CN202492432U - Device for denitrification by SBR combined with anaerobic ammoxidation of landfill leachate - Google Patents

Device for denitrification by SBR combined with anaerobic ammoxidation of landfill leachate Download PDFInfo

- Publication number

- CN202492432U CN202492432U CN2011205126703U CN201120512670U CN202492432U CN 202492432 U CN202492432 U CN 202492432U CN 2011205126703 U CN2011205126703 U CN 2011205126703U CN 201120512670 U CN201120512670 U CN 201120512670U CN 202492432 U CN202492432 U CN 202492432U

- Authority

- CN

- China

- Prior art keywords

- water tank

- reactor

- sbr

- anammox

- peristaltic pump

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02W—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO WASTEWATER TREATMENT OR WASTE MANAGEMENT

- Y02W10/00—Technologies for wastewater treatment

- Y02W10/10—Biological treatment of water, waste water, or sewage

Landscapes

- Purification Treatments By Anaerobic Or Anaerobic And Aerobic Bacteria Or Animals (AREA)

Abstract

本实用新型涉及一种垃圾渗滤液SBR与厌氧氨氧化组合脱氮装置,属于低碳氮(C/N)比高浓度氨氮垃圾渗滤液生物脱氮技术领域。该装置设有一体化水箱、SBR短程硝化反应器、厌氧氨氧化反应器;一体化水箱中的前置水箱和后置水箱通过出水管和蠕动泵与SBR短程硝化反应器相连通,后置水箱通过出水管和蠕动泵与厌氧氨氧化反应器底部相连接,厌氧氨氧化反应器设有自循环管路,并通过出水管和蠕动泵与SBR前置水箱相连接;所述方法包括以下步骤:启动SBR短程硝化反应器、启动厌氧氨氧化反应器、SBR短程硝化反应器与厌氧氨氧化反应器串联运行。本实用新型的装置适用于垃圾填埋场的晚期垃圾渗滤液的有机物去除与短程脱氮,工艺先进,节能降耗优势明显。

The utility model relates to a combination denitrification device of landfill leachate SBR and anaerobic ammonium oxidation, which belongs to the technical field of biological denitrification of landfill leachate with low carbon-to-nitrogen (C/N) ratio and high concentration ammonia nitrogen. The device is equipped with an integrated water tank, SBR short-range nitrification reactor, and anaerobic ammonium oxidation reactor; The water tank is connected to the bottom of the anammox reactor through an outlet pipe and a peristaltic pump, and the anammox reactor is provided with a self-circulation pipeline, and is connected to the SBR front water tank through an outlet pipe and a peristaltic pump; the method includes The following steps: start the SBR short-cut nitrification reactor, start the anaerobic ammonium oxidation reactor, and run the SBR short-cut nitrification reactor and the anaerobic ammonium oxidation reactor in series. The device of the utility model is suitable for the removal of organic matter and short-range denitrification of late-stage landfill leachate, and has advanced technology and obvious advantages of energy saving and consumption reduction.

Description

技术领域 technical field

本实用新型涉及一种垃圾渗滤液SBR与厌氧氨氧化组合脱氮装置,属于低碳氮(C/N)比高浓度氨氮废水生物脱氮技术领域,适用于晚期垃圾渗滤液等低C/N比的高氨氮废水的生物脱氮。 The utility model relates to a combined denitrification device for landfill leachate SBR and anaerobic ammonium oxidation, which belongs to the technical field of biological denitrification of waste water with low carbon nitrogen (C/N) ratio and high concentration ammonia nitrogen, and is suitable for low C/N of late stage landfill leachate and the like. Biological denitrification of high ammonia-nitrogen wastewater with N ratio. the

背景技术 Background technique

近几年来,随着城市固体废物产量的不断增加,填埋法逐渐成为世界上应用最广泛的处理和处置方法。填埋产生的渗滤液因具有成分复杂、水质水量变化大、有机物和氨氮浓度高、微生物营养元素比例失调等水质特点,使其处理成为国际范围内尚未解决的难题之一。采用单一的处理技术往往不能经济高效的处理渗滤液,需要不同特点的工艺联合使用。有机碳源的严重缺乏是晚期渗滤液脱氮效率无法提高的屏障,而外加有机碳源会大幅度的增加污水脱氮的费用。因此,需要提出更为有效的脱氮的装置和方法。 In recent years, with the increasing output of municipal solid waste, landfilling has gradually become the most widely used treatment and disposal method in the world. The leachate produced by landfill has the characteristics of complex composition, large changes in water quality and quantity, high concentration of organic matter and ammonia nitrogen, and imbalance of microbial nutrient elements, making its treatment one of the unsolved problems in the international scope. It is often impossible to treat leachate economically and efficiently by using a single treatment technology, and a combination of processes with different characteristics is required. The serious lack of organic carbon source is the barrier that the denitrification efficiency of late leachate cannot be improved, and the addition of organic carbon source will greatly increase the cost of sewage denitrification. Therefore, more effective denitrification devices and methods need to be proposed. the

污水生物脱氮通过硝化将NH4 +-N转化为NO3 --N,再通过反硝化将NO3 --N转化为氮气从水中逸出。反硝化阶段以NO3 --N为电子受体,有机物作为电子供体,将氨氮转化为氮气完成生物脱氮。但对于高NH4 +-N晚期垃圾渗滤液脱氮而言,其C/N比仅在1左右,由于有机碳源严重不足,导致传统生物脱氮效率只能达到10%左右。 Sewage biological denitrification converts NH 4 + -N into NO 3 - -N through nitrification, and then converts NO 3 - -N into nitrogen through denitrification and escapes from the water. In the denitrification stage, NO 3 - -N is used as the electron acceptor, organic matter is used as the electron donor, and ammonia nitrogen is converted into nitrogen to complete biological denitrification. However, for high NH 4 + -N late stage landfill leachate denitrification, the C/N ratio is only about 1. Due to the serious shortage of organic carbon sources, the efficiency of traditional biological denitrification can only reach about 10%.

