CN202498030U - Multilayer screen - Google Patents

Multilayer screen Download PDFInfo

- Publication number

- CN202498030U CN202498030U CN2012200854041U CN201220085404U CN202498030U CN 202498030 U CN202498030 U CN 202498030U CN 2012200854041 U CN2012200854041 U CN 2012200854041U CN 201220085404 U CN201220085404 U CN 201220085404U CN 202498030 U CN202498030 U CN 202498030U

- Authority

- CN

- China

- Prior art keywords

- screen

- screen cloth

- sieve pore

- sieve aperture

- utility

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 239000004744 fabric Substances 0.000 claims description 34

- 239000011148 porous material Substances 0.000 abstract 6

- 229910000831 Steel Inorganic materials 0.000 abstract 1

- 238000005299 abrasion Methods 0.000 abstract 1

- 150000001875 compounds Chemical class 0.000 abstract 1

- 239000004615 ingredient Substances 0.000 abstract 1

- 230000002787 reinforcement Effects 0.000 abstract 1

- 239000010959 steel Substances 0.000 abstract 1

- 238000012216 screening Methods 0.000 description 6

- 239000000463 material Substances 0.000 description 5

- 230000003014 reinforcing effect Effects 0.000 description 2

- 239000000126 substance Substances 0.000 description 2

- 238000003466 welding Methods 0.000 description 2

- 230000002950 deficient Effects 0.000 description 1

- 239000013536 elastomeric material Substances 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 238000005194 fractionation Methods 0.000 description 1

- 229910052500 inorganic mineral Inorganic materials 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 239000011707 mineral Substances 0.000 description 1

- 230000002035 prolonged effect Effects 0.000 description 1

- 238000010298 pulverizing process Methods 0.000 description 1

Images

Landscapes

- Combined Means For Separation Of Solids (AREA)

Abstract

The utility model discloses a multilayer screen, composed of an upper screen, a middle screen, a lower screen, a sieve pore A, a sieve pore B and a sieve pore C, wherein the dimension of the sieve pore A of the upper screen is more than or equal to 28*30mm, the dimension of the sieve pore B of the middle screen is more than or equal to 18*32mm, and the dimension of the sieve pore C of the lower screen is less than or equal to 10*34mm. The screens are interwoven and welded by steel reinforcements, and surfaces of the screens are formed by mixing synthetic size added with rubber compound ingredients. The multilayer screen disclosed by the utility model has the advantages of light weight, high abrasion resistance, low noise in operation, high efficiency and long service life.

Description

Technical field

The utility model belongs to the vibration screening machinery field, mainly relates to the multi-deck screen net vibrating screen of higher disposal ability and screening efficiency.

Background technology

The classification of mineral grain generally is to be accomplished by vibratory sieve, is multilayer and need the screen cloth of the used vibratory sieve of material of multiple fractionation.Because the number of plies of screen cloth that vibratory sieve adopts is relevant with the granularity requirements of stock grading, so how much a stage material of the routine maximum of accounting has a direct relation in the disposal ability of vibratory sieve and the material composition.Existing multilayer vibratory sieve is in operation, above the more one deck screen cloth of material, and windrow and putty easily.Thicker material moves on screen cloth, has directly influenced the disposal ability and the screening efficiency of vibratory sieve.

The utility model content

In order to overcome the defective of above-mentioned prior art, the utility model provides a kind of multilayer screen cloth, and described multilayer screen cloth can effectively improve the screening efficiency of vibratory sieve lower screen.

The utility model is realized through following scheme; A kind of multilayer screen cloth; Form by upper strata screen cloth, middle level screen cloth, lower screen, sieve aperture A, sieve aperture B, sieve aperture C; The sieve aperture A size of said upper strata screen cloth is made as>=28x30mm, and the sieve aperture B size of middle level screen cloth is made as>=18x32mm, and the sieve aperture C size of lower screen is made as≤10x34mm.

Said screen cloth is by the reinforcing bar welding that interweaves, and the surface all adopts synthetic size to add that rubber chemicals are mixing to form, and makes rubber and screen cloth that high strength bond property arranged, and makes Rubber screen that good draftability arranged at work, guarantees that rubber can not break away from.

The utility model is compared the outstanding advantage of prior art: the screen size that reduces upper strata screen cloth, middle level screen cloth, lower screen is crossed by described multi-deck screen Netcom; Make not only that the ore grain size that drops down onto lower screen is corresponding to be reduced; And effectively raise the screening efficiency of vibratory sieve lower screen, thereby impelled ore crusher to fully play maximal efficiency greatly; The utility model prolonged the service life of vibration screen, and wire side is smooth, tensile strength is good because the use elastomeric material has improved the endurance life of screen cloth, and plasticity is big, has reduced working strength of workers and production cost.

Description of drawings

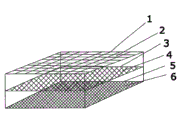

Fig. 1 is the structural representation of a kind of multilayer screen cloth of the utility model;

Wherein: 1-upper strata screen cloth; 2-sieve aperture A; 3-middle level screen cloth; 4-sieve aperture B; The 5-lower screen; 6-sieve aperture C.

