CN112554431A - Novel integrated keel and ceiling system for assembled ceiling and mounting method - Google Patents

Novel integrated keel and ceiling system for assembled ceiling and mounting method Download PDFInfo

- Publication number

- CN112554431A CN112554431A CN202011574375.0A CN202011574375A CN112554431A CN 112554431 A CN112554431 A CN 112554431A CN 202011574375 A CN202011574375 A CN 202011574375A CN 112554431 A CN112554431 A CN 112554431A

- Authority

- CN

- China

- Prior art keywords

- plate

- ceiling

- riser

- top surface

- keel

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 238000000034 method Methods 0.000 title claims abstract description 17

- 239000012634 fragment Substances 0.000 claims abstract description 19

- 238000005452 bending Methods 0.000 claims description 9

- 239000000725 suspension Substances 0.000 claims description 7

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 claims description 6

- 229910052782 aluminium Inorganic materials 0.000 claims description 6

- 239000000758 substrate Substances 0.000 claims description 4

- 238000009434 installation Methods 0.000 abstract description 22

- 238000005034 decoration Methods 0.000 description 12

- 230000008901 benefit Effects 0.000 description 6

- 238000005516 engineering process Methods 0.000 description 4

- 238000012545 processing Methods 0.000 description 4

- WSFSSNUMVMOOMR-UHFFFAOYSA-N Formaldehyde Chemical compound O=C WSFSSNUMVMOOMR-UHFFFAOYSA-N 0.000 description 3

- 238000009413 insulation Methods 0.000 description 3

- 239000000463 material Substances 0.000 description 3

- 238000010521 absorption reaction Methods 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- 238000012986 modification Methods 0.000 description 2

- 230000004048 modification Effects 0.000 description 2

- 238000002360 preparation method Methods 0.000 description 2

- 230000008569 process Effects 0.000 description 2

- 230000000007 visual effect Effects 0.000 description 2

- 229910000831 Steel Inorganic materials 0.000 description 1

- 238000004378 air conditioning Methods 0.000 description 1

- 230000003796 beauty Effects 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 238000004891 communication Methods 0.000 description 1

- 230000007547 defect Effects 0.000 description 1

- 238000013461 design Methods 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 239000011521 glass Substances 0.000 description 1

- 229910052602 gypsum Inorganic materials 0.000 description 1

- 239000010440 gypsum Substances 0.000 description 1

- 230000036541 health Effects 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 239000011490 mineral wool Substances 0.000 description 1

- 238000004321 preservation Methods 0.000 description 1

- 230000002265 prevention Effects 0.000 description 1

- 239000010959 steel Substances 0.000 description 1

- 238000009423 ventilation Methods 0.000 description 1

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04B—GENERAL BUILDING CONSTRUCTIONS; WALLS, e.g. PARTITIONS; ROOFS; FLOORS; CEILINGS; INSULATION OR OTHER PROTECTION OF BUILDINGS

- E04B9/00—Ceilings; Construction of ceilings, e.g. false ceilings; Ceiling construction with regard to insulation

- E04B9/06—Ceilings; Construction of ceilings, e.g. false ceilings; Ceiling construction with regard to insulation characterised by constructional features of the supporting construction, e.g. cross section or material of framework members

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04B—GENERAL BUILDING CONSTRUCTIONS; WALLS, e.g. PARTITIONS; ROOFS; FLOORS; CEILINGS; INSULATION OR OTHER PROTECTION OF BUILDINGS

- E04B9/00—Ceilings; Construction of ceilings, e.g. false ceilings; Ceiling construction with regard to insulation

-

- E—FIXED CONSTRUCTIONS

- E04—BUILDING

- E04B—GENERAL BUILDING CONSTRUCTIONS; WALLS, e.g. PARTITIONS; ROOFS; FLOORS; CEILINGS; INSULATION OR OTHER PROTECTION OF BUILDINGS

- E04B9/00—Ceilings; Construction of ceilings, e.g. false ceilings; Ceiling construction with regard to insulation

- E04B9/22—Connection of slabs, panels, sheets or the like to the supporting construction

- E04B9/28—Connection of slabs, panels, sheets or the like to the supporting construction with the slabs, panels, sheets or the like having grooves engaging with horizontal flanges of the supporting construction or accessory means connected thereto

Landscapes

- Engineering & Computer Science (AREA)

- Architecture (AREA)

- Physics & Mathematics (AREA)

- Electromagnetism (AREA)

- Civil Engineering (AREA)

- Structural Engineering (AREA)

