CN202495897U - Starting circuit for 60 type concrete towed pump - Google Patents

Starting circuit for 60 type concrete towed pump Download PDFInfo

- Publication number

- CN202495897U CN202495897U CN2012200467814U CN201220046781U CN202495897U CN 202495897 U CN202495897 U CN 202495897U CN 2012200467814 U CN2012200467814 U CN 2012200467814U CN 201220046781 U CN201220046781 U CN 201220046781U CN 202495897 U CN202495897 U CN 202495897U

- Authority

- CN

- China

- Prior art keywords

- relay

- contactor

- time

- output

- alternating

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 238000012423 maintenance Methods 0.000 abstract description 6

- 238000011426 transformation method Methods 0.000 abstract 1

- 238000004804 winding Methods 0.000 description 8

- 239000000853 adhesive Substances 0.000 description 6

- 230000001070 adhesive effect Effects 0.000 description 6

- 230000005611 electricity Effects 0.000 description 6

- 238000000034 method Methods 0.000 description 5

- 238000006243 chemical reaction Methods 0.000 description 3

- 238000010586 diagram Methods 0.000 description 3

- 239000004821 Contact adhesive Substances 0.000 description 2

- 230000009471 action Effects 0.000 description 2

- 230000008859 change Effects 0.000 description 2

- 238000005516 engineering process Methods 0.000 description 2

- 230000006872 improvement Effects 0.000 description 2

- 230000009466 transformation Effects 0.000 description 2

- 230000008901 benefit Effects 0.000 description 1

- 238000007689 inspection Methods 0.000 description 1

- 238000007634 remodeling Methods 0.000 description 1

- 230000008672 reprogramming Effects 0.000 description 1

- 230000001131 transforming effect Effects 0.000 description 1

Images

Landscapes

- Motor And Converter Starters (AREA)

Abstract

The utility model pertains to the technical filed of concrete machinery, and specifically relates to a starting circuit for a 60 type concrete towed pump. The starting circuit comprises a first alternating-current contactor, a second alternating-current contactor, a third alternating-current contactor, a first output relay, a second output relay, a third output relay, a first input relay, and a second input relay. The starting circuit is characterized in that an intermediate relay is connected in series in a first alternating-current contactor coil circuit, and a time relay is connected in parallel in a first alternating-current contactor coil. A DELIXI HH53P intermediate relay is adopted as the intermediate relay KA, and a DELIXI JSZ3 time relay is adopted as the time relay KT. According to the utility model, a simple and applicable transformation method is achieved, the device maintenance time is greatly shortened, and the device utilization rate is improved. Moreover, device maintenance cost is reduced, the normal starting of the concrete towed pump can be satisfied, device failure is solved timely, and normal operation of production is guaranteed.

Description

Technical field

The utility model belongs to the concreting machinery technical field, is specifically related to a kind of 60 type concrete and drags formula pump startup circuit.

Background technology

The formula pump drags at one the 60 type concrete of producing in 2002 of labour in my company, and when occurring starting the 90kw motor often in the use, the situation that motor can't start makes this concrete drag the formula pump not work.Normal repairing need be changed the PLC programmable controller, and concrete to drag the PLC programmable controller of formula pump be an equipment one cover program, change the PLC programmable controller; The professional of producer needs reprogramming; Thereby maintenance time is long, causes equipment to be stopped work for a long time; Utilance is low, and maintenance cost is high.

Drag the problem that formula pump master motor can't start often, equipment is stopped work for a long time in order to solve 60 type concrete, main electric motor starting has been carried out technical Analysis for we and decision undergoes technological transformation to main electric motor starting circuit.

Master's electric motor starting belonged to open loop control when this concrete formula of dragging pumped factory, and star-triangle conversion drives three main A.C. contactors through the PLC programmable controller by pre-set programs and carries out.Motor can not normally start, and reason is to carry out star-triangle conversion, analyzes reason through us and thinks: the reason that can not carry out star-triangle conversion is a PLC programmable controller delay procedure fault, causes the equipment motor to start.So we drag formula pump startup circuit to carry out technological transformation to 60 type concrete, through use more than a year, the phenomenon that motor can not normally start do not occur.

