CN201651298U - Sealing device characterized by corrosion resistance, high temperature resistance and high pressure resistance - Google Patents

Sealing device characterized by corrosion resistance, high temperature resistance and high pressure resistance Download PDFInfo

- Publication number

- CN201651298U CN201651298U CN2010201106462U CN201020110646U CN201651298U CN 201651298 U CN201651298 U CN 201651298U CN 2010201106462 U CN2010201106462 U CN 2010201106462U CN 201020110646 U CN201020110646 U CN 201020110646U CN 201651298 U CN201651298 U CN 201651298U

- Authority

- CN

- China

- Prior art keywords

- sealing

- seal

- column

- cylindrical

- high pressure

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Landscapes

- Pressure Vessels And Lids Thereof (AREA)

Abstract

The utility model discloses a sealing device characterized by corrosion resistance, high temperature resistance and high pressure resistance, and aims to solve the problem that the sealing performance is poor in the prior art. The sealing device at least includes a sealing column with a columnar sealing surface and a sealing cylinder with a cylindrical sealing surface, wherein the cylindrical sealing surface of the sealing cylinder and the columnar sealing surface of the sealing column are matched with each other; the sealing column is mounted behind the sealing cylinder, a sealing cavity is formed between the front end of the sealing column and the inside of the sealing cylinder, and at least one rubber sealing piece and a metal sealing piece are arranged on the sealing column, and are arranged at interval axially. Through the adoption of the sealing device having the structure, the cylindrical sealing surface tightly presses the outer sides of the metal sealing piece, the rubber sealing piece and a retainer ring with certain pressure; the columnar sealing surface tightly presses the inner sides of the metal sealing piece, the rubber sealing piece and a retainer ring with certain pressure; therefore, the cylinder and column sealing is realized under the conditions of corrosion medium, high temperature and high pressure.

Description

Technical field

The utility model relates to a kind of corrosion-resistant and high-temperature resistant high pressure seal, is applicable to the sealing of cylindrical shape sealing surface and cylindrical seal face, is specially adapted to the sealing of cylinder and cylinder under Korrosionsmediums such as hydrogen sulfide and the high-temperature and high-pressure conditions.

Background technique

Existing corrosion-resistant and high-temperature resistant high pressure seal is a kind of to be to adopt the metal seal sealing, and another kind is to adopt rubber seal, retaining ring sealing.The problem of first kind of structure existence is that high pressure sealing performance is unreliable.The problem of second kind of structure existence is rubber seal, the back-up ring that can not avoid in the aggressive medium corrosion seal arrangement.

The model utility content

For overcoming above-mentioned defective, the purpose of this utility model provides a kind of corrosion-resistant and high-temperature resistant high pressure seal simple in structure, easy to use.

For achieving the above object, the utility model corrosion-resistant and high-temperature resistant high pressure seal, at least comprise sealing column with cylindrical seal face and the sealing drum with cylindrical shape sealing surface, the cylindrical shape sealing surface of described sealing drum and the cylindrical seal face of sealing column are suitable; After described sealing column is installed in sealing drum, in sealing column front end and the inner airtight chamber that forms of sealing drum, be provided with a rubber seal and a metal seal at least on described sealing column, described rubber seal and metal seal axially spaced-apart are provided with.

Wherein, axially be provided with the twice groove at least, in described groove, be respectively equipped with rubber seal at described sealing column leading portion.

Wherein, also be provided with a Sealing shield ring in described groove, described Sealing shield ring is arranged on nearly sealing drum one side.

Wherein, the cylindrical shape sealing surface of described sealing drum is inside and outside two sections, and the diameter of outer cylindrical section shape sealing surface forms step greater than the diameter of inner segment cylindrical shape sealing surface between inside and outside two sections; Cylindrical section shape sealing surface is provided with annular boss outside the segment trailer correspondence before described sealing column; Described metal seal is arranged between annular boss and the step.

Adopt the seal arrangement of said structure, the cylindrical shape sealing surface compresses the outside of metal seal, rubber seal, back-up ring with certain pressure, the cylindrical seal face compresses the then interior of metal seal, rubber seal, back-up ring with certain pressure, realizes the sealing of cylinder and cylinder under aggressive medium, high-temperature and high-pressure conditions.The overall structure novelty, metal seal, rubber seal, back-up ring surface are not perishable, can use under high-temperature and high-pressure conditions, and be safe and reliable, long service life.

