CN201848500U - Sand temperature regulator - Google Patents

Sand temperature regulator Download PDFInfo

- Publication number

- CN201848500U CN201848500U CN2010205812489U CN201020581248U CN201848500U CN 201848500 U CN201848500 U CN 201848500U CN 2010205812489 U CN2010205812489 U CN 2010205812489U CN 201020581248 U CN201020581248 U CN 201020581248U CN 201848500 U CN201848500 U CN 201848500U

- Authority

- CN

- China

- Prior art keywords

- temperature

- sand

- pipe

- water

- circulation

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 239000004576 sand Substances 0.000 title claims abstract description 41

- 238000001816 cooling Methods 0.000 claims abstract description 38

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims abstract description 36

- 244000035744 Hura crepitans Species 0.000 claims abstract description 22

- 239000002689 soil Substances 0.000 abstract description 8

- 230000009286 beneficial effect Effects 0.000 abstract 1

- 238000004134 energy conservation Methods 0.000 abstract 1

- 239000008399 tap water Substances 0.000 description 5

- 235000020679 tap water Nutrition 0.000 description 5

- 230000000694 effects Effects 0.000 description 3

- 238000005057 refrigeration Methods 0.000 description 3

- 241000196324 Embryophyta Species 0.000 description 2

- 238000004140 cleaning Methods 0.000 description 2

- 238000009434 installation Methods 0.000 description 2

- 230000001172 regenerating effect Effects 0.000 description 2

- 230000036760 body temperature Effects 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 238000012423 maintenance Methods 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 230000001105 regulatory effect Effects 0.000 description 1

- 238000003466 welding Methods 0.000 description 1

Images

Landscapes

- Road Paving Structures (AREA)

Abstract

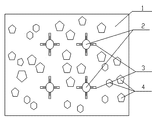

The utility model discloses a sand temperature regulator comprising a sand box (1), temperature reduction pipes (2), circulation pipes and sands (4), wherein the temperature reduction pipes (2) are arranged in the sand box (1) in a distributing way; one end of each temperature reduction pipe (2) is a water inlet, while the other end of each temperature reduction pipe is a water outlet; the water inlet and the water outlet of each temperature reduction pipe (2) are respectively positioned and connected on two ends of one circulation pipe outside the sand box (1); the sand box (1) is internally filled with the sands (4); and the outer wall of each circulation pipe is welded with cooling fins (3). In the utility model, the temperature of circulation water of a regulator is reduced by utilizing underground low-temperature soil, and then the temperature of the sands is reduced by utilizing the low temperature of the circulation water through the sand temperature regulator; and the utilization of clean renewable energy is beneficial to energy conservation and emission reduction.

Description

Technical field

The utility model relates to sand temperature modulator.

Background technology

Foundry enterprise is regulated the common way of sand temperature: one, supporting corresponding cooling tower and cooling circulating water system in the sandbox regulator system, the high-temperature water of sand temperature modulator circulating water outlet enters the cooling tower radiating and cooling, and then recycles.This mode summer because the outdoor temperature height, cooled circulating water temperature is generally at 28-36 ℃, therefore a lot of times can not be satisfied the technological requirement of sand temperature modulator, the temperature of reclaimed sand can't be reduced to the scope of 10-25 ℃ technological requirement, for reaching technological requirement, often reduce circulating water temperature by adding ice cube in the system, can satisfy technological requirement though do like this, but increased the cost input, and system will consume great amount of water resources at circulation time, need constantly system to be replenished running water,, therefore be unfavorable for energy-saving and emission-reduction to keep the balance of system; Two, the refrigeration plant and the sand temperature modulator of purchase special use are supporting, the high-temperature water of sand temperature modulator circulating water outlet has special-purpose refrigeration plant to force cooling, enter the circulation of sand temperature modulator again, this method advantage is a good refrigeration effect, the sand temperature control is guaranteed, shortcoming is that the one-time investment of equipment is big, and the operation and maintenance cost height, and is less economical.

