CN202542815U - Multi-liquid quantitative machine - Google Patents

Multi-liquid quantitative machine Download PDFInfo

- Publication number

- CN202542815U CN202542815U CN2012201370835U CN201220137083U CN202542815U CN 202542815 U CN202542815 U CN 202542815U CN 2012201370835 U CN2012201370835 U CN 2012201370835U CN 201220137083 U CN201220137083 U CN 201220137083U CN 202542815 U CN202542815 U CN 202542815U

- Authority

- CN

- China

- Prior art keywords

- liquid

- quantitative machine

- peristaltic pump

- fluid

- outlet

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 239000007788 liquid Substances 0.000 title claims abstract description 79

- 230000002572 peristaltic effect Effects 0.000 claims abstract description 19

- 239000012530 fluid Substances 0.000 claims description 15

- 238000000034 method Methods 0.000 abstract description 3

- 238000007599 discharging Methods 0.000 abstract 1

- 230000002950 deficient Effects 0.000 description 1

- 238000012856 packing Methods 0.000 description 1

Images

Landscapes

- Devices For Dispensing Beverages (AREA)

Abstract

The utility model relates to a multi-liquid quantitative machine which comprises a plurality of liquid suction peristaltic pumps and at least one liquid distribution outlet, wherein a plurality of liquid storage containers are respectively connected to liquid suction inlets of the plurality of liquid suction peristaltic pumps through pipelines, liquid output ends of the plurality of liquid suction peristaltic pumps are respectively connected with the pipelines, and tail ends of the pipelines for discharging liquid are gathered and then communicated with the at least one liquid distribution outlet. According to the multi-liquid quantitative machine, multiple liquids can be mixed, and manual mixing after distribution is not needed. The liquid suction inlets of the liquid distribution outlet are directly connected with the plurality of liquid storage containers so as to avoid secondary pollution generated in the process that a liquid is transferred from an original liquid storage device to a liquid storage box of the quantitative machine. The multi-liquid quantitative machine has the advantages of simple structure, strong practicability and wide application range.

Description

Technical field

The utility model relates to a kind of many kinds liquid quantitative machine.

Background technology

At present; The structure of the many kinds liquid quantitative machine on the market is generally: different types of liquid is stored in respectively in the different liquid Storage Box of quantitative machine; Fluid pipeline one end of each kind is connected in its pairing Storage Box, and the other end is connected to the liquid outlet of quantitative machine through a switch.This structure has following defective: need earlier liquid to be taken out from the original packing bag, pour in the said Storage Box this process easy generation of secondary pollution; As the liquid that needs plurality of classes to mix, then need open the pairing switch of each kind earlier, receive liquid, with the artificial allotment of liquid of all categories, should use inconvenience again.

The utility model content

In view of this, be necessary, provide a kind of later-model easy to use and can avoid many kinds liquid quantitative machine of secondary pollution to the problem of mentioning in the background technology.

The purpose of the utility model realizes through following technical scheme:

A kind of many kinds liquid quantitative machine, it comprises:

A plurality of liquid suck peristaltic pump and at least one liquid distributes outlet;

The fluid intake that said a plurality of liquid sucks peristaltic pump inserts a plurality of liquid containers through pipeline respectively; Said a plurality of liquid sucks the liquid mouth difference connecting tube of peristaltic pump, and the end that is used for trickle of these a plurality of pipelines gathers the back and distributes outlet to be communicated with said at least one liquid.

The quantity that said liquid sucks peristaltic pump is 2-12.

Said many kinds liquid quantitative machine also comprises a fluid centralised arrangement; Said at least one liquid distributes outlet to be arranged on the said fluid centralised arrangement, and the liquid mouth institute bonded assembly pipe end of said liquid suction peristaltic pump is arranged in the said fluid centralised arrangement and with said at least one liquid and distributes the inlet of outlet to be communicated with.

Compared with prior art, the advantage of the utility model is:

1, because set a plurality of liquid suck peristaltic pumps can work simultaneously, and all liq sucks the liquid that peristaltic pump sucks and all can distribute outlet be communicated with same liquid simultaneously, so can realize the liquid mixing of many kinds, artificial mixed after need not to distribute;

2, said liquid distributes a plurality of liquid containers of fluid intake direct connection of outlet, has avoided being transferred in the original storage device of liquid by liquid issuable secondary pollution in the process in the fluid storage box of quantitative machine;

3, simple in structure, practical, have wide range of applications.

Description of drawings

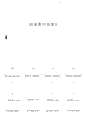

Fig. 1 is the structural principle scheme drawing of the utility model.

The specific embodiment

As shown in Figure 1, kind liquid quantitative machine more than the utility model, it comprises: four liquid suck peristaltic pump 1, fluid centralised arrangements 3 and four liquid being arranged on the said fluid centralised arrangement 3 distribute outlet 5; The fluid intake 11 that these four liquid suck peristaltic pump 1 inserts four liquid containers 2 through pipeline respectively; Said a plurality of liquid sucks the liquid mouth difference connecting tube of peristaltic pump 1; The end that is used for trickle of these a plurality of pipelines is summarized in the said fluid centralised arrangement 3, distributes outlet 5 to be communicated with said four liquid again.