The specific embodiment

As shown in Figure 1: a kind of multilayer screen cloth; Form by upper strata screen cloth 1, middle level screen cloth 3, lower screen 5, sieve aperture A2, sieve aperture B4, sieve aperture C6; The sieve aperture A2 size of said upper strata screen cloth 1 is made as>=28x30mm; The sieve aperture B4 size of middle level screen cloth 3 is made as>=18x32mm, and the sieve aperture C6 size of lower screen 5 is made as≤10x34mm.

Said screen cloth is by the reinforcing bar welding that interweaves, and the surface all adopts synthetic size to add that rubber chemicals are mixing to form, and makes rubber and screen cloth that high strength bond property arranged, and makes Rubber screen that good draftability arranged at work, guarantees that rubber can not break away from.

In the time of in ore gets into disintegrating machine, owing to reduced the sieve aperture A2 size of upper strata screen cloth 1, thus effectively increased ore upper strata internal circulating load in disintegrating machine, make ore that the longer pulverizing time arranged; The sieve aperture B4 that utilizes middle level screen cloth 3 simultaneously further effectively impels disintegrating machine to give full play to performance as the buffer zone, reduces the sieve aperture C6 of lower screen 5 at last, has realized how broken few mill, and the screening efficiency of lower screen 3 is improved fully.

What should explain at last is: carefully do not state part in the above content for prior art, do not state so run business into particular one, said embodiment is the described technical scheme of unrestricted the utility model also in order to explanation the utility model only; Therefore, although this specification has carried out detailed explanation to the utility model with reference to each above-mentioned embodiment,, those of ordinary skill in the art should be appreciated that still and can make amendment or be equal to replacement the utility model; And all do not break away from the technical scheme and the improvement thereof of the spirit and the scope of the utility model, all should be encompassed in the claim scope of the utility model.

Claims (1)

1. multilayer screen cloth; Form by upper strata screen cloth, middle level screen cloth, lower screen, sieve aperture A, sieve aperture B, sieve aperture C; It is characterized in that being: the sieve aperture A size of said upper strata screen cloth is made as>=28x30mm; The sieve aperture B size of middle level screen cloth is made as>=18x32mm, and the sieve aperture C size of lower screen is made as≤10x34mm.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2012200854041U CN202498030U (en) | 2012-03-02 | 2012-03-02 | Multilayer screen |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2012200854041U CN202498030U (en) | 2012-03-02 | 2012-03-02 | Multilayer screen |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN202498030U true CN202498030U (en) | 2012-10-24 |

Family

ID=47034658

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN2012200854041U Expired - Fee Related CN202498030U (en) | 2012-03-02 | 2012-03-02 | Multilayer screen |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN202498030U (en) |

-

2012

- 2012-03-02 CN CN2012200854041U patent/CN202498030U/en not_active Expired - Fee Related

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN107008645A (en) | Inclined double-deck excited vibration screen device | |

| CN201070621Y (en) | Multi-layer mesh screen vibrating screen | |

| CN201423348Y (en) | Screen mesh of high-intensity composite high-frequency sieve | |

| CN202498030U (en) | Multilayer screen | |

| CN204602591U (en) | Ore dressing high-frequency screen device | |

| CN215430258U (en) | Decoration and fitment rubbish resourceful treatment system | |

| CN103316837B (en) | A kind of composite metal screen | |

| CN203494773U (en) | Compound screening device | |

| CN207385937U (en) | One kind leaves formula anti-blockage holes sieve plate | |

| CN203448301U (en) | Thick sand and fine sand separator | |

| CN204412428U (en) | A kind of Vehicular concrete reclaims, reducing mechanism | |

| CN202683472U (en) | Abrasive liner plate for vibration sieve discharge port | |

| CN201082414Y (en) | Abrasion-proof screen mesh | |

| KR20130128853A (en) | 2 rows parallel vibration selector of slag ball | |

| CN204110807U (en) | vibrating feeder | |

| CN204107853U (en) | A kind of relaxation sieve screen cloth | |

| CN206763081U (en) | F sand abrasive blast equipments | |

| CN208082867U (en) | The polyurethane screen of vibrating screen interlaced arrangement sieve pore | |

| CN203044078U (en) | Energy-saving and environment-friendly crusher | |

| CN210546318U (en) | Shale shaker for civil engineering | |

| CN220371599U (en) | Porous vibrating screen mesh | |

| CN207641629U (en) | Bucket elevator | |

| CN208600179U (en) | A kind of screening machine having both blower | |

| CN2928238Y (en) | Composite lattic board for self grinder | |

| CN202570610U (en) | Screening machine blade with abrasion resistant rubber plates |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| CF01 | Termination of patent right due to non-payment of annual fee |

Granted publication date: 20121024 Termination date: 20150302 |

|

| EXPY | Termination of patent right or utility model |