- Finishing Walls (AREA)

Abstract

The invention discloses a novel integrated keel and ceiling system of an assembled ceiling and an installation method. A novel integral type fossil fragments of assembled furred ceiling includes: a top plate; one end of the first vertical plate is fixedly connected to the middle position of the top plate; the first inclined plate and the second inclined plate are symmetrically arranged on two sides of the first vertical plate, the first end of the first inclined plate is fixedly connected with the first end of the top plate, the first end of the second inclined plate is fixedly connected with the second end of the top plate, and the distance between the first end of the first inclined plate and the first vertical plate is greater than the distance between the second end of the first inclined plate and the first vertical plate; and the second vertical plate and the third vertical plate are symmetrically arranged, the second vertical plate and the third vertical plate are symmetrically arranged on two sides of the first vertical plate, the first end of the second vertical plate is fixedly connected with the second end of the first inclined plate, and the first end of the third vertical plate is fixedly connected with the second end of the second inclined plate.

Description

Technical Field

The invention relates to the technical field of ceiling decoration, in particular to a novel integrated keel and ceiling system of an assembled ceiling and an installation method.

Background

The suspended ceiling is a decoration of the top decoration of the residential environment of a house, in short, the ceiling decoration, and is one of important parts of indoor decoration. The suspended ceiling has the functions of heat preservation, heat insulation, sound insulation and sound absorption, and is also a hidden layer for the projects of electric, ventilation air-conditioning, communication, fire prevention, alarm line equipment and the like. The house ornamentation furred ceiling is common environment in the house ornamentation, and the furred ceiling is different according to the material of decorative board, and the classification is also different. The ceiling decoration material is a main basis for distinguishing ceiling names, and mainly comprises a light steel keel gypsum board ceiling, a mineral wool board ceiling, a splint ceiling, a special-shaped strip aluminum gusset plate ceiling, a square paint-plated aluminum gusset plate ceiling, a colored drawing glass ceiling, an aluminum honeycomb perforated acoustic panel ceiling, a whole-house duplex ceiling and the like. The decorative board takes a very important position in the whole decoration of a room, and the top surface of the room is properly decorated, so that the indoor environment can be beautified, and a colorful indoor space artistic image can be created. When the ceiling decoration material and the design scheme are selected, the principles of saving money, firmness, safety, beauty and practicability are followed.

The industrial assembly technology and the assembly type decoration have the advantages of being green, free of pollution, easy to maintain and free of formaldehyde release, are widely applied in the decoration industry, and the assembly type ceiling technology has a very important position in practical application as an indoor decoration technology. With the advance of factory production and modularized installation in the architectural decoration field, the technology of the current fabricated suspended ceiling is gradually mature, and the problem that different methods are found for installing the suspended ceiling becomes to be urgently solved at present. The installation of the top surface veneer of the existing integrated ceiling is usually to directly clamp two adjacent top surface veneer in the triangular keel, for example, chinese patent CN 201610967547.8 discloses a building ceiling structure, which comprises a plurality of main keels, wherein the ceiling is provided with a plurality of rows of installation holes, the installation holes are internally provided with wall connecting pieces, the main keels are installed on the ceiling through the wall connecting pieces, and the building ceiling structure also comprises a plurality of triangular keels; the main keel and the triangular keel are connected through a triangular keel hanging piece, the triangular keel is provided with buckling plates, the edges of the buckling plates are provided with clamping edges turned upwards, and the clamping edges of two adjacent buckling plates (namely the top surface decorative panel) are clamped in the same triangular keel. Make a triangle fossil fragments can peg graft two adjacent top surface decorative boards simultaneously like this, because top surface decorative board weight is great, long-time back of using, the tight face of clamp of triangle fossil fragments can take place deformation and then influence its clamp force to the top surface decorative board, and the top surface decorative board just has the risk that drops from the triangle fossil fragments like this, and there is the potential safety hazard to indoor resident personnel's life health. On the other hand, after the assembly mode is completed, the lower part of the suspended ceiling is a whole plane, the two adjacent top surface decorative panels are spliced seamlessly, the top surface decorative panels cannot guarantee the consistent smoothness of the edge part of each top surface decorative panel due to the problem of the preparation process, and therefore after splicing, the phenomenon that the splicing seams are uneven and inconsistent due to the fact that the edge parts of the top surface decorative panels are uneven can occur, the integral visual effect of the suspended ceiling is poor, and the attractiveness is affected.

