CN202497480U - Steam sterilizing container with split locking block structure - Google Patents

Steam sterilizing container with split locking block structure Download PDFInfo

- Publication number

- CN202497480U CN202497480U CN2012201356166U CN201220135616U CN202497480U CN 202497480 U CN202497480 U CN 202497480U CN 2012201356166 U CN2012201356166 U CN 2012201356166U CN 201220135616 U CN201220135616 U CN 201220135616U CN 202497480 U CN202497480 U CN 202497480U

- Authority

- CN

- China

- Prior art keywords

- lock dog

- container

- split type

- fixed

- fixing head

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Landscapes

- Apparatus For Disinfection Or Sterilisation (AREA)

Abstract

The utility model discloses a steam sterilizing container with a split locking block structure. The steam sterilizing container comprises a container cylinder body (1), a quickly-opened door panel (8) and a split locking block (7), wherein a container flange (3) is arranged on the container cylinder body (1); a locking block fixing plate (4) is arranged on the container flange (3) and is also fixed on a container outer interlayer (2); the split locking block (7) is fixed on the locking block fixing plate (4); the quickly-opened door panel (8) is connected with a door fixing hinge (11) through a movable door hinge (10); the door fixing hinge (11) is fixed on the container cylinder body (1); and the split locking block (7) is arranged on the quickly-opened door panel (8). According to the steam sterilizing container disclosed by the utility model, due to the adoption of the structure, a locking device is enabled to easily operate; meanwhile, the integral attractiveness of the container is improved; and the surface cleanness and lower cost are obtained.

Description

Technical field

This utility model relates to a kind of steam sterilization pressure vessel, specifically is a kind of steam sterilization container with split type lock dog structure.

Background technology

Steam sterilization equipment is one of main sterilizing installation of pharmaceuticals industry, occupies important production status in pharmaceuticals industry.Its groundwork principle is to reach sterilization effect at the inner high steam that feeds of steriliser, has extensive use at aspects such as medical treatment, pharmacy.At present; Steam sterilization equipment primary structure employing rectangle and cylinder type are as the main pressurized element of equipment; The locking device of container mainly contains two kinds of dentation bolt and lock pins; The quick operating valve of dentation bolt formula mainly relies on the mobile alignment or the dentation bolt that staggers of going of quick operating valve self, to realize the open and close of quick operating valve, the overall structure of quick operating valve and entire container itself is had relatively high expectations; The mechanical precision of dentation bolt is had relatively high expectations, and be difficult for to make and generally adopts antiseptic property bad but make than the material that is easier to make (ordinary carbon steel); The lockpin-type quick opening structure comprises lockhole that is arranged on the container casing and the lock pin that is arranged in the quick operating valve panel; Influence overall appearance outside but its cassette locking device is exposed, it is also not quite convenient that cleaning is got up; Simultaneously; The quick operating valve opposite house surface evenness of this structure is had relatively high expectations, and generally adopts machining process to be shaped now, and processing cost is higher.

The utility model content

This utility model provides a kind of steam sterilization container with split type lock dog structure, has solved locking device in the past and has been difficult for making, and influences overall appearance, bolt material limited use, and the high problem of processing cost.

This utility model is that the technical solution problem mainly realizes through following technical scheme: the steam sterilization container with split type lock dog structure; Comprise shell, quick operating valve panel and split type lock dog; Said shell is provided with vessel flange, is fixed with the lock dog fixing head on the vessel flange, and said lock dog fixing head also is fixed on the container outside sandwich; Said split type lock dog is fixed on the lock dog fixing head; Said quick operating valve panel is connected with the door fixed hinge through the door hinges, and the door fixed hinge is fixed on the shell, and the quick operating valve panel is provided with split type lock dog.

Be provided with evenly distributed split type dentation lock dog in the quick operating valve panel; Shell is provided with same evenly distributed lock dog; Two groups of lock dogs cooperatively interact, and the lock dog on the shell adopts single split type lock dog assembling, is fixed on the vessel flange on the shell.

Said split type lock dog is through being bolted on the lock dog fixing head.

