CN113164287B - Disposable diaper having a disposable diaper - Google Patents

Disposable diaper having a disposable diaper Download PDFInfo

- Publication number

- CN113164287B CN113164287B CN201980080806.7A CN201980080806A CN113164287B CN 113164287 B CN113164287 B CN 113164287B CN 201980080806 A CN201980080806 A CN 201980080806A CN 113164287 B CN113164287 B CN 113164287B

- Authority

- CN

- China

- Prior art keywords

- belt

- composite

- main body

- continuous

- layer

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/15577—Apparatus or processes for manufacturing

- A61F13/15756—Applying tabs, strips, tapes, loops; Knotting the ends of pads

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/15577—Apparatus or processes for manufacturing

- A61F13/15585—Apparatus or processes for manufacturing of babies' napkins, e.g. diapers

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/15577—Apparatus or processes for manufacturing

- A61F13/15707—Mechanical treatment, e.g. notching, twisting, compressing, shaping

- A61F13/15739—Sealing, e.g. involving cutting

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/45—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the shape

- A61F13/49—Absorbent articles specially adapted to be worn around the waist, e.g. diapers

- A61F13/49007—Form-fitting, self-adjusting disposable diapers

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/45—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the shape

- A61F13/49—Absorbent articles specially adapted to be worn around the waist, e.g. diapers

- A61F13/494—Absorbent articles specially adapted to be worn around the waist, e.g. diapers characterised by edge leakage prevention means

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/45—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the shape

- A61F13/49—Absorbent articles specially adapted to be worn around the waist, e.g. diapers

- A61F13/494—Absorbent articles specially adapted to be worn around the waist, e.g. diapers characterised by edge leakage prevention means

- A61F13/49406—Absorbent articles specially adapted to be worn around the waist, e.g. diapers characterised by edge leakage prevention means the edge leakage prevention means being at the crotch region

- A61F13/49413—Absorbent articles specially adapted to be worn around the waist, e.g. diapers characterised by edge leakage prevention means the edge leakage prevention means being at the crotch region the edge leakage prevention means being an upstanding barrier

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/45—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the shape

- A61F13/49—Absorbent articles specially adapted to be worn around the waist, e.g. diapers

- A61F13/494—Absorbent articles specially adapted to be worn around the waist, e.g. diapers characterised by edge leakage prevention means

- A61F13/49466—Absorbent articles specially adapted to be worn around the waist, e.g. diapers characterised by edge leakage prevention means the edge leakage prevention means being at the waist region

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/45—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the shape

- A61F13/49—Absorbent articles specially adapted to be worn around the waist, e.g. diapers

- A61F13/496—Absorbent articles specially adapted to be worn around the waist, e.g. diapers in the form of pants or briefs

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/15577—Apparatus or processes for manufacturing

- A61F2013/15821—Apparatus or processes for manufacturing characterized by the apparatus for manufacturing

- A61F2013/15861—Apparatus or processes for manufacturing characterized by the apparatus for manufacturing for bonding

- A61F2013/1591—Apparatus or processes for manufacturing characterized by the apparatus for manufacturing for bonding via adhesive

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/45—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the shape

- A61F13/49—Absorbent articles specially adapted to be worn around the waist, e.g. diapers

- A61F13/494—Absorbent articles specially adapted to be worn around the waist, e.g. diapers characterised by edge leakage prevention means

- A61F13/49406—Absorbent articles specially adapted to be worn around the waist, e.g. diapers characterised by edge leakage prevention means the edge leakage prevention means being at the crotch region

- A61F13/49413—Absorbent articles specially adapted to be worn around the waist, e.g. diapers characterised by edge leakage prevention means the edge leakage prevention means being at the crotch region the edge leakage prevention means being an upstanding barrier

- A61F2013/4944—Absorbent articles specially adapted to be worn around the waist, e.g. diapers characterised by edge leakage prevention means the edge leakage prevention means being at the crotch region the edge leakage prevention means being an upstanding barrier having multiple barriers

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/45—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the shape

- A61F13/49—Absorbent articles specially adapted to be worn around the waist, e.g. diapers

- A61F13/494—Absorbent articles specially adapted to be worn around the waist, e.g. diapers characterised by edge leakage prevention means

- A61F2013/4948—Absorbent articles specially adapted to be worn around the waist, e.g. diapers characterised by edge leakage prevention means the edge leakage prevention means being elastic

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/45—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the shape

- A61F13/49—Absorbent articles specially adapted to be worn around the waist, e.g. diapers

- A61F13/494—Absorbent articles specially adapted to be worn around the waist, e.g. diapers characterised by edge leakage prevention means

- A61F2013/49493—Absorbent articles specially adapted to be worn around the waist, e.g. diapers characterised by edge leakage prevention means the edge leakage prevention means being or forming three-dimensional barrier with raised lateral side-or end-wall

Abstract

The invention provides a method for manufacturing a disposable diaper capable of forming a pocket by a waist belt properly. A method for manufacturing a disposable diaper comprises: a main body continuous body conveying step (S20) for conveying a main body continuous body (C11) formed by connecting structural members of the main body (11) including the skin surface side sheet in the front-back direction; a composite manufacturing step (S100) for manufacturing a belt composite in which a first waist belt and a second waist belt, which are respectively disposed on a first main body section and a second main body section adjacent to each other in a main body conveyance direction which is a conveyance direction of a main body continuum, are connected to each other in a front-rear direction and have a main body adhesive for joining to the main body continuum; a tape joining step (S40) of joining the tape composite to the continuous body of the main body so as to straddle a main body boundary that is a boundary between the first main body and the second main body; and a cutting step (S50) for cutting the main body continuous body and the tape composite body at the main body boundary.

Description

Technical Field

The present invention relates to a method for manufacturing a disposable diaper having a waist belt.

Background

A disposable diaper having a waist band disposed on the skin-facing surface side of a skin-facing side sheet in a rear waistline region is known (see, for example, patent document 1). A joining region to be joined to the skin surface side sheet is provided at an opposing portion of the waist band located closest to the skin surface side sheet. The waist belt is folded back at the rear end edge of the joining region toward the side away from the skin-side sheet with a fold extending in the width direction as a base point. The folded-back waist band is raised from the joining region of the waist band and the skin-surface-side sheet by being contracted by the elastic member. A pocket opening toward the front side is formed by a space sandwiched between a folded-back region and a joining region of the waist belt. The pocket accommodates therein excrement moving toward the waist opening side.

Prior art documents

Patent document

Patent document 1: U.S. patent publication No. 2018/71155

Disclosure of Invention

The waist belt of patent document 1 is separated from the rear end edge of the disposable diaper. In the method of manufacturing a disposable diaper of patent document 1, a waist belt is joined to a main body continuous body in which structural members of the disposable diaper are continuous in the front-rear direction, and the main body continuous body is cut at positions of outer edges in the front-rear direction of the diaper, thereby obtaining the respective diapers. In this case, if the waist belt is disposed in the vicinity of the rear end edge of the disposable diaper, the waist belt may be cut off accidentally. In addition, the end of the waist belt may be curled or twisted during conveyance, resulting in poor shaping.

