CN202498026U - An eccentric wheel of a shaking screen used in the course of processing master batches - Google Patents

An eccentric wheel of a shaking screen used in the course of processing master batches Download PDFInfo

- Publication number

- CN202498026U CN202498026U CN2012200467388U CN201220046738U CN202498026U CN 202498026 U CN202498026 U CN 202498026U CN 2012200467388 U CN2012200467388 U CN 2012200467388U CN 201220046738 U CN201220046738 U CN 201220046738U CN 202498026 U CN202498026 U CN 202498026U

- Authority

- CN

- China

- Prior art keywords

- eccentric wheel

- utility

- model

- shaking screen

- eccentric

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Classifications

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02W—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO WASTEWATER TREATMENT OR WASTE MANAGEMENT

- Y02W30/00—Technologies for solid waste management

- Y02W30/50—Reuse, recycling or recovery technologies

- Y02W30/62—Plastics recycling; Rubber recycling

Landscapes

- Combined Means For Separation Of Solids (AREA)

Abstract

本实用新型公开了一种母粒加工过程中用振荡筛偏心轮,包括带有安装孔的偏心轮本体,所述安装孔的偏心距离为4-10mm。本实用新型通过减小安装孔的偏心距离来减小振荡筛的振荡幅度。

The utility model discloses an eccentric wheel of an oscillating sieve used in masterbatch processing, which comprises an eccentric wheel body with a mounting hole, and the eccentric distance of the mounting hole is 4-10 mm. The utility model reduces the vibration amplitude of the vibration screen by reducing the eccentric distance of the installation hole.

Description

技术领域 technical field

本实用新型涉及母粒加工领域,特别涉及一种母粒加工过程中用的振荡筛偏心轮。The utility model relates to the field of master batch processing, in particular to an eccentric wheel of an oscillating screen used in the master batch processing process.

背景技术 Background technique

在现有技术中,母粒加工的过程需要多个步骤,从挤出机中挤出的物料经过水槽进入切粒机中,经过切粒机加工之后的成品物料进入振荡筛中,使成品物料通过振荡筛振荡过滤,过滤后的成品物料再经过移动式上料机落入到盛料车中。In the prior art, the process of masterbatch processing requires multiple steps. The material extruded from the extruder enters the pelletizer through the water tank, and the finished material processed by the pelletizer enters the vibrating screen to make the finished material Vibrating and filtering through the vibrating sieve, the filtered finished materials are then dropped into the filling cart through the mobile feeding machine.

现有的振荡筛的偏心轮上有安装孔10,其偏心距离为30mm,使得振荡筛的振荡幅度偏大。

实用新型内容 Utility model content

本实用新型的目的在于提供一种母粒加工过程中用振荡筛偏心轮,以解决现有技术中振荡筛的振荡幅度偏大的问题。The purpose of the utility model is to provide an eccentric wheel of an oscillating screen used in the processing of masterbatches, so as to solve the problem that the oscillation amplitude of the oscillating screen is too large in the prior art.

为了实现上述目的,本实用新型的技术方案如下:In order to achieve the above object, the technical scheme of the utility model is as follows:

母粒加工过程中用振荡筛偏心轮,其特征在于,包括带有安装孔的偏心轮本体,所述安装孔的偏心距离为4-10mm。The eccentric wheel of the oscillating sieve used in the processing of the masterbatch is characterized in that it includes an eccentric wheel body with a mounting hole, and the eccentric distance of the mounting hole is 4-10 mm.

在本实用新型的一个实施例中,所述安装孔的偏心距离为5mm。In one embodiment of the present utility model, the eccentric distance of the installation hole is 5mm.

在本实用新型的一个实施例中,所述安装孔的两侧均设置有一个方便拆装的螺丝孔。In one embodiment of the present invention, a screw hole for easy assembly and disassembly is provided on both sides of the installation hole.

本实用新型通过减小安装孔的偏心距离来减小振荡筛的振荡幅度。The utility model reduces the vibration amplitude of the vibration screen by reducing the eccentric distance of the installation hole.

