CN202490801U - High-temperature and environment-friendly plastic cleaner - Google Patents

High-temperature and environment-friendly plastic cleaner Download PDFInfo

- Publication number

- CN202490801U CN202490801U CN2012200977412U CN201220097741U CN202490801U CN 202490801 U CN202490801 U CN 202490801U CN 2012200977412 U CN2012200977412 U CN 2012200977412U CN 201220097741 U CN201220097741 U CN 201220097741U CN 202490801 U CN202490801 U CN 202490801U

- Authority

- CN

- China

- Prior art keywords

- sealed casing

- utility

- model

- sealed

- pulling screw

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 239000004033 plastic Substances 0.000 title claims abstract description 12

- 229920003023 plastic Polymers 0.000 title claims abstract description 12

- 239000002985 plastic film Substances 0.000 claims abstract description 12

- 238000007599 discharging Methods 0.000 claims abstract description 4

- 230000005540 biological transmission Effects 0.000 claims 1

- 239000000463 material Substances 0.000 claims 1

- 230000009286 beneficial effect Effects 0.000 abstract description 4

- 238000005202 decontamination Methods 0.000 abstract description 4

- 230000003588 decontaminative effect Effects 0.000 abstract description 4

- 230000000694 effects Effects 0.000 abstract description 3

- 238000004140 cleaning Methods 0.000 description 8

- 230000007812 deficiency Effects 0.000 description 1

- 230000007613 environmental effect Effects 0.000 description 1

- 238000003912 environmental pollution Methods 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 238000003756 stirring Methods 0.000 description 1

- 230000032258 transport Effects 0.000 description 1

Images

Classifications

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02W—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO WASTEWATER TREATMENT OR WASTE MANAGEMENT

- Y02W30/00—Technologies for solid waste management

- Y02W30/50—Reuse, recycling or recovery technologies

- Y02W30/62—Plastics recycling; Rubber recycling

Landscapes

- Processing And Handling Of Plastics And Other Materials For Molding In General (AREA)

Abstract

本实用新型提供一种塑料高温环保清洁器,它包括有机架、固定在该机架上的密封壳体、往密封壳体内传输蒸汽的蒸汽管、用于带动密封壳体内的塑料片前进的拉料螺杆以及驱动该拉料螺杆旋转的电机,其中,所述的拉料螺杆对应安装在密封壳体内,蒸汽管对应设在该密封壳体一侧,并且上述密封壳体的相对两端对应安装有进料单元和出料单元。本实用新型在采用了上述方案后,其最大优点在于本实用新型一改传统的开放式结构,通过密封壳体来达到一个节能省耗的有益效果,同时,本实用新型的自动化程度高,无需人手搅拌塑料片,塑料片在密封壳体内由拉料螺杆拉动的同时进行充分搅拌,进而使得本实用新型的去污效果佳。

The utility model provides a plastic high-temperature environment-friendly cleaner, which includes a frame, a sealed casing fixed on the frame, a steam pipe for transmitting steam into the sealed casing, and a device for driving the plastic sheets in the sealed casing to advance. The pulling screw and the motor that drives the pulling screw to rotate, wherein the pulling screw is correspondingly installed in the sealed housing, the steam pipe is correspondingly arranged on one side of the sealed housing, and the opposite ends of the sealed housing are corresponding A feeding unit and a discharging unit are installed. After the utility model adopts the above scheme, its biggest advantage is that the utility model changes the traditional open structure and achieves a beneficial effect of energy saving and consumption saving through the sealed casing. At the same time, the utility model has a high degree of automation and does not need The plastic sheet is manually stirred, and the plastic sheet is fully stirred while being pulled by the pulling screw rod in the sealed casing, so that the decontamination effect of the utility model is good.

Description

技术领域 technical field

本实用新型涉及环保清洁塑料的技术领域,尤其是指一种塑料高温环保清洁器。 The utility model relates to the technical field of environment-friendly and clean plastics, in particular to a plastic high-temperature environment-friendly cleaner. the

背景技术 Background technique

业内习知,塑料厂用的塑料清洗设备普遍采用开放式结构,并且该清洗设备内的塑料片大都由人工进行搅拌,这样既费时又麻烦,而且所需的清洁剂量大,成本高,塑料片的清洗质量也低,很难达到预期的有益效果且环境污染大,尤其在工作量比较大时,工作效率低,工人的劳动强度大,产品的质量更难得到保证。因此,现在伴随机电一体化的发展,大多数塑料厂家渴望通过一种行之有效的器械来取代以上设备。 It is known in the industry that the plastic cleaning equipment used in plastic factories generally adopts an open structure, and most of the plastic sheets in the cleaning equipment are manually stirred, which is time-consuming and troublesome, and requires a large cleaning dose and high cost. The cleaning quality is also low, it is difficult to achieve the expected beneficial effect and the environmental pollution is large, especially when the workload is relatively large, the work efficiency is low, the labor intensity of the workers is high, and the quality of the product is more difficult to guarantee. Therefore, now with the development of mechatronics, most plastic manufacturers are eager to replace the above equipment with an effective device. the