On the other hand, the assembly of two adjacent top surface decorative panels is usually realized by forming a clamping groove with a regular shape on the side surface of the top surface decorative panel, for example, chinese patent CN201911401591.2 discloses a ceiling connector, a ceiling assembly and a ceiling assembly. The furred ceiling connecting piece includes the locating plate, connects the first board of establishing of inlaying, the second of establishing on the locating plate and inlays the board and the third and establish the board, and first inlay establishes the board and inlays with the second and establish the board and set up relatively, and the second inlays establishes the board and inlays with the third and establish the board and set up relatively. The suspended ceiling component comprises a first top plate, a second top plate and a suspended ceiling connecting piece; the first top plate is provided with a first clamping groove, and the second top plate is provided with a second clamping groove; the first embedded end is embedded in the first clamping groove, the second embedded end is embedded in the second clamping groove, the first embedded protrusion abuts against two opposite groove walls in the first clamping groove, and the second embedded protrusion abuts against two opposite groove walls in the second clamping groove. The suspended ceiling assembly comprises a keel, a top plate connecting piece and at least two suspended ceiling components, wherein the at least two suspended ceiling components are sequentially arranged. This kind of mode through seting up the joint recess in the side of top surface decorative board has increased the processing degree of difficulty of top surface decorative board, and need strict control to set up the shape of recess in the course of working, the size is even unanimous, otherwise, the problem that splice seam shape, size are inconsistent appears easily after the top surface decorative board equipment for the holistic visual effect of furred ceiling is poor, influences the aesthetic property.

Disclosure of Invention

In order to overcome the defects of the prior art, the invention aims to provide a novel integrated keel of an assembled ceiling, a ceiling system and an installation method.

In order to solve the problems, the invention adopts the following technical scheme:

a novel integral type fossil fragments of assembled furred ceiling includes:

a top plate;

one end of the first vertical plate is fixedly connected to the middle position of the top plate;

the first inclined plate and the second inclined plate are symmetrically arranged on two sides of the first vertical plate, a first end of the first inclined plate is fixedly connected with a first end of the top plate, a first end of the second inclined plate is fixedly connected with a second end of the top plate, and the distance between the first end of the first inclined plate and the first vertical plate is greater than the distance between the second end of the first inclined plate and the first vertical plate; and

the second riser and the third riser that the symmetry set up, the second riser the third riser symmetry sets up the both sides of first riser, the first end of second riser with the second end fixed connection of first swash plate, the first end of third riser with the second end fixed connection of second swash plate.

Preferably, still include first diaphragm and the second diaphragm that the symmetry set up, first diaphragm second diaphragm symmetry sets up the both sides of first riser, the first end of first diaphragm with the second end fixed connection of first swash plate, the second end fixed connection of first diaphragm is in on the first riser, the first end of second diaphragm with the second end fixed connection of second swash plate, the second end fixed connection of second diaphragm is in on the first riser.

Preferably, still including the first concave arc and the concave arc of second of symmetry setting, first concave arc the concave arc symmetry of second sets up the both sides of first riser, the first end of first concave arc with the second end fixed connection of second riser, the first end of the concave arc of second with the second end fixed connection of third riser.

The invention also provides a ceiling system which comprises the novel integrated keel of the assembled ceiling, the top surface veneer and the top hanging piece; the upper end of the top hanging piece is fixedly connected to the suspended ceiling base layer component, and the lower end of the top hanging piece is connected with the upper end of the integrated keel; one end of the top surface veneer is provided with a clamping joint which is bent upwards, and the top surface veneer is clamped with the clamping groove of the integrated keel through the clamping joint.

Preferably, the width of a splicing seam between two adjacent top surface veneers is 2-3 mm.

Preferably, the suspended ceiling base layer member comprises a hanging rod and a main keel, one end of the hanging rod is fixed on a ceiling, the other end of the hanging rod is connected with the main keel through a connecting piece, and the upper end of the top hanging piece is fixedly connected on the main keel.

Preferably, the upper end of the top hanging piece is provided with a hook, the lower end of the top hanging piece is provided with a clamping groove, the top hanging piece is connected to the main keel in a hanging mode through the hook at the upper end, and the top hanging piece is connected to the integrated keel through the clamping groove at the lower end in a clamping mode with the first inclined plate and the second inclined plate.

Preferably, the top facing panel is a honeycomb aluminous gusset panel.

