CN111358335A - Detachable grading and filtering device of handheld dust collector - Google Patents

Detachable grading and filtering device of handheld dust collector Download PDFInfo

- Publication number

- CN111358335A CN111358335A CN202010265972.9A CN202010265972A CN111358335A CN 111358335 A CN111358335 A CN 111358335A CN 202010265972 A CN202010265972 A CN 202010265972A CN 111358335 A CN111358335 A CN 111358335A

- Authority

- CN

- China

- Prior art keywords

- detachable

- dust

- air

- filtering device

- sponge

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L5/00—Structural features of suction cleaners

- A47L5/12—Structural features of suction cleaners with power-driven air-pumps or air-compressors, e.g. driven by motor vehicle engine vacuum

- A47L5/22—Structural features of suction cleaners with power-driven air-pumps or air-compressors, e.g. driven by motor vehicle engine vacuum with rotary fans

- A47L5/24—Hand-supported suction cleaners

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L9/00—Details or accessories of suction cleaners, e.g. mechanical means for controlling the suction or for effecting pulsating action; Storing devices specially adapted to suction cleaners or parts thereof; Carrying-vehicles specially adapted for suction cleaners

- A47L9/10—Filters; Dust separators; Dust removal; Automatic exchange of filters

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L9/00—Details or accessories of suction cleaners, e.g. mechanical means for controlling the suction or for effecting pulsating action; Storing devices specially adapted to suction cleaners or parts thereof; Carrying-vehicles specially adapted for suction cleaners

- A47L9/10—Filters; Dust separators; Dust removal; Automatic exchange of filters

- A47L9/16—Arrangement or disposition of cyclones or other devices with centrifugal action

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L9/00—Details or accessories of suction cleaners, e.g. mechanical means for controlling the suction or for effecting pulsating action; Storing devices specially adapted to suction cleaners or parts thereof; Carrying-vehicles specially adapted for suction cleaners

- A47L9/10—Filters; Dust separators; Dust removal; Automatic exchange of filters

- A47L9/16—Arrangement or disposition of cyclones or other devices with centrifugal action

- A47L9/1608—Cyclonic chamber constructions

Abstract

The invention particularly discloses a detachable grading filtering device of a handheld dust collector, which comprises a motor assembly; the motor assembly includes a housing; a cavity is arranged in the shell; a driving air suction motor is arranged on one side of the cavity; also comprises a dust barrel; the side wall of the dust barrel is provided with an air inlet; the dust barrel is detachably connected with the shell; a cyclone cylinder assembly is arranged in the dust barrel; and a HEPA component is arranged between the cyclone cylinder component and the driving air suction motor. The invention improves the dust filtration performance of the whole product by increasing the filtration grade and improving the dust filtration effect of each grade.

Description

Technical Field

The invention relates to the field of dust collectors, in particular to a detachable grading filtering device of a handheld dust collector.

Background

Along with the better and better quality of life, the sanitary requirements of people on the household environment are higher and higher, but because the life pressure and the working pressure are increased with the rise day by day, the sanitary requirements are urgently released from the heavy household cleaning and sanitary work, so a large amount of household cleaning equipment is available on the market to improve the household environmental sanitation, for example, dust collectors, sweeping robots, mopping machines and the like of various brands are available, the traditional dust collector generally only can not exceed four-stage filtration, and the dust filtration effect of each stage is poor, so that the cleaning effect is seriously influenced; the traditional dust collector generally only can not exceed four-stage filtration, and the dust filtration effect of each stage is poor, so that the cleaning effect is seriously influenced.

Therefore, we propose a detachable graded filtering device of a handheld dust collector to solve the existing technical problems.

Disclosure of Invention

The technical problem to be solved by the invention is that: the utility model provides a hierarchical filter equipment of hand-held type dust catcher detachable, through increasing filtration grade and promoting the filter equipment of straining the dirt effect at different levels and then improving whole product and strain the dirt effect.