而厌氧氨氧化具有如下优点:由于厌氧氨氧化菌是自养菌,碳酸盐/二氧化碳是其生长所需的无机碳源,所以氨氮的氧化无需分子氧参与,同时亚硝态氮的还原也无需有机碳源,这将大大降低污水好氧生物脱氮的运行费用;Anammox微生物的增长率(倍增时间为11d)与产率(0.11g[VSS]/g[NH4 +])是非常低的,故污泥产量低,然而氮的转化率却为0.25mg[N]/(mg[SS]·d),与传统的好氧硝化旗鼓相当;在不投加任何化学药品的条件下,既能降低污水处理厂的运行费用,又能够实现氮的高效去除。对低C/N比高氨氮的渗滤液垃圾渗滤液而言,实现厌氧氨氧化反应是其脱氮的最佳途径,同时也是与其水质特点最为适合的脱氮技术。 And anammox has the following advantages: Since anammox bacteria are autotrophic bacteria, carbonate/carbon dioxide is the inorganic carbon source required for their growth, so the oxidation of ammonia nitrogen does not require the participation of molecular oxygen, while the oxidation of nitrite nitrogen The reduction also does not require organic carbon sources, which will greatly reduce the operating costs of aerobic biological denitrification of sewage; the growth rate (doubling time of 11d) and production rate (0.11g[VSS]/g[NH 4 + ]) of Anammox microorganisms are It is very low, so the sludge output is low, but the conversion rate of nitrogen is 0.25mg[N]/(mg[SS]·d), which is comparable to the traditional aerobic nitrification; under the condition of not adding any chemicals , can not only reduce the operating cost of the sewage treatment plant, but also realize the efficient removal of nitrogen. For the leachate landfill leachate with low C/N ratio and high ammonia nitrogen, the realization of anammox reaction is the best way to denitrify it, and it is also the most suitable denitrification technology for its water quality characteristics.

实用新型内容 Utility model content

本实用新型的目的是为了解决上述技术问题,提出一种垃圾渗滤液SBR与厌氧氨氧化组合脱氮装置,即首先实现城市垃圾填埋场渗滤液中高浓度NH4 +-N的短程硝化反应,而后再实现厌氧氨氧化反应,最终实现经济高效的垃圾渗滤液自养脱氮的装置与方法。 The purpose of this utility model is to solve the above-mentioned technical problems, and propose a combination denitrification device of landfill leachate SBR and anaerobic ammonium oxidation, that is, to firstly realize the short-range nitrification reaction of high-concentration NH 4 + -N in the leachate of urban landfill sites , and then realize the anaerobic ammonium oxidation reaction, and finally realize the device and method of cost-effective autotrophic denitrification of landfill leachate.

本实用新型的目的是通过以下技术方案来实现的: The purpose of this utility model is achieved by the following technical solutions:

一种垃圾渗滤液SBR与厌氧氨氧化组合脱氮装置,其特征在于: A combined denitrification device for landfill leachate SBR and anaerobic ammonium oxidation, characterized in that:

该装置包括一体化水箱,SBR短程硝化反应器、厌氧氨氧化反应器;一体化水箱包括原 水箱、后置水箱、前置水箱以及置于原水箱、后置水箱和前置水箱中间的加热水箱,加热水箱中设置有温控加热装置;原水箱通过第一进水管和第一蠕动泵与前置水箱相连接,原水箱通过第四进水管和第七蠕动泵和厌氧氨氧化反应器相连通;一体化水箱中的前置水箱通过第二进水管与第四蠕动泵和SBR短程硝化反应器相连通,SBR短程硝化反应器通过第一出水管和第五蠕动泵与后置水箱相连接,后置水箱通过第三进水管和第三蠕动泵与厌氧氨氧化反应器底部相连接,厌氧氨氧化反应器设有第二回流管和第六蠕动泵用于自循环,厌氧氨氧化反应器通过第二蠕动泵与第一回流管和前置水箱相连接; The device includes an integrated water tank, SBR short-range nitrification reactor, and anaerobic ammonium oxidation reactor; the integrated water tank includes a raw water tank, a rear water tank, a front water tank, and a heating device placed between the raw water tank, the rear water tank, and the front water tank. Water tank, the heating water tank is equipped with a temperature-controlled heating device; the raw water tank is connected to the front water tank through the first water inlet pipe and the first peristaltic pump, and the raw water tank is connected to the anaerobic ammonia oxidation reactor through the fourth water inlet pipe and the seventh peristaltic pump The front water tank in the integrated water tank is connected with the fourth peristaltic pump and the SBR short-range nitrification reactor through the second water inlet pipe, and the SBR short-range nitrification reactor is connected with the rear water tank through the first water outlet pipe and the fifth peristaltic pump. connection, the rear water tank is connected to the bottom of the anammox reactor through the third water inlet pipe and the third peristaltic pump, and the anammox reactor is provided with a second return pipe and a sixth peristaltic pump for self-circulation, anaerobic The ammonia oxidation reactor is connected with the first return pipe and the front water tank through the second peristaltic pump;

SBR短程硝化反应器自上而下设置数个第一取样阀门,第二进水管上设有进水控制阀;第一出水管上设有排水阀;SBR短程硝化反应器设有机械搅拌装置;在SBR短程硝化反应器底部设有曝气头,曝气头与曝气泵通过曝气管相连,曝气管上设有第一气体流量计;SBR短程硝化反应器匹配设置有DO仪、ORP仪以及pH仪; The SBR short-range nitrification reactor is equipped with several first sampling valves from top to bottom, the second water inlet pipe is equipped with a water inlet control valve; the first water outlet pipe is equipped with a drain valve; the SBR short-range nitrification reactor is equipped with a mechanical stirring device; There is an aeration head at the bottom of the SBR short-range nitrification reactor, and the aeration head is connected with the aeration pump through an aeration pipe. meter and pH meter;

