CN202492017U - Accountant special-purpose gluewater cylinder - Google Patents

Accountant special-purpose gluewater cylinder Download PDFInfo

- Publication number

- CN202492017U CN202492017U CN2012200047837U CN201220004783U CN202492017U CN 202492017 U CN202492017 U CN 202492017U CN 2012200047837 U CN2012200047837 U CN 2012200047837U CN 201220004783 U CN201220004783 U CN 201220004783U CN 202492017 U CN202492017 U CN 202492017U

- Authority

- CN

- China

- Prior art keywords

- glue

- nozzle

- mouth

- cylinder

- support plate

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 239000003292 glue Substances 0.000 claims abstract description 45

- 238000007789 sealing Methods 0.000 claims abstract description 11

- 238000001035 drying Methods 0.000 description 2

- 238000009434 installation Methods 0.000 description 2

- 239000007788 liquid Substances 0.000 description 2

- 238000010586 diagram Methods 0.000 description 1

- 238000001125 extrusion Methods 0.000 description 1

- 230000005484 gravity Effects 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 239000002699 waste material Substances 0.000 description 1

Images

Classifications

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02W—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO WASTEWATER TREATMENT OR WASTE MANAGEMENT

- Y02W90/00—Enabling technologies or technologies with a potential or indirect contribution to greenhouse gas [GHG] emissions mitigation

- Y02W90/10—Bio-packaging, e.g. packing containers made from renewable resources or bio-plastics

Landscapes

- Closures For Containers (AREA)

Abstract

本实用新型公开了一种会计专用胶水筒,包括筒体,筒体口部拧紧有密封帽,密封帽上部固设有条形支撑板,支撑板上间隔设有喷嘴,支撑板内设有将喷嘴与筒体口部连接的通道,喷嘴口部设有上盖,上盖末端通过胶条连接在一起。所述喷嘴口部呈朝向一致的楔形。在粘贴时,可以将筒体倾斜一定角度以配合喷嘴的楔形面,有助于提高涂抹胶水的流畅性和控制胶水流速。采用这种结构的会计专用胶水筒,结构合理,节省胶水,且使用方便,有助于提高会计人员粘贴台账凭据的效率。

The utility model discloses a special glue cylinder for accounting, which comprises a cylinder body, a seal cap is screwed on the mouth of the cylinder body, a strip-shaped support plate is fixed on the upper part of the seal cap, nozzles are arranged at intervals on the support plate, and a sealing cap is arranged inside the support plate. The channel connecting the nozzle and the mouth of the cylinder, the nozzle mouth is provided with a top cover, and the ends of the top cover are connected together by rubber strips. The mouth of the nozzle is wedge-shaped with consistent orientation. When pasting, the cylinder can be tilted at a certain angle to match the wedge-shaped surface of the nozzle, which helps to improve the smoothness of applying glue and control the flow rate of glue. The special glue container for accounting with this structure has a reasonable structure, saves glue, is convenient to use, and helps to improve the efficiency of accountants in pasting ledger vouchers.

Description

技术领域 technical field

本实用新型涉及一种会计专用胶水筒。 The utility model relates to a special glue container for accounting.