Description of drawings

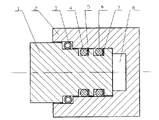

Fig. 1 is the example structure schematic representation of the utility model corrosion-resistant and high-temperature resistant high pressure seal.

Embodiment

Below in conjunction with drawings and Examples the utility model is further described:

Diagram has been described an embodiment of the present utility model.

As shown in Figure 1, the utility model corrosion-resistant and high-temperature resistant high pressure seal, at least comprise sealing column 1 with cylindrical seal face and the sealing drum 2 with cylindrical shape sealing surface, the cylindrical shape sealing surface of described sealing drum and the cylindrical seal face of sealing column are suitable; After described sealing column is installed in sealing drum, in sealing column front end and the inner airtight chamber 8 that forms of sealing drum, on described sealing column, be provided with a rubber seal 6 and a metal seal 3 at least, described rubber seal and metal seal 3 axially spaced-apart settings.

As further improvement of the present utility model, axially be provided with the twice groove at least at described sealing column leading portion, in described groove, be respectively equipped with rubber seal 4,6.In order further to increase sealing effect, in described groove, also be provided with a Sealing shield ring 5,7, described Sealing shield ring is arranged on the front side of rubber seal, promptly near sealing drum one side.

Wherein, the cylindrical shape sealing surface of described sealing drum is inside and outside two sections, and the diameter of outer cylindrical section shape sealing surface forms step greater than the diameter of inner segment cylindrical shape sealing surface between inside and outside two sections; Cylindrical section shape sealing surface is provided with annular boss outside the segment trailer correspondence before described sealing column; Described metal seal 3 is arranged between annular boss and the step.

In summary, seal arrangement of the present utility model has carried out organic combination with metal seal and rubber seal, can realize the sealing of cylinder and cylinder under aggressive medium, high-temperature and high-pressure conditions.The overall structure novelty, metal seal, rubber seal, back-up ring surface are not perishable, can use under high-temperature and high-pressure conditions, and be safe and reliable, long service life.

Below only be the specific descriptions that given with reference to the accompanying drawings embodiment makes; but this embodiment does not limit the application's protection domain; for a person skilled in the art, the modification of being made on content basis disclosed in the utility model can not break away from spirit of the present utility model and category.

Claims (4)

1. a corrosion-resistant and high-temperature resistant high pressure seal comprises sealing column with cylindrical seal face and the sealing drum with cylindrical shape sealing surface at least, and the cylindrical shape sealing surface of described sealing drum and the cylindrical seal face of sealing column are suitable; After described sealing column is installed in sealing drum, in sealing column front end and the inner airtight chamber that forms of sealing drum, it is characterized in that: be provided with a rubber seal and a metal seal on described sealing column at least, described rubber seal and metal seal axially spaced-apart are provided with.

2. corrosion-resistant and high-temperature resistant high pressure seal as claimed in claim 1 is characterized in that: axially be provided with the twice groove at least at described sealing column leading portion, be respectively equipped with rubber seal in described groove.

3. corrosion-resistant and high-temperature resistant high pressure seal as claimed in claim 2 is characterized in that: also be provided with a Sealing shield ring in described groove, described Sealing shield ring is arranged on nearly sealing drum one side.

4. as claim 1,2 or 3 described corrosion-resistant and high-temperature resistant high pressure seals, it is characterized in that: the cylindrical shape sealing surface of described sealing drum is inside and outside two sections, the diameter of outer cylindrical section shape sealing surface forms step greater than the diameter of inner segment cylindrical shape sealing surface between inside and outside two sections; Cylindrical section shape sealing surface is provided with annular boss outside the segment trailer correspondence before described sealing column; Described metal seal is arranged between annular boss and the step.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2010201106462U CN201651298U (en) | 2010-02-09 | 2010-02-09 | Sealing device characterized by corrosion resistance, high temperature resistance and high pressure resistance |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2010201106462U CN201651298U (en) | 2010-02-09 | 2010-02-09 | Sealing device characterized by corrosion resistance, high temperature resistance and high pressure resistance |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN201651298U true CN201651298U (en) | 2010-11-24 |