厌氧氨氧化反应器设有温控加热带装置和圆筒形污泥床,厌氧氨氧化反应器上部设有三相分离器和顶部密封板,该三相分离器的上部与碱液瓶、第二气体流量计连通;圆筒形污泥床上部上清液通过第六蠕动泵进入到圆筒形污泥床底部进行循环;圆筒形污泥床顶部溢出水一部分通过第二出水管排放,一部分回流到前置水箱,厌氧氨氧化反应器外部设有连通污泥床的上下数个第二取样阀。 The anaerobic ammonium oxidation reactor is equipped with a temperature-controlled heating belt device and a cylindrical sludge bed. The upper part of the anaerobic ammonium oxidation reactor is provided with a three-phase separator and a top sealing plate. The upper part of the three-phase separator is connected with the lye bottle, The second gas flowmeter is connected; the upper supernatant of the cylindrical sludge bed enters the bottom of the cylindrical sludge bed through the sixth peristaltic pump for circulation; part of the overflow water at the top of the cylindrical sludge bed is discharged through the second outlet pipe , part of which is returned to the front water tank, and several second sampling valves connecting the upper and lower sides of the sludge bed are arranged outside the anaerobic ammonium oxidation reactor. the

利用上述装置实现垃圾渗滤液短程硝化与厌氧氨氧化组合脱氮的方法,其特征在于包括以下步骤: Utilize above-mentioned device to realize the method for combined denitrification of landfill leachate short-range nitrification and anaerobic ammonium oxidation, it is characterized in that comprising the following steps:

步骤一:启动SBR短程硝化反应器:以实际城市污水处理厂的硝化污泥为接种污泥注入SBR短程硝化反应器,其污泥浓度为5000kg MLSS/m3,同时,以实际城市垃圾填埋场渗滤液为原液并用自来水稀释后注入前置水箱,前置水箱通过第二进水管和第四蠕动泵将稀释后的渗滤液泵入SBR短程硝化反应器;随后启动由曝气头、曝气泵以及曝气管组成的曝气系统对流入SBR短程硝化反应器的垃圾渗滤液进行硝化,反应过程维持溶解氧DO在2mg/L左右,pH值维持在7.8左右,如果pH过高或过低时,则投加NaHCO3使pH值维持在该范围,通过调节第四蠕动泵维持SBR短程硝化反应器进水NH4 +-N负荷为ALR=0.4kgNH4 +-N/m3d左右,通过保持pH值和ALR在上述值使SBR短程硝化反应器中的平均游离氨FA浓度为18mg/L;在上述条件下运行SBR短程硝化反应器,当其出水亚硝酸氮NO2 --N累积率大于95%时,SBR短程硝化得以实现和维持,具备了厌氧氨氧化反应器的进水水质要求; Step 1: Start the SBR short-cut nitrification reactor: use the nitrification sludge of the actual urban sewage treatment plant as the seed sludge to inject into the SBR short-cut nitrification reactor, and the sludge concentration is 5000kg MLSS/m 3 , and at the same time, use the actual urban waste landfill The on-site leachate is the original liquid and diluted with tap water and injected into the front water tank. The front water tank pumps the diluted leachate into the SBR short-range nitrification reactor through the second water inlet pipe and the fourth peristaltic pump; The aeration system composed of pumps and aeration pipes nitrifies the landfill leachate flowing into the SBR short-path nitrification reactor. During the reaction process, the dissolved oxygen DO is maintained at about 2mg/L, and the pH value is maintained at about 7.8. If the pH is too high or too low , then add NaHCO 3 to maintain the pH value in this range, and maintain the NH 4 + -N load of the SBR short-path nitrification reactor by adjusting the fourth peristaltic pump to about ALR=0.4kgNH 4 + -N/m 3 d, The average free ammonia FA concentration in the SBR short-path nitrification reactor is 18 mg/L by keeping the pH value and ALR at the above-mentioned values; when the SBR short-path nitrification reactor is operated under the above-mentioned conditions, when the effluent nitrite nitrogen NO 2 - -N accumulates When the rate is greater than 95%, the SBR short-cut nitrification can be realized and maintained, and the influent water quality requirements of the anammox reactor are met;

步骤二:启动厌氧氨氧化反应器:将某污水处理厂的中试厌氧氨氧化反应器中的具有一定厌氧氨氧化活性的污泥投加到厌氧氨氧化反应器,污泥浓度为5kg MLSS/m3;厌氧氨氧化反应器通过温控加热带装置使得温度控制在35°C,将SBR短程硝化反应器出水与渗滤液原 液用自来水稀释使其亚硝态氮与氨氮的浓度均维持为100mg/L,同时将稀释后的上述混合水按照20L/d的流量泵入到厌氧氨氧化反应器;当厌氧氨氧化反应器出水NH4 +-N与NO2 --N浓度均小于15mg/L时,厌氧氨氧化反应得以实现和维持; Step 2: Start the anammox reactor: add the sludge with certain anammox activity in the pilot anammox reactor of a sewage treatment plant to the anammox reactor, and the sludge concentration 5kg MLSS/m 3 ; the temperature of the anaerobic ammonium oxidation reactor is controlled at 35°C through a temperature-controlled heating belt device, and the effluent and leachate stock solution of the SBR short-range nitrification reactor are diluted with tap water to make the nitrite nitrogen and ammonia nitrogen The concentration is maintained at 100mg/L, and at the same time, the diluted mixed water is pumped into the anammox reactor at a flow rate of 20L/d; when the anammox reactor effluent NH 4 + -N and NO 2 - - When the N concentration is less than 15mg/L, the anammox reaction can be realized and maintained;

