CN113685548A - Sealing method for rubber support spherical hinge in anti-side-rolling torsion bar device - Google Patents

Sealing method for rubber support spherical hinge in anti-side-rolling torsion bar device Download PDFInfo

- Publication number

- CN113685548A CN113685548A CN202110908863.9A CN202110908863A CN113685548A CN 113685548 A CN113685548 A CN 113685548A CN 202110908863 A CN202110908863 A CN 202110908863A CN 113685548 A CN113685548 A CN 113685548A

- Authority

- CN

- China

- Prior art keywords

- sealing

- rubber

- torsion bar

- ball joint

- seal

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 238000007789 sealing Methods 0.000 title claims abstract description 252

- 238000005096 rolling process Methods 0.000 title claims abstract description 20

- 238000000034 method Methods 0.000 title claims abstract description 19

- 239000000428 dust Substances 0.000 description 6

- 238000009434 installation Methods 0.000 description 6

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 6

- 239000010410 layer Substances 0.000 description 4

- 230000007704 transition Effects 0.000 description 4

- 239000002245 particle Substances 0.000 description 3

- 239000011241 protective layer Substances 0.000 description 3

- 239000002356 single layer Substances 0.000 description 3

- 230000000694 effects Effects 0.000 description 2

- 238000012986 modification Methods 0.000 description 2

- 230000004048 modification Effects 0.000 description 2

- 230000037303 wrinkles Effects 0.000 description 2

- 238000009825 accumulation Methods 0.000 description 1

- 238000013016 damping Methods 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 230000002035 prolonged effect Effects 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16J—PISTONS; CYLINDERS; SEALINGS

- F16J15/00—Sealings

- F16J15/16—Sealings between relatively-moving surfaces

- F16J15/32—Sealings between relatively-moving surfaces with elastic sealings, e.g. O-rings

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B61—RAILWAYS

- B61F—RAIL VEHICLE SUSPENSIONS, e.g. UNDERFRAMES, BOGIES OR ARRANGEMENTS OF WHEEL AXLES; RAIL VEHICLES FOR USE ON TRACKS OF DIFFERENT WIDTH; PREVENTING DERAILING OF RAIL VEHICLES; WHEEL GUARDS, OBSTRUCTION REMOVERS OR THE LIKE FOR RAIL VEHICLES

- B61F5/00—Constructional details of bogies; Connections between bogies and vehicle underframes; Arrangements or devices for adjusting or allowing self-adjustment of wheel axles or bogies when rounding curves

- B61F5/02—Arrangements permitting limited transverse relative movements between vehicle underframe or bolster and bogie; Connections between underframes and bogies

- B61F5/22—Guiding of the vehicle underframes with respect to the bogies

- B61F5/24—Means for damping or minimising the canting, skewing, pitching, or plunging movements of the underframes

Landscapes

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Pivots And Pivotal Connections (AREA)

Abstract

The invention relates to the technical field of railway vehicles, in particular to a sealing method of a rubber support spherical hinge in an anti-side-rolling torsion bar device.

Description

Technical Field

The invention relates to the technical field of railway vehicles, in particular to a sealing method of a rubber support spherical hinge in an anti-side-rolling torsion bar device.

Background

The anti-rolling torsion bar device is arranged on the railway vehicle, when the vehicle rolls, the torsion bar shaft and other components provide the required rolling rigidity for the safe operation of the vehicle together, so as to control the rolling vibration of the vehicle and ensure the stability of the vehicle operation.

The anti-rolling torsion bar device comprises a rubber supporting spherical hinge which is fixedly connected to the outer side of the torsion bar shaft through a mounting seat and used for damping and supporting the anti-rolling torsion bar device, and in the running process of a vehicle, in order to prevent sundries such as water, dust and the like from entering the inner side of the rubber supporting spherical hinge from the connecting surface of the rubber supporting spherical hinge and the torsion bar shaft to corrode and damage the torsion bar shaft, a sealing device is usually required to be arranged. In a conventional anti-rolling torsion bar device, the outer side of a mounting seat is usually connected with a torsion arm of a vehicle, a sealing groove is formed in the mounting seat and the torsion arm, and a sealing ring is additionally arranged between the mounting seat and the torsion arm to achieve a sealing effect.