背景技术 Background technique

胶水筒,是用来盛装液体胶水的专用容器。传统的胶水筒,一般包括筒体,筒体口部拧紧有密封帽。使用时,先将密封帽拧开,然后将筒体口部朝下放置,筒体内的液体胶水即可在自身重力或外部挤压力下流出来,从而进行粘贴工作。传统胶水筒,结构简单,成本低,不足之处在于:一、在进行粘贴时,胶水从筒体流出的量很难控制,不是流不出来,就是流出太多,使用起来很不方便。二、对于会计人员而言,工作中,需要粘贴台账凭据的工作较多,而台账凭据的宽度一般都较宽,使用传统胶水筒进行粘贴时,一般都需要将多张台账凭据依次台阶状错叠开来,使各台账凭据北面的根部都露出来,然后倒置传统胶水筒将胶水依次涂抹到台账凭据根部最后粘贴在一起,这样操作虽然有助于提高粘贴台账凭据的效率,但是需要使用大量胶水,造成了浪费,提高了粘贴成本。 Glue cartridge is a special container for holding liquid glue. The traditional glue cylinder generally includes a cylinder body, and the mouth of the cylinder body is tightened with a sealing cap. When in use, first unscrew the sealing cap, and then place the mouth of the cylinder downward, and the liquid glue in the cylinder can flow out under its own gravity or external extrusion force, so as to carry out the pasting work. The traditional glue cartridge has a simple structure and low cost. The disadvantages are: 1. It is difficult to control the amount of glue flowing out of the cartridge when pasting. 2. For accountants, there are many tasks that need to paste ledger vouchers during work, and the width of ledger vouchers is generally wider. When using traditional glue tubes for pasting, it is generally necessary to paste multiple ledger vouchers one by one. The steps are staggered, so that the roots on the north side of each account voucher are exposed, and then the traditional glue tube is inverted to apply glue to the root of the account voucher in turn, and finally pasted together. This operation will help improve the efficiency of pasting the account voucher. Efficiency, but needs to use a large amount of glue, has caused waste, has improved pasting cost.

发明内容 Contents of the invention

本实用新型要解决的技术问题是针对上述不足提供一种结构合理,节省胶水,且使用方便的一种会计专用胶水筒。 The technical problem to be solved by the utility model is to provide a special accounting glue container with reasonable structure, glue saving, and convenient use.

为解决上述技术问题,本会计专用胶水筒包括筒体,筒体口部拧紧有密封帽,其结构特点是:密封帽上部固设有条形支撑板,支撑板上间隔设有喷嘴,支撑板内设有将喷嘴与筒体口部连接的通道,喷嘴口部设有上盖,上盖末端通过胶条连接在一起。 In order to solve the above-mentioned technical problems, the special glue tube for accounting includes a cylinder body, and a sealing cap is tightened at the mouth of the cylinder body. There is a channel connecting the nozzle with the mouth of the cylinder, the nozzle mouth is provided with a cover, and the ends of the cover are connected together by rubber strips.

本结构的会计专用胶水筒是通过间隔涂抹结构来实现节省胶水,且使用方便的。 The special glue container for accounting of this structure saves glue by applying the structure at intervals, and is convenient to use.

间隔涂抹结构主要包括固定连接在密封帽上的支撑板,支撑板上间隔设置有喷嘴,支撑板内部设有将喷嘴和密封帽内腔连接的通道。支撑板不但为喷嘴和通道提供安装载体,还使各喷嘴口部能够排列在一个平面内。这样,在进行涂抹胶水时,各喷嘴流出的胶水将分布在同一个平面内,在粘贴纸件凭据时非常方便,一次可以覆盖较大的平面,尤其适合会计人员使用,有助于提高粘贴效率。由于各个喷嘴是间隔设置的,因此各喷嘴流出的胶水也是间隔开来的,这样在粘贴台账凭据时就可以节省大量胶水,也缩短了操作时间,有助于提高会计人员的工作效率。粘贴完毕后,将筒体回正,胶水回流到筒体内,最后将胶条连接的上盖依次扣合到喷嘴上即可,有助于防止胶水干涸和喷嘴堵塞,为下次使用提供了便利。 The interval smearing structure mainly includes a support plate fixedly connected to the sealing cap, nozzles are arranged at intervals on the support plate, and a channel connecting the nozzles and the inner cavity of the sealing cap is provided inside the support plate. The support plate not only provides the installation carrier for the nozzles and channels, but also enables the mouths of the nozzles to be arranged in a plane. In this way, when applying glue, the glue flowing out of each nozzle will be distributed in the same plane, which is very convenient when pasting paper vouchers, and can cover a larger plane at one time, especially suitable for accountants, and helps to improve pasting efficiency . Since each nozzle is set at intervals, the glue flowing out of each nozzle is also spaced apart, so that a large amount of glue can be saved when pasting ledger vouchers, and the operation time is also shortened, which helps to improve the work efficiency of accountants. After pasting, return the barrel to the right, and the glue will flow back into the barrel. Finally, fasten the upper cover connected by the glue strip to the nozzle in turn, which will help prevent the glue from drying up and the nozzle from clogging, and provide convenience for the next use. .

作为改进,所述喷嘴口部呈朝向一致的楔形。 As an improvement, the mouth of the nozzle is wedge-shaped with consistent orientation.

将喷嘴口部设置成楔形,在粘贴时,可以将筒体倾斜一定角度以配合喷嘴的楔形面,有助于提高涂抹胶水的流畅性和控制胶水流速。 The mouth of the nozzle is set in a wedge shape. When pasting, the cylinder can be tilted at a certain angle to match the wedge-shaped surface of the nozzle, which helps to improve the smoothness of applying glue and control the flow rate of glue.

综上所述,采用这种结构的会计专用胶水筒,结构合理,节省胶水,且使用方便,有助于提高会计人员粘贴台账凭据的效率。 To sum up, the special glue container for accounting with this structure has a reasonable structure, saves glue, and is easy to use, which helps to improve the efficiency of accountants in pasting ledger vouchers.

附图说明 Description of drawings

结合附图对本实用新型做进一步详细说明: The utility model is described in further detail in conjunction with accompanying drawing:

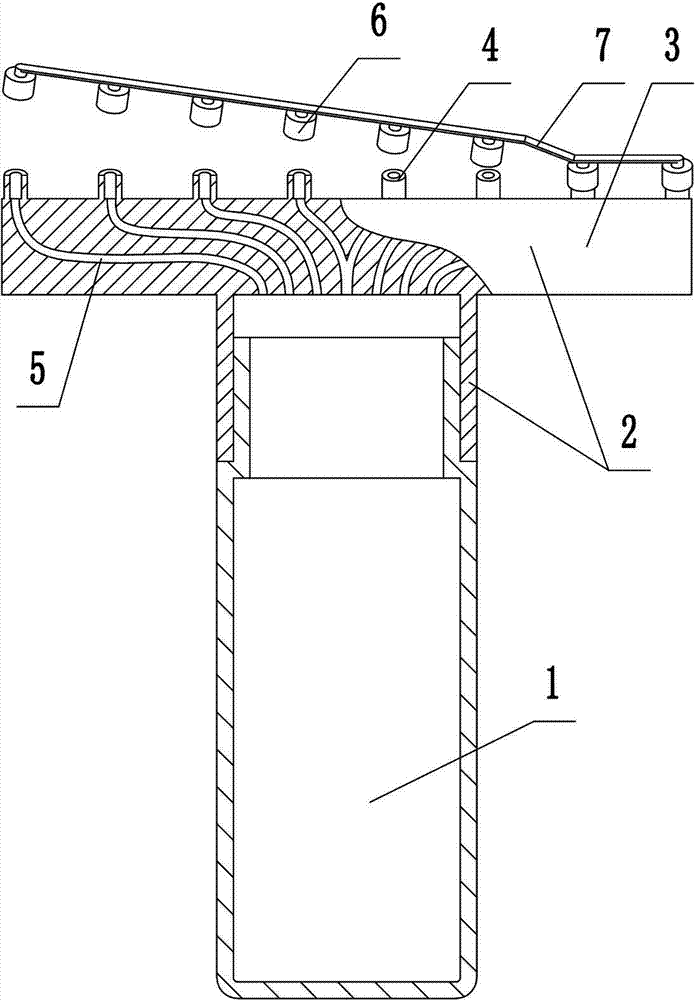

图1为本实用新型的结构示意图。 Fig. 1 is the structural representation of the utility model.

图中:1为筒体,2为密封帽,3为支撑板,4为喷嘴,5为通道,6为上盖,7为胶条。 In the figure: 1 is the cylinder, 2 is the sealing cap, 3 is the support plate, 4 is the nozzle, 5 is the channel, 6 is the upper cover, and 7 is the rubber strip.

具体实施方式 Detailed ways

如图1所示,为该会计专用胶水筒的结构示意图,该会计专用胶水筒包括筒体1,筒体1呈圆柱形,口部向上设置。筒体1口部拧紧有密封帽2,密封帽2上部固设有水平设置的条形支撑板3,支撑板3为一字型平板。支撑板3上间隔设有喷嘴4,支撑板3内设有将喷嘴4与筒体1口部连接的通道5。支撑板3不但为喷嘴4和通道5提供安装载体,还使各喷嘴4口部能够排列在一个平面内。这样,在进行涂抹胶水时,各喷嘴4流出的胶水将分布在同一个平面内,在粘贴纸件凭据时非常方便,一次可以覆盖较大的面积,尤其适合会计人员使用,有助于提高粘贴效率。喷嘴4口部呈朝向一致的楔形。在粘贴时,可以将筒体1倾斜一定角度以配合喷嘴4的楔形面,有助于提高涂抹胶水的流畅性和控制胶水流速。

As shown in Fig. 1 , it is a structural schematic diagram of the special glue tube for accounting. The special glue tube for accounting includes a cylinder body 1, which is cylindrical, and the mouth is set upward. The mouth of cylinder body 1 is screwed with sealing

由于各个喷嘴4是间隔设置的,因此各喷嘴4流出的胶水也是间隔开来的,这样在粘贴台账凭据时就可以节省大量胶水,也缩短了操作时间,有助于提高会计人员的工作效率。粘贴完毕后,将筒体1回正,胶水回流到筒体1内,最后将用胶条7连接在一起的上盖6依次扣合到各个喷嘴4上即可,有助于防止胶水干涸和喷嘴4堵塞,为下次使用提供了便利。

Since each

Claims (2)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2012200047837U CN202492017U (en) | 2012-01-09 | 2012-01-09 | Accountant special-purpose gluewater cylinder |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2012200047837U CN202492017U (en) | 2012-01-09 | 2012-01-09 | Accountant special-purpose gluewater cylinder |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN202492017U true CN202492017U (en) | 2012-10-17 |

Family

ID=46998254

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN2012200047837U Expired - Fee Related CN202492017U (en) | 2012-01-09 | 2012-01-09 | Accountant special-purpose gluewater cylinder |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN202492017U (en) |

-

2012

- 2012-01-09 CN CN2012200047837U patent/CN202492017U/en not_active Expired - Fee Related

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN206058830U (en) | A kind of economizing type automatically cleaning public transport stop board | |

| CN202492017U (en) | Accountant special-purpose gluewater cylinder | |

| CN205020320U (en) | Even mucilage binding of plywood spreading machine is put | |

| CN203975394U (en) | Paste label shelf | |

| CN204488364U (en) | A kind of gumming mechanism of Paper-pasting machine | |

| CN105253403B (en) | A kind of bag type package glue pushes away colloid system | |

| CN202400408U (en) | Glue bottle special for accountant | |

| CN108407339A (en) | A kind of wind wheel blade and its outer reinforcement pouring and molding method | |

| CN211710425U (en) | Accounting bill rubber coating device | |

| CN202741289U (en) | Quick adhesive coating device | |

| CN206924956U (en) | A kind of plank bilayer glue spreading apparatus | |

| CN203355986U (en) | Storage battery cover plate glue spreading tool | |

| CN202169797U (en) | Novel fountain pen | |

| CN203472376U (en) | Solid glue pipe with divider | |

| CN202764397U (en) | Ink cartridge system of ink jet printer | |

| CN206454856U (en) | A kind of glue box form point gum machine | |

| CN207331423U (en) | Graticule side hair labelling machine | |

| CN104418273A (en) | Paint filling device | |

| CN202105772U (en) | Glue adding barrel used for dry type compound machine | |

| CN201385845Y (en) | Extruded glue bottle cap | |

| CN207641799U (en) | Flow-guiding type constant current storage glue groove | |

| CN202319394U (en) | Fountain brush pen capable of writing coherently | |

| CN221869090U (en) | Gluing device | |

| CN207401687U (en) | A kind of smearing integral type glue rifle | |

| CN203209276U (en) | Cylindrical painting machine |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| CF01 | Termination of patent right due to non-payment of annual fee |

Granted publication date: 20121017 Termination date: 20130109 |

|

| CF01 | Termination of patent right due to non-payment of annual fee |