本实用新型的特点可参阅本案图式及以下较好实施方式的详细说明而获得清楚地了解。The features of the utility model can be clearly understood by referring to the drawings of this case and the detailed description of the following preferred embodiments.

附图说明 Description of drawings

图1为现有技术中的振荡筛偏心轮示意图;Fig. 1 is the schematic diagram of the vibrating screen eccentric wheel in the prior art;

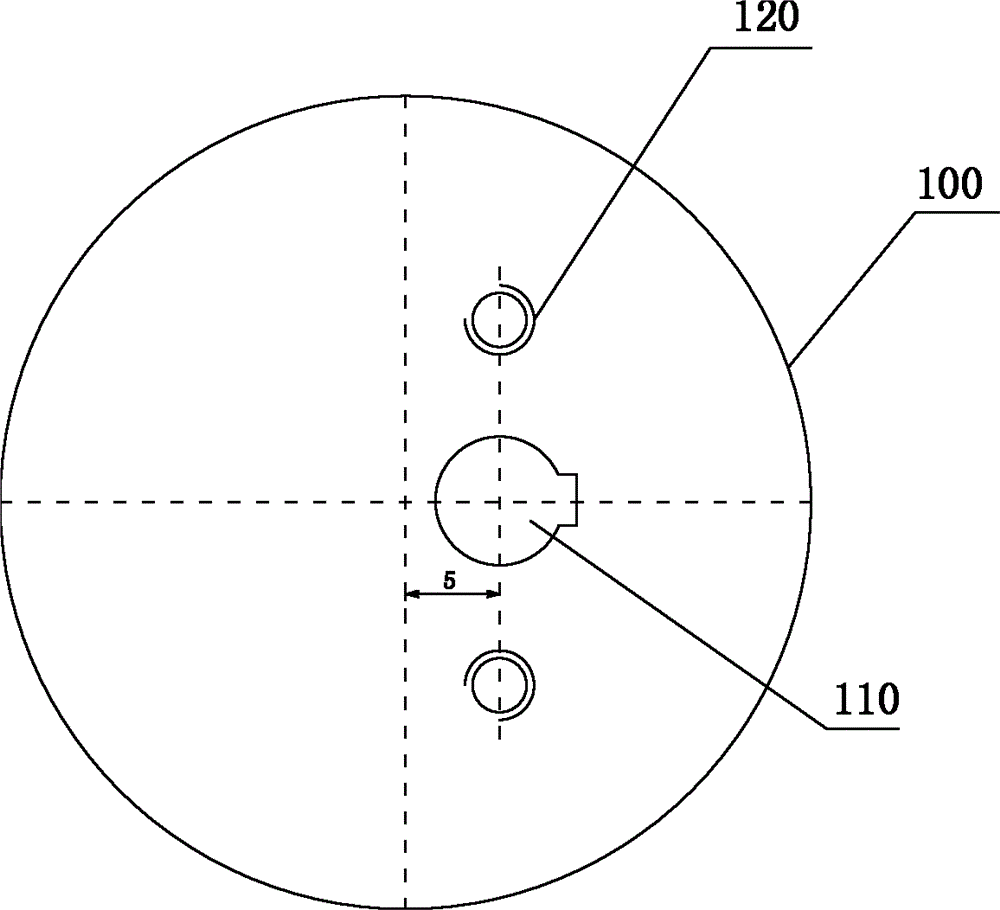

图2为本实用新型的振荡筛偏心轮的结构示意图。Fig. 2 is a structural schematic diagram of the eccentric wheel of the vibrating screen of the present invention.

具体实施方式 Detailed ways

为了使本实用新型实现的技术手段、创作特征、达成目的与功效易于明白了解,下面结合具体实施例进一步阐述本实用新型。In order to make the technical means, creative features, goals and effects achieved by the utility model easy to understand, the utility model will be further elaborated below in conjunction with specific embodiments.