In order to solve the problem of poor sealing of the sealing ring, in the prior art, a paired rubber rod end spherical hinge 1 with a sealing profile appears as shown in fig. 1, the rubber rod end spherical hinge 1 is an integrated rubber rod end spherical hinge 1, the rubber profile at the sealing surface of the rubber rod end spherical hinge 1 and the torsion bar shaft 2 is in an asymmetric structure, specifically, as shown by an asymmetric sealing surface one 4 and a sealing surface two 5, if only one rubber rod end spherical hinge 1 is adopted, the problem of poor sealing in a local direction exists, the coaxiality is low during installation, and the radial rigidity of the rubber support spherical hinge 1 is low, in order to avoid the above problem, two integrated rubber rod end spherical hinges 1 need to be installed on the torsion bar shaft 2 in parallel, so that the end surfaces of two rubber support spherical hinges 1 connected with the installation seat 3 are respectively a sealing surface one 4 or a sealing surface two 5 of the two rubber support spherical hinges 1, and the joints of the two rubber support spherical hinges 1 are respectively a sealing surface two sealing surfaces 5 or a sealing surface two sealing surfaces 5 of the two rubber support spherical hinges 14, the following problems still exist in the structure: 1. the sealing requirement can be met only by assembling and connecting two rubber supporting spherical hinges, so that the material cost of the device is increased, and the installation difficulty is increased; 2. the rubber profile of the rubber support spherical hinge in the prior art is a linear profile, the sealing effect is poor, water, dust or other particles easily enter from the sealing surface of the rubber support spherical hinge and the torsion bar shaft in the running process of a vehicle, and the service life of the anti-rolling torsion bar device is shortened.

Disclosure of Invention

The invention aims to provide a sealing method of a rubber support spherical hinge in an anti-side-rolling torsion bar device, which ensures the sealing performance between the rubber support spherical hinge and a torsion bar shaft and prolongs the service life of the anti-side-rolling torsion bar device by arranging the inner sides of the end surfaces at the two ends of an integrated rubber sleeve into symmetrical sealing profiles.

In order to achieve the purpose, the invention provides the following technical scheme: a sealing method for a rubber supporting spherical hinge in an anti-side-rolling torsion bar device is characterized in that the rubber supporting spherical hinge comprises two petal type inner sleeves and an integrated rubber sleeve, the two petal type inner sleeves are uniformly arranged inside the integrated rubber sleeve, the whole rubber supporting spherical hinge is in a hollow cylindrical shape with an opening, and the inner sides of the end faces of the two ends of the integrated rubber sleeve are arranged into symmetrical sealing profiles so as to ensure the sealing performance between the rubber supporting spherical hinge and a torsion bar shaft.

Preferably, the sealing profile is set as a first sealing conical surface which is inclined from the end surface of the inner sleeve to the central axis L1 of the axial torsion bar shaft outside the rubber supporting spherical hinge; after the assembly, the first sealing conical surface inclining towards the outer side of the rubber support spherical hinge is contacted with the torsion bar shaft to form an end sealing structure for sealing.

Preferably, the sealing profile is set as a second sealing conical surface which is inclined from the end surface of the inner sleeve to the outer side of the rubber supporting spherical hinge and is far away from the central axis L1 of the torsion bar shaft; and after assembly, a second sealing conical surface inclining towards the inner side of the rubber support spherical hinge is contacted with the torsion bar shaft to form an end sealing structure for sealing.

Preferably, the sealing profile is provided as more than two serrated sealing lobes; after assembly, more than two zigzag sealing bulges are contacted with the torsion bar shaft to form an end part multilayer sealing structure for sealing.

Preferably, the two or more serrated sealing protrusions are provided in two, three, or four.

Preferably, the three zigzag sealing bulges are respectively a first sealing bulge wrapped on the outer side of the end face of the inner sleeve and protruding towards the central axis L1 of the rubber support spherical hinge, a second sealing bulge located between the first sealing bulge and the rubber end face and protruding towards the side opposite to the central axis L1 of the rubber support spherical hinge, and a third sealing bulge connecting the first sealing bulge and the rubber end face and protruding towards the central axis L1 of the rubber support spherical hinge; and the first sealing bulge, the second sealing bulge and the third sealing bulge are in contact with the torsion bar shaft and form an end multi-layer sealing structure for sealing.

Preferably, the convex top surfaces of the first sealing bulge, the second sealing bulge and the third sealing bulge are all arc convex top surfaces, and the arc length of the second convex top surface of the second sealing bulge is set to be larger than that of the first convex top surface of the first sealing bulge and that of the third convex top surface of the third sealing bulge; the arc length of the convex top surface of the second sealing concave boss is set to be larger, so that the sealing accommodating space of the second sealing concave boss protruding towards the outer side of the supporting spherical hinge is increased.