Summary of the invention

The purpose of this utility model is: a kind of sand temperature modulator is provided, utilize the soil of underground low temperature that the recirculated water of adjuster is lowered the temperature, utilize the low temperature of recirculated water the sand temperature to be implemented cooling again, utilize the regenerative resource of cleaning, help energy-saving and emission-reduction by sand temperature modulator.

Technical solution of the present utility model is: this sand temperature modulator comprises sandbox, cooling pipe, circulation pipe and sand grains, the cooling of arranging in sandbox is managed, one end of cooling pipe is a water inlet, the other end of cooling pipe is a delivery port, the water inlet of cooling pipe is connected respectively on the two ends that are positioned at the outer circulation pipe of sandbox with delivery port, fills sand grains in the sandbox.

Wherein, on the outer wall of cooling pipe, weld fin.

During installation, the circulation pipe landfill is in surface soil, and circulation pipe is communicated with tap water supply system; During use, when the low temperature running water in the underground circulation pipe at the cooling pipe that under major cycle or effect, enters in the sandbox at water circulating pump, heat exchange takes place by cooling Guan Yuqi in the high temperature sand that is positioned at sandbox, makes the temperature rise of low temperature tap water to 16-17 ℃, makes simultaneously below the sand temperature drop to 27 ℃; Running water after the intensification is got back in the circulation pipe through the cooling pipe, and the underground with low temperature in circulation pipe carries out heat exchange, makes its temperature get back to 15 ℃ low-temperature condition, enters next circulation again.

The utlity model has following advantage: 1, utilize the soil of underground low temperature that the water in the circulation pipe is lowered the temperature, utilize water at low temperature that the sand temperature is implemented cooling again, heat exchange moves under airtight environment, therefore can not produce any influence, energy-conserving and environment-protective to tap water supply system; 2, the sand temperature of high temperature sand is generally at 50-60 ℃, differs 35-45 ℃ with the temperature of low temperature running water, so cooling rate is very fast, improved the efficient of sand temperature modulator greatly; 3, utilize the regenerative resource of cleaning, at 10-27 ℃, the assurance sand mold hardens and forms the sufficient time with the sand temperature control; 4, the outer wall of the cooling pipe of sand temperature modulator design fin increases sand grains and cooling pipe contact area and time, the heat exchanger effectiveness height; 5, the soil of underground low temperature replaces cooling tower and cooling circulating water system, and cost of investment is low; 6, summer underground and water body temperature be 8-15 ℃, the temperature at underground 1.8m place is substantially constant at 15 ℃, surface soil and water body are huge dynamic power balance sysmtes, the relative equilibrium that the soil on the face of land and water body keep energy to accept and disperse naturally, the scope of its fluctuation is far smaller than the change of air, because of its temperature is lower and constant, so can guarantee that sand temperature modulator is reliable, stable.

Description of drawings

Fig. 1 is a structure diagram of the present utility model.

Among the figure: 1 sandbox, 2 cooling pipes, 3 fin, 4 sand grains.

The specific embodiment

Further specify technical solution of the present utility model below in conjunction with accompanying drawing.

As shown in Figure 1, this sand temperature modulator comprises sandbox 1, cooling pipe 2, circulation pipe and sand grains 4, the cooling of arranging in sandbox 1 manages 2, one end of cooling pipe 2 is a water inlet, the other end of cooling pipe 2 is a delivery port, the water inlet of cooling pipe 2 is connected respectively on the two ends that are positioned at the circulation pipe outside the sandbox 1 with delivery port, fills sand grains 4 in the sandbox 1.

Wherein, welding fin 3 on the outer wall of cooling pipe 2.