The utility model content

The technical problem that the utility model will solve is to provide a kind of 60 type concrete simple in structure, that realization is easy, safe and reliable, the assurance motor starts smoothly to drag formula pump startup circuit.

It is following that the utility model solves the problems of the technologies described above the technical scheme of taking: a kind of 60 type concrete drag formula pump startup circuit; Comprise first A.C. contactor, second A.C. contactor, the 3rd A.C. contactor; First output relay, second output relay, the 3rd output relay; First input relay, second input relay; It is characterized in that: in the first ac contactor coil loop, be in series with auxiliary relay, on first ac contactor coil, be parallel with the time relay.

Time relay break contact (being normally closed point) seals in the loop, the 3rd ac contactor coil road, and time relay make contact (promptly normal the battle) seals in the second ac contactor coil loop; First output relay lead-out terminal control auxiliary relay; First A.C. contactor, second A.C. contactor and the 3rd ac contactor coil power supply are directly obtained from control transformer, give the time relay and first A.C. contactor, second A.C. contactor and the power supply of the 3rd A.C. contactor through auxiliary relay.

The utility model is the improvement to delay circuit, and the delay circuit after the improvement comprises increases an auxiliary relay and the alternative former PLC programmable controller delay procedure of the time relay, makes concrete drag the formula pump motor normally to start.

Transform the required electric elements of this Circuits System:

1, moral power west HH53P auxiliary relay is one, the about 40.00 yuan/part of market price;

2, moral power west JSZ

3One in the time relay, the about 30.00 yuan/part of market price;

More than two total expenses: 70.00 yuan.

3, do not transform this Circuits System, change one of PLC programmable controller, the about 2200.00 yuan/part of market price.

The advantage that this Circuits System is transformed:

1, remodeling method is simply suitable, shortens the maintenance of equipment time greatly, has improved usage ratio of equipment.

2, reduce the maintenance of equipment cost, economize on the use of funds about 2130.00 yuan.

The most important thing is improved start-up circuit system, can satisfy concrete and drag the formula pump normally to start, in time solve equipment fault, ensure and produce normal operation, reduce cost.

Description of drawings

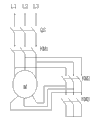

Fig. 1 drags formula pump threephase asynchronous machine " Y-△ " reduced-voltage starting main circuit schematic diagram for existing concrete,

Fig. 2 drags formula pump PLC I/O configuration and winding diagram for existing concrete,

Fig. 3 is the utility model PLC I/O configuration and time relay wiring figure,

Fig. 4 is the utility model auxiliary relay winding diagram.

Among the figure: QS-air switch, KM1-first A.C. contactor, KM2-second A.C. contactor, KM3-the 3rd A.C. contactor, M-threephase asynchronous; L1-first phase line, L2-second phase line, L3-third phase line, SB1-start button SB2-stop button; Y0-first output relay, Y1-second output relay, Y2-the 3rd output relay, X0-first input relay; X1-second input relay, FU-fuse, KA-auxiliary relay, KT-time relay; COM-common ground (negative pole), CON-zero-power line, L-phase line, N-zero line.

Embodiment

Start-up circuit system such as Fig. 1 and shown in Figure 2 before transforming; The first phase line L1, the second phase line L2 are connected with threephase asynchronous M three phase winding head ends through air switch QS with third phase line L1; The first A.C. contactor KM1 is housed between air switch QS and the threephase asynchronous M; The second A.C. contactor KM2, threephase asynchronous M three phase winding tail ends link to each other with the 3rd A.C. contactor KM3.PLC working power common ground COM; The first input relay X0, the second input relay X0, starting button SB1, stop button SB2, zero-power line CON; Fuse F U, the first output relay Y0, the second output relay Y1, the 3rd output relay Y2; The corresponding first A.C. contactor KM1, the 3rd A.C. contactor KM3, the second A.C. contactor KM2 of connecting.