Preferably, the rubber profile at the joint of the first sealing bulge and the end face of the inner sleeve is set as a first arc-shaped joint face.

Preferably, the third sealing protrusion is connected with the integrated rubber end face through the second arc-shaped connecting face.

Preferably, a sealing convex edge is arranged on the rubber molded surface III on one side of the opening of the rubber supporting spherical hinge, a sealing groove matched and assembled with the sealing convex edge is arranged on the rubber molded surface IV on the other side of the opening of the rubber supporting spherical hinge relative to the rubber molded surface III, and the sealing performance of the opening of the rubber supporting spherical hinge after assembly is improved through the matching of the sealing convex edge and the sealing groove.

Has the advantages that:

1. the inner sides of the end faces of the two ends of the integrated rubber sleeve are set to be symmetrical sealing molded surfaces, so that the sealing surfaces at the joint between the rubber supporting spherical hinge and the torsion bar shaft can be better sealed, the coaxiality of the rubber supporting spherical hinge can be improved, the installation difficulty is reduced, and the radial rigidity of the rubber supporting spherical hinge is improved.

2. The sealing profile is set to be a first sealing conical surface which inclines from the end face of the inner sleeve to the outer side of the rubber supporting spherical hinge towards the central axis L1 of the torsion bar shaft or a second sealing conical surface which inclines from the end face of the inner sleeve to the outer side of the rubber supporting spherical hinge towards the central axis L1 far away from the torsion bar shaft, after assembly, the first sealing conical surface or the second sealing conical surface is in contact with the torsion bar shaft to form a single-layer sealing structure at the end part for sealing, and the service life of the anti-side-rolling torsion bar device is prevented from being influenced by water, dust or other particles.

3. The sealing profile is set to be more than two zigzag sealing bulges, and the more than two zigzag sealing bulges are contacted with the torsion bar shaft after assembly to form a multilayer sealing structure at the end part for sealing, so that the service life of the anti-rolling torsion bar device is prevented from being influenced by water, dust or other particles.

Drawings

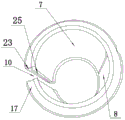

Fig. 1 is a schematic cross-sectional view of a prior art rubber-supported ball joint.

Fig. 2 is a schematic perspective view of a rubber support ball hinge according to an embodiment.

Fig. 3 is a schematic perspective view of a rubber support ball hinge according to an embodiment.

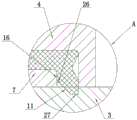

Fig. 4 is a schematic cross-sectional view of a rubber-supported ball hinge according to an embodiment (cut away to avoid an opening of the rubber-supported ball hinge).

Fig. 5 is a partial enlarged view of a portion a in fig. 4.

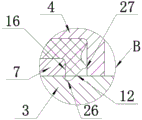

Fig. 6 is a schematic cross-sectional structure diagram of the rubber support ball hinge according to the second embodiment (cut away from the opening of the rubber support ball hinge).

Fig. 7 is a partial enlarged view of fig. 6 at B.

Fig. 8 is a schematic cross-sectional structure view of the rubber support ball hinge according to the third embodiment (cut away to avoid the opening of the rubber support ball hinge).

Fig. 9 is a partial enlarged view at C in fig. 8.

The reference numerals include: 1. a rubber supporting ball hinge I; 2. a rubber supporting spherical hinge II; 3. a torsion bar shaft; 4. a mounting seat; 5. a first sealing surface; 6. a second sealing surface; 7. a first inner sleeve; 8. a second inner sleeve; 9. a rubber sleeve; 10. an opening; 11. a first sealing conical surface; 12. a second sealing conical surface; 13. the first sealing bulge; 14. a second sealing bulge; 15. sealing a third bulge; 16. the end surface of the inner sleeve; 17. a rubber end face; 18. a first convex top surface; 19. a convex top surface II; 20. a convex top surface III; 21. an arc-shaped connecting surface I; 22. an arc-shaped connecting surface II; 23. a rubber molded surface III; 24. a rubber molded surface four; 25. sealing the convex edge; 26. sealing the straight surface I; 27. and sealing the straight surface II.

Detailed Description

The invention is described in further detail below with reference to fig. 2-9.

