CN115780587A - Multi-station bending die for bending automobile plate parts - Google Patents

Multi-station bending die for bending automobile plate parts Download PDFInfo

- Publication number

- CN115780587A CN115780587A CN202211298484.3A CN202211298484A CN115780587A CN 115780587 A CN115780587 A CN 115780587A CN 202211298484 A CN202211298484 A CN 202211298484A CN 115780587 A CN115780587 A CN 115780587A

- Authority

- CN

- China

- Prior art keywords

- bending

- punching

- plate

- assembly

- fixedly connected

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02P—CLIMATE CHANGE MITIGATION TECHNOLOGIES IN THE PRODUCTION OR PROCESSING OF GOODS

- Y02P70/00—Climate change mitigation technologies in the production process for final industrial or consumer products

- Y02P70/10—Greenhouse gas [GHG] capture, material saving, heat recovery or other energy efficient measures, e.g. motor control, characterised by manufacturing processes, e.g. for rolling metal or metal working

Landscapes

- Bending Of Plates, Rods, And Pipes (AREA)

Abstract

The invention discloses a multi-station bending die for bending automobile plate parts, which belongs to the technical field of automobile plate production and comprises a base, wherein a punching assembly, a vertical driving assembly, a cutting assembly, a first bending assembly and a second bending assembly are arranged on the base; the punching component comprises a punching seat and two groups of punching cutters with certain intervals; the two groups of first bending assemblies are respectively positioned on one side of the two groups of punching cutters and are respectively used for bending the two groups of parts; the two groups of second bending assemblies are respectively positioned on one sides of the two groups of first bending assemblies and are respectively used for folding edges of the two groups of parts; the cutting assembly is located on one side of the second bending assembly and used for cutting and blanking two groups of parts. Through the mode, the punching, bending and edge folding equipment is integrated, so that the multi-station synchronous punching, bending, edge folding, cutting and blanking processes can be completed on one equipment at the same time, and the processing efficiency of automobile plate parts is improved.

Description

Technical Field

The invention relates to the technical field of automobile plate production, in particular to a multi-station bending die for bending automobile plate parts.

Background

In the production process of the automobile plate parts, a punching process, a bending process, a flanging process and the like are required. At present, each process is carried out by adopting independent equipment, for example, firstly, a plurality of plate parts are processed by punching equipment, then the plate parts are transported to bending equipment, the plate parts are bent by ninety degrees by the bending equipment, then the plate parts are transported to flanging equipment, and the plate parts are subjected to flanging treatment by the flanging equipment.

The method needs different devices to be adopted to process the automobile plate parts respectively, the devices are difficult to integrate, and multi-station synchronous processing cannot be realized, so the processing efficiency can be further improved.

Based on the technical scheme, the invention designs the multi-station bending die for bending the automobile plate parts so as to solve the problems.

Disclosure of Invention

Aiming at the defects in the prior art, the invention provides a multi-station bending die for bending automobile plate parts.

In order to achieve the purpose, the invention is realized by the following technical scheme:

a multi-station bending die for bending automobile plate parts comprises a base, wherein a punching assembly, a vertical driving assembly, a cutting assembly, a first bending assembly and a second bending assembly are mounted on the base; the driving end of the vertical driving assembly is respectively connected with the punching assembly, the cutting assembly, the first bending assembly and the second bending assembly;

the punching component comprises a punching seat and two groups of punching cutters which are symmetrically arranged and have a certain distance; the punching seat is fixedly connected to the upper end of the base, the two groups of punching cutters are fixedly connected with the driving end of the vertical driving assembly, and the opening ends of the two groups of punching cutters are arranged oppositely; the middle part of the punching cutter is fixedly connected with a plurality of punching rods, a punching cutter movable groove matched with the punching cutter to be inserted is formed in the punching seat, and a punching rod movable groove matched with the punching rod to be inserted is formed in the punching seat;

the first bending assemblies are arranged in two groups, and the two groups of first bending assemblies are respectively positioned on one side of the two groups of punching cutters and are respectively used for bending the two groups of parts; the two groups of first bending assemblies are symmetrically arranged on two sides of the part to be processed;

the two groups of second bending assemblies are respectively positioned at one side of the two groups of first bending assemblies and are respectively used for folding the edges of the two groups of parts; the two groups of second bending assemblies are symmetrically arranged on two sides of the part to be processed;

the cutting assembly is located on one side of the second bending assembly and used for cutting and blanking two groups of parts.