Family

ID=43116533

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN2010201106462U Expired - Fee Related CN201651298U (en) | 2010-02-09 | 2010-02-09 | Sealing device characterized by corrosion resistance, high temperature resistance and high pressure resistance |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN201651298U (en) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102777846A (en) * | 2011-05-13 | 2012-11-14 | 海洋王照明科技股份有限公司 | Explosion-proof signal lamp and sealing structure thereof |

| CN104260114A (en) * | 2014-07-03 | 2015-01-07 | 伊特克斯惰性气体系统(北京)有限公司 | Glove box body and production method thereof |

| CN105715794A (en) * | 2014-12-03 | 2016-06-29 | 威乐(中国)水泵系统有限公司 | High-pressure sealing device |

| CN109723824A (en) * | 2019-02-28 | 2019-05-07 | 青岛伊克斯达智能装备有限公司 | A kind of low leakage rotary dynamic sealing device for waste and old rubber thermal cracking |

-

2010

- 2010-02-09 CN CN2010201106462U patent/CN201651298U/en not_active Expired - Fee Related

Cited By (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102777846A (en) * | 2011-05-13 | 2012-11-14 | 海洋王照明科技股份有限公司 | Explosion-proof signal lamp and sealing structure thereof |

| CN102777846B (en) * | 2011-05-13 | 2015-03-11 | 海洋王照明科技股份有限公司 | Explosion-proof signal lamp and sealing structure thereof |

| CN104260114A (en) * | 2014-07-03 | 2015-01-07 | 伊特克斯惰性气体系统(北京)有限公司 | Glove box body and production method thereof |

| CN104260114B (en) * | 2014-07-03 | 2016-08-10 | 伊特克斯惰性气体系统(北京)有限公司 | Glove box body and preparation method thereof |

| CN105715794A (en) * | 2014-12-03 | 2016-06-29 | 威乐(中国)水泵系统有限公司 | High-pressure sealing device |

| CN109723824A (en) * | 2019-02-28 | 2019-05-07 | 青岛伊克斯达智能装备有限公司 | A kind of low leakage rotary dynamic sealing device for waste and old rubber thermal cracking |

| CN109723824B (en) * | 2019-02-28 | 2024-01-09 | 青岛伊克斯达智能装备有限公司 | Low-leakage rotary dynamic sealing device for thermal cracking of waste rubber and plastic |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| TWM401600U (en) | A seat tube of a bicycle | |

| CN201651298U (en) | Sealing device characterized by corrosion resistance, high temperature resistance and high pressure resistance | |

| CN201925466U (en) | Dual sealing structure | |

| CN203421150U (en) | Box of reduction gear | |

| CN204153362U (en) | Sealing flange pad | |

| CN205190741U (en) | Sealing device who combines radial seal and axial seal | |

| CN210950304U (en) | Sealing structure of connecting pipe | |

| CN205350705U (en) | Stable form blind plate | |

| CN203500774U (en) | Oil and gas pipeline leaking stoppage and pressure discharging device | |

| CN202040323U (en) | Oblique seal ring | |

| CN202501096U (en) | Positioning and sealing device for valve stem of valve | |

| CN201818785U (en) | Sealing check ring | |

| CN202629399U (en) | Two-level sealing flange for pipelines | |

| CN201599407U (en) | Mechanical seal | |

| CN204267807U (en) | A kind of valve inside metallic core | |

| CN204267822U (en) | The valve inside metallic core that a kind of tightness is strong | |

| CN203571311U (en) | Jacket type nonmetal expansion joint | |

| CN205330901U (en) | Convenient hydraulic pressure manual pump of dismantling | |

| CN202884030U (en) | Novel oil seal | |

| CN204114191U (en) | Novel sealing structure gate valve | |

| CN203272819U (en) | Butterfly valve | |

| CN203051757U (en) | Riveting type fabrication hole plug | |

| CN203374815U (en) | Gas sealing split type sealing device | |

| CN202812321U (en) | Star-shaped cinder valve leakage-proof device | |

| CN201439848U (en) | Seawater medium pipeline flange insulating device |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| C17 | Cessation of patent right | ||

| CF01 | Termination of patent right due to non-payment of annual fee |

Granted publication date: 20101124 Termination date: 20140209 |