发明内容 Contents of the invention

本实用新型的目的在于克服现有技术的不足,提供一种安全可靠、环保节能省耗、去污质量高的塑料高温环保清洁器。 The purpose of the utility model is to overcome the deficiencies of the prior art and provide a plastic high-temperature environment-friendly cleaner that is safe, reliable, environmentally friendly, energy-saving, energy-saving, and high in decontamination quality. the

为实现上述目的,本实用新型所提供的技术方案为:一种塑料高温环保清洁器,它包括有机架、固定在该机架上的密封壳体、往密封壳体内传输蒸汽的蒸汽管、用于带动密封壳体内的塑料片前进的拉料螺杆以及驱动该拉料螺杆旋转的电机,其中,所述的拉料螺杆对应安装在密封壳体内,蒸汽管对应设在该密封壳体一侧,并且上述密封壳体的相对两端对应安装有进料单元和出料单元。 In order to achieve the above purpose, the technical solution provided by the utility model is: a plastic high-temperature environmental protection cleaner, which includes a frame, a sealed casing fixed on the frame, a steam pipe for transmitting steam into the sealed casing, The pulling screw used to drive the plastic sheet in the sealed casing forward and the motor driving the pulling screw to rotate, wherein the pulling screw is correspondingly installed in the sealed casing, and the steam pipe is correspondingly arranged on one side of the sealed casing , and the opposite ends of the above-mentioned sealed housing are correspondingly installed with a feeding unit and a discharging unit. the

所述的拉料螺杆主要由螺杆主轴及固定安装在该螺杆主轴上的螺旋式叶片组成,其中,上述的螺旋式叶片上设有多根用于勾住纸类杂物的钩刺。 The pulling screw is mainly composed of a screw main shaft and a helical blade fixedly mounted on the screw main shaft, wherein the helical blade is provided with a plurality of barbs for catching paper debris. the

本实用新型在采用了上述方案后,其最大优点在于本实用新型一改传统的开放式结构,通过密封壳体来达到一个节能省耗的有益效果,同时,本实用新型的自动化程度高,无需人手搅拌塑料片,塑料片在密封壳体内由拉料螺杆拉动的同时进行充分搅拌,进而使得本实用新型的去污效果佳。 After the utility model adopts the above scheme, its biggest advantage is that the utility model changes the traditional open structure and achieves a beneficial effect of energy saving and consumption saving through the sealed casing. At the same time, the utility model has a high degree of automation and does not need The plastic sheet is manually stirred, and the plastic sheet is fully stirred while being pulled by the pulling screw rod in the sealed casing, so that the decontamination effect of the utility model is good. the

附图说明 Description of drawings

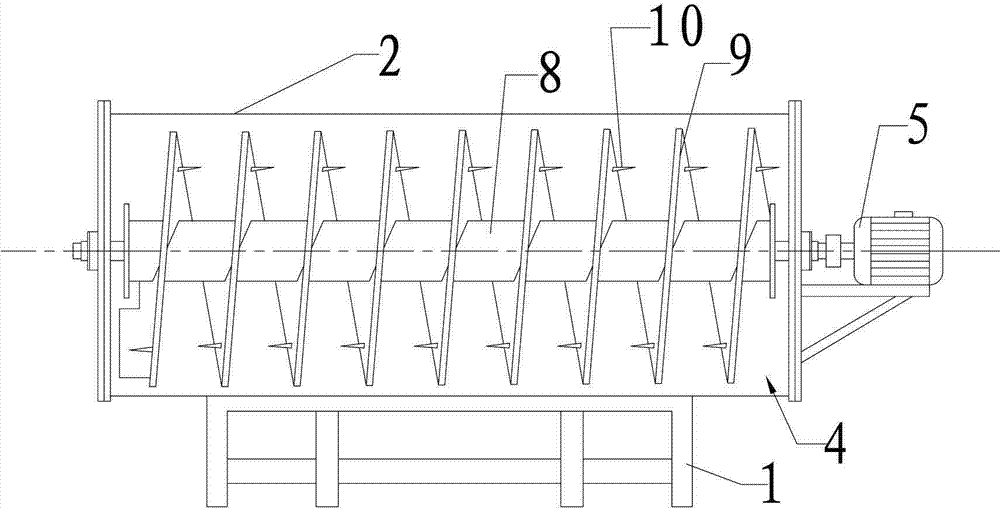

图1为本实用新型的主视图。 Fig. 1 is the front view of the utility model. the

图2为本实用新型的剖视图。 Fig. 2 is a sectional view of the utility model. the

具体实施方式 Detailed ways

下面结合具体实施例对本实用新型作进一步说明。 Below in conjunction with specific embodiment the utility model is further described. the

参见附图1和附图2所示,本实施例所述的塑料高温环保清洁器,它包括有机架1、固定在该机架1上的密封壳体2、往密封壳体2内传输蒸汽的蒸汽管3、用于带动密封壳体2内的塑料片水平前进的拉料螺杆4以及驱动该拉料螺杆4旋转的电机5,其中,本实施例所述的拉料螺杆4对应安装在密封壳体2内,同时蒸汽管3对应设在该密封壳体2一侧,并且上述密封壳体2的相对两端对应安装有进料单元6和出料单元7。而本实施例上述的拉料螺杆4主要由螺杆主轴8及固定安装在该螺杆主轴8上的螺旋式叶片9组成,其中,为了确保本清洗机的清洗质量,本实施例上述的螺旋式叶片9上设有多根用于勾住纸类杂物(标签)的钩刺10,从而有效避免了清洗出来的塑料片还夹杂着其它纸类杂物,影响后续加工质量。总之,采用以上方案后,相比现有技术,本实用新型一改传统的开放式结构,通过采用密封壳体2来达到一个节能省耗的有益效果,有效地降低了生产成本,同时,本实用新型的自动化程度高,无需人手搅拌塑料片,塑料片在密封壳体2内由拉料螺杆4拉动的同时进行充分搅拌,大大减少了清洁剂量,去污效果佳,值得推广。

Referring to accompanying drawing 1 and shown in accompanying

以上所述之实施例只为本实用新型之较佳实施例,并非以此限制本实用新型的实施范围,故凡依本实用新型之形状、原理所作的变化,均应涵盖在本实用新型的保护范围内。 The above-described embodiments are only preferred embodiments of the present utility model, and are not intended to limit the scope of implementation of the present utility model, so all changes made according to the shape and principle of the present utility model should be covered by the scope of the present utility model. within the scope of protection. the

Claims (2)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2012200977412U CN202490801U (en) | 2012-03-15 | 2012-03-15 | High-temperature and environment-friendly plastic cleaner |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2012200977412U CN202490801U (en) | 2012-03-15 | 2012-03-15 | High-temperature and environment-friendly plastic cleaner |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN202490801U true CN202490801U (en) | 2012-10-17 |

Family

ID=46997045

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN2012200977412U Expired - Fee Related CN202490801U (en) | 2012-03-15 | 2012-03-15 | High-temperature and environment-friendly plastic cleaner |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN202490801U (en) |

-

2012

- 2012-03-15 CN CN2012200977412U patent/CN202490801U/en not_active Expired - Fee Related

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN201423378Y (en) | Solar glass washing and drying machine | |

| CN201617163U (en) | Carrot Washing Machine | |

| CN201659645U (en) | A washing machine for cleaning plastic debris | |

| CN210965300U (en) | Resource recovery breaker | |

| CN206136709U (en) | Portable straw cutting device that makes an uproar falls in dust removal | |

| CN202490801U (en) | High-temperature and environment-friendly plastic cleaner | |

| CN201988545U (en) | Delabelling machine | |

| CN204276254U (en) | Small-sized brushing machine | |

| CN204247270U (en) | A kind of breaker for glass breaking pipeline | |

| CN205061842U (en) | A sludge homogeneous crushing and forming device | |

| CN205185146U (en) | Old and useless PE removal of materials reducing mechanism | |

| CN203378472U (en) | Collection device for remaining materials of fine dried noodles | |

| CN204160794U (en) | The oil press charging pendulous device that a kind of motor integration drives | |

| CN204159421U (en) | The dustless ore disintegrating mill of a kind of water saving | |

| CN101882684A (en) | Automatic battery cleaning machine | |

| CN202037631U (en) | Household hand-driving vegetable cutter | |

| CN215656536U (en) | An intelligent cleaning device for the surface of solar panels used in photovoltaic power stations | |

| CN204248345U (en) | One send axis mechanism | |

| CN204054408U (en) | A kind of manpower drives plastic bottle to cut flatting mill | |

| CN206405164U (en) | A kind of novel environment friendly food waste treatment device | |

| CN202702437U (en) | Plastic regeneration processing device | |

| CN203184481U (en) | Dedicated feeder for stainless steel cloth padding stamping bending machine | |

| CN209348792U (en) | A biomass straw screw feeder | |

| CN203020981U (en) | Belt line cleaning device | |

| CN207026060U (en) | A multi-roller body cleaning mechanism for a hydrogen production water tank |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| CF01 | Termination of patent right due to non-payment of annual fee | ||

| CF01 | Termination of patent right due to non-payment of annual fee |

Granted publication date: 20121017 Termination date: 20160315 |