CN202492953U - On-site concrete honeycomb square-box hollow floor slab - Google Patents

On-site concrete honeycomb square-box hollow floor slab Download PDFInfo

- Publication number

- CN202492953U CN202492953U CN2012200541422U CN201220054142U CN202492953U CN 202492953 U CN202492953 U CN 202492953U CN 2012200541422 U CN2012200541422 U CN 2012200541422U CN 201220054142 U CN201220054142 U CN 201220054142U CN 202492953 U CN202492953 U CN 202492953U

- Authority

- CN

- China

- Prior art keywords

- honeycomb square

- square chest

- honeycomb

- floor slab

- drag hook

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 230000003014 reinforcing effect Effects 0.000 claims description 24

- 230000002787 reinforcement Effects 0.000 claims description 23

- 238000011065 in-situ storage Methods 0.000 claims description 8

- 238000010276 construction Methods 0.000 abstract description 12

- 229910000831 Steel Inorganic materials 0.000 abstract description 8

- 239000010959 steel Substances 0.000 abstract description 8

- 239000002699 waste material Substances 0.000 description 6

- 238000005516 engineering process Methods 0.000 description 4

- 238000004519 manufacturing process Methods 0.000 description 3

- 238000006073 displacement reaction Methods 0.000 description 2

- 238000009413 insulation Methods 0.000 description 2

- 210000003205 muscle Anatomy 0.000 description 2

- 208000004350 Strabismus Diseases 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 230000007115 recruitment Effects 0.000 description 1

- 238000007634 remodeling Methods 0.000 description 1

- 238000003466 welding Methods 0.000 description 1

Images

Landscapes

- On-Site Construction Work That Accompanies The Preparation And Application Of Concrete (AREA)

Abstract

The utility model provides an on-site concrete honeycomb square-box hollow floor slab, which aims at solving the problems of the prior art that the surface height difference of the floor slab is large, the appearance quality of the floor slab is poor and the construction quality of the floor slab cannot be guaranteed because of position deviation caused by infirmness in the fixation of honeycomb square boxes. The utility model adopts the technical scheme that the on-site concrete honeycomb square-box hollow floor slab comprises a main beam, an upper row of steel bars and a lower row of steel bars, honeycomb square boxes are arranged between the upper row and the lower row of steel bars, and the honeycomb square boxes are fixed by a steel bar positioning system. The steel bar positioning system can effectively guarantee the accurate position of the honeycomb square boxes, positioning clamps on the left side and the right side ensure that the honeycomb square boxes do not move in the vertical direction, and positioning hooks on four corners ensures that the honeycomb square boxes do not move in the transverse direction, so that the construction quality of the floor slab concrete is guaranteed.

Description

Technical field

The utility model belongs to the building floor technical field, specifically, relates to a kind of cast-in-situ concrete honeycomb square chest cassette ceiling.

Background technology

Because the honeycomb square chest has sound insulation, insulation, lot of advantages such as in light weight, so mostly adopt honeycomb square chest floor in the building operations.In the cast-in-situ concrete honeycomb square chest cassette ceiling construction, because each honeycomb square chest all is independently, common way is with honeycomb square chest and reinforcing bar simply with steel wire lashing together; But when concreting, because each honeycomb square chest size is little, in light weight, when concrete vibration bar vibrates; The honeycomb square chest is floated on concrete; Relative position squints, and the result makes big, the poor flatness of the concrete floor surface discrepancy in elevation, the inner honeycomb square chest of floor skewness; Not only influenced structural safety but also be unfavorable for the impression quality of floor, construction quality can't guarantee.

Summary of the invention

The utility model provides a kind of cast-in-situ concrete honeycomb square chest cassette ceiling, and it can solve that prior art exists because the fixing insecure easy occurrence positions skew of honeycomb square chest causes that the slab surfaces discrepancy in elevation is big, the impression quality of floor and the problem that construction quality can't guarantee.

In order to solve the problems of the technologies described above, the technical scheme of the utility model is,

A kind of cast-in-situ concrete honeycomb square chest cassette ceiling comprises girder, goes up placing of reinforcement and following placing of reinforcement, is putting the honeycomb square chest between the placing of reinforcement up and down, and said honeycomb square chest adopts the reinforcing bar navigation system to fix.

Further, said reinforcing bar navigation system comprises the locator card that is arranged on the honeycomb square chest left and right sides and the location drag hook in four bights.

Again further, the every side of said locator card is provided with two, and locator card is " ⊥ " font structure, is welded on the said placing of reinforcement down.The setting of locator card prevents honeycomb square chest move left and right.

Usually, said locator card adopts the reinforcing bar of diameter 10-12mm to be welded.Usually adopt the steel scrap muscle processing and fabricating on the building site, simple for production, use flexibly, and reduce waste and old reinforcing bar and waste, improve the reinforcing bar utilization ratio.