Furthermore, a discharge hole convenient for cutting waste materials is formed in the position, corresponding to the movable groove of the punching cutter and the movable groove of the punching rod up and down, of the base.

Furthermore, the first bending assembly comprises a guide rod, a first bending seat, a first horizontal pressing plate, a first spring, a first side pressing plate and a mounting top plate; first bending seat fixed connection is in the upper end of base, the first side clamp plate of the lower extreme outside fixedly connected with of installation roof, the equal sliding connection in four angle departments of installation roof has the guide bar, the first horizontal clamp plate of lower extreme fixedly connected with of guide bar, first horizontal clamp plate is located between two first side clamp plates, install first spring on the guide bar, first spring is located between first horizontal clamp plate and the installation roof, installation roof and vertical drive assembly's drive end fixed connection.

Furthermore, the second bending assembly comprises a mounting fixing frame, a second air cylinder, a first wedge-shaped block, a fixing block, a guide rail, a second spring, a connecting fixing block, a second wedge-shaped block, a first wedge-shaped block connecting plate, a second side pressing plate, a third side pressing plate, a second bending seat, a third side pressing plate connecting plate, a transverse plate and an auxiliary supporting block; the second bending seat is fixedly connected to the upper end of the base, the upper end of a first wedge-shaped block connecting plate is fixedly connected with the driving end of the vertical driving assembly, the left side and the right side of the lower end of the first wedge-shaped block connecting plate are fixedly connected with a second side pressing plate used for flanging the left side and the right side of the upper end of a part, the outer side of the first wedge-shaped block connecting plate is fixedly connected with a first wedge-shaped block, the lower end of the first wedge-shaped block is in contact connection with the inclined surface of one end of a second wedge-shaped block, the other end of the second wedge-shaped block is fixedly connected with a third side pressing plate used for flanging the left side and the right side of the lower end of the part, the guide rail is fixedly mounted at the upper end of the base, connecting fixing blocks are fixedly connected to the two side walls of the second wedge-shaped block, the connecting blocks are fixedly connected to one end of a second spring, the other end of the second spring is fixedly connected to the fixing block, the fixing block is fixedly mounted at the upper end of the base and is located at the outer side of the fixing block connecting block; two auxiliary supporting blocks are respectively located below two sets of parts to be flanged, the lower ends of the auxiliary supporting blocks are fixed on the transverse plate, the transverse plate is fixedly connected with the output end of the second air cylinder, the second air cylinder is fixedly connected to the installation fixing frame, the installation fixing frame is fixedly connected to the bottom of the base, and the auxiliary supporting blocks movably penetrate through the base.

Furthermore, the cutting assembly comprises a waste material guide groove, a cutter mounting plate, a finished product cutter and a defective product cutter; the upper end of the cutter mounting plate is fixedly connected with the driving end of the vertical driving assembly, two finished product cutters are fixedly mounted on the front side and the rear side of the lower end of the cutter mounting plate, and a defective product cutter is fixedly mounted on the right side of the lower end of the cutter mounting plate; one end of each waste material guide chute is positioned below the defective product cutters, and one end of each finished product guide chute is positioned below the two finished product cutters; the second bending seat extends to the lower part of the cutter mounting plate.

Furthermore, the distance between the two finished product cutters is the same as that between the two groups of punching cutters, and the positions of the two finished product cutters and the cutting position of the part are arranged in a vertically corresponding mode.

Furthermore, the waste material guide chute and the two finished product guide chutes are fixedly arranged on the base in an inclined manner.

Furthermore, the vertical driving assembly comprises a connecting frame, a sliding plate, a first electric push rod and a guide column; the first electric push rods are fixedly arranged on the top plate, the output ends of the first electric push rods are fixedly connected with the sliding plate below the top plate, four corners of the upper end of the base are respectively and fixedly connected with guide posts, the upper ends of the guide posts are respectively and fixedly connected with four corners of the lower end of the top plate, and the guide posts respectively penetrate through the four corners of the sliding plate and are in sliding connection with the sliding plate; the lower extreme fixedly connected with link of slide, the link is connected with die-cut subassembly, cutting element, first subassembly and the second subassembly of bending respectively.