The invention also provides an installation method of the ceiling system, which comprises the following steps:

(1) fixedly mounting the ceiling substrate member to a ceiling;

(2) fixedly connecting the upper end of the top suspension member to the ceiling base member, and connecting the lower end of the top suspension member to the upper end of the integrated keel;

(3) and the top surface veneer is clamped with the clamping groove of the integral keel in a matching manner through the clamping joint at the end part of the top surface veneer.

Preferably, the top surface veneer is a honeycomb aluminous gusset plate, and the bayonet at the end of the top surface veneer is prepared according to the following method:

(1) bending the end part of the top surface veneer, and forming a V-shaped groove at the bending position;

(2) and bending the bent part of the top surface veneer upwards along the central line of the V-shaped groove to form the clamping connector, wherein the clamping connector is connected with the top surface veneer in an L shape.

Compared with the prior art, the invention has the technical effects that:

the invention provides a novel integrated keel of an assembled ceiling, which can be directly spliced and assembled with two adjacent top surface decorative panels, and splicing seams with consistent shapes and sizes can be formed between the two adjacent top surface decorative panels after assembly, so that the flatness of the plane of the ceiling after installation is enhanced, and the integral attractiveness of the ceiling is improved; on the other hand, compare in the form of direct grafting between traditional top surface decorative board and the triangle fossil fragments, the contact surface between this integral type fossil fragments and the top surface decorative board is bigger, and the joint is more firm, uses safelyr. In addition, the novel integrated keel of the assembled ceiling has a simple structure, can splice and install single top surface decorative panels one by one, is simple and convenient to install and operate, and can improve the installation efficiency of the ceiling.

According to the ceiling system, the two adjacent top surface decorative panels are assembled through the integrated keel, the whole reserved seam of the installed ceiling system is uniform and consistent, and the ceiling system is more attractive. The ceiling system is simple and convenient to install and operate and high in installation efficiency.

The installation method of the ceiling system is simple to operate, has low requirements on the technical level of operators, and can realize the quick assembly of the ceiling system.

Additional advantages, objects, and features of the invention will be set forth in part in the description which follows and in part will become apparent to those having ordinary skill in the art upon examination of the following or may be learned from practice of the invention. The objectives and other advantages of the invention may be realized and attained by the structure particularly pointed out in the written description and claims hereof as well as the appended drawings.

It will be appreciated by those skilled in the art that the objects and advantages that can be achieved with the present invention are not limited to the specific details set forth above, and that these and other objects that can be achieved with the present invention will be more clearly understood from the detailed description that follows.

Drawings

The accompanying drawings, which are included to provide a further understanding of the invention and are incorporated in and constitute a part of this application, illustrate embodiment(s) of the invention and together with the description serve to explain the principles of the invention. Many aspects of the invention will be better understood with reference to the following drawings. The components in the drawings are not necessarily to scale, emphasis instead being placed upon clearly illustrating the principles of the present invention. In the drawings:

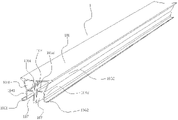

fig. 1 is an isometric view of a novel integral runner for an assembled ceiling provided in accordance with example 1 of the present invention;

FIG. 2 is a schematic cross-sectional view of FIG. 1;

fig. 3 is a schematic view of an assembly structure of a novel integrated keel and a top surface veneer of an assembled ceiling provided in embodiment 1 of the invention;

fig. 4 is a schematic structural diagram of a ceiling system provided in embodiment 2 of the present invention;

FIG. 5 is an enlarged view of a portion of the structure at A in FIG. 4;

fig. 6 is a schematic view of a top surface veneer processing flow provided in embodiment 3 of the present invention.

In the figure, 1, integral type fossil fragments, 2, top surface decorative board, 3, top pendant, 4, jib, 5, main joist, 6, connecting piece, 101, roof, 102, first riser, 1031, first swash plate, 1032, the second swash plate, 1041, the second riser, 1042, the third riser, 1051, first diaphragm, 1052, the second diaphragm, 1061, first concave arc, 1062, the second concave arc, 107, the joint groove, 201, the joint, 301, couple, 302, the joint recess, d, concatenation seam width.

Detailed Description

In order to make the objects, technical solutions and advantages of the present invention more apparent, the present invention will be described in further detail below with reference to the accompanying drawings and examples. It should be understood that the specific embodiments described herein are merely illustrative of the invention and are not intended to limit the invention.

It should be noted that, in order to avoid obscuring the present invention with unnecessary detail, only the structures and/or process steps closely related to the scheme according to the present invention are shown in the drawings, and other details not so related to the present invention are omitted.

