CN201848252U - Distributor for propylene oxide production - Google Patents

Distributor for propylene oxide production Download PDFInfo

- Publication number

- CN201848252U CN201848252U CN2010205810939U CN201020581093U CN201848252U CN 201848252 U CN201848252 U CN 201848252U CN 2010205810939 U CN2010205810939 U CN 2010205810939U CN 201020581093 U CN201020581093 U CN 201020581093U CN 201848252 U CN201848252 U CN 201848252U

- Authority

- CN

- China

- Prior art keywords

- distributor

- propylene oxide

- production

- tower body

- plate

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 238000004519 manufacturing process Methods 0.000 title claims abstract description 21

- GOOHAUXETOMSMM-UHFFFAOYSA-N Propylene oxide Chemical compound CC1CO1 GOOHAUXETOMSMM-UHFFFAOYSA-N 0.000 title claims abstract description 19

- 239000003351 stiffener Substances 0.000 claims description 18

- 210000003141 lower extremity Anatomy 0.000 claims description 3

- 238000007127 saponification reaction Methods 0.000 abstract description 13

- 230000002035 prolonged effect Effects 0.000 abstract description 3

- 239000000126 substance Substances 0.000 abstract description 2

- 230000003014 reinforcing effect Effects 0.000 abstract 1

- 238000009991 scouring Methods 0.000 abstract 1

- 239000007921 spray Substances 0.000 abstract 1

- 239000000463 material Substances 0.000 description 7

- 238000005406 washing Methods 0.000 description 6

- 238000009835 boiling Methods 0.000 description 3

- 238000009434 installation Methods 0.000 description 3

- ATUOYWHBWRKTHZ-UHFFFAOYSA-N Propane Chemical compound CCC ATUOYWHBWRKTHZ-UHFFFAOYSA-N 0.000 description 2

- 238000004140 cleaning Methods 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- 230000009286 beneficial effect Effects 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 238000009826 distribution Methods 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 238000007701 flash-distillation Methods 0.000 description 1

- 239000007788 liquid Substances 0.000 description 1

- 239000007791 liquid phase Substances 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 239000002245 particle Substances 0.000 description 1

- 239000001294 propane Substances 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

- 238000003466 welding Methods 0.000 description 1

Images

Landscapes

- Epoxy Compounds (AREA)

Abstract

The utility model belongs to the filed of chemical devices, particularly relates to a distributor for the propylene oxide production. The distributor is positioned inside a tower body and comprises a feed port, a sleeve, an upper top plate, a lower top plate, and a baffle plate positioned in an annular region between the sleeve and the tower body. The baffle plate is fixedly connected with the upper top plate and the lower top plate, the direction of the baffle plate is opposite to the feed port, and at least one piece of the baffle plate is arranged on each side of the feed port; and a spray nozzle is fixedly connected with one end of the feed port close to the sleeve. The distributor adopting the structure greatly reduces the scouring of saponification raffinate to the distributor, the raffinate splashed on the tower wall is stopped by a reinforcing plate so as to maximally collect the heat in the raffinate, and the service lives of the distributor and a steam ejector are greatly prolonged.

Description

Technical field

The utility model belongs to the chemical plant installations field, is specifically related to a kind of production of propylene oxide distributor.

Background technology

At present in producing propylene oxide by chlorohydrination method through about 100 ℃ of the saponification raffinates of saponification column, need to carry out flash distillation to it and reclaim heat through flash tank.Flash tank is a negative-pressure operation, and the saponification raffinate is in fluidized state when entering flash tank, and the saponification raffinate of fluidized state adds that the solid particle of raffinate inside causes seriously washing away nozzle easily like this.For above-mentioned reasons, nozzle can be caused the injector of flash drum overhead often to stop up after washing away, so the life cycle of the distributor of flash tank is all very short.Shut-down is overhauled with regard to needs when the vacuum of flash tank can't satisfy the production needs, and the general time between overhauls(TBO) is about 3 months.Frequent like this shut-down, overhaul, going into operation causes lot of manpower and material resources loss, the production cost of expoxy propane also rises thereupon.

In view of the foregoing, be badly in need of a kind of saponification raffinate of invention and be evenly distributed feed distributor simple in structure, easy for installation, that reliability is high.

Summary of the invention

For addressing the above problem, the utility model provides a kind of saponification raffinate to be evenly distributed, production of propylene oxide distributor simple in structure, easy for installation, that reliability is high.

The utility model is realized by following technical scheme:

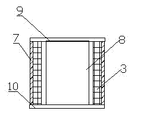

This production of propylene oxide distributor, comprise distributor, distributor is positioned at tower body, comprise charging aperture, sleeve, upper plate, lower roof plate, this distributor also comprises the deflection plate in the annular region between sleeve and tower body, described deflection plate is fixedlyed connected with lower roof plate with upper plate, and the direction of deflection plate is charging aperture dorsad, and deflection plate at least respectively has one in the charging aperture both sides; Described charging aperture is fixedly connected with nozzle near an end of sleeve.

The longitudinal edge of above-mentioned deflection plate is fixedlyed connected with the medial surface of tower body, the angle of the tangential direction of deflection plate and tower body is not more than 90 degree, is preferably 45 degree, and the baffling effect to material under this angle is best, when material during, material is evenly distributed in the tower body by throat-fed.

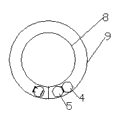

In order to reduce material washing away to tower body, therefore at the medial surface applying stiffener of tower body, stiffener is the tubular structure of longitudinal opening, the last lower limb of stiffener is fixedlyed connected with lower roof plate with upper plate respectively, the lateral surface of stiffener and the medial surface of tower body fit, and the medial surface of stiffener is fixedlyed connected with the longitudinal edge of deflection plate.

The cross-sectional area of said nozzle is not more than the cross-sectional area of charging aperture, when entering charging aperture, material make the saponification raffinate when jetting nozzle, keep certain speed, allow raffinate and nozzle contact-making surface minimum, the boiling of raffinate is just in the inner space of distributor, so just greatly reduce saponification raffinate washing away to distributor, the raffinate that splashes on the tower wall is stopped by stiffener, other liquid phase was seethed with excitement before falling into flash tank bottom liquid level by the distributing disc of the distributor back that evenly distributes, to collect the heat in the raffinate to greatest extent.

1~4 through hole is arranged on the upper plate of distributor, through hole is preferably 2, usually the through hole on the distributor is 40-60, through hole is used for checking and the cleaning distributor, the through hole number causes the heat in the tower body to scatter and disappear more, therefore through hole is reduced the heat that can reduce in the tower body and scatter and disappear, the lid that matches is with it arranged on the through hole.

Production of propylene oxide of the present utility model is with the beneficial effect of distributor; adopted after the distributor of said structure, effectively controlled the locational space of the boiling of saponification raffinate, prevented saponification raffinate washing away distributor; protect tower body, prolonged the service life of distributor greatly.

Description of drawings

Fig. 1 is the structural representation of the charging aperture of known distributor;

Fig. 2 is the structural representation of the charging aperture of the utility model distributor;

Fig. 3 is the structural representation of the upper plate of known distributor;

Fig. 4 is the structural representation of the upper plate of the utility model distributor;

Fig. 5 is the stiffener of the utility model distributor and the structural representation of tower body;

Fig. 6 is that the deflection plate of the utility model distributor and the position of upper plate and lower roof plate concern schematic diagram.

Among the figure: 1-charging aperture, 2-nozzle, 3-deflection plate, 4-through hole, 5-lid, 6-tower body, 7-stiffener, 8-sleeve, 9-upper plate, 10-lower roof plate.

The specific embodiment

Below in conjunction with the drawings and specific embodiments the utility model is done further explanation.

This production of propylene oxide distributor, be positioned at tower body 6, comprise charging aperture 1, sleeve 8, upper plate 9, lower roof plate 10, this distributor also comprises the deflection plate 3 in the annular region between sleeve 8 and tower body 6, deflection plate 3 and upper plate 9 and lower roof plate 10 welding, and the direction of deflection plate 3 is charging aperture 1 dorsad, deflection plate 3 is symmetrical distribution in charging aperture 1 both sides, have 18, in actual production, can set the number of deflection plate 3 according to concrete needs; Distributor also comprises stiffener 7, stiffener 7 is the tubular structure of longitudinal opening, the last lower limb of stiffener 7 welds with upper plate 9 and lower roof plate 10 respectively, and the lateral surface of stiffener 7 and tower body 6 medial surfaces fit, and the medial surface of stiffener 7 is fixedlyed connected with the longitudinal edge of deflection plate 3.

Charging aperture 1 is fixedly connected with nozzle 2 near an end of sleeve 8; nozzle 2 is furnished with elbow and threeway; adopt after this nozzle and the above-mentioned deflection plate; effectively control the locational space of the boiling of saponification raffinate; prevented saponification raffinate washing away to distributor; protect tower body, prolonged the service life of distributor greatly.

Deflection plate 3 is 45 degree with the angle of the tangential direction of tower body 6, and under this angle, 3 pairs of materials of deflection plate can play baffling effect preferably.

The cross-sectional area of said nozzle 2 is not more than the cross-sectional area of charging aperture 1.

Two through holes 4 are arranged on the upper plate of distributor, the position at these two through hole 4 places is symmetrical, usually the through hole 4 on the distributor is 40-60, through hole 4 is used for checking and the cleaning distributor that through hole 4 numbers cause the heat in the tower body to scatter and disappear more, therefore through hole 4 is reduced the heat that can reduce in the tower body 6 and scatters and disappears, the lid 5 that matches is with it arranged on the through hole 4, check and cleared up after the distributor, cover the lid 5 of through hole, distributor is sealed.

Claims (10)

1. production of propylene oxide distributor, this distributor is positioned at tower body, comprise charging aperture, sleeve, upper plate, lower roof plate, it is characterized in that: this distributor also comprises the deflection plate in the annular region between sleeve and tower body, described deflection plate is fixedlyed connected with lower roof plate with upper plate, the direction of deflection plate is charging aperture dorsad, and deflection plate at least respectively has one in the charging aperture both sides; Described charging aperture is fixedly connected with nozzle near an end of sleeve.

2. a kind of production of propylene oxide distributor as claimed in claim 1 is characterized in that: the longitudinal edge of described deflection plate is fixedlyed connected with the medial surface of tower body.

3. a kind of production of propylene oxide distributor as claimed in claim 1 is characterized in that: the angle of the tangential direction of described deflection plate and tower body is not more than 90 degree.

4. a kind of production of propylene oxide distributor as claimed in claim 3 is characterized in that: the angle between the tangential direction of described deflection plate and tower body is 45 degree.

5. a kind of production of propylene oxide distributor as claimed in claim 1, it is characterized in that: described distributor also comprises stiffener, stiffener is the tubular structure of longitudinal opening, the last lower limb of described stiffener is fixedlyed connected with lower roof plate with upper plate respectively, and the lateral surface of described stiffener and the medial surface of tower body fit.

6. a kind of production of propylene oxide distributor as claimed in claim 5 is characterized in that: the medial surface of described stiffener is fixedlyed connected with the longitudinal edge of deflection plate.

7. a kind of production of propylene oxide distributor as claimed in claim 1 is characterized in that: the cross-sectional area of described nozzle is not more than the cross-sectional area of charging aperture.

8. a kind of production of propylene oxide distributor as claimed in claim 1 is characterized in that: 1~4 through hole is arranged on the upper plate of described distributor.

9. a kind of production of propylene oxide distributor as claimed in claim 8 is characterized in that: described through hole is 2.

10. a kind of as claimed in claim 8 or 9 production of propylene oxide distributor is characterized in that: the lid that matches is with it arranged on the described through hole.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2010205810939U CN201848252U (en) | 2010-10-28 | 2010-10-28 | Distributor for propylene oxide production |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2010205810939U CN201848252U (en) | 2010-10-28 | 2010-10-28 | Distributor for propylene oxide production |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN201848252U true CN201848252U (en) | 2011-06-01 |

Family

ID=44090667

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN2010205810939U Expired - Fee Related CN201848252U (en) | 2010-10-28 | 2010-10-28 | Distributor for propylene oxide production |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN201848252U (en) |

-

2010

- 2010-10-28 CN CN2010205810939U patent/CN201848252U/en not_active Expired - Fee Related

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN201848252U (en) | Distributor for propylene oxide production | |

| CN203767340U (en) | Detachable supporting leg for internal floating roof | |

| CN201064699Y (en) | Baffle plate demister | |

| CN206519035U (en) | A kind of novel desulphurization shower | |

| CN107175049B (en) | Liquid distributor for mass transfer tower | |

| JP2009248056A (en) | Electrode washing system of electric dust collector for oil mist | |

| CN203560713U (en) | Inner water spraying tray of boiler starting drain flash tank | |

| CN213356965U (en) | High-efficient spray column of solid system of gathering | |

| CN210386262U (en) | A liquid fruit sprayer for custard apple | |

| CN103495324A (en) | Efficient defogging device for wet desulfurization | |

| CN201871365U (en) | No-clogging linear gas-liquid distributor | |

| CN201124053Y (en) | Rotating feeding apparatus of filter | |

| CN108165725A (en) | A kind of seal for metal tape heat treatment cooling | |

| CN207243512U (en) | For separating the equipment and system of the carbon dioxide in Methane decarbonization liquid | |

| CN216062707U (en) | Alkaline washing tower with wall hanging prevention function | |

| CN211245932U (en) | Dust suppression device | |

| CN201851145U (en) | Spraying device for fully-mechanized mining face chute machine head | |

| CN204865467U (en) | Spray and retrieve jar | |

| CN222002310U (en) | Welding cooling device for cylindrical object | |

| CN104548847A (en) | Novel paint mist catching water rotator | |

| CN206139019U (en) | Coke oven gas tower desulfurizing tower top regeneration groove overflow weir | |

| CN205653147U (en) | Easy change, easy material connect liquid dish | |

| CN204058591U (en) | A kind of automatic sprinkling type phosphatization room | |

| CN205257545U (en) | A dust suppression system for a falling hopper | |

| CN202116504U (en) | A coke quenching tower coke shield |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| CF01 | Termination of patent right due to non-payment of annual fee |

Granted publication date: 20110601 Termination date: 20181028 |

|

| CF01 | Termination of patent right due to non-payment of annual fee |