Advantageous effects

The punching component (2) can realize one-time punching of two groups of parts, and can ensure that the materials of the punching component (2) and subsequent processes are synchronously driven to synchronously move in the process of conveying plates by the equidistant feeding mechanism;

the first bending assembly (5) can be used for bending after compressing the part, so that the position of the part is fixed during bending, and the part is prevented from shifting;

the second bending assembly (6) can ensure that the left side and the right side of the lower end of the part are folded synchronously when the left side and the right side of the upper end of the part are folded;

the cutting assembly (4) can ensure that the cutting and blanking of the waste materials are synchronously finished when the parts are cut and blanked;

the punching, bending and edge folding equipment is integrated, so that the multi-station synchronous punching, bending, edge folding and cutting blanking processes can be completed on one equipment at the same time, and the processing efficiency of automobile plate parts is improved;

the invention can produce two groups of parts at one time, and further improves the processing efficiency of the automobile plate parts.

Drawings

In order to more clearly illustrate the embodiments of the present invention or the technical solutions in the prior art, the drawings used in the embodiments or the prior art descriptions will be briefly described below. It is obvious that the drawings in the following description are only some embodiments of the invention, and that for a person skilled in the art, other drawings can be derived from them without inventive effort.

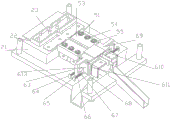

FIG. 1 is a first perspective view of a main structure of a multi-station bending die for bending automobile plate parts, according to the present invention;

FIG. 2 is a structural front view of a multi-station bending die for bending automobile plate parts according to the present invention;

FIG. 3 is a second perspective view of a main structure of a multi-station bending die for bending automobile plate parts according to the present invention;

FIG. 4 isbase:Sub>A sectional view taken along the line A-A of FIG. 2;

FIG. 5 is a sectional view taken along the line B-B of FIG. 2;

FIG. 6 is a sectional view taken along the line C-C of FIG. 2;

FIG. 7 is a sectional view taken along the direction D-D of FIG. 2;

FIG. 8 is a sectional view taken along the line E-E of FIG. 2;

fig. 9 is a schematic structural diagram of a machined part.

The reference numerals in the drawings denote:

1. the device comprises a base 2, a punching component 21, a punching seat 22, a punching cutter 23, a punching rod 24, a discharge hole 25, a movable groove 26 of the punching cutter, a movable groove 3 of the punching rod, a vertical driving component 31, a connecting frame 32, a sliding plate 33, a first electric push rod 34, a guide column 4, a cutting component 41, a finished product guide groove 42, a waste material guide groove 43, a cutter mounting plate 44, a finished product cutter 45, a defective product cutter 5, a first bending component 51, a guide rod 52, a first bending seat 53, a first horizontal pressing plate 54, a first spring 55, a first side pressing plate 56, a mounting top plate 6, a second bending component 61, a mounting frame 62, a second cylinder 63, a first wedge block 64, a fixing block 65, a guide rail 66, a connecting fixing block 68, a second wedge 69, a first wedge connecting plate 610, a second side pressing plate 611, a second bending seat 612, a second bending seat 613, a third side pressing plate 614, a transverse plate 615 and an auxiliary supporting block.

Detailed Description

In order to make the objects, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the drawings in the embodiments of the present invention. It is to be understood that the embodiments described are only a few embodiments of the present invention, and not all embodiments. All other embodiments, which can be derived by a person skilled in the art from the embodiments given herein without making any creative effort, shall fall within the protection scope of the present invention.

The present invention will be further described with reference to the following examples.