Again further, " [ " shape reinforcing bar, said location drag hook hook said placing of reinforcement up and down fixes said honeycomb square chest to the employing of said location drag hook, prevents that the honeycomb square chest from fluctuating.

Preferably, the angle of drag hook is 75 ° above the drag hook of said location, below the angle of drag hook be 45 °.

The utility model has been made a kind of reinforcing bar navigation system of moving, the anti-left and right displacement of anti-floating of special use according to little, the lightweight characteristics of the size of honeycomb square chest, adopts the steel scrap muscle processing and fabricating on the building site; Have: simple for production, to use flexibly, efficiency of construction is high; Can guarantee effectively that honeycomb square chest position is accurate; The locator card of the left and right sides guarantees not fluctuate, and the location drag hook in four bights guarantees not left and right displacement, guarantees the floorslab concrete construction quality.

Concrete operations are following:

At first according to honeycomb square chest floor design drawing, the size of honeycomb square chest, the spacing between the square chest; Confirm the concrete size of reinforcing bar navigation system each several part, recruitment on the ground waste and old diameter 10-12 ㎜ reinforcing bar is welded into two " ⊥ " font locator cards, in four bights of honeycomb square chest with " [ " shape reinforcing bar drag hook hook about placing of reinforcement; Placing of reinforcement all uses special-purpose cushion block up and down; Tie up down earlier row's floor bar during construction, under arrange on the floor bar two " ⊥ " font locator cards of welding, then the honeycomb square chest is put by designing requirement; And hang logical line and check; Placing of reinforcement in the colligation of qualified back, at four angles of honeycomb square chest with " [ " shape location drag hook hooks placing of reinforcement up and down, like this honeycomb square chest with regard to and up and down placing of reinforcement, girder firm be joined together to form a total system; Guarantee the accurate positioning all around of honeycomb square chest, do not float up and down, and when concreting, do not float, be not shifted.After concrete floor was built completion, honeycomb square chest slab surfaces was smooth, smooth, attractive in appearance, and physical dimension is accurate, guaranteed that floor slab construction is quick, high-quality.

The utility model compared with prior art has the following advantages and good effect:

Waste and old reinforcement fabrication on the reinforcing bar positioning system using building site in the utility model cast-in-situ concrete honeycomb square chest cassette ceiling; Processing and fabricating is easy; Use flexibly; Efficiency of construction is high, can effectively guarantee the waste and old reinforcing bar waste of quality, minimizing, the raising reinforcing bar utilization ratio of construction technology, has highly application value; Honeycomb square chest accurate positioning all around, unsteady up and down, and when concreting, do not float, be not shifted.After concrete floor was built completion, honeycomb square chest slab surfaces was smooth, smooth, attractive in appearance, and physical dimension is accurate, guaranteed that floor slab construction is quick, high-quality.

Description of drawings

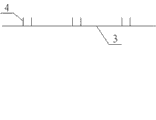

Fig. 1 is the plan view of the said honeycomb square chest of the utility model cassette ceiling;

Fig. 2 is the A-A sectional view of Fig. 1;

Fig. 3 is the partial enlarged drawing at the B place of Fig. 2;

Fig. 4 is the structural representation of the locator card in the reinforcing bar navigation system;

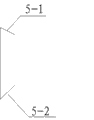

Fig. 5 is the structural representation of location drag hook;

Symbol among the figure and explanation thereof: 1, honeycomb square chest; 2, go up placing of reinforcement; 3, following placing of reinforcement; 4, locator card; 5, location drag hook; 5-1, last drag hook; 5-2, following drag hook.

The specific embodiment

Below in conjunction with accompanying drawing and embodiment the utility model is done further detailed explanation.

As shown in Figure 1, a kind of cast-in-situ concrete honeycomb square chest cassette ceiling comprises girder (not shown on the figure), goes up placing of reinforcement 2 and following placing of reinforcement 3, is putting honeycomb square chest 1 between the placing of reinforcement up and down, and honeycomb square chest 1 adopts the reinforcing bar navigation system to fix.

Shown in Fig. 1-3, the reinforcing bar navigation system comprises the locator card 4 that is arranged on honeycomb square chest 1 left and right sides and the location drag hook 5 in four bights.

Like Fig. 1 and shown in Figure 4, locator card 4 is provided with two in every side of honeycomb square chest 1, and locator card 4 is " ⊥ " font structure, is welded on down on the placing of reinforcement 3.The setting of locator card 4 prevents honeycomb square chest 1 move left and right.

Usually, locator card 4 adopts the reinforcing bar of diameter 10-12mm to be welded.

As shown in Figure 5, " [ " shape reinforcing bar, placing of reinforcement was fixing with honeycomb square chest 1 about location drag hook 5 hooked, and prevented that honeycomb square chest 1 from fluctuating for 5 employings of location drag hook.

Preferably, the angle of drag hook 5-1 is 75 ° on the drag hook 5 of location, and the angle of following drag hook 5-2 is 45 °.Location drag hook 5 adopts the reinforcing bar of diameter 6-8mm.