Further, the rear end edge of the waist belt of patent document 1 is formed by a region folded back to the rear side, and stands up toward the wearer side. In the production of a disposable diaper, the rear end edge of the waist belt tends to curl during conveyance, and there is a possibility that the waist belt may be accidentally twisted. Therefore, the pocket by the lap belt may not be appropriately formed.

Therefore, a method for manufacturing a disposable diaper capable of appropriately forming the pocket by the waist band is desired.

A method for manufacturing a disposable diaper according to one aspect is a method for manufacturing a disposable diaper having a waist belt disposed on a skin-facing surface of a skin-facing side sheet, the method comprising: a main body continuous body conveying step of conveying a main body continuous body in which structural members of the main body portion including the skin surface side sheet are continuously formed in a front-rear direction; a composite manufacturing step of manufacturing a belt composite in which a first waist belt and a second waist belt, which are respectively disposed on a first main body portion and a second main body portion adjacent to each other in a main body conveyance direction that is a conveyance direction of the main body continuum, are connected to each other in the front-rear direction, and the belt composite has a main body adhesive for joining to the main body continuum; a tape joining step of joining the tape composite to the body continuous body so as to straddle a body boundary that is a boundary between the first body portion and the second body portion; and a cutting step of cutting the body continuous body and the tape composite at the body boundary.

Drawings

Fig. 1 is a schematic plan view of a first disposable diaper according to an embodiment viewed from a skin-facing surface side.

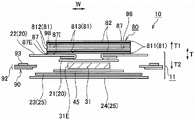

Fig. 2 is a schematic cross-sectional view taken along line 2A-2A shown in fig. 1.

Fig. 3 is a schematic cross-sectional view taken along line 3A-3A shown in fig. 1.

Fig. 4 is a schematic cross-sectional view taken along line 4A-4A shown in fig. 1 in an extended state.

Fig. 5 is a schematic sectional view taken along line 4A-4A shown in fig. 1 in a natural state.

Fig. 6 is a view schematically showing a wearing state in a cross section taken in fig. 5.

FIG. 7 is a cross-sectional view of the second disposable diaper taken along line 4A-4A shown in FIG. 1.

Fig. 8 is a diagram for explaining the overall flow of the method for manufacturing a disposable diaper.

Fig. 9 is a diagram schematically showing a complex transport step in plan view.

Fig. 10 is a view schematically showing the cross section shown in fig. 9.

Detailed Description

(1) Brief description of the embodiments

At least the following matters will be made clear from the description of the present specification and the drawings.

A method for manufacturing a disposable diaper according to one aspect is a method for manufacturing a disposable diaper having a waist belt disposed on a skin-facing surface of a skin-facing side sheet, the method comprising: a main body continuous body conveying step of conveying a main body continuous body in which structural members of a main body portion including the skin surface side sheet are continuously formed in the front-rear direction; a composite manufacturing step of manufacturing the belt composite in which a first waist belt and a second waist belt, which are respectively disposed on a first main body portion and a second main body portion adjacent to each other in a main body conveyance direction that is a conveyance direction of the main body continuum, are connected to each other in the front-rear direction, and the belt composite has a main body adhesive for joining to the main body continuum; a tape joining step of joining the tape composite to the body continuous body so as to straddle a body boundary that is a boundary between the first body portion and the second body portion; and a cutting step of cutting the body continuous body and the tape composite at the body boundary.

According to this aspect, since the tape composite on which the body adhesive is applied is joined to the body continuous body, even when the position of the tape composite relative to the body continuous body is slightly shifted, it is possible to suppress a problem that the body adhesive is exposed from a region where the tape composite and the body continuous body overlap, and a problem that the body adhesive is not disposed in a region where the tape composite and the body continuous body overlap. Therefore, the pocket by the lap belt can be formed appropriately. Since the belt composite is disposed so as to straddle the front-rear direction end edges of the main body portion, the waist belt can be disposed at the front-rear direction outer end edges of the disposable diaper, and the problem of accidentally cutting the waist belt can be suppressed. Further, since the first waist band and the second waist band of the band composite are integrated, it is possible to suppress a problem such as the end portion of the waist band curling or twisting near the outer end edge in the front-rear direction of the disposable diaper.

According to a preferred aspect, in the composite manufacturing step, the body adhesive may be applied to a central region of the tape composite that spans the body boundary. According to this aspect, the rigidity of the disposable diaper in the vicinity of the outer edge in the front-rear direction can be improved by the body adhesive. Further, the waist belt can be joined to the outer edge of the disposable diaper in the front-rear direction. Therefore, the waist belt can be disposed close to the waist opening side. The storage space for the excrement by the waist belt can be formed to a position away from the buttocks, and leakage can be further suppressed.

According to a preferred aspect, the central region may be separated from the outer edge of the belt composite in the front-rear direction. According to this aspect, the waist belt is not joined to the skin-side sheet between the outer edge and the central region of the belt composite in the front-rear direction, and serves as a storage space that is raised from the skin-side sheet. A joining region for joining the waist belt is provided at the outer edge of the disposable diaper in the front-rear direction, and a space for containing excrement can be formed at a position further inward in the front-rear direction than the joining region.

According to a preferred aspect, in the composite manufacturing step, the body adhesive may be applied to side regions located at both ends of the tape composite in the width direction. According to this aspect, the joint regions surrounding the receiving space for excrement can be provided on both sides in the width direction of the receiving space, and lateral leakage of excrement in the receiving space can be suppressed.

According to a preferred aspect, the belt composite may have a first layer that is in contact with the main body continuous body and a second layer that is located on a skin-facing surface side of the first layer, and in the composite manufacturing step, the belt composite may be manufactured such that the first layer and the second layer are separated from each other in a region overlapping the central region and the first layer and the second layer are connected to each other at outer edges of both the front and rear directions of the belt composite. According to the present aspect, the first layer and the second layer of the waist belt are connected at the outer end edges in the front-rear direction of the belt composite and separated in the central region. Since the outer edges of both the front and rear directions of the belt composite are connected, the outer edges of the front and rear directions of the belt composite can be suppressed from curling during conveyance.

According to a preferred aspect, the composite body manufacturing step may include a sheet joining step of folding a sheet in which the first layer and the second layer are continuous at one outer end edge of the belt composite body in the front-rear direction, and joining the first layer and the second layer of the folded sheet at the other outer end edge of the belt composite body in the front-rear direction. According to this aspect, the waist belt can be formed so that the first layer and the second layer are connected to each other at the inner end edges in the front-rear direction of the waist belt (the outer end edges in both the front-rear direction of the belt composite). Further, the outer edge of one of the front and rear direction of the belt composite is folded, and the end edge is less likely to curl than in a structure in which the first layer and the second layer are joined to each other at the outer edge of both the front and rear direction of the belt composite. Further, as compared with the method of bonding the separate first layer and second layer, the positional displacement of the first layer and second layer at the outer end edge in the front-rear direction of the belt composite can be suppressed, and the material cost can be reduced.