步骤三:SBR短程硝化反应器与厌氧氨氧化反应器分别完成启动后,将两者串联运行:其中SBR短程硝化反应器的充水比例为1:1,原水箱中的垃圾渗滤液与厌氧氨氧化反应器出水回流液的混合液经第一蠕动泵和第二蠕动泵泵入到前置水箱,前置水箱中出水通过第四蠕动泵泵入SBR短程硝化反应器,在SBR短程硝化反应器中首先利用渗滤液的碳源作为反硝化的碳源进行脱氮,在反硝化阶段氧化还原电位ORP逐渐下降直到出现平台,同时pH值上升到最高点不再变化时,此时关闭SBR短程硝化反应器的机械搅拌装置,停止缺氧搅拌,停止反硝化,而后开启曝气泵进行曝气硝化,随着硝化过程酸的产生,pH逐渐降低,当氨氮被消耗完,亚硝酸盐浓度达到了最大值,随后pH由于吹脱作用而逐渐增加;同时,DO浓度迅速增加,氨谷和DO突跃点各自出现在pH和DO曲线上,此外,ORP值也随硝化作用的进行而增加直到氨氮被消耗完,亚硝酸盐浓度达到最大值后ORP并不随曝气的继续进行而改变;ORP平台的出现表明硝酸盐和亚硝酸盐不再增加,硝化结束,此时,停止曝气,关闭曝气泵;硝化完成后,静止沉淀30~60分钟,进行泥水分离,开启第五蠕动泵32将上清液泵入后置水箱;后置水箱中出水通过第三蠕动泵从厌氧氨氧化反应器底部泵入,当NO2 --N/NH4 +-N>1.32时,适当增加从原水箱进入厌氧氨氧化反应器的流量,相反当NO2 --N/NH4 +-N<1.32时适当降低从原水箱进入厌氧氨氧化反应器的流量;SBR短程硝化反应器和原水箱混合流入的硝化混合液经过第三蠕动泵和第七蠕动泵进入到厌氧氨氧化反应器完成厌氧氨氧化反应;当厌氧氨氧化反应器总氮负荷达到0.8kg TN/m3d以上,并且系统出水NH4 +-N与NO2 --N去除率大于90%时,系统实现了垃圾渗滤液的全程自养脱氮过程。

Step 3: After the SBR short-range nitrification reactor and the anaerobic ammonium oxidation reactor are started respectively, the two are operated in series: the water filling ratio of the SBR short-range nitrification reactor is 1:1, and the landfill leachate in the raw water tank and the anaerobic ammonium oxidation reactor The mixture of effluent and reflux liquid from the oxygen ammonia oxidation reactor is pumped into the front water tank through the first peristaltic pump and the second peristaltic pump. In the reactor, the carbon source of the leachate is used as the carbon source for denitrification to denitrify. During the denitrification stage, the ORP gradually decreases until a plateau appears, and when the pH value rises to the highest point and does not change, the SBR is turned off at this time. The mechanical stirring device of the short-range nitrification reactor stops anoxic stirring, stops denitrification, and then turns on the aeration pump for aeration and nitrification. With the generation of acid in the nitrification process, the pH gradually decreases. When the ammonia nitrogen is consumed, the concentration of nitrite It reached the maximum value, and then the pH gradually increased due to stripping; at the same time, the DO concentration increased rapidly, and ammonia valleys and DO jump points appeared on the pH and DO curves respectively. In addition, the ORP value also increased with the progress of nitrification The ORP does not change with the continuation of aeration until the ammonia nitrogen is consumed and the nitrite concentration reaches the maximum value; the appearance of the ORP platform indicates that the nitrate and nitrite no longer increase, and the nitrification is over. At this time, the aeration is stopped. Turn off the aeration pump; after nitrification is completed, settle still for 30 to 60 minutes to separate the mud and water, and turn on the fifth

有益效果 Beneficial effect

本实用新型的垃圾渗滤液SBR与厌氧氨氧化组合脱氮装置与现有技术相比,具有下列优点: Compared with the prior art, the landfill leachate SBR and anaerobic ammonium oxidation combined denitrification device of the present utility model has the following advantages:

渗滤液的全程自养脱氮过程: The whole autotrophic denitrification process of leachate:

1)在不投加外加碳源的条件下,实现垃圾渗滤液的高效生物脱氮,解决了高浓度氨氮,低碳氮比的晚期渗滤液的处理难题,大大降低了运行和建设费用。 1) Under the condition of not adding any additional carbon source, the high-efficiency biological denitrification of landfill leachate is realized, which solves the problem of late leachate treatment with high concentration of ammonia nitrogen and low carbon-to-nitrogen ratio, and greatly reduces the operation and construction costs. the

2)短程硝化的实现,使得氨氮的转化方式有别于传统硝化方式,降低了能耗,提高了效率,减少了污泥产量。 2) The realization of short-range nitrification makes the conversion method of ammonia nitrogen different from the traditional nitrification method, reduces energy consumption, improves efficiency, and reduces sludge production. the

3)通过在线检测氧化还原电位ORP和pH值把握短程反硝化的进程,用过程控制的方法实时控制搅拌时间,从而达到节能的目的。而在硝化过程中,氨谷,DO突跃点和ORP平台不仅 精确表明了硝化的终点而节约能耗,同时也避免了过度曝气而维持了较高的亚硝酸积累率。 3) Grasp the process of short-range denitrification by online detection of ORP and pH value, and use the process control method to control the stirring time in real time, so as to achieve the purpose of energy saving. In the nitrification process, the ammonia valley, DO breakthrough point and ORP platform not only accurately indicate the end point of nitrification and save energy, but also avoid excessive aeration and maintain a high nitrous acid accumulation rate. the

4)该技术成熟运行后,不需要添加外加药剂,并且不需要外加水源稀释原液,简化了管理流程,可以直接处理高氨氮浓度的晚期渗滤液。 4) After the technology is mature and running, it does not need to add additional chemicals, and does not need to add water to dilute the original solution, which simplifies the management process and can directly treat late-stage leachate with high ammonia nitrogen concentration. the