In addition, it should be noted that, in the embodiments of the present invention, the term "connected" may be a straight connection or an indirect connection with an additional connecting member in between, unless otherwise specified.

Hereinafter, embodiments of the present invention will be described with reference to the accompanying drawings. In the drawings, the same reference numerals denote the same or similar parts, or the same or similar steps.

Example 1

The embodiment 1 of the invention provides a novel integrated keel for an assembled ceiling, which is structurally shown in fig. 1-3, and the novel integrated keel 1 for the assembled ceiling comprises a top plate 101, a first vertical plate 102, a first inclined plate 1031 and a second inclined plate 1032, wherein the first inclined plate 1031 and the second inclined plate 1032 are symmetrically arranged; one end of the first vertical plate 102 is fixedly connected to the middle position of the top plate 101; the first sloping plate 1031 and the second sloping plate 1032 are symmetrically arranged on two sides of the first vertical plate 102, a first end of the first sloping plate 1031 is fixedly connected with a first end of the top plate 101, a first end of the second sloping plate 1032 is fixedly connected with a second end of the top plate 101, and the distance between the first end of the first sloping plate 1031 and the first vertical plate 102 is greater than the distance between the second end of the first sloping plate 1031 and the first vertical plate 102, i.e. the first sloping plate 1031 and the second sloping plate 1032 incline in an inverted 'eight' shape; the second riser 1041 and the third riser 1042 are symmetrically arranged at two sides of the first riser 102, a first end of the second riser 1041 is fixedly connected with a second end of the first sloping plate 1031, and a first end of the third riser 1042 is fixedly connected with a second end of the second sloping plate 1032. At this time, two clamping grooves 107 with symmetrical structures are formed on two sides of the first vertical plate 102, and the two clamping grooves 107 are respectively used for clamping with two adjacent top surface decorative plates 2.

The integral keel 1 of the embodiment can be directly spliced and assembled with the two adjacent top surface decorative panels 2, splicing seams with the same shape and size can be formed between the two adjacent top surface decorative panels 2 after assembly, the flatness of the plane of the ceiling after installation is enhanced, and the integral attractiveness of the ceiling is improved; on the other hand, compare in the form of direct grafting between traditional top surface decorative board and the triangle fossil fragments, the contact surface between this integral type fossil fragments 1 and the top surface decorative board 2 is bigger, and the joint is more firm, uses safelyr. In addition, the novel integrated keel 1 for the fabricated ceiling is simple in structure, can splice and install the single top surface decorative panels 2 one by one, is simple and convenient to install and operate, and can improve the installation efficiency of the ceiling.

Preferably, the novel integral keel 1 for the fabricated ceiling further comprises a first transverse plate 1051 and a second transverse plate 1052 which are symmetrically arranged, the first transverse plate 1051 and the second transverse plate 1052 are symmetrically arranged at two sides of the first vertical plate 102, a first end of the first transverse plate 1051 is fixedly connected with a second end of the first inclined plate 1031, a second end of the first transverse plate 1051 is fixedly connected to the first vertical plate 102, a first end of the second transverse plate 1052 is fixedly connected with a second end of the second inclined plate 1032, and a second end of the second transverse plate 1052 is fixedly connected to the first vertical plate 102. The first transverse plate 1051 and the second transverse plate 1052 are additionally arranged in the structure of the integrated keel 1, so that the structural rigidity of the integrated keel 1 can be enhanced, the deformation resistance of the integrated keel is improved, and the structure of the integrated keel is more stable; on the other hand, when carrying out the joint between integral type fossil fragments 1 and top surface decorative board 2, first diaphragm 1051 and second diaphragm 1052 can play the effect of limiting plate, prevent that top surface decorative board 2 from excessively going into in integral type fossil fragments 1, do benefit to the planar level and smooth unanimity of furred ceiling after the equipment. At this time, the clamping grooves 107 for clamping the top facing plate 2 are formed between the first vertical plate 102 and the first horizontal plate 1051 and the second horizontal plate 1052 symmetrically arranged at both sides thereof, and the second vertical plate 1041 and the third vertical plate 1042.

Preferably, the novel integral keel 1 for the fabricated ceiling further comprises a first concave arc plate 1061 and a second concave arc plate 1062 which are symmetrically arranged, the first concave arc plate 1061 and the second concave arc plate 1062 are symmetrically arranged at two sides of the first vertical plate 102, a first end of the first concave arc plate 1061 is fixedly connected with a second end of the second vertical plate 1041, and a first end of the second concave arc plate 1062 is fixedly connected with a second end of the third vertical plate 1042. Through connecting first concave arc board 1061 and second concave arc board 1062 respectively at the tip of second riser 1041 and third riser 1042, can make the opening of the joint groove 107 of integral type fossil fragments 1 downside formation be the arc and expand the mouth, more make things convenient for the joint operation between joint groove 107 and the top surface decorative board 2 of integral type fossil fragments 1.