Example 1

Referring to the attached drawings 1-9 of the specification, the multi-station bending die for bending the automobile plate part comprises a base 1, wherein a punching assembly 2, a vertical driving assembly 3, a cutting assembly 4, a first bending assembly 5 and a second bending assembly 6 are mounted on the base 1; the driving end of the vertical driving component 3 is respectively connected with the punching component 2, the cutting component 4, the first bending component 5 and the second bending component 6, and the vertical driving component 3 synchronously drives the punching component 2, the cutting component 4, the first bending component 5 and the second bending component 6 to move;

one side of the punching component 2 is provided with an equidistant feeding mechanism which is used for feeding plates, and the existing structure is adopted, so that the detailed description is omitted;

the punching component 2 comprises a punching seat 21 and two groups of punching cutters 22 which are symmetrically arranged and have a certain distance; the punching seat 21 is fixedly connected to the upper end of the base 1, the two groups of punching cutters 22 are fixedly connected with the driving end of the vertical driving assembly 3, the opening ends of the two groups of punching cutters 22 are oppositely arranged, two groups of parts can be punched at one time, and the distance is set by the two groups of punching cutters 22, so that the materials of the punching assembly 2 and the subsequent processes can be synchronously driven to synchronously move in the process of conveying plates by the equidistant feeding mechanism;

the middle part of the punching cutter 22 is fixedly connected with a plurality of punching rods 23, a punching cutter movable groove 25 which is inserted by matching the punching cutter 22 is formed in the punching seat 21, a punching rod movable groove 26 which is inserted by matching the punching rod 23 is formed in the punching seat 21, and a discharge hole 24 which is convenient for cutting waste materials is formed in the base 1 at the position corresponding to the punching cutter movable groove 25 and the punching rod movable groove 26 up and down;

the plate is placed on the upper portion of the punching seat 21, the vertical driving assembly 3 drives the punching cutter 22 to move downwards to punch the plate, the punching cutter 22 drives the punching rod 23 to move downwards to punch the plate, the punching cutter 22 and the punching rod 23 are respectively inserted into the punching cutter movable groove 25 and the punching rod movable groove 26, and punching waste materials are discharged through the discharge hole 24 in the base 1;

the two groups of first bending assemblies 5 are respectively positioned at one side of the two groups of punching cutters 22 and are respectively used for bending the two groups of parts; the two groups of first bending assemblies 5 are symmetrically arranged on two sides of the part to be processed;

the first bending assembly 5 comprises a guide rod 51, a first bending base 52, a first horizontal pressing plate 53, a first spring 54, a first side pressing plate 55 and a mounting top plate 56; the first bending seat 52 is fixedly connected to the upper end of the base 1, punched parts are transmitted to the first bending seat 52, the outer side of the lower end of the mounting top plate 56 is fixedly connected with first side pressing plates 55, four corners of the mounting top plate 56 are respectively connected with guide rods 51 in a sliding manner, the lower end of each guide rod 51 is fixedly connected with a first horizontal pressing plate 53, each first horizontal pressing plate 53 is positioned between two first side pressing plates 55, each guide rod 51 is provided with a first spring 54, each first spring 54 is positioned between each first horizontal pressing plate 53 and the corresponding mounting top plate 56, and the mounting top plate 56 is fixedly connected with the driving end of the vertical driving assembly 3; the guide rods 51 have a length sufficient to support the first horizontal pressing plate 53 by a distance moved downward by gravity;

the punched part is supported by the first bending seat 52, the vertical driving component 3 drives the installation top plate 56 to move downwards, the installation top plate 56 drives the first horizontal pressing plate 53 to move downwards, the first horizontal pressing plate 53 is in contact with the part under the action of gravity, and along with the downward movement of the first horizontal pressing plate 53, the extrusion force of the first spring 54 on the first horizontal pressing plate 53 is gradually enhanced to compress the part, so that the position of the part is fixed when the part is bent, and the part is prevented from moving; meanwhile, a top plate 56 is installed to drive the first side pressing plates 55 to move downwards, the two first side pressing plates 55 are located above parts of the part to be bent, and the first side pressing plates 55 move downwards to bend the part;

the two groups of second bending assemblies 6 are also arranged, and the two groups of second bending assemblies 6 are respectively positioned at one side of the two groups of first bending assemblies 5 and are respectively used for folding the edges of the two groups of parts; the two groups of second bending assemblies 6 are symmetrically arranged on two sides of the part to be processed;

the second bending assembly 6 comprises a mounting fixing frame 61, a second air cylinder 62, a first wedge-shaped block 63, a fixing block 64, a guide rail 65, a second spring 66, a connecting fixing block 67, a second wedge-shaped block 68, a first wedge-shaped block connecting plate 69, a second side pressing plate 610, a third side pressing plate 611, a second bending seat 612, a third side pressing plate connecting plate 613, a transverse plate 614 and an auxiliary supporting block 615;

