CN202490716U - Aerosol dosing spray valve and matching L-type spray-head button thereof - Google Patents

Aerosol dosing spray valve and matching L-type spray-head button thereof Download PDFInfo

- Publication number

- CN202490716U CN202490716U CN2012200043200U CN201220004320U CN202490716U CN 202490716 U CN202490716 U CN 202490716U CN 2012200043200 U CN2012200043200 U CN 2012200043200U CN 201220004320 U CN201220004320 U CN 201220004320U CN 202490716 U CN202490716 U CN 202490716U

- Authority

- CN

- China

- Prior art keywords

- valve

- shower nozzle

- type

- fixed cap

- spool

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 239000007921 spray Substances 0.000 title claims abstract description 72

- 239000000443 aerosol Substances 0.000 title claims abstract description 66

- 239000000463 material Substances 0.000 claims description 6

- 229920003023 plastic Polymers 0.000 claims description 6

- 239000004033 plastic Substances 0.000 claims description 6

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 claims description 3

- DGAQECJNVWCQMB-PUAWFVPOSA-M Ilexoside XXIX Chemical compound C[C@@H]1CC[C@@]2(CC[C@@]3(C(=CC[C@H]4[C@]3(CC[C@@H]5[C@@]4(CC[C@@H](C5(C)C)OS(=O)(=O)[O-])C)C)[C@@H]2[C@]1(C)O)C)C(=O)O[C@H]6[C@@H]([C@H]([C@@H]([C@H](O6)CO)O)O)O.[Na+] DGAQECJNVWCQMB-PUAWFVPOSA-M 0.000 claims description 3

- 238000005452 bending Methods 0.000 claims description 3

- 125000000484 butyl group Chemical group [H]C([*])([H])C([H])([H])C([H])([H])C([H])([H])[H] 0.000 claims description 3

- 229910052802 copper Inorganic materials 0.000 claims description 3

- 239000010949 copper Substances 0.000 claims description 3

- 229920001084 poly(chloroprene) Polymers 0.000 claims description 3

- 229910052708 sodium Inorganic materials 0.000 claims description 3

- 239000011734 sodium Substances 0.000 claims description 3

- 230000000694 effects Effects 0.000 abstract description 5

- 239000000126 substance Substances 0.000 abstract description 3

- 238000000889 atomisation Methods 0.000 abstract 1

- 238000000034 method Methods 0.000 description 3

- 238000007789 sealing Methods 0.000 description 3

- 239000000047 product Substances 0.000 description 2

- 238000005507 spraying Methods 0.000 description 2

- 238000005516 engineering process Methods 0.000 description 1

- 239000012467 final product Substances 0.000 description 1

- 238000003780 insertion Methods 0.000 description 1

- 230000037431 insertion Effects 0.000 description 1

Images

Landscapes

- Containers And Packaging Bodies Having A Special Means To Remove Contents (AREA)

- Nozzles (AREA)

Abstract

The utility model relates to an aerosol dosing spray valve and a matching L-type spray-head button thereof, comprising the dosing spray valve and the spray head arranged on the dosing spray valve. The spray head is flexibly connected with the dosing spray valve in a seal manner. The aerosol dosing spray valve and the matching L-type spray-head button thereof in the utility model can accurately control the spray amount of aerosol and replace the spray head based on different purposes to reach different atomization effects. The aerosol dosing spray valve has a good seal effect to prevent air pressure leakage. The valve and the button in the utility model is simple in structure, low in cost and long in useful life and easy to popularize and apply in daily chemical products.

Description

Technical field

The utility model relates to a kind of spray valve and shower nozzle thereof, is specifically related to a kind of aerosol and quantitatively sprays valve and supporting L type shower nozzle button thereof.

Background technology

The aerosol spray valve of prior art is made up of parts such as spool, valve rod, springs usually; The amount of the aerosol of ejection also is difficult to control; Sealing effectiveness between each parts neither be very desirable; The situation that often has gas leakage takes place, and the precision of the amount of the aerosol of the also very difficult assurance ejection of design of some quantitative aerosol spray valve is to different environments for use; Spraying the supporting shower nozzle button of valve with aerosol also should be different to some extent; According to the demands of different to the materialization situation of the precision of the amount of the aerosol of required ejection, aerosol, expulsion pressure etc., aerosol spray valve has multiple matching used shower nozzle button, but the aerosol of prior art spray valve is difficult to accomplish.