Its startup principle and start-up course are following: concrete drags formula pump master electric motor starting to belong to open loop control, and star-triangle start drives the first A.C. contactor KM1, the second A.C. contactor KM2 and the 3rd A.C. contactor KM3 through the PLC programmable controller by pre-set programs to carry out.When pressing start button SB1; The first input relay X0 gives working signal of PLC; The PLC program start; PLC programmable controller, the first output relay Y0 and second output relay Y1 action make the first A.C. contactor KM1, the 3rd A.C. contactor KM3 get electric adhesive, and threephase asynchronous M three phase windings are connected into the star connection running.Delay procedure is started working simultaneously; After the 8s time-delay; PLC programmable controller output order discharges the second output relay Y1 dead electricity; The 3rd output relay Y2 gets electric adhesive, and the 3rd A.C. contactor KM3 dead electricity is broken off, and the second A.C. contactor KM2 gets electric adhesive makes threephase asynchronous M three phase windings be connected into the triangle running.Concrete drags the formula pump work to accomplish, and presses stop button SB2, and the equal dead electricity of all relays, A.C. contactor self-insurance are opened, and threephase asynchronous M shuts down.This equipment fault electric circuit inspection is for breaking off through the 3rd A.C. contactor KM3 adhesive behind the PLC programmable controller delay procedure, the second output relay Y1 have output voltage not dead electricity lose and put, the 3rd output relay Y2 no-output voltage not electric adhesive.

With reference to Fig. 3 and Fig. 4: a kind of 60 type concrete that the utility model provides drag formula pump startup circuit, comprise the first A.C. contactor KM1, the second A.C. contactor KM2, the 3rd A.C. contactor KM3, the first output relay Y0; The second output relay Y1; The 3rd output relay Y2, the first input relay X0, the second input relay X1; Phase line L, zero line N; In the first A.C. contactor KM1 wire loop, be in series with auxiliary relay KA, on the first A.C. contactor KM1 coil, be parallel with time relay KT.

Auxiliary relay KA adopts moral power west HH53P auxiliary relay, and time relay KT adopts moral power west JSZ

3The time relay.

Time relay KT normally-closed contact seals in the loop, the 3rd A.C. contactor KM3 coil road, and time relay KT normally opened contact seals in the second A.C. contactor KM2 wire loop; First output relay Y0 lead-out terminal control auxiliary relay KA; The first A.C. contactor KM1, the second A.C. contactor KM2 are connected with the control transformer (not shown) with the 3rd A.C. contactor KM3; The first A.C. contactor KM1, the second A.C. contactor KM2 and the 3rd A.C. contactor KM3 coil power are directly obtained from control transformer, give time relay KT and the first A.C. contactor KM1, the second A.C. contactor KM2 and the 3rd A.C. contactor KM3 power supply through auxiliary relay KA.

The utility model startup principle and start-up course are following: first output relay Y0 lead-out terminal control auxiliary relay KA; The first A.C. contactor KM1, the second A.C. contactor KM2 and the 3rd A.C. contactor KM3 ac contactor coil power supply are directly obtained from control transformer, give time relay KT and three A.C. contactor power supplies through auxiliary relay KA.When pressing start button SB1; The first input relay X0 gives working signal of PLC; The PLC program start; First output relay Y0 action output voltage make auxiliary relay KA get electric normally opened contact adhesive that the D first A.C. contactor KM1 coil is got is electric, simultaneously through time relay KT normally-closed contact make the 3rd A.C. contactor KM3 simultaneously electric, threephase asynchronous M three phase windings are connected into star connection and turn round.Time relay KT work, the moving breakpoint of time relay KT breaks off KM3 ac contactor coil dead electricity contact is broken off behind the 8s, and the normally opened contact adhesive makes the second A.C. contactor KM2 coil get electric adhesive, and the closing of contact makes the motor winding be connected into the delta-connection running.Concrete drags the formula pump work to accomplish, and presses stop button SB2, the equal dead electricity of all relays, and the A.C. contactor self-insurance is opened, and motor shuts down.

Claims (3)

1. a type concrete drags formula pump startup circuit, comprises first A.C. contactor, second A.C. contactor, the 3rd A.C. contactor, first output relay, second output relay, the 3rd output relay, first input relay, second input relay; It is characterized in that: in first A.C. contactor (KM1) wire loop, be in series with auxiliary relay (KA), on first A.C. contactor (KM1) coil, be parallel with the time relay (KT).