The outside of said lock dog fixing head is provided with the container balustrade exterior panelling, and the container balustrade exterior panelling is between split type lock dog and lock dog fixing head.

Said vessel flange is provided with sealing strip.

Said lock dog fixing head is fixed by welding on the vessel flange, and vessel flange is fixed by welding on the shell.

Vessel flange is welded on the shell; The vessel flange welded is fixed with the lock dog fixing head; The lock dog fixing head is welded on the container outside sandwich; Be equipped with on the lock dog fixing head with quick operating valve on the split type lock dog of same size and uniform distances, attractive in appearance and reduce material cost for making vessel surface, the balustrade exterior panelling of container is arranged on the lock dog fixing head outside; Thrust fixed container balustrade exterior panelling when relying on the split type lock dog of assembling, promptly the container balustrade exterior panelling is arranged between split type lock dog and the lock dog fixing head.

This utility model compared with prior art has the following advantages and beneficial effect:

(1) the container balustrade exterior panelling of this utility model is arranged on the lock dog fixing head outside; Like this; Lock dog fixing head on the vessel flange can use that anti-corrosive properties are less demanding, the material of good processability, and split type lock dog can use anti-corrosive properties good, the material of surface aesthetic (rustless steel); Thereby can be applied to more areas, make vessel surface attractive in appearance, bright and clean.

(2) the split type lock dog that adopts of this utility model is assemblied in vessel flange by one lock dog and forms, and it is more convenient that single isolating lock dog is compared whole bolt processing, and material removing rate is relatively low, thereby has reduced Costco Wholesale, has improved stock utilization.

(3) the split type lock dog of this utility model is installed in the container balustrade exterior panelling outside, and the container balustrade exterior panelling has wrapped the lock dog fixing head, makes the lock dog fixing head can adopt the relatively low material of material price, thereby has practiced thrift cost.

Description of drawings

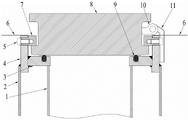

Fig. 1 is the structural representation of this utility model.

The pairing name of Reference numeral is called: 1, shell, 2, the container outside sandwich, 3, vessel flange, 4, the lock dog fixing head; 5, bolt, 6, the container balustrade exterior panelling, 7, split type lock dog, 8, the quick operating valve panel; 9, sealing strip, 10, the door hinges, 11, the door fixed hinge.

The specific embodiment

Below in conjunction with embodiment this utility model is done further to specify, but the embodiment of this utility model is not limited thereto.

Embodiment:

As shown in Figure 1, this utility model comprises shell 1, quick operating valve panel 8 and split type lock dog 7, and shell 1 is provided with vessel flange 3; Be fixed with lock dog fixing head 4 on the vessel flange 3; Lock dog fixing head 4 also is fixed on the container outside sandwich 2, and split type lock dog 7 is fixed on the lock dog fixing head 4, and quick operating valve panel 8 is connected with door fixed hinge 11 through door hinges 10; Door fixed hinge 11 is fixed on the shell 1, and quick operating valve panel 8 is provided with split type lock dog 7.

As preferably, the split type lock dog 7 of present embodiment is fixed on the lock dog fixing head 4 through bolt 5.

The outside of the lock dog fixing head 4 of present embodiment is provided with container balustrade exterior panelling 6, and container balustrade exterior panelling 6 is between split type lock dog 7 and lock dog fixing head 4.

The vessel flange 3 of present embodiment is provided with sealing strip 9.

The lock dog fixing head 4 of present embodiment is fixed by welding on the vessel flange 3, and vessel flange 3 is fixed by welding on the shell 1.

The operation principle of this utility model is: move quick operating valve panel 8, and its fixed split type lock dog 7 moves in the space between adjacent two the split type lock dogs 7 on the shell 1, quick operating valve promptly is opened.

As stated, then can realize this utility model well.