During installation, the circulation pipe landfill is in surface soil, and circulation pipe is communicated with tap water supply system; During use, when the low temperature running water in the underground circulation pipe at the cooling pipe 2 that under major cycle or effect, enters in the sandbox 1 at water circulating pump, the high temperature sand grains 4 that is positioned at sandbox 1 is by cooling pipe 2 and its generation heat exchange, make the temperature rise of low temperature tap water to 16-17 ℃, make simultaneously below the sand grains temperature drop to 27 ℃; Running water after the intensification is got back in the circulation pipe through cooling pipe 2, and the underground with low temperature in circulation pipe carries out heat exchange, makes its temperature get back to 15 ℃ low-temperature condition, enters next circulation again.

Claims (2)

1. sand temperature modulator, it is characterized in that: this sand temperature modulator comprises sandbox (1), cooling pipe (2), circulation pipe and sand grains (4), (2) are managed in the cooling of arranging in sandbox (1), one end of cooling pipe (2) is a water inlet, the other end of cooling pipe (2) is a delivery port, the water inlet of cooling pipe (2) is connected respectively on the two ends that are positioned at the outer circulation pipe of sandbox (1) with delivery port, fills sand grains (4) in the sandbox (1).

2. sand temperature modulator according to claim 1 is characterized in that: wherein, weld fin (3) on the outer wall of cooling pipe (2).

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2010205812489U CN201848500U (en) | 2010-10-28 | 2010-10-28 | Sand temperature regulator |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2010205812489U CN201848500U (en) | 2010-10-28 | 2010-10-28 | Sand temperature regulator |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN201848500U true CN201848500U (en) | 2011-06-01 |

Family

ID=44090913

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN2010205812489U Expired - Fee Related CN201848500U (en) | 2010-10-28 | 2010-10-28 | Sand temperature regulator |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN201848500U (en) |

-

2010

- 2010-10-28 CN CN2010205812489U patent/CN201848500U/en not_active Expired - Fee Related

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN110345549B (en) | Liquid cooling data center waste heat recovery system | |

| CN203464537U (en) | Heat pump photovoltaic system | |

| CN103307803B (en) | Cold and hot water supply device by compositely utilizing energy | |

| CN101424472B (en) | Water-cooling system for production facility | |

| CN203949361U (en) | A kind of intelligent air energy domestic hot-water produces system | |

| CN204923571U (en) | Thermoelectric cold trigeminy supplies system based on heat pump technique and compressed air electric power storage technique | |

| CN104791925A (en) | Energy-saving type open cold supply system for cooling tower | |

| CN204555111U (en) | Energy-saving open cooling tower cold supply system | |

| CN203477891U (en) | Distributed energy comprehensive utilization system for natural gas station | |

| CN201666196U (en) | Waste heat recovery device of diesel generator set | |

| CN203274584U (en) | Mechanical draft cooling tower provided with high-position water collecting device | |

| CN203615655U (en) | Energy-saving device applicable to centralized cooling and heating of thermal power plants | |

| CN202350410U (en) | EVA production line water cooling system | |

| CN110107335A (en) | The big temperature difference cooling of well up and down Heshui ring type, heating system | |

| CN201302325Y (en) | Production equipment water cooling system | |

| CN201848500U (en) | Sand temperature regulator | |

| CN110566277A (en) | device and method suitable for utilizing return air waste heat in high and cold mine | |

| CN201672823U (en) | Device for adjusting air cooling temperature of generator in thermal power plant | |

| CN202008182U (en) | Waste heat recycling, energy saving and heat supply system for cooling water of thermal power plant | |

| CN203810514U (en) | Combined geothermal supplying system | |

| CN204678741U (en) | A kind of absorption refrigerating equipment based on heat pump | |

| CN103256769B (en) | Heat transferring energy-saving system for heat production device in winter | |

| CN203360254U (en) | Smoke cooling device of glass tank furnace | |

| CN203649350U (en) | Self-circulating water cooling system of oxygen-free copper rod upward continuous casting machine | |

| CN202709544U (en) | Multistage condensation comprehensive energy-saving efficient heat exchanger |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| CF01 | Termination of patent right due to non-payment of annual fee |

Granted publication date: 20110601 Termination date: 20151028 |

|

| EXPY | Termination of patent right or utility model |