2. a kind of 60 type concrete as claimed in claim 1 drag formula pump startup circuit; It is characterized in that: the time relay (KT) normally-closed contact seals in the loop, the 3rd A.C. contactor (KM3) coil road, and the time relay (KT) normally opened contact seals in second A.C. contactor (KM2) wire loop; First output relay (Y0) lead-out terminal control auxiliary relay (KA); First A.C. contactor (KM1), second A.C. contactor (KM2) are connected with control transformer with the 3rd A.C. contactor (KM3), give the time relay (KT) and first A.C. contactor (KM1), second A.C. contactor (KM2) and the 3rd A.C. contactor (KM3) power supply through auxiliary relay (KA).

3. according to claim 1 or claim 2 a kind of 60 type concrete drag formula pump startup circuit, it is characterized in that: auxiliary relay (KA) adopts moral power west HH53P auxiliary relay, and the time relay (KT) adopts moral power west JSZ

3The time relay.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2012200467814U CN202495897U (en) | 2012-02-14 | 2012-02-14 | Starting circuit for 60 type concrete towed pump |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2012200467814U CN202495897U (en) | 2012-02-14 | 2012-02-14 | Starting circuit for 60 type concrete towed pump |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN202495897U true CN202495897U (en) | 2012-10-17 |

Family

ID=47002109

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN2012200467814U Expired - Fee Related CN202495897U (en) | 2012-02-14 | 2012-02-14 | Starting circuit for 60 type concrete towed pump |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN202495897U (en) |

-

2012

- 2012-02-14 CN CN2012200467814U patent/CN202495897U/en not_active Expired - Fee Related

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN202524282U (en) | Device for preventing frequency converter from power shaking | |

| CN203589836U (en) | Intelligent control apparatus of starting signal for diesel generating set | |

| CN104332332B (en) | Interlocked control system for electric grounding switch | |

| CN202495897U (en) | Starting circuit for 60 type concrete towed pump | |

| CN203384018U (en) | Air compressor energy-saving cabinet control system | |

| CN205644195U (en) | Control circuit of high pressure prepayment switch electricity behaviour mechanism | |

| CN203324792U (en) | Plant electric power line and equipment monitoring system based on PLC | |

| CN204068769U (en) | A kind of control loop no-harass switch device of low voltage motor | |

| CN203232270U (en) | Automatic restart system of electrical energy collection terminal of transformer station | |

| CN103066550B (en) | Low voltage switch decompression reclosure control power transmission detection method and device | |

| CN110601373A (en) | Telecontrol machine restarting device | |

| CN104518566B (en) | A program-controlled device for automatic switching between generator set and grid power supply | |

| CN203691293U (en) | Mining explosion-proof and intrinsically-safe dual-contactor low-voltage AC soft starter | |

| CN203774865U (en) | A dual power switching circuit for fan power supply and a high-voltage inverter | |

| CN210577949U (en) | Telecontrol machine restarting device | |

| CN202362866U (en) | Prepaid device at 10 kV high-voltage wire-out end of transformer station | |

| CN203219225U (en) | Shield machine hydraulic oil pump start control device | |

| CN206268048U (en) | Air compressor machine frequency conversion system with standby frequency converter | |

| CN205960630U (en) | Three -phase rolling door machine circuit with open -phase protection | |

| CN104050855A (en) | Star-delta starting control experiment board based on PLC | |

| CN203434914U (en) | Double power supply double fan switch protection circuit | |

| CN203911447U (en) | Smart reclosing controller for low-voltage switch voltage loss | |

| CN205911970U (en) | Motor voltage -reduction starting control protection electric circuit | |

| CN203423480U (en) | Control device capable of preventing motor phase loss caused by instability of power grid | |

| CN203135575U (en) | Fingerprint identification remote operation system for transformer station |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| CF01 | Termination of patent right due to non-payment of annual fee |

Granted publication date: 20121017 Termination date: 20210214 |

|

| CF01 | Termination of patent right due to non-payment of annual fee |