Example one

As shown in fig. 2-5, a method for sealing a rubber support ball hinge in an anti-roll torsion bar device, the rubber support ball hinge includes two inner sleeves and an integral rubber sleeve 9, the two inner sleeves are uniformly disposed inside the integral rubber sleeve 9, the whole rubber support ball hinge is in a hollow cylinder shape with an opening 10, and the inner sides of the two end faces of the integral rubber sleeve 9 are set to be symmetrical sealing profiles, so as to ensure the sealing performance between the rubber support ball hinge and the torsion bar shaft 3 and improve the service life of the anti-roll torsion bar device.

As shown in fig. 2 and 3, the two-petal inner sleeves are respectively a first inner sleeve 7 and a second inner sleeve 8, the integrated rubber sleeve 9 is vulcanized on the outer sides of the first inner sleeve 7 and the second inner sleeve 8, the integrated rubber sleeve 9 forms an opening 10 at the junction of the two-petal inner sleeves, and the rubber support ball hinge can be opened towards two sides at the opening 10 and is sleeved on the torsion bar shaft 3. During installation, the rubber support spherical hinge is firstly opened towards two sides through the opening 10, the rubber support spherical hinge is sleeved on the torsion bar shaft 3, and then the rubber support spherical hinge is fixed on the torsion bar shaft 3 by using the installation seat 4 to be pressed on the outer side of the rubber support spherical hinge.

As shown in fig. 4, the rubber profiles at the sealing positions where the integral rubber sleeve 9 contacts the torsion bar shaft 3, that is, the inner sides of the end surfaces at both ends of the rubber sleeve 9 are set as symmetrical sealing profiles, that is, the sealing surface one 5 and the sealing surface two 6 are symmetrical rubber profiles; specifically, the first sealing surface 5 and the second sealing surface 6 are set to be a first sealing conical surface 11 which inclines from the end surface 16 of the inner sleeve to the outer side of the rubber supporting spherical hinge towards the central axis L1 of the torsion bar shaft 3, and a single-layer end sealing structure is formed by the contact between the rubber end surface 17 of the rubber sleeve 9 and the first sealing conical surface 11 after assembly and the torsion bar shaft 3 for sealing; meanwhile, as shown in fig. 5, the first sealing conical surface 11 is connected with the inner sleeve end surface 16 through the first sealing straight surface 26, the first sealing conical surface 11 is in arc transition with the first sealing straight surface 26, the first sealing conical surface 11 is connected with the rubber end surface 17 through the second sealing straight surface 27, and the first sealing conical surface 11 is in arc transition with the second sealing straight surface 27; the first sealing straight surface 26 and the second sealing straight surface 27 are straight surfaces parallel to the central axis L1 of the torsion bar shaft 3, the first sealing straight surface 26 and the second sealing straight surface 27 can improve the radial rigidity of the rubber supporting spherical hinge, and the first sealing straight surface 26 can enable rubber to gradually approach the inner sleeve end surface 16 or the first sealing conical surface 11 when the rubber at the position of the first sealing conical surface 11 is loaded, so that the rubber is prevented from being folded and broken; the length of the first sealing straight surface 26 is set to be smaller than that of the second sealing straight surface 27, and the second sealing straight surface 27 with the longer length can increase the sealing area between the rubber support ball joint and the torsion bar shaft 3, enhance the sealing performance and prolong the service life of the anti-rolling torsion bar device.

As shown in fig. 2 and 3, a sealing rib 25 is arranged on a rubber profile three 23 on one side of the rubber supporting ball hinge opening 10, a sealing groove matched with the sealing rib 25 is arranged on a rubber profile four 24 on the other side of the rubber supporting ball hinge opening 10 opposite to the rubber profile three 23, and the sealing performance of the rubber supporting ball hinge opening 10 after assembly is improved through the matching of the sealing rib 25 and the sealing groove. When the mounting seat 4 is pressed on the outer side of the rubber supporting spherical hinge to fix the rubber supporting spherical hinge on the torsion bar shaft 3, the sealing convex edge 25 on the third rubber profile 23 and the sealing groove on the fourth rubber profile 24 can be matched, assembled and pressed tightly, so that the sealing property between the rubber supporting spherical hinge and the torsion bar shaft 3 is enhanced.

Example two

As shown in fig. 6 and 7, the sealing profile is set as a second sealing conical surface 12 which is inclined from the end surface 16 of the inner sleeve to the outer side of the rubber support spherical hinge away from the central axis L1 of the torque rod shaft 3; after assembly, the second sealing conical surface 12 is in contact with the torsion bar shaft 3 to form an end sealing structure for sealing. After the inner sleeve end face 16 and the second sealing conical surface 12 are assembled, the inner sleeve end face and the second sealing conical surface are in contact with the torsion bar shaft 3 to form a single-layer end sealing structure for sealing; meanwhile, as shown in fig. 7, the second sealing conical surface 12 is connected with the inner sleeve end face 16 through the first sealing straight face 26, the second sealing conical surface 12 is in arc transition with the first sealing straight face 26, the second sealing conical surface 12 is connected with the rubber end face 17 through the second sealing straight face 27, and the second sealing conical surface 12 is in arc transition with the second sealing straight face 27; the first sealing straight surface 26 and the second sealing straight surface 27 are straight surfaces parallel to the central axis L1 of the torsion bar shaft 3, the first sealing straight surface 26 and the second sealing straight surface 27 can improve the radial rigidity of the rubber supporting spherical hinge, and the first sealing straight surface 26 can enable rubber to gradually approach the inner sleeve end surface 16 or the second sealing conical surface 12 when the rubber at the position of the sealing conical surface 12 is loaded, so that rubber wrinkle breakage is avoided; the length of the first sealing straight surface 26 is set to be larger than that of the second sealing straight surface 27, and the first sealing straight surface 26 can increase the sealing area between the rubber support ball hinge and the torsion bar shaft 3, enhance the sealing performance and prolong the service life of the anti-rolling torsion bar device.

EXAMPLE III

As shown in fig. 8 and 9, the seal profile is provided as more than two serrated seal lobes; after assembly, more than two zigzag sealing bulges are contacted with the torsion bar shaft 3 to form an end part multilayer sealing structure for sealing; the more than two zigzag sealing bulges are set to be two, three or four, the three zigzag sealing bulges are set in the embodiment and respectively comprise a first sealing bulge 13 which is wrapped outside the end surface 16 of the inner sleeve and protrudes towards the central axis L1 of the rubber supporting spherical hinge, a second sealing bulge 14 which is positioned between the first sealing bulge 13 and the rubber end surface 17 and protrudes towards the side opposite to the central axis L1 of the rubber supporting spherical hinge, and a third sealing bulge 15 which is connected with the first sealing bulge 13 and the rubber end surface 17 and protrudes towards the central axis L1 of the rubber supporting spherical hinge; and the first sealing bulge 13, the second sealing bulge 14 and the third sealing bulge 15 are in contact with the torsion bar shaft 3 and form an end three-layer sealing structure for sealing. The third sealing bulge 15 is a first sealing protective layer, the second sealing bulge 14 is a second sealing protective layer, and the first sealing bulge 13 is a third sealing protective layer, so that the torsion bar is better protected by the three layers of protection.

As shown in fig. 9, the convex top surfaces of the first sealing protrusion 13, the second sealing protrusion 14 and the third sealing protrusion 15 are all set to be arc convex top surfaces, and the arc length of the second convex top surface 19 of the second sealing protrusion is set to be larger than the arc length of the first convex top surface 18 of the first sealing protrusion 13 and the arc length of the third convex top surface 20 of the third sealing protrusion 15; the arc length of the convex top surface two 19 of the sealing concave second 14 is set to be larger, so that the sealing accommodating space of the sealing concave second 14 protruding towards the outer side of the supporting spherical hinge is improved. The arc length of the convex top surface 19 of the second sealing protrusion 14 is larger, so that when water or dust enters the second sealing protrusion 14 from the third sealing protrusion 15 of the first layer of protection, the second sealing protrusion 14 has larger volume space to accommodate and prevent the water or dust from further entering the first sealing protrusion 13.

As shown in fig. 9, the rubber profile at the joint of the first sealing protrusion 13 and the end face 16 of the inner sleeve is set as a first arc-shaped connecting face 21, and the third sealing protrusion 15 and the integrated rubber end face 17 are connected through a second arc-shaped connecting face 22. Therefore, when the rubber supporting spherical hinge is loaded, the rubber molded surface between the first sealing bulge 13 and the inner sleeve end surface 16 is gradually attached to the inner sleeve end surface 16 or the first sealing bulge 13 through the first arc-shaped connecting surface 21, and the rubber molded surface between the third sealing bulge 15 and the integrated rubber end surface 17 can be gradually attached to the third sealing bulge 15 or the rubber end surface 17 through the second arc-shaped connecting surface 22, so that rubber accumulation wrinkles are prevented from being broken, and the service life of the anti-rolling torsion bar device is prolonged.

