202943101U (en) | 2012-12-20 | 2012-12-20 | Cap tightening clamping piece of tube-making machine |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN202943101U true CN202943101U (en) | 2013-05-22 |

Family

ID=48418817

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN 201220706718 Expired - Fee Related CN202943101U (en) | 2012-12-20 | 2012-12-20 | Cap tightening clamping piece of tube-making machine |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN202943101U (en) |

-

2012

- 2012-12-20 CN CN 201220706718 patent/CN202943101U/en not_active Expired - Fee Related

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN202943101U (en) | Cap tightening clamping piece of tube-making machine | |

| CN202560708U (en) | Fixed connecting member | |

| CN203184525U (en) | Locating block of toothpaste tuber capping motor | |

| CN203283476U (en) | Nozzle positioning block of toothpaste filling machine | |

| CN202943103U (en) | Cap tightening mechanism connecting block of tube-making machine | |

| CN202943104U (en) | Tube-making machine chute steel wire clip | |

| CN203297193U (en) | Toothpaste filling machine cylinder connecting piece | |

| CN202963080U (en) | Front cover of nut fastening mechanism for tubing machine | |

| CN203184514U (en) | Tube body transferring device upper support of toothpaste tube manufacturing machine | |

| CN203294327U (en) | Toothpaste filling machine filling position pressing block positioning piece | |

| CN202624447U (en) | Integrated bicycle lock | |

| CN201934470U (en) | Screw | |

| CN202963079U (en) | Thimble on nut fastening clip of tubing machine | |

| CN203184523U (en) | Front-end three-jaw clamping piece of toothpaste tuber three-jaw mechanism | |

| CN202868259U (en) | Photoelectric eye support of tube machine | |

| CN202992534U (en) | Lower base of cap-fastening mechanism of pipe-making machine | |

| CN202867532U (en) | Connecting rod of filling machine | |

| CN202944768U (en) | Baffle plate for chute of pipe making machine | |

| CN203495074U (en) | Front-end part of tube cap device for toothpaste tube-making machine | |

| CN202742595U (en) | Cooling bracket | |

| CN203294326U (en) | Toothpaste filling machine upper swing rod connecting piece | |

| CN203294325U (en) | Toothpaste filling machine clamp tail shaft | |

| CN203508856U (en) | Conveying belt baffle of toothpaste tube making machine | |

| CN203184524U (en) | Three-jaw fixing support of toothpaste tuber three-jaw mechanism | |

| CN203184484U (en) | Steel belt sliding wheel of toothpaste tube making machine |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| C17 | Cessation of patent right | ||

| CF01 | Termination of patent right due to non-payment of annual fee |

Granted publication date: 20130522 Termination date: 20131220 |