the second bending seat 612 is fixedly connected to the upper end of the base 1, the bent parts are transmitted to the second bending seat 612, the upper end of the first wedge-shaped block connecting plate 69 is fixedly connected with the driving end of the vertical driving assembly 3, the left side and the right side of the lower end of the first wedge-shaped block connecting plate 69 are fixedly connected with a second side pressing plate 610 used for folding the left side and the right side of the upper end of the part, the outer side of the first wedge-shaped block connecting plate 69 is fixedly connected with a first wedge-shaped block 63, the lower end of the first wedge-shaped block 63 is connected with an inclined surface of one end of a second wedge-shaped block 68 in a contact manner, the other end of the second wedge-shaped block 68 is fixedly connected with a third side pressing plate connecting plate 613, the lower ends of the second wedge-shaped block 68 and the third side pressing plate connecting plate 613 are slidably connected to the guide rail 65, the left side and the right side of one end, close to the part, of the third pressing plate connecting plate 613 is fixedly connected with a third pressing plate 611 used for folding the left side and the right side of the lower end of the part, the guide rail 65 is fixedly installed at the upper end of the base 1, both side walls of the second wedge-shaped block 68 are fixedly connected with a fixing block 67, the connecting plate 67, the other end of the second spring 66 is fixedly connected with a fixing block 64, the fixing block 64 is installed at the upper end of the fixing block 64, and the fixing block 64 of the base 1;

the two auxiliary supporting blocks 615 are respectively positioned below the two groups of parts to be flanged, the lower ends of the auxiliary supporting blocks 615 are fixed on a transverse plate 614, the transverse plate 614 is fixedly connected with the output end of a second cylinder 62, the second cylinder 62 is fixedly connected to an installation fixing frame 61, the installation fixing frame 61 is fixedly connected to the bottom of the base 1, and the auxiliary supporting blocks 615 movably penetrate through the base 1;

the punched parts are transmitted to a second bending seat 612, a second air cylinder 62 drives a transverse plate 614 to move upwards, the transverse plate 614 drives two auxiliary supporting blocks 615 to move to the lower parts of two groups of parts to be flanged for supporting, a vertical driving assembly 3 drives a first wedge block connecting plate 69 to move downwards, a second side pressing plate 610 on the left side and the right side of the lower end of the first wedge block connecting plate 69 is used for flanging the left side and the right side of the upper end of the parts, the first wedge block connecting plate 69 drives a first wedge block 63 to move downwards, an inclined surface at the bottom of the first wedge block 63 is in contact with an inclined surface of a second wedge block 68, the first wedge block 63 pushes the second wedge block 68 to move inwards along a guide rail 65, the second wedge block 68 drives a third side pressing plate connecting plate 613 to move inwards, and the left side and the right side of the lower end of the parts are flanged through a third side pressing plate 611 on the left side and the right side of the third side pressing plate connecting plate 613, so that the flanging of the left side and the right side of the whole parts is completed; when needing to be explained, after the part is folded, the vertical driving component 3 moves upwards to reset, drives the second side pressing plate 610 and the third side pressing plate 611 to reset, and the two auxiliary supporting blocks 615 also move downwards to reset under the action of the second air cylinder 62, so that the part is not influenced to move to the cutting component 4; the second bending assembly 6 can ensure that the left side and the right side of the lower end of the part are flanged synchronously when the left side and the right side of the upper end of the part are flanged;

the cutting component 4 is positioned on one side of the second bending component 6 and is used for cutting and blanking two groups of parts;

the cutting assembly 4 comprises a waste material guide chute 42, a cutter mounting plate 43, a finished product cutter 44 and a defective product cutter 45; the upper end of the cutter mounting plate 43 is fixedly connected with the driving end of the vertical driving component 3, two finished product cutters 44 are fixedly mounted on the front side and the rear side of the lower end of the cutter mounting plate 43, the distance between the two finished product cutters 44 is the same as the distance between the two groups of punching cutters 22, the positions of the two finished product cutters 44 and the cutting position of a part are arranged in a vertically corresponding manner, and a defective product cutter 45 is fixedly mounted on the right side of the lower end of the cutter mounting plate 43; the waste material guide chute 42 and the two finished product guide chutes 41 are fixedly arranged on the base 1 in an inclined shape, one end of the waste material guide chute 42 is positioned below the defective product cutter 45, and one ends of the two finished product guide chutes 41 are respectively positioned below the two finished product cutters 44; the second bending seat 612 extends to the lower part of the cutter mounting plate 43 to support the part to be cut;