According to a preferred aspect, in the belt joining step, the belt composite may be joined to the main continuous body such that the other outer edge of the belt composite is located on an upstream side in the main body conveying direction and the one outer edge of the belt composite is located on a downstream side in the main body conveying direction. According to this aspect, the outer edge of one of the tape composites is folded, and the first layer and the second layer of the tape composite are not separated. Since the outer edge of one side of the belt composite is located on the downstream side in the conveying direction, the end of the belt composite is less likely to curl during conveyance, and the belt composite can be conveyed in a stable state.

According to a preferred embodiment, the composite manufacturing step may include: a belt continuous body conveying step of conveying a belt continuous body in which structural members constituting the belt composite are continuous in the width direction of the waist belt; and a tape cutting step of cutting the continuous tape member at a boundary between the tape composite members adjacent to each other in a tape conveying direction, which is a conveying direction of the continuous tape member, to obtain the respective tape composite members, wherein the composite member manufacturing step includes a turning step of rotating the tape composite members so that a front-rear direction of the tape composite members coincides with a front-rear direction of the main body continuous member. According to this aspect, each of the tape composites can be produced from the tape continuous body. Further, the disposable diaper can be manufactured by conveying the continuous body in a state of being continuous in the width direction of the disposable diaper, conveying the continuous body in a state of being continuous in the front-rear direction of the disposable diaper, and joining the tape complex and the continuous body in a line in the same direction after conveying the continuous body and the continuous body in different directions. Further, by conveying the continuous body in a state of being continuous in the width direction, when the adhesive is provided over the entire region in the width direction of the waist belt, the adhesive can be continuously applied in the width direction of the continuous body of the belt, and the occurrence of unevenness in application can be suppressed.

According to a preferred aspect, the composite producing step may include a body adhesive application step of applying the body adhesive to the continuous tape member. According to this aspect, after the body adhesive is applied to the continuous tape body, each tape composite can be manufactured. The body adhesive can be applied continuously as compared to the step of applying the body adhesive to each tape composite. Therefore, the step of applying the body adhesive can be simplified, and the positional deviation of the body adhesive in each tape composite can be suppressed.

According to a preferred aspect, the body adhesive coating step may include: a first coating step of coating the body adhesive with a space in the belt conveying direction; and a second coating step of continuously coating the body adhesive in the belt conveying direction, wherein in the first coating step, the body adhesive is coated on side regions located at both ends of the belt composite in the width direction, and in the second coating step, the body adhesive is coated on a central region located at the center of the belt composite in the front-rear direction so as to overlap with a part of the side regions. According to this aspect, the body adhesive can be applied to the side regions and the central region of the tape composite by the first application step and the second application step. In addition, since the side regions overlap with a part of the central region, the adhesive strength of the region at both ends of the belt composite in the width direction and at the center of the belt composite in the front-rear direction can be increased. The regions at both ends in the width direction of the belt composite and at the center in the front-rear direction of the belt composite are the outer edges of the outer edges in the front-rear direction of the waist belt, that is, the corners located near the waist opening. By increasing the joint strength of the corner portions, the waist belt can be prevented from being unintentionally peeled.

According to a preferred embodiment, the composite manufacturing step may include: a sheet conveying step of conveying a sheet continuous body in which sheets constituting the waist belt are continuous; an elastic member disposing step of disposing an elastic member continuous body in which belt elastic members constituting the waist belt are continuous, on the sheet continuous body; and a fixing material arranging step of arranging fixing materials for fixing the belt elastic members to the sheet continuous body at intervals in the belt conveying direction, wherein in the fixing material arranging step, the fixing materials are not arranged at both ends in the width direction of the belt composite, and the fixing materials are arranged at the center in the width direction of the belt composite. According to this aspect, the center in the width direction of the waist belt is easily raised with respect to the skin surface side sheet by contraction of the belt elastic member, and the storage space for excrement is more easily formed. Further, no fixing material is provided at both ends in the width direction of the belt composite, and the belt elastic member in a contracted state is not disposed. The tape composite has a main body adhesive at both ends in the width direction thereof in the first coating step, and is a portion to be joined to the main body continuous body. The belt composite is made to face-contact the main body continuous body by making it difficult for contraction due to the belt elastic member to occur at both ends of the belt composite in the width direction, and thereby the joint area is easily ensured.

According to a preferred aspect, the continuous body may have a body center region located at the center in a body orthogonal direction orthogonal to the body transport direction, and body side regions located on both sides of the body center region in the body orthogonal direction, and in the body side regions, recessed portions corresponding to leg hole openings of the disposable diaper may be arranged at intervals in the transport direction, and the body center region may be located on an inner side in the body orthogonal direction than the recessed portions, and in the tape joining step, the tape composite may be arranged only in the body center region. According to this aspect, the recessed portion is not formed in the central region of the main body, and the structural members of the disposable diaper continue in the conveyance direction. On the other hand, the main body side region is formed with depressions at intervals, and the structural member of the disposable diaper is discontinuous in the conveyance direction. Therefore, in the main body side region, when the main body continuous body is pulled in the conveying direction, tension may not be applied uniformly, causing variation in tension, and stable conveyance may not be performed. In contrast, in the body central region, when the body continuous body is pulled in the conveying direction, tension is uniformly applied, and stable conveyance is possible. By disposing the belt composite in the center region of the main body, the curling of the waist belt due to the curling of the main body continuum can be suppressed, and the waist belt can be stably conveyed.

(2) Disposable diaper with integrated simple structure

Hereinafter, a disposable diaper according to an embodiment will be described with reference to the drawings. In the following description of the drawings, the same or similar parts are denoted by the same or similar reference numerals. However, the drawings are schematic, and it should be noted that the ratio of the dimensions and the like are different from those in reality. Therefore, specific dimensions and the like should be determined with reference to the following description. In addition, the drawings may include portions having different dimensional relationships or ratios from each other.

