CN201848138U - Filter element with exhaust valve - Google Patents

Filter element with exhaust valve Download PDFInfo

- Publication number

- CN201848138U CN201848138U CN2010201681055U CN201020168105U CN201848138U CN 201848138 U CN201848138 U CN 201848138U CN 2010201681055 U CN2010201681055 U CN 2010201681055U CN 201020168105 U CN201020168105 U CN 201020168105U CN 201848138 U CN201848138 U CN 201848138U

- Authority

- CN

- China

- Prior art keywords

- filter element

- filter core

- water

- air bleeding

- bleeding valve

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims abstract description 33

- 230000000740 bleeding effect Effects 0.000 claims description 26

- 238000001914 filtration Methods 0.000 description 5

- 230000000694 effects Effects 0.000 description 4

- 238000005516 engineering process Methods 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 238000000034 method Methods 0.000 description 1

- 230000002035 prolonged effect Effects 0.000 description 1

- 238000007789 sealing Methods 0.000 description 1

Images

Landscapes

- Filtering Materials (AREA)

Abstract

The utility model discloses a filter element with an exhaust valve, which comprises a water inlet, a water outlet, a water inlet hole, a hollow wire, a filter element shell, a hollow wire protecting shell, a filter element cover, a rubber ring, the exhaust valve, an exhaust channel and an exhaust hole. The exhaust valve is mounted on the filter element cover in a threaded connection manner, the rubber ring is arranged between the exhaust valve and the filter element cover, and the exhaust channel and the exhaust hole are disposed in the exhaust valve. During working, water enters the filter element via the water inlet, the water in the filter element enters the hollow wire via the water inlet hole and flows out via the water outlet after being filtered via the hollow wire, after the filter element is filled with the water, the exhaust valve can be opened, and air in the filter element can be exhausted from the exhaust hole via the exhaust channel. Filtered water quantity of the hollow wire is increased, so that the hollow wire can realize full-load operation, and economic benefit of enterprises is increased.

Description

Technical field

The utility model relates to the filter core of purifier inside, relates in particular to the filter core that has discharge valve apparatus.

Background technology

At present, generally the filter core of Shi Yonging does not have exhaust apparatus, when water enters from water inlet, by the inlet opening, flows out through after the filtration of macaroni yarn.But because the effect of pressure, the filter core internal upper part has air, causes the moisture storage capacity in the filter core to reduce, and the water yield of filtration has also reduced.Water can not be full of whole filter core, above a part of macaroni yarn can not realize filtration, lost the value that filter core exists.This filter core has prolonged the activity duration of water filtration, has reduced the production cost of enterprise.

Summary of the invention

The technical problems to be solved in the utility model is: a kind of filter core that has discharge valve apparatus is provided, and when making filter core work, water can be full of whole filter core.

The technical scheme of the utility model technical solution problem is: a kind of filter core that has discharge valve apparatus; comprise water inlet, delivery port, inlet opening, macaroni yarn, delivery port, filter case, macaroni yarn containment vessel, filter core lid, rubber ring, air bleeding valve, exhaust passage and steam vent, air bleeding valve is installed in any one of filter core lid by thread connecting mode.

The technique effect of utility model is: the utility model is when work, water enters filter core inside by water inlet, the water of filter core inside enters macaroni yarn by the inlet opening, water is flowed out by delivery port by after the filtration of macaroni yarn, after filter core inside charges into water, can open air bleeding valve, the air in the filter core be discharged from steam vent by the exhaust passage.Increase the water yield that macaroni yarn filters, macaroni yarn can be operated at full capacity, improved economic benefit of enterprises.

Description of drawings

The utility model is described in more detail below in conjunction with the drawings and specific embodiments.

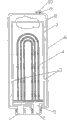

Fig. 1 is a profile of the present utility model.

Fig. 2 is the off working state figure of air bleeding valve.

Fig. 3 is the working state figure of air bleeding valve.

Among the figure: 1, water inlet, 2, delivery port, 3, the inlet opening, 4, macaroni yarn, 5, delivery port, 6, filter case, 7, the macaroni yarn containment vessel, 8, the filter core lid, 9, rubber ring, 10, air bleeding valve, 11, the exhaust passage, 12, steam vent.

The specific embodiment

As shown in Figure 1, the utility model is a kind of filter core that has discharge valve apparatus, comprises water inlet (1), delivery port (2), macaroni yarn (4) and air bleeding valve (10), and air bleeding valve (10) is installed in any one of filter core lid (8) by thread connecting mode.Described air bleeding valve (10) also can be plug-in with the connected mode of filter core lid (8).Filter case (6) is provided with water inlet (1) and delivery port (2).When filter core is worked, water flows into filter core inside by water inlet (1), the water of filter core inside flows into macaroni yarn (4) by inlet opening (3), and the water after macaroni yarn (4) filters is flowed out by delivery port (2) at last by the delivery port (2) on delivery port (5) the inflow filter core housing of filter core inside.