In view of the above problems, the utility model discloses a kind of aerosol and quantitatively spray valve and supporting L type shower nozzle button thereof.It has technical characterictic as mentioned below, to solve existing problem.

The utility model content

The purpose of the utility model provides a kind of aerosol and quantitatively sprays valve and supporting L type shower nozzle button thereof; It can guarantee that aerosol quantitatively sprays, and can change different supporting shower nozzles according to the different purposes of aerosol, guarantees accurate spray amount; And the atomizing situation is desirable, is difficult for gas leakage.

The purpose that the utility model aerosol quantitatively sprays valve and supporting L type shower nozzle button thereof realizes through following technical scheme: a kind of aerosol quantitatively sprays valve and supporting L type shower nozzle button comprises quantitative spray valve and is arranged on the shower nozzle on the quantitative spray valve; Described shower nozzle and quantitatively spray valve flexible connection, and be tightly connected between described shower nozzle and the quantitative spray valve.

Described quantitative spray valve comprises spool, inner washer, fixed cap, outer washer, spring, valve chamber and suction pipe; The central authorities of described fixed cap are provided with a through hole, and described spool fixedly is inserted in the through hole on the fixed cap, and described valve chamber is arranged in the fixed cap; And described valve chamber and fixed cap are tightly connected, and the lower end of described spool is nested with in the upper end of valve chamber through fixed cap, and described inner washer is arranged in the fixed cap; Described inner washer is nested with on described spool, and described inner washer is between fixed cap and valve chamber, and described outer washer is arranged in the outer of fixed cap; Be tightly connected with described fixed cap; Described spring is nested with on spool, is positioned at described valve chamber, and an end of described spring is fixedly connected with spool; The other end of described suction pipe is provided with the lower end of valve chamber, is tightly connected with described valve chamber.

Described valve core diameter scope is the 2-3 millimeter, and the partial-length scope that spool exposes above fixed cap is the 10.7-10.9 millimeter, and the middle part of described spool is to outer lug, described inner washer is close to be arranged in the fixed cap.

Above-mentioned aerosol quantitatively sprays valve and supporting L type shower nozzle button thereof; Wherein, swell on the mediad of described fixed cap, form a trapezoidal cavity; The upper end of the lower end of described spool, inner washer and valve chamber is arranged in this trapezoidal cavity; The edge of described fixed cap bends downwards, and described outer washer is stuck in the bending place of fixed cap, and the bottleneck of matching used aerosol is tightly connected through described outer washer and fixed cap.

Above-mentioned aerosol quantitatively sprays valve and supporting L type shower nozzle button thereof, and wherein, described spool is that plastics or copper or high-density plastic's material are processed.

Above-mentioned aerosol quantitatively sprays valve and supporting L type shower nozzle button thereof, and wherein, the inner chamber lower end of described valve chamber is provided with a circle boss, and the upper end of described suction pipe is provided with a circle groove, and boss and the groove on the suction pipe in the described valve chamber are suitable.

Above-mentioned aerosol quantitatively sprays valve and supporting L type shower nozzle button thereof, and wherein, described inner washer is that fourth sodium or neoprene or butyl or the fine material of fourth are processed.

Above-mentioned aerosol quantitatively sprays valve and supporting L type shower nozzle button thereof; Wherein, described shower nozzle is made up of atomizer and head body, is provided with L type inner chamber in the described head body; One end of described L type inner chamber is connected with atomizer; The upper end of the other end and spool is suitable, through described L type inner chamber shower nozzle is connected with quantitative spray valve seal, and is provided with one in the inner chamber of the end that is connected with atomizer of L type inner chamber and limits platform.

Above-mentioned aerosol quantitatively sprays valve and supporting L type shower nozzle button thereof; Wherein, The altitude range of described restriction platform is the 3.5-4.5 millimeter; The inside diameter ranges of the end that described L type inner chamber is connected with atomizer approximately is the 2-3.5 millimeter, and the diameter range of described atomizer approximately is the 3.5-4.5 millimeter, and the end of atomizer and head body is provided with the oblique angle.

The utility model aerosol quantitatively sprays valve and supporting L type shower nozzle button thereof owing to adopted such scheme, makes it compared with prior art, has following advantage and good effect:

1, the utility model aerosol quantitatively sprays the spray volume that valve and supporting L type shower nozzle button thereof can be controlled aerosol accurately, and can change shower nozzle according to different purposes, reach different atomizing effects, and sealing effectiveness is good, prevents that air pressure from leaking.

2, the utility model aerosol quantitatively spray valve and supporting L type shower nozzle press-button structure simple, cost is lower, long service life is easy to popularization and application on daily chemical products.

Below; To do further explanation through concrete embodiment; Yet embodiment only is giving an example of the optional embodiment of the utility model, and its disclosed characteristic only is used to explain and set forth the technical scheme of the utility model, and is not used in the protection domain that limits the utility model.

Description of drawings

In order better to understand the utility model, the accompanying drawing for your guidance that can quote with reference to this specification, in the accompanying drawing:

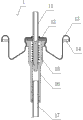

Fig. 1 is the cutaway view that aerosol that the utility model aerosol quantitatively sprays valve and supporting L type shower nozzle button thereof quantitatively sprays valve.

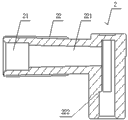

Fig. 2 is the cutaway view that the utility model aerosol quantitatively sprays the L type E3 shower nozzle of valve and supporting L type shower nozzle button thereof.

Fig. 3 is the cutaway view that the utility model aerosol quantitatively sprays the L type E4 shower nozzle of valve and supporting L type shower nozzle button thereof.

Fig. 4 is the cutaway view that the utility model aerosol quantitatively sprays the L type XB shower nozzle of valve and supporting L type shower nozzle button thereof.

Fig. 5 is the cutaway view that the utility model aerosol quantitatively sprays the L type GB shower nozzle of valve and supporting L type shower nozzle button thereof.

Fig. 6 is the cutaway view that the utility model aerosol quantitatively sprays the L type RB shower nozzle of valve and supporting L type shower nozzle button thereof.

Fig. 7 is the cutaway view that the utility model aerosol quantitatively sprays the L type MB shower nozzle of valve and supporting L type shower nozzle button thereof.

Fig. 8 is the cutaway view that the utility model aerosol quantitatively sprays the L type KB shower nozzle of valve and supporting L type shower nozzle button thereof.

Fig. 9 is the cutaway view that the utility model aerosol quantitatively sprays the L type SB shower nozzle of valve and supporting L type shower nozzle button thereof.

The specific embodiment

According to the claim and the disclosed content of utility model content of the utility model, the technical scheme of the utility model is specific as follows said.

See also shown in the accompanying drawing 1; The utility model aerosol quantitatively sprays valve and supporting L type shower nozzle button comprises quantitative spray valve 1 and is arranged on shower nozzle 2 (not shown in figure 1)s on the quantitative spray valve 1; Described shower nozzle 2 and quantitatively spray valve 1 flexible connection, and be tightly connected between shower nozzle 2 and the quantitative spray valve 1.

Quantitatively spray valve 1 comprises spool 11, inner washer 12, fixed cap 13, outer washer 14, spring 15, valve chamber 16 and suction pipe 17; The central authorities of described fixed cap 13 are provided with a through hole (not shown), and described spool 11 fixedly is inserted in the through hole on the fixed cap 13, and described valve chamber 16 is arranged in the fixed cap 13; And valve chamber 16 is tightly connected with fixed cap 13, and the lower end of spool 11 is nested with in the upper end of valve chamber 16 through fixed cap 13, and inner washer 12 is arranged in the fixed cap 13; Inner washer 12 is nested with on described spool 11, and inner washer 12 is between fixed cap 13 and valve chamber 16, and described outer washer 14 is arranged in the outer of fixed cap 13; Be tightly connected with fixed cap 13; Described spring 15 is nested with on spool 11, is positioned at valve chamber 16, and the upper end of spring 15 is fixedly connected with spool 11; One end of described suction pipe 17 is provided with the lower end of valve chamber 16, is tightly connected with valve chamber 16.

Described spool 11 diameters are about the 2-3 millimeter; Preferred 2.8 millimeters, the partial-length scope that spool 11 exposes above fixed cap 13 is about the 10.7-10.9 millimeter, and the middle part of spool 11 is to outer lug; Inner washer 12 is close to is arranged in the fixed cap 13, limit the scope that moves up and down of spool 11.Described spool 11 can adopt materials such as plastics, copper, high-density plastic to process.

Described inner washer 12 can adopt materials such as fourth sodium, neoprene, butyl, Ding Qing to process.

Swell on the mediad of described fixed cap 13; Form a trapezoidal cavity; The upper end of the lower end of described spool 11, inner washer 12 and valve chamber 16 is arranged in this trapezoidal cavity; The edge of fixed cap 13 bends downwards, and outer washer 14 is stuck in the bending place of fixed cap 13, and the bottleneck of matching used aerosol is tightly connected through outer washer 14 and fixed cap 13.

The inner chamber lower end of described valve chamber 16 is provided with a circle boss, and the upper end of described suction pipe 17 is provided with a circle groove, and boss and the groove on the suction pipe 17 in the described valve chamber 16 are suitable, and valve chamber 16 and suction pipe 17 are tightly connected.

Described shower nozzle 2 is made up of atomizer 21 and head body 22; Be provided with L type inner chamber 221 in the described head body 22; One end of described L type inner chamber 221 is connected with atomizer 21, and the upper end of the other end and spool 11 is suitable, through L type inner chamber 221 shower nozzle 2 and quantitative spray valve 1 is tightly connected; And be provided with a restriction platform 222 in the inner chamber of the end that L type inner chamber 221 is connected with atomizer 21; Described restriction platform 222 promptly limits the length that spool 11 inserts in the shower nozzle 2 with the distance of L type inner chamber 221 bottoms, and the height of restriction platform 222 is used to limit the length that spool 11 inserts shower nozzle 2, and aerosol is through atomizer 21 atomizing back ejections; The altitude range of described restriction platform 222 is the 3.5-4.5 millimeter; The inside diameter ranges of the end that described L type inner chamber is connected with atomizer 21 approximately is the 2-3.5 millimeter; The diameter range of described atomizer 21 approximately is the 3.5-4.5 millimeter; And atomizer 21 is provided with the oblique angle with the end of head body 22, so that the ejection of aerosol.According to different purposes; It is 8 kinds that shower nozzle 2 is divided into; Be respectively L type E3 shower nozzle, L type E4 shower nozzle, L type XB shower nozzle, L type GB shower nozzle, L type RB shower nozzle, L type MB shower nozzle, L type KB shower nozzle and L type SB shower nozzle; Please, only need select required shower nozzle model during use, get final product in the upper end insertion head body with spool 11 successively referring to shown in the accompanying drawing 2-accompanying drawing 9.

Embodiment 1:L type E3 shower nozzle,

See also shown in the accompanying drawing 2, the end that L type E3 shower nozzle is connected with spool 11 column that is square, and be respectively equipped with four cylindrical support column on the corner angle of square column, and the end Lower Half that L type E3 shower nozzle is connected with atomizer 21 is cylindric, and it is rectangular-shaped that the first half is; The altitude range of described restriction platform 222 is the 3.5-4 millimeter; Preferred 3.7 millimeters, the inside diameter ranges of the end that described L type inner chamber 221 is connected with atomizer 21 approximately is the 2-2.5 millimeter, preferred 2.3 millimeters; The diameter range of described atomizer 21 approximately is the 4-4.5 millimeter; Preferred 4.2 millimeters, and the end of atomizer 21 and L type E3 shower nozzle is provided with the oblique angle, so that the ejection of aerosol.

See also shown in the accompanying drawing 3, the L type E4 shower nozzle column that is square is respectively equipped with four oblique angles on the corner angle of the end that L type E4 shower nozzle is connected with atomizer 21; The altitude range of described restriction platform 222 is the 3.5-4 millimeter; Preferred 3.8 millimeters, the inside diameter ranges of the end that described L type inner chamber 221 is connected with atomizer 21 approximately is the 3-3.5 millimeter, preferred 3.4 millimeters; The diameter range of described atomizer 21 approximately is the 4-4.5 millimeter; Preferred 4.27 millimeters, and the end of atomizer 21 and L type E4 shower nozzle is provided with the oblique angle, so that the ejection of aerosol.

Embodiment 3, L type XB shower nozzle,

See also shown in the accompanying drawing 4, the end that L type XB shower nozzle is connected with spool 11 column that is square, the end that L type XB shower nozzle is connected with atomizer 21 is cylindric, the corner mediad sunken inside of L type XB shower nozzle, both sides respectively are provided with chimb; The altitude range of described restriction platform 222 is the 4-4.5 millimeter; Preferred 4.1 millimeters, the inside diameter ranges of the end that described L type inner chamber 221 is connected with atomizer 21 approximately is the 2.5-3 millimeter, preferred 2.8 millimeters; The diameter range of described atomizer 21 approximately is the 3.5-4 millimeter; Preferred 3.9 millimeters, and the end of atomizer 21 and L type XB shower nozzle is provided with the oblique angle, so that the ejection of aerosol.

Embodiment 4:L type GB shower nozzle,

See also shown in the accompanying drawing 5, the end that L type GB shower nozzle is connected with spool 11 is oval column, and the end that L type GB shower nozzle is connected with atomizer 21 is cylindric, and the body diameter of corner is less, and it is one square by platform that the corner of L type GB shower nozzle is provided with; The altitude range of described restriction platform 222 is the 3.5-4 millimeter; Preferred 3.8 millimeters, the inside diameter ranges of the end that described L type inner chamber 221 is connected with atomizer 21 approximately is the 2.3-2.8 millimeter, preferred 2.5 millimeters; The diameter range of described atomizer 21 approximately is the 4-4.5 millimeter; Preferred 4.2 millimeters, and the end of atomizer 21 and L type GB shower nozzle is provided with the oblique angle, so that the ejection of aerosol.

Embodiment 5:L type RB shower nozzle,

See also shown in the accompanying drawing 6, the end that L type RB shower nozzle is connected with spool 11 is oval column, and the end that L type RB shower nozzle is connected with atomizer 21 is cylindric, and the body diameter of corner is less, and it is one square by platform that the corner of L type RB shower nozzle is provided with; The altitude range of described restriction platform 222 is the 4-4.5 millimeter; Preferred 4.2 millimeters, the inside diameter ranges of the end that described L type inner chamber 221 is connected with atomizer 21 approximately is the 2.3-2.8 millimeter, preferred 2.5 millimeters; The diameter range of described atomizer 21 approximately is the 4-4.5 millimeter; Preferred 4.2 millimeters, and the end of atomizer 21 and L type RB shower nozzle is provided with the oblique angle, so that the ejection of aerosol.

Embodiment 6:L type MB shower nozzle,

See also shown in the accompanying drawing 7, the end that L type MB shower nozzle is connected with spool 11 is oval column, the rounded petal-shaped of an end that L type MB shower nozzle is connected with atomizer 21, and the body diameter of corner is less, and it is one square by platform that the corner of L type MB shower nozzle is provided with; The altitude range of described restriction platform 222 is the 4-4.5 millimeter; Preferred 4.2 millimeters, the inside diameter ranges of the end that described L type inner chamber 221 is connected with atomizer 21 approximately is the 3-3.5 millimeter, preferred 3.4 millimeters; The diameter range of described atomizer 21 approximately is the 4-4.5 millimeter; Preferred 4.27 millimeters, and the end of atomizer 21 and L type MB shower nozzle is provided with the oblique angle, so that the ejection of aerosol.

Embodiment 7:L type KB shower nozzle,

See also shown in the accompanying drawing 8; The end that L type KB shower nozzle is connected with spool 11 column that is square, the end first half that L type KB shower nozzle is connected with atomizer 21 is hexagonal cylindrical, and Lower Half is semi-cylindrical; The upper end, corner of L type KB shower nozzle is flat, forms a level by platform; The altitude range of described restriction platform 222 is the 3.5-4 millimeter; Preferred 3.8 millimeters, the inside diameter ranges of the end that described L type inner chamber 221 is connected with atomizer 21 approximately is the 3-3.5 millimeter, preferred 3.4 millimeters; The diameter range of described atomizer 21 approximately is the 4-4.5 millimeter; Preferred 4.1 millimeters, and the end of atomizer 21 and L type KB shower nozzle is provided with the oblique angle, so that the ejection of aerosol.

Embodiment 8:L type SB shower nozzle,

See also shown in the accompanying drawing 9; The end that L type SB shower nozzle is connected with spool 11 column that is square; And be respectively equipped with four cylindrical support column on the corner angle of square column, the end Lower Half that L type SB shower nozzle is connected with atomizer 21 is cylindric, and it is rectangular-shaped that the first half is; The corner mediad sunken inside of L type SB shower nozzle, both sides respectively are provided with chimb; The altitude range of described restriction platform 222 is the 3.5-4 millimeter; Preferred 3.7 millimeters, the inside diameter ranges of the end that described L type inner chamber 221 is connected with atomizer 21 approximately is the 2-2.5 millimeter, preferred 2.3 millimeters; The diameter range of described atomizer 21 approximately is the 4-4.5 millimeter; Preferred 4.2 millimeters, and the end of atomizer 21 and L type SB shower nozzle is provided with the oblique angle, so that the ejection of aerosol.

In sum, the utility model aerosol quantitatively sprays valve and supporting L type shower nozzle button can be controlled the spray volume of aerosol accurately, and can change shower nozzle according to different purposes, reaches different atomizing effects, and sealing effectiveness is good, prevents that air pressure from leaking; The utility model is simple in structure, and cost is lower, and long service life is easy to popularization and application on daily chemical products.

Foregoing is enumerating of the utility model aerosol specific embodiment of quantitatively spraying valve and supporting L type shower nozzle button thereof; For the wherein not equipment of detailed description and structure, be to be understood that to taking existing common apparatus in this area and universal method to implement.

Claims (7)

1. an aerosol quantitatively sprays valve and supporting L type shower nozzle button thereof; Comprise quantitative spray valve and be arranged on the shower nozzle on the quantitative spray valve; It is characterized in that: described shower nozzle and quantitatively spray valve flexible connection, and be tightly connected between described shower nozzle and the quantitative spray valve;

Described quantitative spray valve comprises spool, inner washer, fixed cap, outer washer, spring, valve chamber and suction pipe; The central authorities of described fixed cap are provided with a through hole, and described spool fixedly is inserted in the through hole on the fixed cap, and described valve chamber is arranged in the fixed cap; And described valve chamber and fixed cap are tightly connected, and the lower end of described spool is nested with in the upper end of valve chamber through fixed cap, and described inner washer is arranged in the fixed cap; Described inner washer is nested with on described spool, and described inner washer is between fixed cap and valve chamber, and described outer washer is arranged in the outer of fixed cap; Be tightly connected with described fixed cap; Described spring is nested with on spool, is positioned at described valve chamber, and an end of described spring is fixedly connected with spool; The other end of described suction pipe is provided with the lower end of valve chamber, is tightly connected with described valve chamber;

Described valve core diameter scope is the 2-3 millimeter, and the partial-length scope that spool exposes above fixed cap is the 10.7-10.9 millimeter, and the middle part of described spool is to outer lug, described inner washer is close to be arranged in the fixed cap.

2. aerosol according to claim 1 quantitatively sprays valve and supporting L type shower nozzle button thereof; It is characterized in that: swell on the mediad of described fixed cap; Form a trapezoidal cavity, the upper end of the lower end of described spool, inner washer and valve chamber is arranged in this trapezoidal cavity, and the edge of described fixed cap bends downwards; Described outer washer is stuck in the bending place of fixed cap, and the bottleneck of matching used aerosol is tightly connected through described outer washer and fixed cap.

3. aerosol according to claim 1 quantitatively sprays valve and supporting L type shower nozzle button thereof, it is characterized in that: described spool is that plastics or copper or high-density plastic's material are processed.

4. aerosol according to claim 1 quantitatively sprays valve and supporting L type shower nozzle button thereof; It is characterized in that: the inner chamber lower end of described valve chamber is provided with a circle boss; The upper end of described suction pipe is provided with a circle groove, and boss and the groove on the suction pipe in the described valve chamber are suitable.

5. aerosol according to claim 1 quantitatively sprays valve and supporting L type shower nozzle button thereof, it is characterized in that: described inner washer is that fourth sodium or neoprene or butyl or the fine material of fourth are processed.

6. aerosol according to claim 1 quantitatively sprays valve and supporting L type shower nozzle button thereof; It is characterized in that: described shower nozzle is made up of atomizer and head body; Be provided with L type inner chamber in the described head body, an end of described L type inner chamber is connected with atomizer, and the upper end of the other end and spool is suitable; Through described L type inner chamber shower nozzle is connected with quantitative spray valve seal, and is provided with one in the inner chamber of the end that is connected with atomizer of L type inner chamber and limits platform.

7. quantitatively spray valve and supporting L type shower nozzle button thereof according to claim 1 or 6 described aerosols; It is characterized in that: the altitude range of described restriction platform is the 3.5-4.5 millimeter; The inside diameter ranges of the end that described L type inner chamber is connected with atomizer is the 2-3.5 millimeter; The diameter range of described atomizer is the 3.5-4.5 millimeter, and the end of atomizer and head body is provided with the oblique angle.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2012200043200U CN202490716U (en) | 2012-01-06 | 2012-01-06 | Aerosol dosing spray valve and matching L-type spray-head button thereof |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2012200043200U CN202490716U (en) | 2012-01-06 | 2012-01-06 | Aerosol dosing spray valve and matching L-type spray-head button thereof |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN202490716U true CN202490716U (en) | 2012-10-17 |

Family

ID=46996960

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN2012200043200U Expired - Fee Related CN202490716U (en) | 2012-01-06 | 2012-01-06 | Aerosol dosing spray valve and matching L-type spray-head button thereof |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN202490716U (en) |

-

2012

- 2012-01-06 CN CN2012200043200U patent/CN202490716U/en not_active Expired - Fee Related

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN205203711U (en) | Conveniently scribble device of medicine | |

| US20090173807A1 (en) | Atomizer | |

| CN202479070U (en) | Liquid-gas two-phase atomizing nozzle | |

| CN105557667A (en) | Adjustable spraying head for garden agent spraying device | |

| CN203860309U (en) | Liquid atomization spraying charging device | |

| CN202490716U (en) | Aerosol dosing spray valve and matching L-type spray-head button thereof | |

| IE812513L (en) | Electrostatic spraying. | |

| CN203635378U (en) | Rotary type wide-angle sprayer for landscaping | |

| CN202492048U (en) | 20 mm aerosol dosing spray valve | |

| CN202490717U (en) | Aerosol special-purpose dosing spray valve and matching L-type spray-head button thereof | |

| CN103212516B (en) | Ampere force driving micro spraying device | |

| CN103521371A (en) | Agricultural sprayer nozzle device free of water dripping and water leakage | |

| CN202492047U (en) | 20 mm aerosol continuous spray valve | |

| CN203400818U (en) | Ultrasonic atomizer | |

| CN208146259U (en) | A kind of more spray head aerosol bottles | |

| CN202219210U (en) | Atomization device | |

| CN202179966U (en) | Steel shower type injection liquid reactor | |

| CN202778788U (en) | Aerosol equipment | |

| CN204396207U (en) | For the dual-purpose spiral nozzle in forest industry seedling culture booth | |

| CN222901410U (en) | A snap-on multi-fluid atomizing nozzle | |

| CN106622739A (en) | Spray body structure based on irrigating and pesticide spraying integration | |

| CN206652380U (en) | The special spray bottle of interior decoration air pollution | |

| CN220406111U (en) | Atomizing sheet module capable of atomizing oily or viscous liquid and atomizing equipment | |

| CN202346155U (en) | Spray bottle capable of spraying water easily | |

| CN211412442U (en) | An environmentally friendly ink spraying device on the surface of a pipe |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| C17 | Cessation of patent right | ||

| CF01 | Termination of patent right due to non-payment of annual fee |

Granted publication date: 20121017 Termination date: 20140106 |