The disposable diaper is a tape-type disposable diaper. The disposable diaper of the present invention may be a tape-type disposable diaper or a pants-type disposable diaper. The disposable diaper of the present embodiment is configured to be continuously manufactured by a manufacturing method described later. The first disposable diaper 10X and the second disposable diaper 10Y which are continuous on the production line have a different structure in a part of the waist belt. In the present embodiment, the first disposable diaper 10X is explained in detail, and the same structure of the first disposable diaper 10X and the second disposable diaper 10Y is explained as the structure of the common disposable diaper 10, and the structure of the second disposable diaper 10Y different from the first disposable diaper 10X is explained later. Fig. 1 is a schematic plan view of a first disposable diaper 10 according to the embodiment, as viewed from the skin-facing surface side. Fig. 2 is a schematic sectional view taken along the 2A-2A section of the disposable diaper shown in fig. 1. Fig. 3 is a schematic cross-sectional view taken along section 3A-3A of the disposable diaper shown in fig. 1. Fig. 1 to 3 show a disposable diaper in an extended state. In the present invention, the elongation state refers to the following state: the disposable diaper 10 is stretched to a state where no wrinkles are formed. In the present invention, the natural state refers to the following state: the disposable diaper 10 contained in the package is taken out of the package and left to stand in an atmosphere of 20 ℃. + -. 2 ℃ and a relative humidity of 60%. + -. 5% RH for 24 hours. Fig. 4 is a schematic cross-sectional view taken along line 4A-4A shown in fig. 1 in an extended state. Fig. 5 is a schematic sectional view taken along line 4A-4A shown in fig. 1 in a natural state. In the schematic cross-sectional views shown in fig. 2 to 5, the respective members are shown separated in the thickness direction T for convenience of explanation, but are in contact in the thickness direction T in an actual product. Fig. 6 is a view schematically showing a wearing state in a cross section taken in fig. 5. The BL shown in fig. 6 shows the contour line of the body of the wearer.

The disposable diaper 10 has a front-back direction L and a width direction W orthogonal to each other. The front-back direction L is defined by a direction extending to the front side and the back side of the body. In other words, the front-back direction L is a direction extending in the front-back direction in the disposable diaper 10 after being unfolded. The disposable diaper 10 has a thickness direction T orthogonal to both the front-back direction L and the width direction W. The thickness direction T extends along the skin facing surface side T1 facing the wearer and the non-skin facing surface side T2 opposite to the skin facing surface side T1.

The disposable diaper 10 has a front waistline region S1, a rear waistline region S2, and a crotch region S3. The front waistline region S1 is a region opposed to the front waistline (abdomen) of the wearer. The back waistline region S2 is a region facing the back waistline (back) of the wearer, and includes a region on which the body is placed when worn. The crotch region S3 is a region located in the crotch of the wearer and disposed between the front waistline region S1 and the rear waistline region S2. The crotch region S3 is a region provided with leg hole openings 65 arranged around the legs of the wearer. The leg hole openings 65 are portions recessed inward in the width direction from the outer edge of the disposable diaper.

The disposable diaper 10 has a main body portion 11 and a waist belt 80. The main body 11 has at least an absorbent core 31 and a skin side sheet 20. The waist belt 80 is disposed on the skin-facing surface side of the body 11. The main body portion 11 includes an absorbent core 31 containing an absorbent material. The absorbent core 31 contains absorbent material such as comminuted pulp or superabsorbent polymers (SAP) or mixtures thereof. The absorbent core 31 may be covered with a core wrap not shown. The absorbent core 31 and the core wrap may be used to constitute an absorbent body. The core wrap layer may be formed of a crepe paper or an SMS nonwoven fabric, and is disposed on the skin-facing surface side T1 of the absorbent core 31 and the non-skin-facing surface side T2 of the absorbent core 31.

As shown in fig. 2 and 3, the main body 11 of the disposable diaper 10 includes a skin-side sheet 20, and the skin-side sheet 20 is positioned closer to the skin-facing surface side T1 than the absorbent core 31. The skin-side sheet 20 covers the absorbent core 31 and is disposed over the entire disposable diaper 10. The skin-side sheet 20 of the present embodiment includes a top sheet 21 and a pair of side sheets 22. In the disposable diaper having the core wrap, the skin-side sheet 20 is a sheet positioned closer to the skin-facing surface side T1 than the core wrap. The surface sheet 21 may be disposed across the center of the width direction W of the absorbent core 31. The side sheets 22 may be arranged to cover both outer sides of the front sheet 21. The front sheet 21 and the side sheets 22 may be made of liquid-permeable sheets such as nonwoven fabric and perforated plastic film, for example.

Here, the outer side portion in the present invention means a portion that includes an outer edge in the width direction W and occupies a certain range in the width direction W, and the outer edge means an outer edge in the width direction W. The inner side portion is a portion that includes an inner edge in the width direction W and occupies a certain range in the width direction W, and the inner edge is an inner edge in the width direction W.

The main body portion 11 of the disposable diaper 10 has a non-skin-side sheet 25, and the non-skin-side sheet 25 is positioned closer to the non-skin facing surface side T2 than the absorbent core 31. The non-skin-side sheet 25 covers the absorbent core 31 and is disposed over the entire disposable diaper. The non-skin-side sheet 25 of the present embodiment includes a back sheet 23 and an exterior sheet 24. In the disposable diaper having the core wrap, the non-skin surface side sheet 25 is a sheet located closer to the non-skin surface side T2 than the core wrap. The back sheet 23 is a liquid-impermeable sheet, and a laminate nonwoven fabric mainly composed of a polyethylene sheet, polypropylene, or the like, a breathable resin film, a sheet obtained by joining a breathable resin film to a nonwoven fabric such as a spun-bonded nonwoven fabric or a spunlace nonwoven fabric, or the like can be used. The exterior sheet 24 may be provided on the non-skin-facing surface side T2 of the back sheet 23. The outer sheet 24 may be made of a liquid-permeable nonwoven fabric. The length of the back sheet 23 in the width direction W may be shorter than the length of the exterior sheet 24 in the width direction W, and the length of the back sheet 23 in the front-rear direction L may be shorter than the length of the exterior sheet 24 in the front-rear direction L.

The fastening tape 90 is provided in the rear waist region S2. The fastening band 90 has a base 92 and a locking portion 93. At least a part of the base portion 92 is joined between the skin-side sheet 20 and the non-skin-side sheet 25, and extends outward in the width direction W from the skin-side sheet 20 and the non-skin-side sheet 25. The locking portion 93 is provided on the base portion 92, and is detachably engaged with the target portion 95 (see fig. 1). The fastening tape 90 extends in the width direction W in the rear waistline region S2, and is engaged with the target portion 95 to hold the disposable diaper 10 on the body of the wearer. The target portions 95 are disposed in the front waistline region S1, and are configured to be engaged with the fastening tapes 90, respectively.

The disposable diaper 10 has a waist belt 80 in the back waistline region S2, and the waist belt 80 is disposed on the skin-facing surface side T1 of the skin-facing side sheet 20. The waist belt 80 is configured to be stretchable in the width direction, to be lifted from the skin-side sheet 20 when worn, and to form a first pocket P1 for receiving excrement. The first pocket P1 accommodates excrement moving toward the waist opening 66 side, and constitutes the pocket of the present invention. The structure of the waist belt 80 will be described in detail later. The waist opening 66 is a portion which is formed by the rear end edge 10R and the front end edge 10F of the disposable diaper and surrounds the waist in a state where the fastening tape 90 is fastened to the target portion 95. The waist opening 66 may be formed by a front end edge of the body portion and a rear end edge of the body portion.

A leg hole elastic member 42 extending in the front-rear direction L may be provided between the side sheet 22 and the back sheet 23 or between the side sheet 22 and the exterior sheet 24. The leg hole elastic members 42 may be formed of band-shaped stretchable panels stretchable in the front-rear direction L. The disposable diaper 10 is fitted around the leg circumferences when worn by contraction of the leg circumference elastic members 42. The leg hole elastic members 42 are disposed along the leg hole opening portions 65 in at least the crotch region S3 at positions outward of the absorbent core 31 in the width direction W. The leg hole elastic members 42 are disposed between the exterior sheet 24 and the side sheet 22 and between the back sheet 23 and the side sheet 22.

Waist elastic members 45 extending in the width direction W may be provided between the side sheet 22 and the back sheet 23 and between the side sheet 22 and the exterior sheet 24. The waist elastic member 45 may be formed of a substantially rectangular stretch panel which stretches in the width direction W. The waist elastic member 45 is joined between the skin-side sheet 20 and the non-skin-side sheet 25. More specifically, as shown in fig. 4, the waist elastic members 45 are joined between the absorbent core 31 and the non-skin-side sheet 25 or between the skin-side sheet 20 and the non-skin-side sheet 25 in a state of being elongated in the width direction W. The disposable diaper 10 fits around the waist when worn by contraction of the waist elastic member 45. The waist elastic members 45 are disposed at least in the rear waist region S2.

(3) Structure of waist belt

Next, the structure of the waist belt 80 will be described in detail. The waist belt 80 has a first waist belt 80X of the first disposable diaper 10X and a second waist belt of the second disposable diaper 10Y. Fig. 2 to 6 are sectional views of a first disposable diaper 10X having a first waist belt 80X, and fig. 7 is a sectional view of a second disposable diaper 10Y having a second waist belt 80Y with reference to fig. 4. The waist belt 80 may have a sheet 81 and a belt elastic member 82. The sheet 81 may be a stack of a plurality of sheets. The belt elastic member 82 may be engaged with the sheet 81. In another mode, the waist belt 80 may not have the belt elastic member 82 and the sheet 81 itself may have elasticity. The sheet 81 of the waist belt 80 of the present embodiment may have a three-layer structure including a first nonwoven fabric layer 811, a second nonwoven fabric layer 812, and a film layer 813 disposed between the first nonwoven fabric layer 811 and the second nonwoven fabric layer 812. The first nonwoven fabric layer 811 and the second nonwoven fabric layer 812 may be formed of the same nonwoven fabric. The first nonwoven fabric layer 811 is located on the side of the waist belt 80 closest to the skin-side sheet 20. In other embodiments, the waist belt 80 may be formed of only the film layer 813, or may be formed of only the film layer 813 and the first nonwoven layer 811. The first nonwoven fabric layer 811 and the second nonwoven fabric layer 812 may be formed of different nonwoven fabrics.

The waist belt 80 may have a first layer 83 and a second layer 86, the first layer 83 being in contact with the skin-facing side sheet 20 of the body 11, and the second layer 86 being positioned closer to the skin-facing surface side T1 than the first layer 83. It may be that the first layer 83 and the second layer 86 are each constituted by the sheet 81 of three-layer construction. The first layer 83 of the first waist belt 80X is continuous with the second layer 86 at the outer edge (front end edge) of the waist belt 80 on the crotch region side, and is separated at the outer edge (rear end edge) of the waist belt 80 on the waist opening side. The first layer 83 is a portion that can be brought into contact with the skin-side sheet 20. The first layer 83 and the second layer 86 of the first waist belt 80X are connected and laminated to each other via the fold FL. The first layer 83 of the first waist band is formed by a portion that is not folded back with the fold line FL as a base point. The fold FL is located at the front end edge of the first layer. The first layer of the present embodiment is located on the rear side of the fold line FL. In fig. 4, the first layer 83 of the first waist belt 80X is indicated by hatching.

The first layer and the second layer of the second waist belt 80Y are not connected but joined via a joint in a laminated state. That is, the inner end edge in the front-rear direction of the waist belt is not formed with the fold FL, and the end edge joining portion 99 is provided in which the front end edge of the first layer 83 and the front end edge of the second layer 86 are joined. In fig. 7, a first nonwoven layer 811 of the second layer 86 is joined to a second nonwoven layer 812. In the sheet folding step S115 to be described later, the nonwoven fabric continuous body C811 constituting the second nonwoven fabric layer 812 and the first nonwoven fabric layer 811 is folded back at the inner end edge of the second layer 86, and the first nonwoven fabric layer 811 and the second nonwoven fabric layer 812 of the second layer 86 are disposed with the film layer 813 interposed therebetween. In the first and second waist belts, the same reference numerals are used for the same structures and the description thereof is omitted.

The belt elastic member 82 is made of a linear or belt-like elastic member, and is fixed to the sheet 81 in a state of being elongated in the width direction W. The belt elastic member 82 of the present embodiment is fixed between the first nonwoven layer 811 and the film layer 813. The belt elastic members 82 are disposed at intervals in the front-rear direction L. The belt elastic member 82 is provided in plurality in each of the first layer 83 and the second layer 86.

The lumbar belt 80 has a rising portion 85 configured to be able to rise with respect to the skin surface side sheet 20, and a base end portion including a base end edge serving as a rising fulcrum of the rising portion 85. The base end portion has a first base end portion 87 located at the outer side portion of the waist belt 80 and a second base end portion 84 located at the rear end portion of the waist belt 80. The first proximal portion 87 and the second proximal portion 84 are portions where the first layer 83 is joined to the skin surface side sheet 20. In fig. 1, the first base end 87 and the second base end 84 are indicated by hatching differently. The first layer 83 of the waist belt 80 is joined to the skin side sheet 20 in a region where the first base end 87 and the second base end 84 overlap, and forms a rising portion that can rise with respect to the skin side sheet 20 in the other region.

As shown in fig. 5 and 6, a first pocket P1 that opens toward the front side is formed by a space that is sandwiched between the standing portion of the first layer and the skin side sheet 20. The excrement spreading from the crotch region S3 side to the waist opening 66 side can be received by the first pocket P1. The rear end edge of the first pocket P1 is the front end edge 84F of the second base end portion 84, and the outer edge of the first pocket P1 is the inner edge of the first base end portion 87. That is, the first pocket P1 is surrounded by the front end edge 84F of the second base end 84 and the inner edges of the pair of first base end 87. The front end edge of the first pocket P1 becomes the front end edge of the first layer 83.

The first base end edge is a boundary between the first base end portion 87 and the rising portion 85, and is adjacent to the rising portion 85 in the width direction W. The first base end edge is constituted by an inner edge 87I (see fig. 2) of the first base end portion 87. The first base end 87 extends outward in the width direction W from the first base end edge. The outer edge 87E of the first proximal end portion 87 may be disposed in the vicinity of the outer edge 80E of the waist belt 80, and may reach the outer edge 80E of the waist belt 80. The second base end edge is a boundary between the second base end portion 84 and the rising portion 85, and is adjacent to the rising portion 85 in the front-rear direction. The second base end edge is constituted by a leading end edge 84F (see fig. 4) of the second base end portion 84. The second base end portion 84 extends rearward from the second base end edge. The rear end edge 84R of the second base end portion 84 may extend to the rear end edge 80R of the waist belt 80, or may coincide with the rear end edge 10R of the disposable diaper 10.

The waist belt 80 is configured to be stretchable and contractible in the width direction W. The waist belt 80 may be configured to be stretchable in the width direction by the belt elastic member 82, or may be configured to be stretchable in the width direction by making the sheet stretchable. The waist belt 80 may be configured such that at least the rising portion is contractible, or may be configured such that the whole of the rising portion and the base end portion is contractible.

At least a part of the second layer 86 constitutes the rising portion 85. The second layer 86 is a portion folded back toward the skin surface side with the fold line FL as a base point or a portion joined to the first layer via a joining portion. In fig. 4 and 7, the second layer 86 is a portion of the waist band not marked with diagonal lines. The second layer 86 is located on the side away from the skin side sheet 20 and serves as a body contact region. Since the second layer 86 is provided to contact the body, the storage space by the first pocket P1 is more easily secured. The waist belt 80 of the modified example may not have the second layer 86. That is, the waist band may be constituted only by the first layer 83, and the fold FL extending in the width direction may not be formed in the waist band.

The second layer 86 extends rearward from the front end edge 83F of the first layer 83. In the extended state, the rear end edge 86R of the second layer 86 and the rear end edge 83R of the first layer 83 may coincide in the front-rear direction L. As shown in fig. 2 and 3, the outer side portion of the second layer 86 is joined to the first layer 83 via a side joining portion 98. The side joint portions 98 are provided in a pair on both sides of the second layer 86 in the width direction. The second layer 86 in the region between the pair of side joining portions 98 constitutes an erected portion 85 erected toward the wearer with respect to the first layer 83.

The rising portion 85 is provided across the first layer 83 and the second layer 86. At least a part of the rising portion 85 is configured to be able to rise toward the skin facing surface side with respect to the proximal end portion. The second pocket P2, which opens to the waist opening 66 side, is formed by the second layer 86 and the first layer 83. As shown in fig. 6, when the first layer 83 is separated from the body in a state where the second layer 86 is in contact with the skin in a worn state, the space of the second pocket P2 is deformed by the movement of the body. For example, when the wearer is in a state of being bent forward, and the waist opening 66 is separated from the waist of the wearer, the space between the second layer 86 and the first layer 83 expands, and the rising portion 85 of the waist band 80 easily follows the body. Therefore, leakage of excrement to the waist opening 66 side can be suppressed. In addition, the rising portion 85 can rise from the base end portion, and even when excrement seeps out in the vicinity of the base end portion, the excrement hardly reaches the wearer. Therefore, the adhesion of excrement to the skin can be suppressed.

The waist belt 80 may be disposed in the rear waist region S2 in the vicinity of the waist opening 66. The front end edge 80F of the waist belt 80 may be located more rearward than the front end edge 90F of the fastening belt 90. The rear end edge 80R of the waist belt may coincide with the rear end edge 10R of the disposable diaper. The outer edge 80E of the waist belt 80 may be positioned further outward in the width direction than the outer edge 31E of the absorbent core 31, or may be positioned further inward in the width direction than the inner edge of the fastening belt 90. The front end edge 84F of the second base end portion 84 may be positioned more rearward than the rear end edge 31R of the absorbent core 31 in the extended state. In the disposable diaper 10 of the present embodiment, the rear end edge 84R of the second base end portion 84, the rear end edge 83R of the first layer 83, the rear end edge 80R of the waist belt, and the rear end edge 10R of the disposable diaper 10 are aligned in the front-rear direction L.

(4) Method for manufacturing disposable diaper

Next, a method for manufacturing the disposable diaper having the above-described structure will be described with reference to fig. 8 to 10. Fig. 8 is a diagram for explaining the overall flow of the method for manufacturing a disposable diaper. The method of manufacturing a disposable diaper is configured to continuously manufacture a first disposable diaper 10X and a second disposable diaper 10Y. A method for manufacturing a disposable diaper includes at least: a body continuous body conveying step S20 of conveying a body continuous body C11 in which the structural members of the body 11 are continuously formed in the front-rear direction; a composite production step S100 of producing a belt composite M80 in which the waist belt 80 is connected in the front-rear direction; a tape joining step S40 of joining the tape complex M80 on the main body continuous body C11; and a cutting step S50 of cutting the main body continuous body C11 and the tape composite M80.

In the body continuous body conveying step S20, the body continuous body C11 in which the structural members of the body portion 11 are continuous in the front-rear direction L is conveyed. The body conveyance direction MD11, which is the conveyance direction of the body continuous body C11, is along the front-back direction L of the disposable diaper 10. The body continuous body C11 includes at least a first body portion 11X and a second body portion 11Y adjacent to each other in the body conveyance direction MD11, and the first body portion and the second body portion may be repeatedly continuous. The first body portion 11X constitutes a first disposable diaper 10X, and the second body portion 11Y constitutes a second disposable diaper 10Y. The main body continuous body C11 has at least: a continuous skin sheet formed by continuously forming the skin side sheet 20; an absorbent core 31 disposed at a distance in the front-rear direction; and a continuous non-skin surface sheet formed by continuously forming the non-skin surface side sheet 25, which are laminated in the thickness direction.

The waist belt 80 is disposed at the boundary between the first body portion 11X and the second body portion 11Y. Therefore, in the mode in which the rear end edge of the first body portion 11X is continuous with the rear end edge of the second body portion 11Y, the waist belt 80 is disposed at least on the rear end edge 10R side of the disposable diaper 10, and in the mode in which the rear end edge of the first body portion 11X is continuous with the front end edge of the second body portion 11Y, the waist belt 80 is disposed on both the rear end edge side and the front end edge side of the disposable diaper. In the body continuous body C11 of the present embodiment, the rear end edge 11R of the first body portion 11X is continuous with the rear end edge 11R of the second body portion 11Y. The front end edge of the second body portion 11Y is connected to the front end edge of the first body portion 11X located on the opposite side. In the mode in which the rear end edge of the first body portion 11X is connected to the rear end edge of the second body portion 11Y, the waist belt 80 can be efficiently disposed in the first body portion 11X and the second body portion 11Y, respectively, without transferring the waist belt 80 to the first body portion 11X and the second body portion 11Y, respectively. In addition, the waist belt 80 can be disposed close to the waist opening 66 side. The storage space for the excrement by the waist belt can be formed to reach a position away from the buttocks, and leakage can be further suppressed.

In the composite manufacturing step S100, a tape composite M80 having a body adhesive HM for joining to the body continuous body C11 is manufactured, the waist tape 80 being connected in the front-rear direction L. The belt complex M80 has a first waist belt 80X disposed in the first body portion 11X and a second waist belt 80Y disposed in the second waist belt 80Y, and is connected to each other in the front-rear direction of the disposable diaper. In the belt complex M80, only the first waist belt 80X is connected to the second waist belt 80Y. In the belt composite M80, the outer end edge in the front-rear direction L of the first waist belt 80X is connected to the outer end edge in the front-rear direction L of the second waist belt 80Y. In the belt composite M80 of the present embodiment, the rear end edge of the first waist belt 80X is connected to the rear end edge of the second waist belt 80Y. The belt composite M80 can be obtained from a belt continuous body C80 (see fig. 9) in which the structural members constituting the belt composite M80 are continuous in the width direction. The composite production step S100 will be described in detail later.

In the tape joining step S40, the tape complex M80 and the body continuous body C11 are joined so as to straddle the body boundary BL11, which is the boundary between the first body portion 11X and the second body portion 11Y. The body boundary BL11 of the present embodiment is a boundary between the rear end edge of the first body portion 11X and the rear end edge of the second body portion 11Y, and is along the width direction of the disposable diaper. In the state of being joined in the tape joining step S40, the front-rear direction L of the tape composite M80 is along the front-rear direction of the main body continuous body C11. The joining of the body continuous body C11 and the tape composite M80 is performed by the body adhesive HM applied to the tape composite M80 in the composite manufacturing step S100. A portion located on the first body portion 11X side with respect to the body boundary BL11 constitutes a first waist belt 80X, and a portion located on the second body portion 11Y side with respect to the body boundary BL11 constitutes a second waist belt 80Y.

In the cutting step S50, the body continuous body C11 and the tape composite M80 are cut at the body boundary BL 11. The body boundary BL11 is along a body orthogonal direction CD11 orthogonal to the body conveyance direction MD 11. The main body continuous body C11 and the tape composite M80 are cut along the main body orthogonal direction CD11 by a cutting device such as a cutter. In this way, the first disposable diaper 10X and the second disposable diaper 10Y are formed continuously, and the respective disposable diapers can be obtained.

The method of manufacturing disposable diapers is configured such that each disposable diaper is obtained after manufacturing the tape composite M80 and joining the tape composite M80 to the main body continuous body C11. Therefore, the waist belt 80 can be disposed at the outer end edge in the front-rear direction of the disposable diaper. Since the belt composite is disposed so as to straddle the front-rear direction end edges of the main body portion, the waist belt can be disposed at the front-rear direction outer end edges of the disposable diaper, and the problem of accidentally cutting the waist belt can be suppressed. Specifically, as a comparative example, there is a production method in which: instead of joining the belt composite to the main body continuous body C11 and cutting the main body continuous body C11, waist belts corresponding to the respective disposable diapers are formed in advance, and the waist belts themselves are joined to the main body continuous body C11. In the present embodiment, the disposable diapers are obtained by cutting the body continuous body C11 together with the tape complex M80, as compared with the manufacturing method of the comparative example, and therefore, the problem of accidentally cutting the waist tape 80 can be suppressed. Therefore, the pocket by the lap belt 80 can be formed appropriately. Further, since the first waist band and the second waist band of the band composite are integrated, it is possible to suppress troubles such as curling or twisting of the end portion of the waist band in the vicinity of the outer edge in the front-rear direction of the disposable diaper. In addition, the waist belt 80 is not separated from the outer edge of the disposable diaper in the front-rear direction, and the rigidity near the waist opening 66 of the disposable diaper can be increased by the waist belt 80. Therefore, troubles such as curling or twisting in the vicinity of the waist opening during transportation can be suppressed. Further, the respective waist belts 80 are obtained after joining the belt composite M80 to the main body continuous body C11. In the manufacture of the waist belt 80, the front-rear outer end edge of the first waist belt 80X is continuous with the front-rear outer end edge of the second waist belt 80Y, and the front-rear outer end edge of the waist belt 80 is difficult to lift. Therefore, the twisting of the waist belt 80 caused by the curling of the outer end edge of the waist belt 80 can be suppressed.

Since the tape composite M80 coated with the body adhesive HM is joined to the body continuous body C11, even when the position of the tape composite M80 relative to the body continuous body C11 is slightly shifted, it is possible to suppress a problem that the body adhesive is exposed from a region where the tape composite M80 and the body continuous body C11 overlap, and a problem that the body adhesive is not disposed in a region where the tape composite M80 and the body continuous body C11 overlap.

As shown in fig. 8, the body continuum C11 may have a body central region R12 and body side regions R11, the body central region R12 being located at the center in the body orthogonal direction CD11, the body side regions R11 being located at both sides in the body orthogonal direction CD11 with respect to the body central region. The body side region R11 is continuous with the body central region R12 in the body conveyance direction MD 11. The body side region R11 is a region in which the recessed portions corresponding to the leg hole openings 65 of the disposable diaper 10 are arranged at intervals in the body conveying direction. The main body side region R11 is located inward of the recessed portions corresponding to the leg hole openings 65 in the main body orthogonal direction CD 11. No recess corresponding to the leg hole opening 65 is formed in the body center region R12. The main body side regions R11 and the main body central region R12 are alternately arranged in the main body orthogonal direction CD 11.

In the tape joining step S40, the tape composite M80 may be disposed only in the main body central region R12. That is, the tape complex M80 may be disposed so as not to overlap the main body side region R11. In the body central region R12 of the body continuous body C11, the structural members of the disposable diaper continue in the body conveyance direction MD 11. On the other hand, the main body side region R11 of the main body continuum C11 is formed with depressions at intervals, and the structural members of the disposable diaper are discontinuous in the main body conveyance direction MD 11. Therefore, in the main body side region R11 of the main body continuous body C11, when the main body continuous body C11 is pulled in the main body conveyance direction MD11, tension may not be applied uniformly, and the tension may be deviated, and stable conveyance may not be performed. In contrast, in the body central region R12 of the body continuous body C11, when the body continuous body C11 is pulled in the body conveyance direction MD11, tension is uniformly applied, and stable conveyance is possible. By disposing the belt complex M80 in the body central region R12 of the body continuous body C11, the curling of the waist belt 80 due to the curling of the body continuous body C11 can be suppressed, and the waist belt 80 can be stably conveyed.

Next, the composite production step S100 will be described in detail with reference to fig. 9 and 10. Fig. 9 is a view schematically showing a complex transport step in plan view, and fig. 10 is a view schematically showing a cross section shown in fig. 9. The composite producing step S100 may include a tape continuous body conveying step S110, a tape cutting step S120, and a rotating step S130.

In the belt continuous body conveying step S110, the belt continuous body C80 in which the structural members constituting the belt complex M80 are continuous in the width direction W of the waist belt 80 is conveyed. The belt conveyance direction MD80, which is the conveyance direction of the belt continuum C80, is along the width direction W of the waist belt 80 in the state of being arranged on the disposable diaper 10. That is, the widthwise outer edge of one tape complex M80 is continuous with the widthwise outer edge of the adjacent tape complex M80.

In the tape cutting step S120, the tape continuous body C80 is cut at the tape boundary BL80 which is the boundary of the adjacent tape composites M80 in the tape conveyance direction MD80, and each tape composite M80 is obtained. The belt conveying direction MD80 is along the width direction of the waist belt 80. The belt boundary BL80 is along the belt orthogonal direction CD80 orthogonal to the belt conveying direction MD80 and along the front-rear direction L of the waist belt 80. In the tape cutting step S120, the tape continuous body C80 is cut along the front-back direction L of the waist tape 80, whereby each tape composite M80 can be obtained.

In the rotation step S130, the tape composite M80 is rotated so that the front-rear direction L of the tape composite M80 coincides with the front-rear direction L of the main body continuous body C11. The body conveyance direction MD11 of the body continuum C11 is along the front-back direction L of the disposable diaper 10, and the belt conveyance direction MD80 of the belt continuum C80 is along the width direction W of the disposable diaper. In the production line of the disposable diaper 10, when the body conveyance direction MD11 is parallel to the belt conveyance direction MD80, for example, and when the front-rear direction L of the disposable diaper in the body continuous body C11 does not coincide with the front-rear direction L of the disposable diaper in the belt composite M80, it is difficult to smoothly set the belt composite M80 on the body continuous body C11. In the turning step S130, the front-back direction of the disposable diaper in the body continuous body C11 is aligned with the front-back direction of the disposable diaper in the tape composite M80, and the tape composite M80 can be easily set on the body continuous body C11 with a gap in the body conveying direction. That is, the disposable diaper can be manufactured by conveying the belt continuous body C80 in a state of being continuous in the width direction of the disposable diaper, conveying the body continuous body C11 in a state of being continuous in the front-rear direction of the disposable diaper, and then joining the belt complex M80 and the body continuous body C11 on the contour line in the same direction. Further, by conveying the continuous body in a state of being continuous in the width direction, when the adhesive is provided over the entire region in the width direction of the waist belt, the adhesive can be continuously applied in the width direction of the continuous body of the belt, and the occurrence of unevenness of the adhesive can be suppressed. In the present embodiment, the main body conveyance direction MD11 is parallel to the belt conveyance direction MD80, and the belt composite M80 is rotated by 90 degrees with respect to the belt conveyance direction MD80 in the rotation step S130. The turning step S130 is performed before the tape joining step S40.

The belt continuous body conveying step S110 of the composite body manufacturing step S100 may include a nonwoven fabric conveying step (sheet conveying step) S111, a film conveying step (sheet conveying step) S112, a fixing material disposing step S113, an elastic member disposing step S114, a sheet bending step S115, a sheet joining step S116, a first coating step (body adhesive material coating step) S117, and a second coating step (body adhesive material coating step) S118.

In the nonwoven fabric conveying step (sheet conveying step) S111, a nonwoven fabric continuous body (sheet continuous body) C811 in which nonwoven fabrics constituting the first nonwoven fabric layer 811 and the second nonwoven fabric layer 812 are continuous is conveyed. The first nonwoven fabric layer 811 and the second nonwoven fabric layer 812 are composed of the same sheet. As shown in fig. 10(a), the region which is not folded back in the sheet folding step S115 constitutes the second nonwoven fabric layer 812, and the region which is folded back in the sheet folding step S115 constitutes the first nonwoven fabric layer 811.

The film conveying step (sheet conveying step) S112 is provided downstream of the nonwoven fabric conveying step (sheet conveying step) S111 in the belt conveying direction MD 80. In the film conveying step (sheet conveying step) S112, a film continuous body (sheet continuous body) C813 formed by continuously conveying films constituting the film layer 813 is disposed on the nonwoven fabric continuous body C811. In the nonwoven fabric conveying step S111 and the film conveying step S112, a sheet continuous body C81 in which the sheets 81 constituting the waist belt 80 are continuous is conveyed. At this time, an adhesive is applied to at least one of the continuous nonwoven fabric body C811 and the continuous film body C813, and the continuous nonwoven fabric body C811 and the continuous film body C813 are bonded via the adhesive. Fig. 10(a) is a cross section along line 10A-10A of fig. 9. The length of the film continuous body C813 in the cross-belt direction CD80 was half the length of the nonwoven fabric continuous body C811 in the cross-belt direction CD 80. The continuous nonwoven fabric C811 is folded in the sheet folding step S115 provided downstream of the film conveying step S112 in the belt conveying direction MD80, whereby a continuous sheet C81 can be produced in which the sheet 81 constituting the waist belt 80 is continuous. Fig. 10(B) is a cross section along the line 10B-10B of fig. 9, showing the sheet continuous body C81 after the sheet bending step S115.

The fixing material arranging step S113 is provided on the downstream side in the belt conveying direction MD80 with respect to the sheet conveying step. In the fixing material arranging step S113, fixing materials for fixing the belt elastic members 82 to the sheet continuous body C81 are arranged at intervals in the belt conveying direction MD 80. The fixing material may be an adhesive. The fixing material disposing step S113 may be on the downstream side of the belt conveying direction MD80 with respect to the elastic member disposing step S114, or may be on the upstream side of the belt conveying direction MD80 with respect to the elastic member disposing step S114. In the fixing material arranging step S113 of the present embodiment, the adhesive is applied to the belt elastic member 82 on the upstream side in the belt conveyance direction MD80 with respect to the elastic member arranging step S114. In another embodiment, the sheet continuous body C81 may be coated with an adhesive. In the fixing material disposing step S113, the fixing material may be disposed at the center in the width direction of the tape composite M80 without disposing the fixing material at both ends in the width direction of the tape composite M80. The center in the width direction of the waist belt 80 is easily raised with respect to the skin-surface-side sheet by contraction of the belt elastic member 82, and a space for accommodating excrement is more easily formed. The belt elastic members 82 in the contracted state are not disposed, and no fixing material is provided at both ends in the width direction of the belt composite M80. The tape composite M80 has a main body adhesive HM at both ends in the width direction thereof in accordance with a first application step described later, and is a portion to be joined to the main body continuous body C11. More specifically, the first body adhesive HM87 formed in the first application step constitutes the first proximal end portion 87 and is joined to the skin surface side sheet 20. The contraction by the belt elastic member 82 is made difficult to occur at both ends in the width direction of the belt composite M80, and the belt composite M80 and the main body continuous body C11 are brought into surface contact, whereby the joint area is easily ensured. In the fixing material arranging step S113, preferably, no fixing material is provided in the region overlapping with the first body adhesive HM87 constituting the first base end portion 87. With this structure, the bonding area between the tape composite M80 and the main body continuous body C11 can be more easily secured.