the vertical driving assembly 3 drives the cutter mounting plate 43 to move downwards, the cutter mounting plate 43 drives the two finished product cutters 44 to cut two groups of parts, the cut parts are discharged through the finished product guide chutes 41 below the cut parts, and fig. 9 is a schematic structural diagram of the processed parts. Meanwhile, the cutter mounting plate 43 drives the defective cutter 45 to cut the waste on the right sides of the two groups of parts, and the cut waste is discharged through the waste guide chute 42 below the waste; the cutting assembly 4 can ensure that the cutting and blanking of the waste materials are synchronously finished when the parts are cut and blanked;

the vertical driving assembly 3 comprises a connecting frame 31, a sliding plate 32, a first electric push rod 33 and a guide column 34; a plurality of first electric push rods 33 are fixedly arranged on the top plate, the output ends of the first electric push rods 33 are fixedly connected with a sliding plate 32 below the top plate, four corners of the upper end of the base 1 are respectively and fixedly connected with guide posts 34, the upper ends of the guide posts 34 are respectively and fixedly connected with four corners of the lower end of the top plate, and the guide posts 34 respectively penetrate through the four corners of the sliding plate 32 and are in sliding connection with the sliding plate 32; the lower end of the sliding plate 32 is fixedly connected with a connecting frame 31, and the connecting frame 31 is fixedly connected with the punching cutter 22, the cutter mounting plate 43, the mounting top plate 56 and the first wedge-shaped block connecting plate 69 respectively;

through starting first electric putter 33, first electric putter 33 drive slide 32 vertically reciprocates along guide post 34, and guide post 34 drive link 31 vertically reciprocates, and link 31 drives die-cut cutter 22, cutter mounting panel 43, installation roof 56 and first wedge connecting plate 69 and vertically reciprocates, cuts in step, processes such as bending, hem, blank.

By integrating punching, bending and edge folding equipment, the multi-station synchronous punching, bending, edge folding and cutting blanking processes can be completed on one equipment at the same time, and the processing efficiency of automobile plate parts is improved;

simultaneously, two groups of parts can be produced at one time, and the machining efficiency of the automobile plate part is further improved.

The above examples are only intended to illustrate the technical solution of the present invention, but not to limit it; although the present invention has been described in detail with reference to the foregoing embodiments, it will be understood by those of ordinary skill in the art that: the technical solutions described in the foregoing embodiments may still be modified, or some technical features may be equivalently replaced; such modifications and substitutions do not depart from the spirit and scope of the corresponding technical solutions.

Claims (8)

1. The utility model provides an automobile panel part is bent with multistation mould of bending, includes base (1), its characterized in that:

the punching assembly (2), the vertical driving assembly (3), the cutting assembly (4), the first bending assembly (5) and the second bending assembly (6) are arranged on the base (1); the driving end of the vertical driving assembly (3) is connected with the punching assembly (2), the cutting assembly (4), the first bending assembly (5) and the second bending assembly (6) respectively;

the punching assembly (2) comprises a punching seat (21) and two groups of punching cutters (22) with a certain distance; the punching seat (21) is fixedly connected to the upper end of the base (1), the two punching tools (22) are fixedly connected with the driving end of the vertical driving assembly (3), and the opening ends of the two punching tools (22) are arranged oppositely; the middle part of the punching cutter (22) is fixedly connected with a plurality of punching rods (23), the punching seat (21) is internally provided with a punching cutter movable groove (25) which is inserted by matching with the punching cutter (22), and the punching seat (21) is internally provided with a punching rod movable groove (26) which is inserted by matching with the punching rod (23);

the two groups of first bending assemblies (5) are arranged, and the two groups of first bending assemblies (5) are respectively positioned on one side of the two groups of punching cutters (22) and are respectively used for bending the two groups of parts;

the two groups of second bending assemblies (6) are also arranged, and the two groups of second bending assemblies (6) are respectively positioned at one side of the two groups of first bending assemblies (5) and are respectively used for folding the edges of the two groups of parts;

and the cutting assembly (4) is positioned on one side of the second bending assembly (6) and is used for cutting and blanking two groups of parts.