The above examples are only illustrative and not restrictive, and those skilled in the art can make modifications to the embodiments of the present invention as required without any inventive contribution thereto after reading the present specification, but all such modifications are intended to be protected by the following claims.

Claims (10)

1. A sealing method of a rubber supporting spherical hinge in an anti-side-rolling torsion bar device is characterized in that the inner sides of the end faces of two ends of an integrated rubber sleeve (9) are arranged into symmetrical sealing profiles to ensure the sealing performance between the rubber supporting spherical hinge and a torsion bar shaft (3).

2. The method for sealing a rubber-supported ball joint in an anti-roll torsion bar apparatus according to claim 1, wherein the seal profile is set to a first seal cone surface (11) inclined from the inner race end surface (16) toward the center axis L1 of the side torsion bar shaft (3) outside the rubber-supported ball joint; after assembly, the first sealing conical surface (11) is in contact with the torsion bar shaft (3) to form an end sealing structure for sealing.

3. The method for sealing a rubber-supported ball joint in an anti-roll torsion bar apparatus according to claim 1, wherein the seal profile is set to a second seal taper surface (12) inclined from the inner housing end surface (16) toward the outside of the rubber-supported ball joint to a direction away from a central axis L1 of the torsion bar shaft (3); after assembly, the second sealing conical surface (12) is in contact with the torsion bar shaft (3) to form an end sealing structure for sealing.

4. A method of sealing a rubber-backed ball joint in an anti-roll torsion bar apparatus according to claim 1, wherein the seal profile is provided as two or more serrated seal protrusions; after assembly, more than two zigzag sealing bulges are contacted with the torsion bar shaft (3) to form an end part multilayer sealing structure for sealing.

5. A method of sealing a rubber-backed ball joint in an anti-roll torsion bar apparatus according to claim 4, wherein the two or more serrated seal protrusions are provided in two, three, or four.

6. The method for sealing a rubber-supported ball joint in an anti-roll torsion bar apparatus according to claim 5, wherein the serrated sealing protrusions are provided in three, namely, a first sealing protrusion (13) wrapped outside the end surface (16) of the inner housing and protruding toward the central axis L1 of the rubber-supported ball joint, a second sealing protrusion (14) located between the first sealing protrusion (13) and the end surface (17) of the rubber-supported ball joint and protruding toward a side opposite to the central axis L1 of the rubber-supported ball joint, and a third sealing protrusion (15) connecting the first sealing protrusion (13) and the end surface (17) of the rubber-supported ball joint and protruding toward the central axis L1 of the rubber-supported ball joint; and the first sealing bulge (13), the second sealing bulge (14) and the third sealing bulge (15) are in contact with the torsion bar shaft (3) and form an end multi-layer sealing structure for sealing.

7. The method for sealing a rubber-backed ball joint in an anti-roll torsion bar apparatus according to claim 6, wherein the convex top surfaces of the first seal projection (13), the second seal projection (14) and the third seal projection (15) are all set to be circular-arc convex top surfaces, and the arc length of the second convex top surface (19) of the second seal projection (14) is set to be greater than the arc length of the first convex top surface (18) of the first seal projection (13) and the arc length of the third convex top surface (20) of the third seal projection (15); the arc length of the convex top surface of the sealing concave second (14) is set to be larger, so that the sealing accommodating space of the sealing concave second (14) is increased.

8. A method for sealing a rubber-backed ball joint in an anti-roll torsion bar apparatus according to claim 7, characterized in that a rubber profile at a junction of the first seal projection (13) and the end surface (16) of the inner race is set to a first arcuate joint surface (21).

9. A method of sealing a rubber-backed ball joint in an anti-roll torsion bar apparatus according to claim 8, characterized in that the third sealing protrusion (15) is connected to the rubber end surface (17) of the integrated rubber boot (9) via the second arcuate connecting surface (22).

10. A method of sealing a rubber-backed ball joint in an anti-roll torsion bar apparatus according to any one of claims 1 to 9, wherein a sealing rib (25) is provided on a rubber profile three (23) on one side of the opening (10) of the rubber-backed ball joint, and a sealing groove fitted with the sealing rib (25) is provided on a rubber profile four (24) on the other side of the opening (10) of the rubber-backed ball joint with respect to the rubber profile three (23), so that the sealing performance after fitting at the opening (10) of the rubber-backed ball joint is improved by the fitting of the sealing rib (25) with the sealing groove.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202110908863.9A CN113685548A (en) | 2021-08-09 | 2021-08-09 | Sealing method for rubber support spherical hinge in anti-side-rolling torsion bar device |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202110908863.9A CN113685548A (en) | 2021-08-09 | 2021-08-09 | Sealing method for rubber support spherical hinge in anti-side-rolling torsion bar device |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN113685548A true CN113685548A (en) | 2021-11-23 |

Family

ID=78579239

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202110908863.9A Pending CN113685548A (en) | 2021-08-09 | 2021-08-09 | Sealing method for rubber support spherical hinge in anti-side-rolling torsion bar device |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN113685548A (en) |

Citations (19)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB1042265A (en) * | 1963-03-23 | 1966-09-14 | Continental Gummi Werke Ag | Elastomeric bearing bush |

| JPS59128408U (en) * | 1983-02-18 | 1984-08-29 | トヨタ自動車株式会社 | Stabilizer bushings in vehicle suspensions |

| US5013166A (en) * | 1989-01-31 | 1991-05-07 | Hutchinson | Torsion bar bearing |

| US5058867A (en) * | 1988-10-27 | 1991-10-22 | Toyoda Gosei Co., Ltd. | Cylindrical vibration damping bushing |

| JPH04107332A (en) * | 1990-08-25 | 1992-04-08 | Kurashiki Kako Co Ltd | Slide type bush and its manufacture |

| JPH04272526A (en) * | 1991-02-22 | 1992-09-29 | Toyoda Gosei Co Ltd | Stabilizer bush |

| DE19527340A1 (en) * | 1994-07-26 | 1996-02-01 | Ntn Toyo Bearing Co Ltd | Seal for bearing |

| WO2006112092A1 (en) * | 2005-04-06 | 2006-10-26 | Toyota Jidosha Kabushiki Kaisha | Stabilizer bush |

| JP2007050777A (en) * | 2005-08-18 | 2007-03-01 | Toyota Motor Corp | Stabilizer bush |

| JP2007176274A (en) * | 2005-12-27 | 2007-07-12 | Bridgestone Corp | Stabilizer bush |

| JP2007253737A (en) * | 2006-03-22 | 2007-10-04 | Tokai Rubber Ind Ltd | Stabilizer bush |

| CN101090834A (en) * | 2005-12-15 | 2007-12-19 | 本田技研工业株式会社 | Stabilizer bush |

| JP2009255888A (en) * | 2008-03-26 | 2009-11-05 | Tokai Rubber Ind Ltd | Stabilizer bush |

| CN202623846U (en) * | 2012-06-21 | 2012-12-26 | 单红艳 | Rubber support bushing of transverse stabilizer bar |

| CN204713088U (en) * | 2015-07-02 | 2015-10-21 | 株洲时代新材料科技股份有限公司 | A kind of Anti-side rolling torsion bar for railway vehicle horizontal stop motion mechanism of elasticity |

| WO2016141623A1 (en) * | 2015-03-10 | 2016-09-15 | 株洲时代新材料科技股份有限公司 | Spherical hinge type rubber elastic element |

| CN108071721A (en) * | 2016-11-16 | 2018-05-25 | 东洋橡胶工业株式会社 | Lining of stabilizer |

| CN110566569A (en) * | 2019-09-25 | 2019-12-13 | 博戈橡胶塑料(株洲)有限公司 | Manufacturing method of lightweight joint with rubber metal spherical hinge |

| CN110936972A (en) * | 2019-11-19 | 2020-03-31 | 株洲时代新材料科技股份有限公司 | Anti-axial-movement method for anti-side-rolling torsion bar assembly and anti-side-rolling torsion bar assembly |

-

2021

- 2021-08-09 CN CN202110908863.9A patent/CN113685548A/en active Pending

Patent Citations (19)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB1042265A (en) * | 1963-03-23 | 1966-09-14 | Continental Gummi Werke Ag | Elastomeric bearing bush |

| JPS59128408U (en) * | 1983-02-18 | 1984-08-29 | トヨタ自動車株式会社 | Stabilizer bushings in vehicle suspensions |

| US5058867A (en) * | 1988-10-27 | 1991-10-22 | Toyoda Gosei Co., Ltd. | Cylindrical vibration damping bushing |

| US5013166A (en) * | 1989-01-31 | 1991-05-07 | Hutchinson | Torsion bar bearing |

| JPH04107332A (en) * | 1990-08-25 | 1992-04-08 | Kurashiki Kako Co Ltd | Slide type bush and its manufacture |

| JPH04272526A (en) * | 1991-02-22 | 1992-09-29 | Toyoda Gosei Co Ltd | Stabilizer bush |

| DE19527340A1 (en) * | 1994-07-26 | 1996-02-01 | Ntn Toyo Bearing Co Ltd | Seal for bearing |

| WO2006112092A1 (en) * | 2005-04-06 | 2006-10-26 | Toyota Jidosha Kabushiki Kaisha | Stabilizer bush |

| JP2007050777A (en) * | 2005-08-18 | 2007-03-01 | Toyota Motor Corp | Stabilizer bush |

| CN101090834A (en) * | 2005-12-15 | 2007-12-19 | 本田技研工业株式会社 | Stabilizer bush |

| JP2007176274A (en) * | 2005-12-27 | 2007-07-12 | Bridgestone Corp | Stabilizer bush |

| JP2007253737A (en) * | 2006-03-22 | 2007-10-04 | Tokai Rubber Ind Ltd | Stabilizer bush |

| JP2009255888A (en) * | 2008-03-26 | 2009-11-05 | Tokai Rubber Ind Ltd | Stabilizer bush |

| CN202623846U (en) * | 2012-06-21 | 2012-12-26 | 单红艳 | Rubber support bushing of transverse stabilizer bar |

| WO2016141623A1 (en) * | 2015-03-10 | 2016-09-15 | 株洲时代新材料科技股份有限公司 | Spherical hinge type rubber elastic element |

| CN204713088U (en) * | 2015-07-02 | 2015-10-21 | 株洲时代新材料科技股份有限公司 | A kind of Anti-side rolling torsion bar for railway vehicle horizontal stop motion mechanism of elasticity |

| CN108071721A (en) * | 2016-11-16 | 2018-05-25 | 东洋橡胶工业株式会社 | Lining of stabilizer |

| CN110566569A (en) * | 2019-09-25 | 2019-12-13 | 博戈橡胶塑料(株洲)有限公司 | Manufacturing method of lightweight joint with rubber metal spherical hinge |

| CN110936972A (en) * | 2019-11-19 | 2020-03-31 | 株洲时代新材料科技股份有限公司 | Anti-axial-movement method for anti-side-rolling torsion bar assembly and anti-side-rolling torsion bar assembly |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN102149930B (en) | Ball joint and method of manufacturing same | |

| US8888082B2 (en) | Mount bushing of stabilizer bar for vehicle | |

| RU2570983C2 (en) | Vehicle and spherical joint for vehicle front suspension | |

| EP2868501B1 (en) | Ball joint | |

| EP1233195B1 (en) | Ball joint seal | |

| KR100618258B1 (en) | Free-foam foam insert for center pin and knuckle arm assembly | |

| US6817599B2 (en) | Vibration damping bushing | |

| JP4118690B2 (en) | Ball joint | |

| CN113685548A (en) | Sealing method for rubber support spherical hinge in anti-side-rolling torsion bar device | |

| CN1060442C (en) | Universal joint for steering column | |

| JP2008506908A (en) | Bearing device | |

| CN113503309B (en) | Method for reducing deflection torsional rigidity of multilayer rod end spherical hinge and multilayer rod end spherical hinge | |

| JPS58170609A (en) | Suspension bushing construction | |

| KR102654322B1 (en) | Ball Joint | |

| KR20070093592A (en) | Body suspension structure of the front suspension lower link | |

| KR101986328B1 (en) | Integral Structure of Protection Tube and Upper Pad with Variable Pitch for Car's Suspension Coil Spring | |

| KR20070096696A (en) | Pillow ball bush | |

| JP3549056B2 (en) | Ball joint for stabilizer | |

| KR100245215B1 (en) | Suspension bushing | |

| JPH0614095Y2 (en) | Slip bushing | |

| JPS6342234Y2 (en) | ||

| CN119641841B (en) | Gas spring and damper assembly, automobile suspension and vehicle | |

| JP2005106117A (en) | Connected structure | |

| CN222793612U (en) | Steering mechanism and vehicle thereof | |

| CN220974314U (en) | Gear shaft for a steering system of a motor vehicle |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| RJ01 | Rejection of invention patent application after publication | ||

| RJ01 | Rejection of invention patent application after publication |

Application publication date: 20211123 |