The direction of arrow is liquid flow direction among Fig. 1.

The quantity that said liquid sucks peristaltic pump 1 is chosen as 2-12.

The above embodiment has only expressed several kinds of embodiments of the utility model, and it describes comparatively concrete and detailed, but can not therefore be interpreted as the restriction to the utility model claim.Should be pointed out that for the person of ordinary skill of the art under the prerequisite that does not break away from the utility model design, can also make some distortion and improvement, these all belong to the protection domain of the utility model.Therefore, the protection domain of the utility model patent should be as the criterion with accompanying claims.

Claims (3)

1. the machine of kind liquid quantitative more than a kind is characterized in that: comprising:

A plurality of liquid suck peristaltic pump and at least one liquid distributes outlet;

The fluid intake that said a plurality of liquid sucks peristaltic pump inserts a plurality of liquid containers through pipeline respectively; Said a plurality of liquid sucks the liquid mouth difference connecting tube of peristaltic pump, and the end that is used for trickle of these a plurality of pipelines gathers the back and distributes outlet to be communicated with said at least one liquid.

2. many kinds liquid quantitative machine according to claim 1 is characterized in that, the quantity that said liquid sucks peristaltic pump is 2-12.

3. many kinds liquid quantitative machine according to claim 1; It is characterized in that; Said many kinds liquid quantitative machine also comprises a fluid centralised arrangement; Said at least one liquid distributes outlet to be arranged on the said fluid centralised arrangement, and the liquid mouth institute bonded assembly pipe end of said liquid suction peristaltic pump is arranged in the said fluid centralised arrangement and with said at least one liquid and distributes the inlet of outlet to be communicated with.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2012201370835U CN202542815U (en) | 2012-04-01 | 2012-04-01 | Multi-liquid quantitative machine |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2012201370835U CN202542815U (en) | 2012-04-01 | 2012-04-01 | Multi-liquid quantitative machine |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN202542815U true CN202542815U (en) | 2012-11-21 |

Family

ID=47163481

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN2012201370835U Expired - Lifetime CN202542815U (en) | 2012-04-01 | 2012-04-01 | Multi-liquid quantitative machine |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN202542815U (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN110785356A (en) * | 2017-06-26 | 2020-02-11 | 3M创新有限公司 | Liquid additive delivery system and method for ensuring that substantially only liquid is disposed within a container |

-

2012

- 2012-04-01 CN CN2012201370835U patent/CN202542815U/en not_active Expired - Lifetime

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN110785356A (en) * | 2017-06-26 | 2020-02-11 | 3M创新有限公司 | Liquid additive delivery system and method for ensuring that substantially only liquid is disposed within a container |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN202542815U (en) | Multi-liquid quantitative machine | |

| CN204261574U (en) | A kind of double helix pipe-line mixer | |

| MX2023007107A (en) | Dental amalgam separation and recycling system. | |

| CN202971352U (en) | Jet pump for oil return of water source heat pump air conditioning compressor | |

| CN202463254U (en) | Ink-injected pen refill | |

| CN203584795U (en) | Novel circulation oil pump | |

| CN103240235A (en) | Plastic film cleaning apparatus | |

| CN202939505U (en) | Automatic adding system used in liquid preparation | |

| CN207905101U (en) | A kind of integrated pump station Accrete clearing device | |

| CN105642142A (en) | Liquid mixer capable of being directly connected into liquid pipeline | |

| CN202460518U (en) | Novel separator pump | |

| CN201851047U (en) | Multistage cyclone desanding device | |

| CN208594280U (en) | Multidirectional inlet type actication of culture tank | |

| CN203856698U (en) | Diaphragm pump | |

| CN202449445U (en) | Pipe orifice mechanism for horizontal storage tank | |

| CN202494250U (en) | Liquid distributor | |

| CN202832451U (en) | Chemical medicine adding device of multifunctional drilling fluid | |

| CN203329668U (en) | Sanding and paint-mixing device used for paint production | |

| CN202613946U (en) | Microwave drying cooling water device | |

| CN202900227U (en) | Gas and liquid separation device for oil well | |

| CN203159258U (en) | Water treatment chemicals charging device | |

| CN202707318U (en) | Oil transportation device of diesel engine | |

| CN109908777A (en) | A kind of preliminary mixing arrangement of new material reagent | |

| CN208745096U (en) | The defoaming device of wind electricity blade resin | |

| CN202355221U (en) | Bagged water connector |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| C41 | Transfer of patent application or patent right or utility model | ||

| TR01 | Transfer of patent right |

Effective date of registration: 20150924 Address after: 519000, Guangdong, Zhuhai District, Doumen Toyama Industrial Zone, Nanan village, building No. 2 on the third floor Patentee after: ZHUHAI MINGLE ELECTRIC APPLIANCE CO., LTD. Address before: 3 building, 2 floor, CXS Science Park, Mount Everest Road, dry town, Doumen District, Zhuhai, Guangdong, 519000 Patentee before: Zhuhai Minle Industry & Trade Co., Ltd. |

|

| CX01 | Expiry of patent term | ||

| CX01 | Expiry of patent term |

Granted publication date: 20121121 |