CN202166350U - Parallel fluid sherardizing aluminum flat pipe for a vehicle air-condition condenser - Google Patents

Parallel fluid sherardizing aluminum flat pipe for a vehicle air-condition condenser Download PDFInfo

- Publication number

- CN202166350U CN202166350U CN2011200297310U CN201120029731U CN202166350U CN 202166350 U CN202166350 U CN 202166350U CN 2011200297310 U CN2011200297310 U CN 2011200297310U CN 201120029731 U CN201120029731 U CN 201120029731U CN 202166350 U CN202166350 U CN 202166350U

- Authority

- CN

- China

- Prior art keywords

- flat pipe

- sherardizing

- flat tube

- pipe

- parallel fluid

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Landscapes

- Rigid Pipes And Flexible Pipes (AREA)

Abstract

The utility model relates to a parallel fluid sherardizing aluminum flat pipe for a vehicle air-condition condenser. The flat pipe is composed of a pipe wall and ribs perpendicular with the direction of the pipe wall. The flat pipe is uniformly divided into 5-15 cavities by the ribs along the length direction of the flat pipe and a sherardizing layer is arranged on the outer surface of the pipe wall. The thickness of the flat pipe is relative small, the relative large heat exchange area is obtained, the occupy space is smaller very much, therefore the miniaturization, high efficiency and light weighting of the parallel fluid sherardizing aluminum flat pipe is realized. The multi-cavity structure increases the heat transfer area of the parallel fluid sherardizing aluminum flat pipe and also increases the heat conductivity rate. In the situation of same heat exchange amount in same unit time, the relative less flat pipe can achieve the heat transfer object and the resource waste can be reduced. The sherardizing layer prevents the outer surface of the flat pipe from contacting with the air and other material, thus the corrosion resistance and the oxidation resistance of the flat pipe is increased, therefore the service life of the parallel fluid sherardizing aluminum flat pipe is greatly prolonged and the production cost of the material is saved.

Description

Technical field

The utility model relates to a kind of automotive air-conditioning condenser with concurrent flow spray zinc-aluminium flat tube.

Background technology

Because the development trend of automobile industry is good greatly; And country advocates environmental emission reduction energetically; In the time of owning a car also to car require increasingly highly, the air conditioning for automobiles performance has become good one examination of automobile important step, air conditioning for automobiles extensively adopts the used concurrent flow of band-tube evaporator and condenser, parallel flow evaporators and condenser to spray the zinc-aluminium flat tube; Process the cavity of a plurality of two section openings at the length direction of concurrent flow spray zinc-aluminium flat tube; Will increase heat transfer area like this, heat transfer coefficient also increases, and its heat-transfer effect also can reach certain improvement.

Commonly used is that copper goods aluminium comes fabrication of parallel stream spray zinc-aluminium flat tube, for the material of concurrent flow spray zinc-aluminium flat tube, with copper as matrix material; The density of copper is big and be not easy to processing, and thickness is difficult to reduce on straightening and cutting machine, is not easy to produce; And; The price comparison of copper is expensive, is that matrix material comes fabrication of parallel stream spray zinc-aluminium flat tube if adopt copper in a large number, will increase the production use cost greatly; As matrix material, because aluminium flat conduit directly is exposed to the surface in the air aborning, very easily corrosion is easy to wear out, and has seriously reduced the service life of flat tube with aluminium.

Summary of the invention

To above-mentioned shortcoming, the utility model technical issues that need to address provide a kind of automotive air-conditioning condenser with concurrent flow spray zinc-aluminium flat tube.

The technical scheme that the utility model adopts is:

A kind of automotive air-conditioning condenser is with concurrent flow spray zinc-aluminium flat tube, and flat tube is formed by tube wall with perpendicular to the muscle of tube wall direction, and said muscle is divided into 5 ~ 15 cavitys to flat tube along the length direction of flat tube, and said tube wall appearance is provided with sprays the zinc layer.

The width of said flat tube is 15.98 ~ 25.4mm, and the thickness of said flat tube is 1 ~ 2mm.

Said thickness of pipe wall is 0.3 ~ 0.4mm, and said muscle is thick to be 0.3 ~ 0.4mm.

The thickness of said spray zinc layer is 10 ~ 15um.

The utility model has the advantages that: the thickness of flat tube is less, when having big heat exchange area, occupies little room, thereby realizes miniaturization, high efficiency, lightweight; A plurality of cavity body structures have increased the heat transfer area of concurrent flow spray zinc-aluminium flat tube, have improved pyroconductivity; Under the identical condition of identical heat of unit interval, use less flat tube just can reach expection heat transfer target, reduced the waste of resource; Spray zinc layer prevents contacting of flat tube outer surface and air and other materials; Improve the corrosion resistance and the oxidation resistant ability of flat tube, thereby prolonged the service life of concurrent flow spray zinc-aluminium flat tube greatly, practiced thrift the production cost of material.

Description of drawings

Below in conjunction with the accompanying drawing and the specific embodiment the utility model is described in further detail.

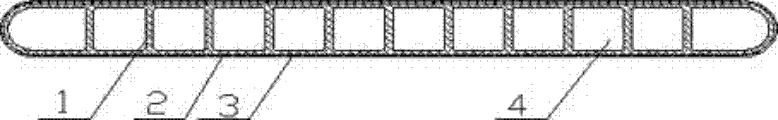

Fig. 1 is the structural representation of the utility model.

Wherein: 1, muscle, 2, tube wall, 3, spray zinc layer, 4, cavity.

The specific embodiment

In order to deepen understanding to the utility model, will combine embodiment and accompanying drawing that the utility model is done further to detail below, this embodiment only is used to explain the utility model, does not constitute the qualification to the utility model protection domain.