Example 2

The embodiment 2 of the invention provides a ceiling system, the structure of which is shown in fig. 4 and 5, and the ceiling system comprises a novel integrated keel 1 of an assembled ceiling, a top surface veneer 2 and a top hanging piece 3 in the embodiment 1; the upper end of the top hanging piece 3 is fixedly connected to the suspended ceiling base layer component, and the lower end of the top hanging piece 3 is connected with the upper end of the integrated keel 1; one end of the top surface veneer 2 is provided with a clamping joint 201 which is bent upwards, and the top surface veneer 2 is clamped with the clamping groove 107 of the integral keel 1 through the clamping joint 201.

According to the ceiling system, the two adjacent top surface decorative panels 2 are assembled through the integrated keel 1, the whole reserved seam of the installed ceiling system is uniform and consistent, and the ceiling system is more attractive. The ceiling system is simple and convenient to install and operate and high in installation efficiency.

Preferably, the width of a splicing seam between two adjacent top surface veneers 2 is 2-3 mm. The too wide or too narrow splicing seam can not control the seam and has beautiful appearance. More preferably, the width d of the splice seam between two adjacent top surface veneers 2 is 2.5mm, which makes the actual installation easier. In addition, the process splicing seam is formed after the two adjacent top surface decorative panels 2 of the suspended ceiling system are assembled, and when the local top surface decorative panel 2 of the suspended ceiling is damaged and needs to be replaced, compared with the suspended ceiling which is spliced seamlessly, the process splicing seam is more convenient for an operator to detach the single top surface decorative panel 2 from the suspended ceiling.

Preferably, the suspended ceiling base member comprises a suspender 4 and a main keel 5, one end of the suspender 4 is fixed on the ceiling, the other end of the suspender 4 is connected with the main keel 5 through a connecting piece 6, and the upper end of the top hanging piece 3 is fixedly connected on the main keel 5. More preferably, the upper end of the top hanging piece 3 is provided with a hook 301, the lower end of the top hanging piece 3 is provided with a clamping groove 302, the top hanging piece 3 is hung on the main keel 5 through the hook 301 at the upper end, and the top hanging piece 3 is clamped with the first sloping plate 1031 and the second sloping plate 1032 of the integrated keel 1 through the clamping groove 302 at the lower end. In this way, the main keel 5 of the suspended ceiling base layer component is fixedly connected with the top hanging piece 3 in a hook 301 mode, which is equivalent to clamping; and the top hanging piece 3 is connected with the integrated keel 1 in a clamping manner, and all parts of the whole ceiling system are connected in a simple and convenient clamping manner, so that the assembly operation of the ceiling is simpler and more convenient, and the installation efficiency is improved.

Preferably, the top facing sheet 2 is a honeycomb aluminous gusset. The honeycomb aluminum buckle plate not only has good functions of sound absorption, heat insulation and the like, but also has light weight, convenient installation and operation, durable after installation and difficult damage.

Example 3

The embodiment 3 of the invention also provides an installation method of the ceiling system, which comprises the following steps:

(1) fixedly mounting the ceiling substrate member to a ceiling;

(2) the upper end of the top hanging piece 3 is fixedly connected to the suspended ceiling base layer component, and the lower end of the top hanging piece 3 is connected with the upper end of the integrated keel 1;

(3) the top veneer 2 is matched and clamped with the clamping groove 107 of the integral keel 1 through the clamping joint 201 at the end part of the top veneer. A top surface decorative board 2 is connected respectively to the left and right sides of an integral type fossil fragments 1, assembles each top surface decorative board 2 to integral type fossil fragments 1 in proper order on, up to accomplishing the installation of whole furred ceiling.

The installation method of the ceiling system is simple to operate, has low requirements on the technical level of operators, and can realize the quick assembly of the ceiling system.

Preferably, the top veneer 2 is a honeycomb aluminous gusset plate, and the clamping joint 201 at the end of the top veneer 2 is prepared according to the following method, the preparation flow is shown in fig. 6, and the processing sequence from a to B to C is carried out:

(1) bending the end part of the top veneer 2, and forming a V-shaped groove at the bending position;

(2) and bending the bent part of the top surface veneer 2 upwards along the center line of the V-shaped groove to form a clamping joint 201, wherein the clamping joint 201 is connected with the top surface veneer 2 in an L shape.

The top surface veneer 2 is assembled with the integrated keel 1 in a clamping mode through the bent clamping joint 201 at the end part of the top surface veneer 2, and compared with a mode that a clamping groove is formed in the side surface of the top surface veneer 2, the processing flow of the top surface veneer 2 is simpler, the shape and the size of the assembled splicing seam are uniform, and the integral ceiling is more attractive.

The present invention is not limited to the above-described specific embodiments, and various modifications and variations are possible. Any modifications, equivalents, improvements and the like made to the above embodiments in accordance with the technical spirit of the present invention should be included in the scope of the present invention.

Claims (10)

1. The utility model provides a novel integral type fossil fragments of assembled furred ceiling which characterized in that includes:

a top plate;

one end of the first vertical plate is fixedly connected to the middle position of the top plate;

the first inclined plate and the second inclined plate are symmetrically arranged on two sides of the first vertical plate, a first end of the first inclined plate is fixedly connected with a first end of the top plate, a first end of the second inclined plate is fixedly connected with a second end of the top plate, and the distance between the first end of the first inclined plate and the first vertical plate is greater than the distance between the second end of the first inclined plate and the first vertical plate; and

the second riser and the third riser that the symmetry set up, the second riser the third riser symmetry sets up the both sides of first riser, the first end of second riser with the second end fixed connection of first swash plate, the first end of third riser with the second end fixed connection of second swash plate.

2. The novel integral type fossil fragments of assembled furred ceiling of claim 1, its characterized in that still includes first diaphragm and the second diaphragm that the symmetry set up, first diaphragm, the second diaphragm symmetry sets up the both sides of first riser, the first end of first diaphragm with the second end fixed connection of first swash plate, the second end fixed connection of first diaphragm is in on the first riser, the first end of second diaphragm with the second end fixed connection of second swash plate, the second end fixed connection of second diaphragm is in on the first riser.

3. The novel integral type fossil fragments of assembled furred ceiling of claim 2, characterized in that still includes first concave arc and the second concave arc of symmetry setting, first concave arc, the second concave arc symmetry sets up the both sides of first riser, the first end of first concave arc with the second end fixed connection of second riser, the first end of second concave arc with the second end fixed connection of third riser.

4. A suspended ceiling system, which is characterized by comprising the novel integrated keel, the top surface veneer and the top hanging piece of the fabricated suspended ceiling as claimed in any one of claims 1-3; the upper end of the top hanging piece is fixedly connected to the suspended ceiling base layer component, and the lower end of the top hanging piece is connected with the upper end of the integrated keel; one end of the top surface veneer is provided with a clamping joint which is bent upwards, and the top surface veneer is clamped with the clamping groove of the integrated keel through the clamping joint.

5. The suspended ceiling system of claim 4, wherein the width of the splicing seam between two adjacent top surface decorative panels is 2-3 mm.

6. A suspended ceiling system according to claim 5, wherein the suspended ceiling substrate member includes a suspension bar and a main runner, the suspension bar being fixed to the ceiling at one end and connected at the other end to the main runner by a connector, the top suspension member being fixedly connected at its upper end to the main runner.

7. The suspended ceiling system of claim 6, wherein a hook is arranged at the upper end of the top hanging piece, a clamping groove is arranged at the lower end of the top hanging piece, the top hanging piece is hung on the main keel through the hook at the upper end, and the top hanging piece is clamped with the first inclined plate and the second inclined plate of the integrated keel through the clamping groove at the lower end.

8. A suspended ceiling system according to claim 7, wherein the top facing sheet is a honeycomb aluminum gusset.

9. A method of installing a suspended ceiling system according to any one of claims 4 to 8, comprising the steps of:

(1) fixedly mounting the ceiling substrate member to a ceiling;

(2) fixedly connecting the upper end of the top suspension member to the ceiling base member, and connecting the lower end of the top suspension member to the upper end of the integrated keel;

(3) and the top surface veneer is clamped with the clamping groove of the integral keel in a matching manner through the clamping joint at the end part of the top surface veneer.

10. The method of installing a ceiling system of claim 9, wherein the top facing sheet is a honeycomb aluminum gusset, and the snap joints at the ends of the top facing sheet are prepared by:

(1) bending the end part of the top surface veneer, and forming a V-shaped groove at the bending position;

(2) and bending the bent part of the top surface veneer upwards along the central line of the V-shaped groove to form the clamping connector, wherein the clamping connector is connected with the top surface veneer in an L shape.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202011574375.0A CN112554431A (en) | 2020-12-28 | 2020-12-28 | Novel integrated keel and ceiling system for assembled ceiling and mounting method |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202011574375.0A CN112554431A (en) | 2020-12-28 | 2020-12-28 | Novel integrated keel and ceiling system for assembled ceiling and mounting method |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN112554431A true CN112554431A (en) | 2021-03-26 |

Family

ID=75033565

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202011574375.0A Pending CN112554431A (en) | 2020-12-28 | 2020-12-28 | Novel integrated keel and ceiling system for assembled ceiling and mounting method |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN112554431A (en) |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN205990692U (en) * | 2016-08-11 | 2017-03-01 | 浙江得春实业有限公司 | A kind of furred ceiling |

| CN111005487A (en) * | 2019-12-30 | 2020-04-14 | 浙江亚厦装饰股份有限公司 | Reinforcing piece, panel subassembly and assembled furred ceiling |

| CN211622212U (en) * | 2019-12-25 | 2020-10-02 | 北京马尔贝拉科技发展有限公司 | Decorate quick mounting structure of furred ceiling |

| CN214614965U (en) * | 2020-12-28 | 2021-11-05 | 浙江亚厦装饰股份有限公司 | Novel integral type fossil fragments of assembled furred ceiling and furred ceiling system |

-

2020

- 2020-12-28 CN CN202011574375.0A patent/CN112554431A/en active Pending

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN205990692U (en) * | 2016-08-11 | 2017-03-01 | 浙江得春实业有限公司 | A kind of furred ceiling |

| CN211622212U (en) * | 2019-12-25 | 2020-10-02 | 北京马尔贝拉科技发展有限公司 | Decorate quick mounting structure of furred ceiling |

| CN111005487A (en) * | 2019-12-30 | 2020-04-14 | 浙江亚厦装饰股份有限公司 | Reinforcing piece, panel subassembly and assembled furred ceiling |

| CN214614965U (en) * | 2020-12-28 | 2021-11-05 | 浙江亚厦装饰股份有限公司 | Novel integral type fossil fragments of assembled furred ceiling and furred ceiling system |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN112443076A (en) | Connecting member of ceiling decorative panel, ceiling system and mounting method | |

| CN112554425A (en) | Fall-level ceiling connecting piece capable of being installed rapidly, ceiling system and installation method | |

| CN112443127A (en) | Directly-card-inserting special-shaped veneer, ceiling system and installation method | |

| CN111962746A (en) | I-shaped part for connecting adjacent panels and installation method | |

| CN214614965U (en) | Novel integral type fossil fragments of assembled furred ceiling and furred ceiling system | |

| CN214614935U (en) | Can install fast and fall level furred ceiling connecting piece and furred ceiling system | |

| CN214461713U (en) | Connecting component and furred ceiling system of furred ceiling decorative board | |

| CN214614957U (en) | Connecting component and suspended ceiling system for single veneer upper jacking | |

| CN112554431A (en) | Novel integrated keel and ceiling system for assembled ceiling and mounting method | |

| CN212427763U (en) | Component for quickly connecting ceiling boards | |

| CN215670809U (en) | But special-shaped decorative board of direct card formula and furred ceiling system | |

| CN212427762U (en) | Structure for preventing middle deformation of ceiling board | |

| CN215253889U (en) | Drop level furred ceiling binding off structure | |

| CN214614961U (en) | General embedded decorative board mosaic structure of furred ceiling | |

| CN212427748U (en) | I-shaped part for connecting adjacent panels | |

| CN217128684U (en) | Suspended ceiling structure with small top surface installation space | |

| CN215670458U (en) | Splicing component | |

| CN214531438U (en) | Scale formula furred ceiling structure | |

| CN112554428A (en) | Connecting member for single veneer upper jacking, ceiling system and mounting method | |

| CN211037499U (en) | Slim fossil fragments furred ceiling structure | |

| CN208650379U (en) | A kind of ceiling hanging code | |

| CN209323918U (en) | A kind of arc glass ceiling device of wall and the transition of smallpox nature | |

| CN221168338U (en) | Glass fiber suspended ceiling with windproof and air pressure-resistant shaking mechanism | |

| CN215253888U (en) | Close mounting structure that pieces together of decorative board | |

| CN215888902U (en) | Ceiling plate with embedded hanging pieces |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination |