CN202491403U - Cooling device of double-screw extruder - Google Patents

Cooling device of double-screw extruder Download PDFInfo

- Publication number

- CN202491403U CN202491403U CN2012200986568U CN201220098656U CN202491403U CN 202491403 U CN202491403 U CN 202491403U CN 2012200986568 U CN2012200986568 U CN 2012200986568U CN 201220098656 U CN201220098656 U CN 201220098656U CN 202491403 U CN202491403 U CN 202491403U

- Authority

- CN

- China

- Prior art keywords

- heat exchange

- screw extruder

- water

- double

- cooling device

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 238000001816 cooling Methods 0.000 title claims abstract description 15

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims abstract description 27

- 238000004519 manufacturing process Methods 0.000 description 3

- 230000015572 biosynthetic process Effects 0.000 description 1

- 238000009835 boiling Methods 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 239000011159 matrix material Substances 0.000 description 1

- 238000000034 method Methods 0.000 description 1

Images

Landscapes

- Extrusion Moulding Of Plastics Or The Like (AREA)

Abstract

The utility model relates to a cooling device of a double-screw extruder, which comprises a jacket, a heat exchange water pool and pipelines. The jacket arranged on the outer wall of a barrel of the double-screw extruder is provided with a water inlet and a water outlet; the water inlet and the water outlet are respectively communicated with the heat exchange water pool by the pipelines; radiating fins are arranged on the pipelines; the heat exchange water pool is connected with a cooling tower. According to the utility model, water resources are saved; the temperature of the barrel is effectively controlled; the reliable guarantee is provided for the normal operation of equipment; and the product quality is ensured.

Description

Technical field

The utility model relates to a kind of double screw extruder, relates in particular to a kind of cooling device of double screw extruder.

Background technology

Double screw extruder is as a kind of general plastic matrix manufacturing equipment.In process of production, the charging aperture of double screw extruder need cool off it, to guarantee normal production because the heat transfer of barrel temperature causes the charging aperture temperature to rise gradually.The type of cooling commonly used is: the heat exchanger through being installed in the screw rod below carries out heat exchange; These heat exchanger two ends are provided with water inlet pipe and outlet pipe; The circulating water that brings out water formation through end water inlet one carries out heat exchange; Take place to cause the heat exchange weak effect through regular meeting, make the quality of product can not get guaranteeing because of fouling.

The utility model content

The purpose of the utility model provides a kind of recycle water resource, effectively the application cylinder temperature, guarantee the cooling device of the double screw extruder of product quality.

The utility model is achieved in that a kind of cooling device of double screw extruder; Comprise chuck, heat exchange pond, pipeline; It is characterized in that: the chuck that is loaded on the cylinder body outer wall of double screw extruder is provided with water inlet and delivery port; Water inlet and delivery port are communicated with the heat exchange pond through pipeline respectively, and pipeline is provided with fin, and the heat exchange pond is connected with cooling tower.

The utility model has been practiced thrift water resource, has effectively controlled barrel temperature, has guaranteed product quality.

Description of drawings

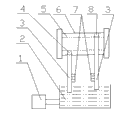

Fig. 1 is the utility model master TV structure sketch map.

Among the figure 1, cooling tower, 2, heat exchange pond, 3, pipeline, 4, water inlet, 5, cylindrical shell, 6, chuck, 7, fin, 8, delivery port.

The specific embodiment

Below in conjunction with accompanying drawing the utility model is done further to describe:

With reference to accompanying drawing; A kind of cooling device of double screw extruder; Comprise chuck 6, heat exchange pond 2, pipeline 3, it is characterized in that: the chuck 6 that is loaded on cylindrical shell 5 outer walls of double screw extruder is provided with water inlet 4 and delivery port 3, and water inlet 4 is communicated with heat exchange pond 2 through pipeline 3 respectively with delivery port 3; Pipeline 3 is provided with fin 7, and heat exchange pond 2 is connected with cooling tower 1.During practical implementation, through water is injected chuck, utilize water to cool off, the water of heat exchange is got back in the heat exchange pond through delivery port and corresponding pipeline again; Recycle water resource, save water resource, and avoided water to produce fouling, through fin is installed because of boiling; Increase heat exchange area, improved heat exchange property, effectively controlled the temperature of the cylindrical shell of double screw extruder; Cooling effect is good, for the normal operation of equipment provides reliable assurance, has guaranteed the quality of product.