As shown in Figure 2, when air bleeding valve (10) when not working, air bleeding valve (10) is screwed into filter core lid (8) by screw thread, between air bleeding valve (10) and the filter core lid (8) the effect rubber ring (9) that seals has been arranged, it is not tight to prevent that air bleeding valve (10) is connected with filter core lid (8), and gas leak phenomenon is arranged.At this moment, exhaust passage (11) sealing.

As shown in Figure 3; when air bleeding valve (10) is worked; by rotating exhaust valve (10); the exhaust passage (11) of air bleeding valve (10) is opened; gas in the filter core is discharged filter core by exhaust passage (11); because the existence of atmospheric pressure; the water of filter core inside can be full of whole macaroni yarn (4); at this moment; macaroni yarn (4) all enters duty, avoids the idle phenomenon of filter core top macaroni yarn (4), when water has been full of in the macaroni yarn containment vessel (7); can open air bleeding valve (10), air is discharged by exhaust passage (11) and steam vent (12).

The unspecified content of present embodiment is prior art.The utility model is that the embodiment that mentions with reference to the accompanying drawings is illustrated, and this is one of them embodiment, and those skilled in the art can obtain to inspire from present embodiment, is out of shape to obtain other embodiment.Therefore, protection domain of the present utility model should be determined according to the protection domain of claim.

Claims (4)

1. filter core that has air bleeding valve; comprise water inlet (1), delivery port (2), inlet opening (3), macaroni yarn (4), filter case (6), macaroni yarn containment vessel (7), filter core lid (8), rubber ring (9), air bleeding valve (10), exhaust passage (11) and steam vent (12), it is characterized in that: air bleeding valve (10) is installed on the filter core lid (8) by thread connecting mode.

2. the filter core that has air bleeding valve according to claim 1 is characterized in that: be provided with rubber ring (9) between air bleeding valve (10) and the filter core lid (8).

3. the filter core that has air bleeding valve according to claim 1 is characterized in that: be provided with exhaust passage (11) and steam vent (12) in the air bleeding valve (10).

4. the filter core that has air bleeding valve according to claim 1 is characterized in that: described air bleeding valve (10) also can be plug-in with the connected mode of filter core lid (8).

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2010201681055U CN201848138U (en) | 2010-03-27 | 2010-03-27 | Filter element with exhaust valve |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2010201681055U CN201848138U (en) | 2010-03-27 | 2010-03-27 | Filter element with exhaust valve |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN201848138U true CN201848138U (en) | 2011-06-01 |

Family

ID=44090553

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN2010201681055U Expired - Fee Related CN201848138U (en) | 2010-03-27 | 2010-03-27 | Filter element with exhaust valve |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN201848138U (en) |

-

2010

- 2010-03-27 CN CN2010201681055U patent/CN201848138U/en not_active Expired - Fee Related

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN204073676U (en) | Compressed-air filter | |

| CN108404614A (en) | A kind of interaction switch type compressed air purifier | |

| CN108468833A (en) | A kind of interaction switching pressurized air purification valve body | |

| CN205710934U (en) | A kind of hydrogen making machine outlet stable-pressure device | |

| CN202125385U (en) | Fuel oil filter | |

| CN201848138U (en) | Filter element with exhaust valve | |

| CN208340443U (en) | A kind of interaction switch type compressed air purifier | |

| CN202366540U (en) | Automatic cleaning filter | |

| CN201410332Y (en) | Filter valve for paint sand mill | |

| CN217202704U (en) | A breather valve for ferment fermentation cylinder | |

| CN208586290U (en) | Pressure protector for anaerobic fermentation tank body | |

| CN203303805U (en) | Oil-gas separation device | |

| CN203281091U (en) | Spherical superficial layer medium filter | |

| CN209431086U (en) | A kind of external deaerating plant with filtering function | |

| CN203212524U (en) | Coke oven flue gas adsorption device | |

| CN204126776U (en) | A kind of Novel air filter assembly with canister | |

| CN204051323U (en) | A kind of air cleaner | |

| CN204219945U (en) | Natural gas aerating machine filter | |

| CN205730902U (en) | A kind of external-compression type purpose ceramic-film filter of band recoil | |

| CN205025837U (en) | Modified Structure of Centrifugal Pump Filter Used in Alcohol and Ketone Production Unit | |

| CN204619524U (en) | Pressure water storage tub water purification machine casing | |

| CN2681808Y (en) | Apparatus for filtering petroleum blue gas | |

| CN203329541U (en) | Filter drum type vacuum filter | |

| CN203425607U (en) | Filter bottle device for water purifier | |

| CN105781834B (en) | Engine diesel oil purifier |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| CF01 | Termination of patent right due to non-payment of annual fee |

Granted publication date: 20110601 Termination date: 20150327 |

|

| EXPY | Termination of patent right or utility model |