如图2所示,母粒加工过程中用振荡筛偏心轮,包括带有安装孔110的偏心轮本体100,为了减小振荡筛的振荡幅度,安装孔的偏心距离为4-10mm。在本实施例中,安装孔的偏心距离为5mm。As shown in Figure 2, the eccentric wheel of the vibrating screen used in the processing of masterbatches includes an

另外,在安装孔的两侧均设置有一个方便拆装的螺丝孔120。In addition, a

本实用新型通过减小安装孔的偏心距离来减小振荡筛的振荡幅度。The utility model reduces the vibration amplitude of the vibration screen by reducing the eccentric distance of the installation hole.

以上显示和描述了本实用新型的基本原理、主要特征和本实用新型的优点。本行业的技术人员应该了解,本实用新型不受上述实施例的限制,上述实施例和说明书中描述的只是本实用新型的原理,在不脱离本实用新型精神和范围的前提下本实用新型还会有各种变化和改进,这些变化和改进都落入要求保护的本实用新型的范围内。本实用新型要求的保护范围由所附的权利要求书及其等同物界定。The basic principles, main features and advantages of the present utility model have been shown and described above. Those skilled in the industry should understand that the utility model is not limited by the above-mentioned embodiments. The above-mentioned embodiments and descriptions describe only the principle of the utility model. There will be various changes and improvements, and these changes and improvements all fall within the scope of the claimed utility model. The protection scope required by the utility model is defined by the appended claims and their equivalents.

Claims (3)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2012200467388U CN202498026U (en) | 2012-02-14 | 2012-02-14 | An eccentric wheel of a shaking screen used in the course of processing master batches |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2012200467388U CN202498026U (en) | 2012-02-14 | 2012-02-14 | An eccentric wheel of a shaking screen used in the course of processing master batches |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN202498026U true CN202498026U (en) | 2012-10-24 |

Family

ID=47034654

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN2012200467388U Expired - Fee Related CN202498026U (en) | 2012-02-14 | 2012-02-14 | An eccentric wheel of a shaking screen used in the course of processing master batches |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN202498026U (en) |

-

2012

- 2012-02-14 CN CN2012200467388U patent/CN202498026U/en not_active Expired - Fee Related

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN203356038U (en) | Pneumatic vibrating screen | |

| CN202753307U (en) | Plastic master batch screening blast lifting device | |

| CN202498026U (en) | An eccentric wheel of a shaking screen used in the course of processing master batches | |

| CN201921827U (en) | Floating vibrating screen | |

| CN203158749U (en) | Moveable-type distributing device | |

| CN202539072U (en) | Multilayer vibration screen | |

| CN202778675U (en) | Crushing sorting system for producing permanent magnet material | |

| CN203526040U (en) | Iron removal vibrating sieve for ceramic tile production | |

| CN203141690U (en) | Hoop of reclaimed rubber filter | |

| CN201567050U (en) | A dual-mass vibrating feeder | |

| CN202572692U (en) | Novel granulating machine | |

| CN202238606U (en) | Drum screen for screening fertilizer | |

| CN202316279U (en) | Simple screening machine | |

| CN204035537U (en) | Rolling-type desanding shake table | |

| CN205128368U (en) | Buggy and coal cinder separator device | |

| CN203140293U (en) | Ferric phosphate sieving device | |

| CN203642650U (en) | Automatic vibration feeding device for sand drying system | |

| CN203262169U (en) | Tea dispersion machine | |

| CN206083108U (en) | Device is select to efficient raw materials | |

| CN204470069U (en) | A kind of multiaspect screen layers vibratory sieve | |

| CN203125314U (en) | Glass positioning roller component for glass edging machine | |

| CN203695396U (en) | Rotating and vibrating type screening instrument | |

| CN203664006U (en) | Device for removing metal impurities in powder materials | |

| CN203155518U (en) | Backflow glue filtering apparatus of glue applicator | |

| CN205413291U (en) | Be applied to diatomaceous earth recycling apparatus of environmental protection 3D printing consumables production |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| CF01 | Termination of patent right due to non-payment of annual fee | ||

| CF01 | Termination of patent right due to non-payment of annual fee |

Granted publication date: 20121024 Termination date: 20180214 |