附图说明 Description of drawings

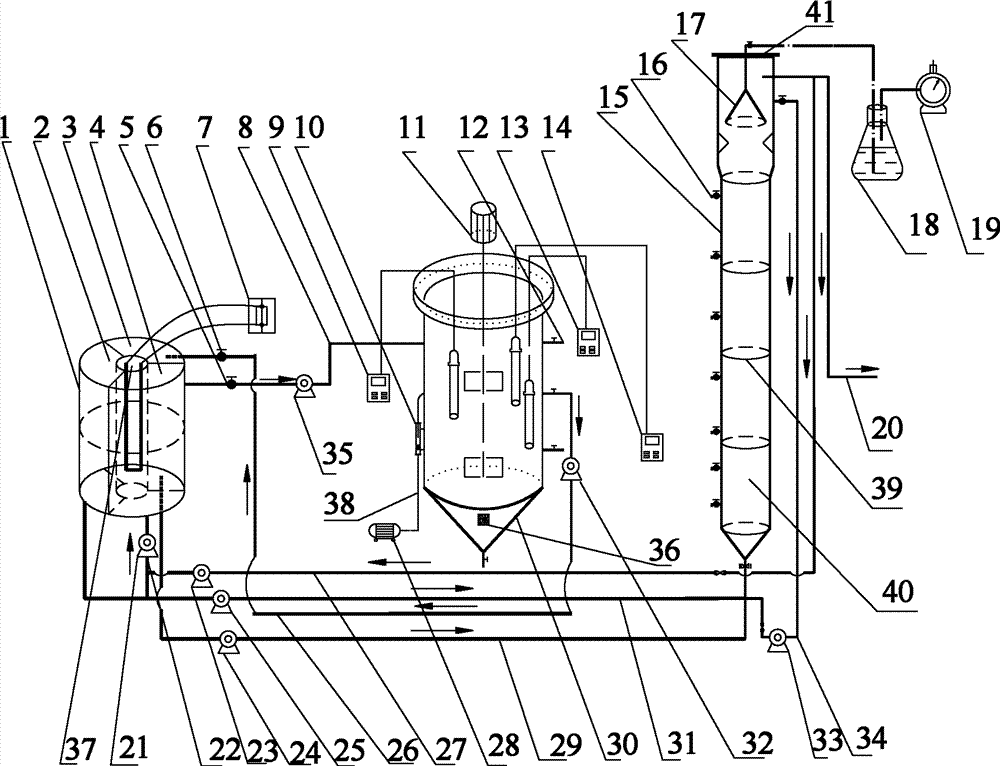

图1为本实用新型的垃圾渗滤液SBR与厌氧氨氧化组合脱氮装置结构示意图。 Fig. 1 is a structural schematic diagram of a combination denitrification device for landfill leachate SBR and anaerobic ammonium oxidation of the present invention. the

图中:1-一体化水箱;2-原水箱;3-后置水箱;4-前置水箱;5-进水控制阀;6-排水阀;7-温控加热装置;8-第二进水管;9-DO仪;10-第一气体流量计;11-机械搅拌装置;12-第一取样阀;13-ORP仪;14-pH仪;15-厌氧氨氧化反应器;16-第二取样阀;17-三相分离器;18-碱液瓶;19-第二气体流量计;20-第二出水管;21-第一蠕动泵;22-第一进水管;23-第二蠕动泵;24-第三蠕动泵;25-第七蠕动泵;26-第一出水管;27-第一回流管;28-曝气泵;29-第三进水管;30-SBR短程硝化反应器;31-第四进水管;32-第五蠕动泵;33-第六蠕动泵;34-第二回流管;35-第四蠕动泵;36-曝气头;37-加热水箱;38-曝气管;39-温控加热带装置;40-圆筒形污泥床;41-顶部密封板; In the figure: 1-integrated water tank; 2-raw water tank; 3-rear water tank; 4-front water tank; 5-water inlet control valve; 6-drain valve; 7-temperature control heating device; 8-second inlet Water pipe; 9-DO instrument; 10-first gas flow meter; 11-mechanical stirring device; 12-first sampling valve; 13-ORP instrument; 14-pH instrument; 15-anammox reactor; 16-the first Two sampling valves; 17-three-phase separator; 18-lye bottle; 19-second gas flow meter; 20-second outlet pipe; 21-first peristaltic pump; 22-first water inlet pipe; 23-second Peristaltic pump; 24-third peristaltic pump; 25-seventh peristaltic pump; 26-first outlet pipe; 27-first return pipe; 28-aeration pump; 29-third water inlet pipe; 30-SBR short-range nitrification reaction 31-the fourth water inlet pipe; 32-the fifth peristaltic pump; 33-the sixth peristaltic pump; 34-the second return pipe; 35-the fourth peristaltic pump; 36-aeration head; 37-heating water tank; 38- Aeration pipe; 39-temperature-controlled heating belt device; 40-cylindrical sludge bed; 41-top sealing plate;

具体实施方式 Detailed ways

下面结合附图和实施例对本实用新型作进一步的说明: Below in conjunction with accompanying drawing and embodiment the utility model is further described:

如图1所示,本实用新型的垃圾渗滤液SBR与厌氧氨氧化组合脱氮装置,包括一体化水箱1,SBR短程硝化反应器30、厌氧氨氧化反应器15;一体化水箱包括原水箱2、后置水箱3、前置水箱4以及置于原水箱2、后置水箱3和前置水箱4中间的加热水箱37,加热水箱中设置有温控加热装置7;原水箱2通过第一进水管22和第一蠕动泵21与前置水箱4相连接,原水箱2通过第四进水管31和第七蠕动泵25和厌氧氨氧化反应器15相连通;一体化水箱中的前置水箱4通过第二进水管8与第四蠕动泵35和SBR短程硝化反应器30相连通,SBR短程硝化反应器30通过第一出水管26和第五蠕动泵32与后置水箱3相连接,后置水箱3通过第三进水管29和第三蠕动泵24与厌氧氨氧化反应器15底部相连接,厌氧氨氧化反应器15设有第二回流管34和第六蠕动泵33用于自循环,厌氧氨氧化反应器15通过第二蠕动泵23与第一回流管27和前置水箱4相连接;

As shown in Figure 1, the combined denitrification device for landfill leachate SBR and anammox of the present utility model includes an integrated water tank 1, an SBR short-range nitrification reactor 30, and anammox reactor 15; the integrated water tank includes the original The water tank 2, the rear water tank 3, the front water tank 4 and the heating water tank 37 placed in the middle of the original water tank 2, the rear water tank 3 and the front water tank 4, the heating water tank is provided with a temperature control heating device 7; the original water tank 2 passes through the first A water inlet pipe 22 and the first peristaltic pump 21 are connected to the front water tank 4, and the raw water tank 2 is connected to the anaerobic ammonium oxidation reactor 15 through the fourth water inlet pipe 31 and the seventh peristaltic pump 25; the front water tank in the integrated water tank The water tank 4 communicates with the fourth peristaltic pump 35 and the SBR short-path nitrification reactor 30 through the second water inlet pipe 8, and the SBR short-path nitrification reactor 30 is connected with the rear water tank 3 through the first water outlet pipe 26 and the fifth peristaltic pump 32 , the rear water tank 3 is connected with the bottom of the anammox reactor 15 through the third water inlet pipe 29 and the third peristaltic pump 24, and the anammox reactor 15 is provided with the second return pipe 34 and the sixth peristaltic pump 33. For self-circulation, the anammox

SBR短程硝化反应器30自上而下设置数个第一取样阀门12,第二进水管8上设有进水控制阀5;第一出水管26上设有排水阀6;SBR短程硝化反应器30设有机械搅拌装置11;在SBR短程硝化反应器30底部设有曝气头36,曝气头36与曝气泵28通过曝气管38相连,曝气管38上设有第一气体流量计10;SBR短程硝化反应器30匹配设置有DO仪9、ORP仪13以及pH仪14;

The SBR short-

厌氧氨氧化反应器15设有温控加热带装置39和圆筒形污泥床40,厌氧氨氧化反应器15 上部设有三相分离器17和顶部密封板41,该三相分离器17的上部与碱液瓶18、第二气体流量计19连通;圆筒形污泥床40上部上清液通过第六蠕动泵33进入到圆筒形污泥床40底部进行循环;圆筒形污泥床40顶部溢出水一部分通过第二出水管20排放,一部分回流到前置水箱4,厌氧氨氧化反应器15外部设有连通污泥床的上下数个第二取样阀16。

The anammox

其中,一体化水箱1总体积为52L,分为四个部分,其中原水箱2,前置水箱4,后置水箱3,加热水箱37的体积分别为30L,10L,10L,2L。SBR短程硝化反应器30内径为12cm,外径为13cm,高为40cm,总有效容积为4.5L。厌氧氨氧化反应器15为圆柱形,由有机玻璃组成,其上部分内径、外径和高度分别为80mm、90mm、450mm,下部分内径、外径和高度分别为60mm、70mm、1450mm,上下部分由50mm高的圆台形有机玻璃管连接,有效容积为5.5L。厌氧氨氧化反应器15设有三相分离器,距顶部的距离为200mm,并从反应器底部开始,每间距200mm在侧壁上设置取样口,共5个。

Wherein, the integrated water tank 1 has a total volume of 52L and is divided into four parts, wherein the volumes of the

取北京市某填垃圾埋场场的渗滤液,其氨氮浓度高达2200mg/L,COD/NH4 +-N=1.4,为典型晚期垃圾渗滤液。具体方法为: The leachate from a landfill in Beijing was taken. The ammonia nitrogen concentration was as high as 2200mg/L, and COD/NH 4 + -N=1.4, which is a typical late-stage landfill leachate. The specific method is:

步骤一:启动SBR短程硝化反应器30:以实际城市污水处理厂的硝化污泥为接种污泥注入SBR短程硝化反应器30,其污泥浓度为5000kg MLSS/m3,同时,以实际城市垃圾填埋场渗滤液为原液并用自来水稀释后注入前置水箱4,前置水箱通过第二进水管8和第四蠕动泵35将稀释后的渗滤液泵入SBR短程硝化反应器30;随后启动由曝气头36、曝气泵28以及曝气管38组成的曝气系统对流入SBR短程硝化反应器30的垃圾渗滤液进行硝化,反应过程维持溶解氧DO在2mg/L左右,pH值维持在7.8左右,如果pH过高或过低时,则投加NaHCO3使pH值维持在该范围,通过调节第四蠕动泵35维持SBR短程硝化反应器30进水NH4 +-N负荷为ALR=0.4kgNH4 +-N/m3d左右,通过保持pH值和ALR在上述值使SBR短程硝化反应器30中的平均游离氨FA浓度为18mg/L;在上述条件下运行SBR短程硝化反应器30,当其出水亚硝酸氮NO2 --N累积率大于95%时,SBR短程硝化得以实现和维持,具备了厌氧氨氧化反应器的进水水质要求;

Step 1: Start the SBR short-cut nitrification reactor 30: Inject the nitrification sludge of the actual urban sewage treatment plant into the SBR short-

步骤二:启动厌氧氨氧化反应器15:将某污水处理厂的中试厌氧氨氧化反应器中的具有一定厌氧氨氧化活性的污泥投加到厌氧氨氧化反应器15,污泥浓度为5kg MLSS/m3;厌氧氨氧化反应器15通过温控加热带装置39使得温度控制在35°C,将SBR短程硝化反应器30出水与渗滤液原液用自来水稀释使其亚硝态氮与氨氮的浓度均维持为100mg/L,同时将稀释后的上述混合水按照20L/d的流量泵入到厌氧氨氧化反应器15;当厌氧氨氧化反应器15出水NH4 +-N与NO2 --N浓度均小于15mg/L时,厌氧氨氧化反应得以实现和维持;

Step 2: start the anammox reactor 15: add the sludge with a certain anammox activity in the pilot anammox reactor of a certain sewage treatment plant to the anammox

步骤三:SBR短程硝化反应器30与厌氧氨氧化反应器15分别完成启动后,将两者串联 运行:其中SBR短程硝化反应器30的充水比例为1:1,原水箱2中的垃圾渗滤液与厌氧氨氧化反应器15出水回流液的混合液经第一蠕动泵21和第二蠕动泵23泵入到前置水箱4,前置水箱4中出水通过第四蠕动泵35泵入SBR短程硝化反应器30,在SBR短程硝化反应器30中首先利用渗滤液的碳源作为反硝化的碳源进行脱氮,在反硝化阶段氧化还原电位ORP逐渐下降直到出现平台,同时pH值上升到最高点不再变化时,此时关闭SBR短程硝化反应器30的机械搅拌装置11,停止缺氧搅拌,停止反硝化,而后开启曝气泵28进行曝气硝化,随着硝化过程酸的产生,pH逐渐降低,当氨氮被消耗完,亚硝酸盐浓度达到了最大值,随后pH由于吹脱作用而逐渐增加;同时,DO浓度迅速增加,氨谷和DO突跃点各自出现在pH和DO曲线上,此外,ORP值也随硝化作用的进行而增加直到氨氮被消耗完,亚硝酸盐浓度达到最大值后ORP并不随曝气的继续进行而改变;ORP平台的出现表明硝酸盐和亚硝酸盐不再增加,硝化结束,此时,停止曝气,关闭曝气泵28;硝化完成后,静止沉淀30~60分钟,进行泥水分离,开启第五蠕动泵32将上清液泵入后置水箱3;后置水箱3中出水通过第三蠕动泵24从厌氧氨氧化反应器15底部泵入,当NO2 --N/NH4 +-N>1.32时,适当增加从原水箱2进入厌氧氨氧化反应器15的流量,相反当NO2 --N/NH4 +-N<1.32时适当降低从原水箱进入厌氧氨氧化反应器15的流量;SBR短程硝化反应器30和原水箱2混合流入的硝化混合液经过第三蠕动泵24和第七蠕动泵25进入到厌氧氨氧化反应器15完成厌氧氨氧化反应;当厌氧氨氧化反应器总氮负荷达到0.8kg TN/m3d以上,并且系统出水NH4 +-N与NO2 --N去除率大于90%时,系统实现了垃圾渗滤液的全程自养脱氮过程。

Step 3: After the SBR short-

在垃圾渗滤液平均氨氮浓度为2200mg/L,COD/NH4 +-N=1.4的条件下,稳定运行的试验结果表明:A/O反应器短程硝化反应器NO2 --N累积率为96%以上,系统出水的总氮TN小于48mg/L,TN去除率大于81%,出水NH4 +-N与NO2 --N均小于16mg/L,厌氧氨氧化UASB的总氮负荷为0.7Kg TN/m3左右。 Under the condition that the average concentration of ammonia nitrogen in the landfill leachate is 2200mg/L and COD/NH 4 + -N=1.4, the test results of stable operation show that the accumulation rate of NO 2 - -N in the short-range nitrification reactor of the A/O reactor is 96 % or more, the total nitrogen TN of the system effluent is less than 48mg/L, the TN removal rate is greater than 81%, the effluent NH 4 + -N and NO 2 - -N are both less than 16mg/L, and the total nitrogen load of the anaerobic ammonium oxidation UASB is 0.7 About Kg TN/ m3 .

以上是本实用新型的一个典型实施例,本实用新型的实施不限于此。 The above is a typical embodiment of the utility model, and the implementation of the utility model is not limited thereto. the

Claims (1)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2011205126703U CN202492432U (en) | 2011-12-09 | 2011-12-09 | Device for denitrification by SBR combined with anaerobic ammoxidation of landfill leachate |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2011205126703U CN202492432U (en) | 2011-12-09 | 2011-12-09 | Device for denitrification by SBR combined with anaerobic ammoxidation of landfill leachate |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN202492432U true CN202492432U (en) | 2012-10-17 |

Family

ID=46998668

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN2011205126703U Expired - Lifetime CN202492432U (en) | 2011-12-09 | 2011-12-09 | Device for denitrification by SBR combined with anaerobic ammoxidation of landfill leachate |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN202492432U (en) |

Cited By (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102515350A (en) * | 2011-12-09 | 2012-06-27 | 北京工业大学 | Apparatus and method for nitrogen removal by combining garbage leachate SBR and anaerobic ammoxidation |

| CN103435227A (en) * | 2013-08-27 | 2013-12-11 | 北京工业大学 | Device and method for biological denitrification of landfill leachate through SBR (Sequencing Batch Reactor) short-cut nitrification-SBBR anaerobic ammonia oxidation combined process |

| CN103539319A (en) * | 2013-10-31 | 2014-01-29 | 华北电力大学 | Garbage leachate treating device |

| CN110156152A (en) * | 2019-01-21 | 2019-08-23 | 广东工业大学 | A kind of quick short-range nitrification start-up method and its application |

| CN111732192A (en) * | 2020-06-24 | 2020-10-02 | 盐城工学院 | A short-range nitrification-anammox denitrification process for convective distributed influent water |

| WO2022242040A1 (en) * | 2021-05-20 | 2022-11-24 | 北京工业大学 | Method and apparatus for treating mid-term and late landfill leachates by process combining endogenous denitrification and autotrophic nitrogen removal |

| CN119118364A (en) * | 2024-09-24 | 2024-12-13 | 井冈山大学 | An anaerobic ammonium oxidation denitrification device suitable for rare earth tail water |

-

2011

- 2011-12-09 CN CN2011205126703U patent/CN202492432U/en not_active Expired - Lifetime

Cited By (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102515350A (en) * | 2011-12-09 | 2012-06-27 | 北京工业大学 | Apparatus and method for nitrogen removal by combining garbage leachate SBR and anaerobic ammoxidation |

| CN102515350B (en) * | 2011-12-09 | 2013-07-10 | 北京工业大学 | Apparatus and method for nitrogen removal by combining garbage leachate SBR and anaerobic ammoxidation |

| CN103435227A (en) * | 2013-08-27 | 2013-12-11 | 北京工业大学 | Device and method for biological denitrification of landfill leachate through SBR (Sequencing Batch Reactor) short-cut nitrification-SBBR anaerobic ammonia oxidation combined process |

| CN103539319A (en) * | 2013-10-31 | 2014-01-29 | 华北电力大学 | Garbage leachate treating device |

| CN110156152A (en) * | 2019-01-21 | 2019-08-23 | 广东工业大学 | A kind of quick short-range nitrification start-up method and its application |

| CN111732192A (en) * | 2020-06-24 | 2020-10-02 | 盐城工学院 | A short-range nitrification-anammox denitrification process for convective distributed influent water |

| WO2022242040A1 (en) * | 2021-05-20 | 2022-11-24 | 北京工业大学 | Method and apparatus for treating mid-term and late landfill leachates by process combining endogenous denitrification and autotrophic nitrogen removal |

| US12410082B2 (en) | 2021-05-20 | 2025-09-09 | Beijing University Of Technology | Method for treating middle and mature landfill leachate by endogenous denitrification combined autotrophic nitrogen removal process |

| CN119118364A (en) * | 2024-09-24 | 2024-12-13 | 井冈山大学 | An anaerobic ammonium oxidation denitrification device suitable for rare earth tail water |

| CN119118364B (en) * | 2024-09-24 | 2025-08-22 | 井冈山大学 | An anaerobic ammonium oxidation denitrification device suitable for rare earth tail water |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN102515350B (en) | Apparatus and method for nitrogen removal by combining garbage leachate SBR and anaerobic ammoxidation | |

| CN101289264B (en) | Device and method for denitrification combined with short-cut nitrification and anaerobic ammonium oxidation of sludge digestion liquid | |

| CN109721156B (en) | Apparatus and method for treatment of late-stage landfill leachate with integrated intermittent aeration/short-path denitrification-anammox | |

| CN106186308B (en) | Integrated anaerobic ammonia oxidation granular sludge denitrification device and control method thereof | |

| CN102515429B (en) | Device and method for combined denitrification of anoxic-oxic (A/O) shortcut nitrification and anaerobic ammonia oxidation of late-stage landfill leachate | |

| CN104860482B (en) | The method of up-flow anaerobic sludge blanket+anoxic/aerobic+anaerobic ammonia oxidation reactor PROCESS FOR TREATMENT treatment of advanced stage landfill leachate advanced nitrogen | |

| CN103058461B (en) | Municipal sewage partial nitrification and anaerobic ammonia oxidation denitrification method capable of enhancing energy recuperation | |

| CN104860471B (en) | Half partial nitrification and anaerobic ammonia oxidation combined process late landfill leachate denitrifying device and method | |

| CN109721157B (en) | Device and method for treating late landfill leachate through shortcut nitrification/anaerobic ammonia oxidation/shortcut denitrification-anaerobic ammonia oxidation process | |

| CN202492432U (en) | Device for denitrification by SBR combined with anaerobic ammoxidation of landfill leachate | |

| CN102515428B (en) | Combined device for synchronous denitrification and methanogenesis as well as autotrophic nitrogen removal of landfill leachate and method thereof | |

| CN109574218B (en) | Device and method for treating late landfill leachate through shortcut nitrification-fermentation/denitrification-anaerobic ammonia oxidation process | |

| CN102583885A (en) | Technology and method for treating urban sewage by three-section short-cut nitrification/ anaerobic ammonia oxidation | |

| CN102101746A (en) | Low-carbon urban sewage biological phosphorus removal and autotrophic biological nitrogen removal device and method | |

| CN103102044B (en) | Method for strengthening autotrophic denitrification effect of urban sewage by using oxidation ditch | |

| CN109721158A (en) | Half short distance nitration/bis- anaerobic ammonia oxidation process processing treatment of advanced stage landfill leachate apparatus and method | |

| CN105130128A (en) | Later-period landfill leachate A/O (anoxic/oxic) half short-cut nitrification and UASB (upflow anaerobic sludge blanket) anaerobic ammonia oxidation combined nitrogen removal device and method | |

| CN111422983A (en) | A short-path nitrification-anammox two-stage sewage treatment device and process | |

| CN105692904A (en) | Method and device for achieving integrated anaerobic ammonia oxidation autotrophic denitrification of urban sewage | |

| CN109485149A (en) | A kind of apparatus and method for realizing treatment of advanced stage landfill leachate advanced nitrogen and excess sludge reduction | |

| CN100534928C (en) | Short-path deep biological denitrogenation method for city garbage percolate | |

| CN104528933B (en) | The method that mud realizes flowing municipal sewage autotrophic denitrification continuously is processed based on FNA | |

| CN105712584A (en) | Denitrification method and device for synchronously treating livestock farm biogas liquid wastewater and municipal sewage through combination of segmented partial nitrification and anaerobic ammonia oxidation | |

| CN101805096B (en) | Method for treating rubbish percolates of different times for deep denitrification by using bipolar USAB+A/O+SBR process | |

| CN109467186A (en) | A kind of ammonia nitrogen wastewater partial pre-nitrification-anaerobic ammonia oxidation high-efficiency denitrification method |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| AV01 | Patent right actively abandoned |

Granted publication date: 20121017 Effective date of abandoning: 20130710 |

|

| AV01 | Patent right actively abandoned |

Granted publication date: 20121017 Effective date of abandoning: 20130710 |

|

| RGAV | Abandon patent right to avoid regrant |