Claims (1)

1. the cooling device of a double screw extruder; Comprise chuck (6), heat exchange pond (2), pipeline (3); It is characterized in that: the chuck (6) that is loaded on cylindrical shell (5) outer wall of double screw extruder is provided with water inlet (4) and delivery port (3); Water inlet (4) and delivery port (3) are communicated with heat exchange pond (2) through pipeline (3) respectively, and pipeline (3) is provided with fin (7), and heat exchange pond (2) are connected with cooling tower (1).

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2012200986568U CN202491403U (en) | 2012-03-16 | 2012-03-16 | Cooling device of double-screw extruder |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2012200986568U CN202491403U (en) | 2012-03-16 | 2012-03-16 | Cooling device of double-screw extruder |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN202491403U true CN202491403U (en) | 2012-10-17 |

Family

ID=46997642

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN2012200986568U Expired - Fee Related CN202491403U (en) | 2012-03-16 | 2012-03-16 | Cooling device of double-screw extruder |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN202491403U (en) |

-

2012

- 2012-03-16 CN CN2012200986568U patent/CN202491403U/en not_active Expired - Fee Related

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN205448787U (en) | Bushing type phase transition energy storage equipment | |

| CN202491403U (en) | Cooling device of double-screw extruder | |

| CN202734571U (en) | Internal-circulation cooling system of intermediate frequency furnace | |

| CN201776899U (en) | A cooling device for a twin-screw extruder | |

| CN202707645U (en) | Hydraulic oil tank for injection molding machine | |

| CN201413065Y (en) | Chemical heat exchanger | |

| CN203928359U (en) | A kind of electric instant-heating type heater | |

| CN203687692U (en) | Ultra-long double-row circular copper tube integral core | |

| CN203184036U (en) | Cooling water circulating device for laboratory | |

| CN203360420U (en) | Jacket tank | |

| CN201876162U (en) | Coaxial spiral tubes heat exchanger | |

| CN202571049U (en) | Hydraulic expand tube fixture for boiler tube | |

| CN205897926U (en) | Copper hot exchange pipe | |

| CN203075911U (en) | A batching tank water circulation system for soft capsule workshop | |

| CN204881272U (en) | Used heat hydrothermal can high -efficient recovery unit | |

| CN203264312U (en) | Cooling device for triple-effect energy-saving concentrator | |

| CN203726800U (en) | Cooling device of polyvinyl chloride (PVC) solid-wall tube production equipment | |

| CN202528441U (en) | Cooling device of screw rod extruder manufacturing polyvinyl chloride (PVC) sheets using waste polyvinyl chloride (PVC) | |

| CN203869300U (en) | Water heater | |

| CN203764242U (en) | Double jacketed reaction kettle | |

| CN103837009B (en) | Cooling circulating type exchanger for high pressure fluid | |

| CN203944385U (en) | A kind of for the synthetic cooling reaction system of white glue with vinyl | |

| CN202507517U (en) | Cooling water tank of plastic granulator | |

| CN202715402U (en) | Double pipe type circulation heat exchange matching system | |

| CN203577772U (en) | Cooling device for producing epoxy hardener |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| TR01 | Transfer of patent right |

Effective date of registration: 20180525 Address after: 214500 Yongxing Road, four pier, Xinqiao Town, Jingjiang, Taizhou, Jiangsu (Tai Nan Village) Patentee after: Jiangsu Sanbao new Mstar Technology Ltd Address before: 214500 Yongxing Road, four pier, Xinqiao Town, Jingjiang, Taizhou, Jiangsu Patentee before: Jiangsu Shuangbao Technology Co., Ltd. |

|

| TR01 | Transfer of patent right | ||

| CF01 | Termination of patent right due to non-payment of annual fee |

Granted publication date: 20121017 Termination date: 20190316 |

|

| CF01 | Termination of patent right due to non-payment of annual fee |