The above; It only is the preferred embodiment of the utility model; Be not to be the restriction of the utility model being made other form, any professional and technical personnel of being familiar with possibly utilize the technology contents of above-mentioned announcement to change or be modified as the equivalent embodiment of equivalent variations.But every the utility model technical scheme content that do not break away to any simple modification, equivalent variations and remodeling that above embodiment did, still belongs to the protection domain of the utility model technical scheme according to the technical spirit of the utility model.

Claims (6)

1. a cast-in-situ concrete honeycomb square chest cassette ceiling comprises girder, goes up placing of reinforcement and following placing of reinforcement, is putting the honeycomb square chest between the placing of reinforcement up and down, and it is characterized in that: said honeycomb square chest adopts the reinforcing bar navigation system to fix.

2. honeycomb square chest cassette ceiling according to claim 1 is characterized in that: said reinforcing bar navigation system comprises the locator card that is arranged on the honeycomb square chest left and right sides and the location drag hook in four bights.

3. honeycomb square chest cassette ceiling according to claim 2 is characterized in that: the every side of said locator card is provided with two, and locator card is " ⊥ " font structure, is welded on the said placing of reinforcement down.

4. honeycomb square chest cassette ceiling according to claim 3 is characterized in that: said locator card adopts the reinforcing bar of diameter 10-12mm to be welded.

5. honeycomb square chest cassette ceiling according to claim 3 is characterized in that: " [ " shape reinforcing bar, said location drag hook hook said placing of reinforcement up and down fixes said honeycomb square chest to the employing of said location drag hook.

6. honeycomb square chest cassette ceiling according to claim 5 is characterized in that: the angle of drag hook is 75 ° above the drag hook of said location, below the angle of drag hook be 45 °.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2012200541422U CN202492953U (en) | 2012-02-20 | 2012-02-20 | On-site concrete honeycomb square-box hollow floor slab |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2012200541422U CN202492953U (en) | 2012-02-20 | 2012-02-20 | On-site concrete honeycomb square-box hollow floor slab |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN202492953U true CN202492953U (en) | 2012-10-17 |

Family

ID=46999188

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN2012200541422U Expired - Fee Related CN202492953U (en) | 2012-02-20 | 2012-02-20 | On-site concrete honeycomb square-box hollow floor slab |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN202492953U (en) |

-

2012

- 2012-02-20 CN CN2012200541422U patent/CN202492953U/en not_active Expired - Fee Related

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN104532749A (en) | Support used for construction of upper beam of main tower of suspension bridge | |

| CN203361427U (en) | Novel hollow concrete floor plate | |

| CN202324616U (en) | Triangular steel truss supporting formwork system with high-altitude big-overhanging structure | |

| CN102535525B (en) | Structure and method utilizing anti-floating anchor rods to support underground raft plates | |

| CN203808249U (en) | Column stirrup cage assembly for beam-column joint core region | |

| CN102094391B (en) | Positioning construction method for top reinforcing mesh in railway bridge support platform | |

| CN202492953U (en) | On-site concrete honeycomb square-box hollow floor slab | |

| CN204385629U (en) | A kind of support for the construction of suspension bridge king-tower top rail | |

| CN202954437U (en) | Reinforced steel concrete beam column | |

| CN204959795U (en) | Self -supporting does not have row no mould basement flat slab floor | |

| CN204551172U (en) | A kind of prefabricated road surface of assembled steel reinforced concrete hollow | |

| CN204510806U (en) | The longitudinal edge cover bracket of building plain form rack system | |

| CN102852384A (en) | Fence upright | |

| CN103603266B (en) | Multilayer bridge overhanging isolation structure | |

| CN203008371U (en) | Cast-in-place concrete stand suspended mold installation structure | |

| CN204199691U (en) | A kind of handrail formwork for placing structure of spiral stairs | |

| CN205206315U (en) | Run -in runs formwork support system of stair more | |

| CN202611077U (en) | Light steel keel boom back supporting member | |

| CN202831387U (en) | Prestressed reinforced concrete composite beam with concavo-convex composite surface | |

| CN109386004A (en) | The simplification structure of foundation pit lattice column and reinforced concrete brace junction | |

| CN201679128U (en) | Honeycomb core floor slab | |

| CN104712063A (en) | Earthquake-resistant energy-dissipation connecting structure for steel joists and girders | |

| CN208396119U (en) | A kind of double center of circle arrow saltire arch ceiling structures | |

| CN204959794U (en) | Field word roof beam pile cap and flat slab floor structure system | |

| CN205046840U (en) | Concrete wall post template is propped up and is established location structure |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| CF01 | Termination of patent right due to non-payment of annual fee | ||

| CF01 | Termination of patent right due to non-payment of annual fee |

Granted publication date: 20121017 Termination date: 20200220 |