Claims (5)

1. the steam sterilization container that has split type lock dog structure; It is characterized in that: comprise shell (1), quick operating valve panel (8) and split type lock dog (7); Said shell (1) is provided with vessel flange (3); Be fixed with lock dog fixing head (4) on the vessel flange (3); Said lock dog fixing head (4) also is fixed on the container outside sandwich (2), and said split type lock dog (7) is fixed on the lock dog fixing head (4), and said quick operating valve panel (8) is connected with door fixed hinge (11) through door hinges (10); Door fixed hinge (11) is fixed on the shell (1), and said quick operating valve panel (8) is provided with split type lock dog (7).

2. the steam sterilization container with split type lock dog structure according to claim 1 is characterized in that: said split type lock dog (7) is fixed on the lock dog fixing head (4) through bolt (5).

3. the steam sterilization container with split type lock dog structure according to claim 1; It is characterized in that: the outside of said lock dog fixing head (4) is provided with container balustrade exterior panelling (6), and container balustrade exterior panelling (6) is positioned between split type lock dog (7) and the lock dog fixing head (4).

4. the steam sterilization container with split type lock dog structure according to claim 1 is characterized in that: said vessel flange (3) is provided with sealing strip (9).

5. the steam sterilization container with split type lock dog structure according to claim 1; It is characterized in that: said lock dog fixing head (4) is fixed by welding on the vessel flange (3), and vessel flange (3) is fixed by welding on the shell (1).

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2012201356166U CN202497480U (en) | 2012-04-01 | 2012-04-01 | Steam sterilizing container with split locking block structure |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2012201356166U CN202497480U (en) | 2012-04-01 | 2012-04-01 | Steam sterilizing container with split locking block structure |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN202497480U true CN202497480U (en) | 2012-10-24 |

Family

ID=47034111

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN2012201356166U Expired - Lifetime CN202497480U (en) | 2012-04-01 | 2012-04-01 | Steam sterilizing container with split locking block structure |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN202497480U (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103372227A (en) * | 2013-08-01 | 2013-10-30 | 成都老肯科技股份有限公司 | Hydrogen peroxide low temperature plasma sterilizer with openable panel |

-

2012

- 2012-04-01 CN CN2012201356166U patent/CN202497480U/en not_active Expired - Lifetime

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103372227A (en) * | 2013-08-01 | 2013-10-30 | 成都老肯科技股份有限公司 | Hydrogen peroxide low temperature plasma sterilizer with openable panel |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN202497480U (en) | Steam sterilizing container with split locking block structure | |

| CN201695083U (en) | Insertion plate valve for vacuum film coating production line | |

| CN204216434U (en) | Low-voltage comprehensive distribution cabinet | |

| CN201457988U (en) | Water sealing device for top covers of low pressure cabinet and low pressure bucket | |

| CN201705921U (en) | System with single-group plug used together with double vessels | |

| CN201791412U (en) | Subframe fixing device of horizontal spring squeezing machine | |

| CN203189714U (en) | Locking device of quick open door | |

| CN202490213U (en) | Quick door opening structure for split locking-piece steam sterilizer | |

| CN204704171U (en) | A kind of full-automatic built-in commutation hydraulic booster pump | |

| CN202171390U (en) | Novel kiln body cooling device | |

| CN201790896U (en) | Medical terminal box and medical tower crane | |

| CN201581042U (en) | Preparation, storage and outwards conveying device of methylamine water solution | |

| CN202014033U (en) | Hinge structure for cabinet door | |

| CN201866278U (en) | Valve stem limit device for stop valve with rotary driving device | |

| CN201786180U (en) | Metal door frame with sealing groove | |

| CN202316459U (en) | Groove cover of cleaning equipment | |

| CN202962995U (en) | Cleaning device for reaction kettle | |

| CN201198694Y (en) | Internal flat hinge for bathing room | |

| CN201649963U (en) | Safe | |

| CN203300981U (en) | Box structure of combined transformer | |

| CN201530490U (en) | Transferring window used in bottling production line | |

| CN202666522U (en) | Multipurpose stainless steel filter | |

| CN203525949U (en) | Drum type gluing device for production of palm fiber mattress | |

| CN203066784U (en) | Door angle structure of control cabinet | |

| CN203321190U (en) | Stainless steel door and window framework |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| CX01 | Expiry of patent term | ||

| CX01 | Expiry of patent term |

Granted publication date: 20121024 |