2. The multi-station bending die for bending the automobile plate parts according to claim 1, wherein the base (1) is provided with a discharge hole (24) convenient for cutting waste materials at a position corresponding to the upper part and the lower part of the movable grooves (25) of the punching tool and the movable grooves (26) of the punching rod.

3. The multi-station bending die for bending the automobile plate parts according to claim 1, wherein the first bending assembly (5) comprises a guide rod (51), a first bending seat (52), a first horizontal pressing plate (53), a first spring (54), a first side pressing plate (55) and a mounting top plate (56); first seat (52) fixed connection that bends is in the upper end of base (1), the first side board (55) of the lower extreme outside fixedly connected with of installation roof (56), the equal sliding connection in four angle departments of installation roof (56) has guide bar (51), the first horizontal pressing plate (53) of lower extreme fixedly connected with of guide bar (51), first horizontal pressing plate (53) are located between two first side boards (55), install first spring (54) on guide bar (51), first spring (54) are located between first horizontal pressing plate (53) and installation roof (56), the drive end fixed connection of installation roof (56) and vertical drive assembly (3).

4. The multi-station bending die for bending the automobile plate component as claimed in claim 1, wherein the second bending assembly (6) comprises a mounting fixing frame (61), a second air cylinder (62), a first wedge-shaped block (63), a fixing block (64), a guide rail (65), a second spring (66), a connecting fixing block (67), a second wedge-shaped block (68), a first wedge-shaped block connecting plate (69), a second side pressing plate (610), a third side pressing plate (611), a second bending seat (612), a third side pressing plate connecting plate (613), a transverse plate (614) and an auxiliary supporting block (615); the second bending seat (612) is fixedly connected to the upper end of the base (1), the upper end of a first wedge block connecting plate (69) is fixedly connected with the driving end of the vertical driving assembly (3), the left side and the right side of the lower end of the first wedge block connecting plate (69) are fixedly connected with a second side pressing plate (610) used for folding the left side and the right side of the upper end of a part, the outer side of the first wedge block connecting plate (69) is fixedly connected with a first wedge block (63), the lower end of the first wedge block (63) is in contact connection with an inclined surface at one end of a second wedge block (68), the other end of the second wedge block (68) is fixedly connected with a third side pressing plate (611) used for folding the left side and the right side of the lower end of the part, the lower ends of the second wedge block (68) and a third side pressing plate connecting plate (613) are both in sliding connection on the guide rail (65), the left side and the right side of one end of the third pressing plate connecting plate (613) close to the part are fixedly connected with a third side pressing plate (611) used for folding the left side and the right side of the lower end of the part, both side of the guide rail (65) are fixedly mounted at the upper end of the base (64), the fixed block (67), the fixed block (64) is connected with the fixed block (67), and the fixed block (64) of the fixed block (67), and the fixed block (64); the two auxiliary supporting blocks (615) are respectively located below the two groups of parts to be flanged, the lower ends of the auxiliary supporting blocks (615) are fixed on a transverse plate (614), the transverse plate (614) is fixedly connected with the output end of a second air cylinder (62), the second air cylinder (62) is fixedly connected to an installation fixing frame (61), the installation fixing frame (61) is fixedly connected to the bottom of the base (1), and the auxiliary supporting blocks (615) movably penetrate through the base (1).

5. The multi-station bending die for bending the automobile plate parts as claimed in claim 4, wherein the cutting assembly (4) comprises a scrap material guide groove (42), a cutter mounting plate (43), a finished product cutter (44) and a defective product cutter (45); the upper end of the cutter mounting plate (43) is fixedly connected with the driving end of the vertical driving assembly (3), two finished product cutters (44) are fixedly mounted on the front side and the rear side of the lower end of the cutter mounting plate (43), and a defective product cutter (45) is fixedly mounted on the right side of the lower end of the cutter mounting plate (43); one end of the waste material guide chute (42) is positioned below the defective product cutter (45), and one end of each finished product guide chute (41) is positioned below each finished product cutter (44); the second bending seat (612) extends to the lower part of the cutter mounting plate (43).

6. The multi-station bending die for bending the automobile plate parts according to claim 5, wherein the distance between the two finished product cutters (44) is the same as the distance between the two groups of punching cutters (22), and the positions of the two finished product cutters (44) and the cutting positions of the parts are arranged in a vertically corresponding manner.

7. The multi-station bending die for bending the automobile plate parts as claimed in claim 6, wherein the scrap material guide chute (42) and the two finished product guide chutes (41) are fixedly arranged on the base (1) in an inclined manner.

8. The multi-station bending die for bending the automobile plate parts according to claim 1, wherein the vertical driving assembly (3) comprises a connecting frame (31), a sliding plate (32), a first electric push rod (33) and a guide column (34); the first electric push rods (33) are fixedly arranged on the top plate, the output ends of the first electric push rods (33) are fixedly connected with a sliding plate (32) below the top plate, four corners of the upper end of the base (1) are respectively and fixedly connected with guide columns (34), the upper ends of the guide columns (34) are respectively and fixedly connected with four corners of the lower end of the top plate, and the guide columns (34) respectively penetrate through the four corners of the sliding plate (32) and are in sliding connection with the sliding plate (32); the lower extreme fixedly connected with link (31) of slide (32), link (31) are connected with die-cut subassembly (2), cutting element (4), first subassembly (5) and the second subassembly (6) of bending respectively.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202211298484.3A CN115780587A (en) | 2022-10-24 | 2022-10-24 | Multi-station bending die for bending automobile plate parts |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202211298484.3A CN115780587A (en) | 2022-10-24 | 2022-10-24 | Multi-station bending die for bending automobile plate parts |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN115780587A true CN115780587A (en) | 2023-03-14 |

Family

ID=85433515

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202211298484.3A Pending CN115780587A (en) | 2022-10-24 | 2022-10-24 | Multi-station bending die for bending automobile plate parts |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN115780587A (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN116786686A (en) * | 2023-08-25 | 2023-09-22 | 成都市锦华实用电器研究所有限公司 | Plate bending and punching device |

-

2022

- 2022-10-24 CN CN202211298484.3A patent/CN115780587A/en active Pending

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN116786686A (en) * | 2023-08-25 | 2023-09-22 | 成都市锦华实用电器研究所有限公司 | Plate bending and punching device |

| CN116786686B (en) * | 2023-08-25 | 2023-10-24 | 成都市锦华实用电器研究所有限公司 | Plate bending and punching device |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN115780631A (en) | Door lock hardware punch forming equipment and using method | |

| CN212577311U (en) | Composite punching die | |

| CN115780587A (en) | Multi-station bending die for bending automobile plate parts | |

| CN111438292B (en) | Mold for manufacturing condenser end plate, punch device and manufacturing method | |

| CN111715785A (en) | Full-automatic production line for stamping and shearing metal plates and use method | |

| CN114260367B (en) | Multidirectional positioning stamping die and using equipment thereof | |

| CN110576098B (en) | Automatic wire pressing frame bending machine combined with die and working method thereof | |

| CN211191665U (en) | Device for flanging and bending support | |

| CN219899913U (en) | Forming die | |

| CN115318954B (en) | Condenser panel processing die and processing method thereof | |

| CN212216891U (en) | Mould and punch press device of preparation condenser end plate | |

| CN114850319A (en) | Continuous forming processing equipment for drawer slide rail components | |

| CN210450558U (en) | Negative angle bending die | |

| CN113458236A (en) | Reinforced rear cross beam mold and control method thereof | |

| CN220444801U (en) | Multi-specification aluminum parting strip V-shaped hole punching device | |

| CN219256577U (en) | Ordinary continuous stamping die | |

| CN219945225U (en) | Junction box processing device | |

| CN221473166U (en) | U-shaped blocking piece rapid prototyping device | |

| CN213256611U (en) | Continuous stamping die for staggered-layer plates | |

| CN213436773U (en) | Automatic stamping and positioning mechanism | |

| CN219966750U (en) | Quick forming die for busbar soft die sample | |

| CN118143118B (en) | Die-cut device of window frame section bar | |

| CN220278428U (en) | Punching device | |

| CN216857922U (en) | Machining die for manufacturing section bar by plate type filter screen | |

| CN216606921U (en) | One-step forming die for multi-break-angle workpiece |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination |