A kind of type defoaming device

Technical field

The utility model belongs to the environmental protection equipment technical field, specifically relates to a kind of type defoaming device.

Background technology

At present, at environmental technology field, especially in the aerobic biochemical field, it is too much foam to occur through the biochemistry pool of being everlasting, even can overflow the pond face, takes away the situation of biochemical sludge.

Produce the foam reason at present mainly by following several kinds of reasons:

1. contain washing composition or tensio-active agent etc. and produce the foamy material;

2. be a good oxygen activity mud and be in early growth period, a large amount of organic substances decomposes not exclusively, also can produce a large amount of foams;

3. the aerobic biochemical pond receives the organic wastewater with high concentration impact, causes mikrobe because of nutritious a large amount of breedings, also can produce significant foam;

4. weather significantly cooling suddenly also can cause the aerobic biochemical pond to produce a large amount of foams.

Summary of the invention

The utility model technical problem to be solved is to eliminate foam, thereby guarantees the stably reaching standard of aerobic biochemical system operation.

To achieve these goals, the technical scheme of the utility model is following:

A kind of type defoaming device; Comprise whipping appts, bio-aeration pool and secondary sedimentation basins; The volume pump of said whipping appts connects an end of a line mixer; Said line mixer is connected said secondary sedimentation basins with an end of volume pump homonymy through a lift pump, and the other end of said line mixer connects the spray piping of bio-aeration pool; It is characterized in that the last half side spray apertures that is distributed with of the spray piping of said bio-aeration pool.

Said whipping appts comprises a skimmer throwing device; Be provided with a whisking appliance that skimmer and water are mixed at the discharge port downside of skimmer throwing device, the volume pump of said whipping appts is connected with a cover and skimmer is thrown in is carried out the full-automatic electric control system that control is thrown in the gap.

Two both sides, front and back that are arranged at the bio-aeration pool top before and after the spray piping of said connection bio-aeration pool divides; The outlet conduit that connects secondary sedimentation basins respectively; Said two spray pipings respectively and be provided with one between the said outlet conduit and be used to control the time relay whether lift pump opens and closes, the said time relay is connected with a cover the last half side spray apertures of spray piping is carried out the full-automatic electric control system that the gap spray is controlled.

The last half side spray apertures of said spray piping is 45 degree that make progress, and lift pump pressure is 0.6MPa.

The beneficial effect of the utility model is that the spray apertures on the spray piping forms sprinkling system, utilizes the secondary sedimentation basins water outlet, is driven in the sprinkling system with lift pump, utilizes the effect of spray water, eliminates foam.When sprinkling system is not enough to eliminate foamy, can also launch the volume pump of whipping appts, skimmer is added in the sprinkling system; The utility model can be controlled its spray time and whether start the froth breaking medicine system through the full-automatic electric control system of skimmer and the full-automatic electric control system of spray apertures according to practical situation.

Description of drawings

Specify the utility model below in conjunction with accompanying drawing and embodiment:

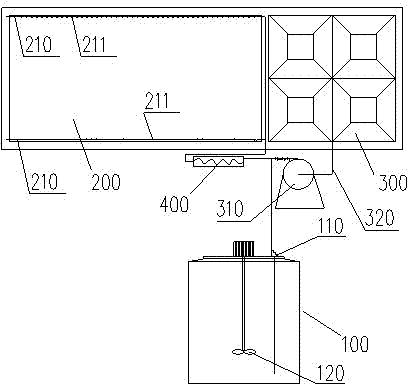

Fig. 1 is to be the two dimensional structure synoptic diagram of a kind of type defoaming device of the utility model.

Embodiment

For technique means, creation characteristic that the utility model is realized, reach purpose and be easy to understand understanding with effect, below in conjunction with concrete diagram, further set forth the utility model.

Referring to Fig. 1, a kind of type defoaming device comprises whipping appts 100, bio-aeration pool 200 and secondary sedimentation basins 300, and wherein, whipping appts 100 shown in Figure 1 is the main synoptic diagram of looking, and bio-aeration pool 200 is a schematic top plan view with secondary sedimentation basins 300.The volume pump 110 of said whipping appts 100 connects an end of a line mixer 400; Said line mixer 400 is connected said secondary sedimentation basins 300 with an end of volume pump 110 homonymies through a lift pump 310, and the other end of said line mixer 400 connects the spray piping 210 of bio-aeration pool 200; The last half side spray apertures 211 that is distributed with of the spray piping 210 of said bio-aeration pool.

Wherein, Said whipping appts 100 comprises a skimmer throwing device (not marking among the figure); Be provided with a whisking appliance 120 that skimmer and water are mixed at the discharge port downside of skimmer throwing device, the volume pump 110 of said whipping appts is connected with a cover and skimmer is thrown in is carried out the full-automatic electric control system (not marking among the figure) that control is thrown in the gap.

210 fens two of front and back of the spray piping of said connection bio-aeration pool 200 are arranged at the both sides, front and back above the bio-aeration pool; The outlet conduit 320 that connects secondary sedimentation basins respectively; Said two spray pipings 210 respectively and be provided with one between the said outlet conduit 320 and be used to control the time relay whether lift pump opens and closes, the said time relay is connected with a cover the last half side spray apertures of spray piping 210 is carried out the full-automatic electric control system (not marking among the figure) that the gap spray is controlled.

Wherein, the last half side spray apertures of said spray piping 210 is 45 degree that make progress, and lift pump pressure is 0.6MPa.

The principle of work of the utility model is, the spray apertures on the spray piping forms sprinkling system, and the last half side spray apertures of said spray piping 210 is for upwards 45 spending; Lift pump pressure is 0.6MPa; Like this, guaranteed that the spray water outlet covers and had suffered the pond face, thereby reached the purpose of froth breaking.

The utility model be towards the dense chemical industry of height, pharmacy waste water and specially designed because type defoaming device is widely used, high because of water inlet COD concentration again, the wastewater treatment difficulty is big, variation water quality is big.

So; When only depending on sprinkling system to realize froth breaking, then the volume pump of whipping appts and skimmer throwing device are not worked under the control of corresponding full-automatic electric control system, and sprinkling system is gap or utilize the secondary sedimentation basins water outlet incessantly under the effect of corresponding full-automatic electric control system according to actual needs; Be driven in the sprinkling system with lift pump; Lift pump opens and closes through corresponding time relay control, utilizes the effect of spray water, eliminates foam.When sprinkling system is not enough to eliminate foamy, can also launch the volume pump of whipping appts according to practical situation, skimmer is added in the sprinkling system; Simultaneously, the work of skimmer throwing device is added to skimmer in the agitated pool of whipping appts, and is by whisking appliance that the stirring solvent in skimmer and the whipping appts is even.The purpose of froth breaking can be reached like this, froth breaking running cost can be saved again.

More than show and described the advantage of ultimate principle, principal character and the utility model of the utility model.The technician of the industry should understand; The utility model is not restricted to the described embodiments; The just principle of describing in the foregoing description and the specification sheets of the utility model; The utility model also has various changes and modifications under the prerequisite that does not break away from the utility model spirit and scope, and these variations and improvement all fall in the scope of the utility model that requires protection.The protection domain that the utility model requires is defined by appending claims and equivalent thereof.