Full-automatic ability of swimming bottle managing machine

Technical field

The utility model belongs to mechanical equipment technical field, especially relates to a kind of full-automatic ability of swimming bottle managing machine.

Background technology

The production Technology of modern brewery finalizes the design almost, and in the whole process of production, the packing production of beer is that the technology content to equipment has certain requirement in the whole process of production.Simultaneously, beer packing also is with a maximum link of operation in the whole process of production.Sack bag, woven bag packing are mainly adopted in the appearance of the recovery of beer bottle and new bottle, and the arrangement that need the beer bottle in sack bag, the woven bag be taken out one by one is good so that get into next link.Because the beer bottle quantity that beer factory needs every day is huge; Need great amount of manpower to put bottle in order; Traditional beer enterprise all is to adopt the artificial arrangement of accomplishing bottle, just through manual work bottle is taken out bottle in containers such as woven bag one by one, erects then; It is extremely low that this kind mode is produced effectiveness, and required artificial quantity is huge and labor strength is also high.

Present domestic each employed beer vial of tame beer manufactory, most of employing bale packing is main, and the bottle of these bale packings can not directly get on the Beer Production streamline.If bottle will get into production line; Must adopt and artificial take out each bottle one by one in the gunnysack that (bottle in the gunnysack must not arbitrarily be poured out; Otherwise can the bottleneck seals at be damaged, that just equals bottle and scraps), put it into again and mould in the case; To mould case then and move on the defeated punch-out equipment, unload bottle by Cargo unloader.Through above-mentioned former complicated step at first, also need spend huge manpower, material resources, financial resources (unsafe factor) etc.Also give each big, in, small-sized beer producer has increased production cost, directly reduces the business economic benefit.For the damage, the automaticity that improves filling production lines that in Beer Production, reduce human factor, reduce labor strength, reduce production costs, it is present required design a bottle managing machine that can put bottle (clean, bottle is erected) automatically in order.

The utility model content

The utility model technical problem to be solved is: a kind of full-automatic ability of swimming bottle managing machine that can clean bottle, the automatic erect bottle of ability, less manpower automatically and increase benefit is provided.

The technical scheme that the utility model is taked is: a kind of full-automatic ability of swimming bottle managing machine; Comprise frame; Be provided with bottle washing apparatus successively, carry bottle-sorting device, bottle erecting device and go out bottle by job order on the described frame; Described bottle washing apparatus comprises water tank, and water tank is positioned at an end of frame, and water tank is provided with the bubble generator.

Described water tank bottom is provided with broken bottle transport, comprises that an end is positioned at water tank bottom and the other end is positioned at the outer transport tape of water tank, and transport tape connects drive motors through transmission device.

The beneficial effect of the utility model is: the full-automatic ability of swimming bottle managing machine of the utility model can realize fully that automation can realize the cleaning of body, removes label, impurity on the body automatically, less manpower and increasing benefit.

Description of drawings

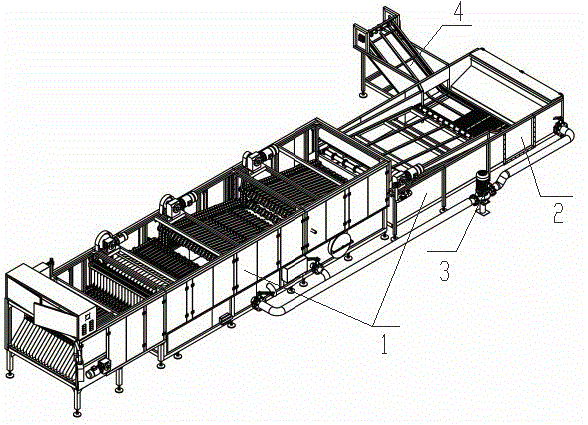

Fig. 1 is the utility model schematic perspective view.

Among the figure, 1, frame, 2, water tank, 3, bubble produces gas, 4, transport tape.

The specific embodiment

Below in conjunction with accompanying drawing the utility model is further specified.

With reference to shown in Figure 1; A kind of full-automatic ability of swimming bottle managing machine of the utility model; Comprise frame 1, be provided with bottle washing apparatus successively, carry bottle-sorting device, bottle erecting device and go out bottle by job order on the described frame 1 that described bottle washing apparatus comprises water tank 2; Water tank 2 is positioned at an end of frame 1, and water tank 2 inwalls are provided with bubble generator 3.Wherein the bubble generator can be purchased from market; Tracheae the inner of described bubble generation gas 3 is arranged on the inwall and the inner bottom part of water tank 2; The bubble of being convenient to produce is come-up from water tank 2 waters surface below, attached to the outer surface of beer bottle, under the buoyancy of a large amount of bubbles; Things such as label on the beer bottle outer surface and impurity are floated together, play the effect of cleaning beer bottle.In addition, the beer bottle after having cleaned enters into next link carrying bottle-sorting device, bottle erecting device and go out under the effect of bottle.Wherein carry bottle-sorting device, bottle erecting device and go out bottle and repeat no more here with existing bottle managing machine operation principle is consistent, the inventive point of the utility model just is to clean automatically the label and the impurity on beer bottle surface, less manpower and increasing benefit.

Described water tank 2 bottoms are provided with broken bottle transport, comprise that an end is positioned at water tank 2 bottoms and the other end is positioned at the transport tape 4 outside the water tank 2, and transport tape 4 connects drive motors through transmission device.Owing in the work, a large amount of beer bottles is poured in the water tank 2, can be occurred the fragmentation of beer bottle unavoidably; Broken bottle sheet after the fragmentation all can sink to the inner bottom part of water tank 2, because the interior ground of water tank 2 is not provided with transport tape 4, that is to say; Broken bottle sheet all drops on transport tape 4; Under the drive of motor, transport tape 4 takes the broken bottle sheet on it outside water tank 2 to, realizes the cleaning work of broken bottle sheet.