As shown in Figure 1, a kind of automotive air-conditioning condenser of the utility model is with concurrent flow spray zinc-aluminium flat tube, and flat tube is by tube wall 2 and form perpendicular to the muscle 1 of tube wall direction; The width of flat tube is 17mm; The thickness of flat tube is 1.5mm, and tube wall 2 is thick to be 0.3mm, and muscle 1 is thick to be 0.3mm; Muscle 1 is divided into 10 cavitys 4 to flat tube along the length direction of flat tube, and tube wall 2 appearances are provided with the spray zinc layer 3 that thickness is 10um.The thickness of flat tube is less, when having big heat exchange area, occupies little space, thereby realizes miniaturization, high efficiency, lightweight; A plurality of cavity body structures have increased the heat transfer area of concurrent flow spray zinc-aluminium flat tube, have improved pyroconductivity; Under the identical condition of identical heat of unit interval, use less flat tube just can reach expection heat transfer target, reduced the waste of resource; Spray zinc layer prevents contacting of flat tube outer surface and air and other materials; Improve the corrosion resistance and the oxidation resistant ability of flat tube, thereby prolonged the service life of concurrent flow spray zinc-aluminium flat tube greatly, practiced thrift the production cost of material.

Claims (4)

1. an automotive air-conditioning condenser is with concurrent flow spray zinc-aluminium flat tube; It is characterized in that; Flat tube is formed by tube wall with perpendicular to the muscle of tube wall direction, and said muscle is divided into 5 ~ 15 cavitys to flat tube along the length direction of flat tube, and said tube wall appearance is provided with spray zinc layer.

2. a kind of automotive air-conditioning condenser according to claim 1 is characterized in that with concurrent flow spray zinc-aluminium flat tube the width of said flat tube is 15.98 ~ 25.4mm, and the thickness of said flat tube is 1 ~ 2mm.

3. a kind of automotive air-conditioning condenser according to claim 1 is characterized in that with concurrent flow spray zinc-aluminium flat tube said thickness of pipe wall is 0.3 ~ 0.4mm, and said muscle is thick to be 0.3 ~ 0.4mm.

4. a kind of automotive air-conditioning condenser according to claim 1 is characterized in that with concurrent flow spray zinc-aluminium flat tube the thickness of said spray zinc layer is 10 ~ 15um.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2011200297310U CN202166350U (en) | 2011-01-28 | 2011-01-28 | Parallel fluid sherardizing aluminum flat pipe for a vehicle air-condition condenser |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2011200297310U CN202166350U (en) | 2011-01-28 | 2011-01-28 | Parallel fluid sherardizing aluminum flat pipe for a vehicle air-condition condenser |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN202166350U true CN202166350U (en) | 2012-03-14 |

Family

ID=45802169

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN2011200297310U Expired - Fee Related CN202166350U (en) | 2011-01-28 | 2011-01-28 | Parallel fluid sherardizing aluminum flat pipe for a vehicle air-condition condenser |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN202166350U (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN114993093A (en) * | 2022-04-02 | 2022-09-02 | 扬州瑞斯乐复合金属材料有限公司 | Production method of micro-channel aluminum flat tube with corrosion potential gradient layered distribution |

-

2011

- 2011-01-28 CN CN2011200297310U patent/CN202166350U/en not_active Expired - Fee Related

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN114993093A (en) * | 2022-04-02 | 2022-09-02 | 扬州瑞斯乐复合金属材料有限公司 | Production method of micro-channel aluminum flat tube with corrosion potential gradient layered distribution |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN202166350U (en) | Parallel fluid sherardizing aluminum flat pipe for a vehicle air-condition condenser | |

| CN107171037B (en) | Battery water-cooling plate | |

| CN104696061A (en) | Aluminum plastic radiator water tank for vehicle | |

| CN102032818A (en) | Efficient reinforced anti-vibration tube piece-shell-and-tube heat exchanger | |

| CN201297884Y (en) | Straight-tooth seamless internal thread copper pipe | |

| CN201318897Y (en) | Multi-channel aluminum flat tube for air conditioners | |

| CN201318898Y (en) | Aluminum flat tube for air conditioners | |

| CN201514141U (en) | Heat exchange tube with rows of pits | |

| CN204461176U (en) | A kind of flat tube for parallel-flow evaporator | |

| CN201155627Y (en) | Special-shaped channel hole flat tube | |

| CN201281442Y (en) | Indoor set heat exchanger of air conditioner for kitchen | |

| CN216250286U (en) | Aluminum alloy radiator of transformer | |

| CN204787449U (en) | Novel corrosion -resistant evaporimeter of tube sheet formula | |

| CN208820023U (en) | A kind of electric automobile power battery refrigerating module multiple flow passages ratio-frequency welded tube | |

| CN102798299A (en) | Parallel flow warm-air core body | |

| CN204006814U (en) | A kind of truck automobile air conditioner parallel flow condenser | |

| CN203022867U (en) | Aluminum-casting automotive heat radiator | |

| CN201569321U (en) | Non-planar radiating fin radiator | |

| CN202485281U (en) | Hydrophobic aluminum sheet | |

| CN2467999Y (en) | Tubing | |

| CN218063726U (en) | Automobile-used steel pipe that radiating effect is good | |

| CN2436729Y (en) | Pressure-resistant corrosion-resistant composite butterfly valve | |

| CN202991219U (en) | Heat radiating pipe with different wall thicknesses | |

| CN203259045U (en) | Micro-channel pipe used for air conditioning evaporator | |

| CN201573513U (en) | Polymer multi-hole conjoined automobile air duct |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| CF01 | Termination of patent right due to non-payment of annual fee |

Granted publication date: 20120314 Termination date: 20180128 |

|

| CF01 | Termination of patent right due to non-payment of annual fee |