A detachable graded filtering device of a handheld dust collector comprises a motor assembly; the motor assembly includes a housing; a cavity is arranged in the shell; a driving air suction motor is arranged on one side of the cavity; also comprises a dust barrel; the side wall of the dust barrel is provided with an air inlet; the dust barrel is detachably connected with the shell; a cyclone cylinder assembly is arranged in the dust barrel; and a HEPA component is arranged between the cyclone cylinder component and the driving air suction motor.

Adopt above-mentioned technical scheme: the dirt bucket is installed in complete machine upper portion front end, the main effect is that the dirt is held and is formed the whirlwind die cavity with other parts, constitute first order filtration, most dust particle can be isolated, whirlwind section of thick bamboo subassembly is installed inside the dirt bucket, the main action is let the dirt bucket produce the whirlwind that has the direction of rotation, produce suction after the drive induced draft motor circular telegram, outside air flows into the dirt bucket along the air intake in, form whirlwind through the effect of whirlwind section of thick bamboo subassembly, filterable speed can be accelerated on the one hand, on the other hand can avoid large granule thing to cause the jam.

Preferably, the cyclone cartridge assembly comprises a cyclone cartridge; one end of the cyclone cylinder is provided with an upper cover; and the middle part of the upper cover is provided with a through hole for communicating the dust barrel with the cavity.

Further preferably, a lower cover is arranged in the middle of the cyclone cylinder; and a stainless steel mesh is sleeved between the lower cover and the upper cover.

Further preferably, a first filtering sponge is arranged between the upper cover and the HEPA component.

Further preferably, the upper cover is provided with an air guide block; the air guide block is arranged corresponding to the air inlet.

Further preferably, a stop block is arranged at the air outlet end of the air guide block; the stop block and the air guide block are rotatably installed.

Further preferably, the other end of the air guide block is provided with a curved surface; the curved surface is spirally arranged along the outer wall of the stainless steel net.

Adopt above-mentioned technical scheme: after the drive induced draft motor circular telegram produced suction, outside air flows into in the dirt bucket along the air intake, through the guide effect of air guide piece and curved surface, make the air rotatory and form whirlwind along a whirlwind section of thick bamboo, the lower cover can isolate most dust particles, and whirlwind not only can accelerate filterable speed, can also avoid large granule thing to cause the stainless steel mesh to block up, first filtration sponge and sea handkerchief subassembly are passed respectively along the through-hole of covering to whirlwind after the stainless steel mesh filters, the filter effect is better.

Preferably, the motor assembly further comprises a second filter sponge; the second filtering sponge is arranged in an inverted U shape; the second filter sponge is arranged at one end, far away from the driving air suction motor, of the cavity.

Further preferably, the side wall of the shell is symmetrically provided with air outlets; the air outlet corresponds to the position of the second filtering sponge.

Further preferably, a heat dissipation bump is arranged on the outer side wall of the shell; the heat dissipation projection is arranged around the circumferential direction of the housing.

Adopt above-mentioned technical scheme: the air spills over from the air outlet again after the sponge is filtered to the second, and the most dust particle that the one-level filtration left over in further separation goes out to promote the air quality of discharge shell, the heat dissipation lug be provided with do benefit to the area of contact of increase shell and air, can lead away the heat that the motor produced that induced drafts of drive rapidly, guarantee that the drive motor that induced drafts is in normal temperature within range work.

Compared with the prior art, the invention has the following beneficial effects: the invention is driven by a motor to generate suction force and form cyclone, air passes through a specific path with various filtering devices and places dust particles at the bottom of a dust barrel, thereby realizing the complete isolation of the dust particles and clean air and finally achieving the cleaning effect, and the passing filtering devices are mainly divided into five stages, namely five filtering devices, namely a dust barrel cyclone filter, a steel mesh filter, a front-stage sponge filter, a middle-stage HEPA filter and a tail-end sponge filter; the dust barrel is arranged at the front end of the upper part of the whole machine and mainly used for storing dust and forming a cyclone cavity with other parts to form a first-stage filter, most dust particles can be separated out, the cyclone barrel assembly is arranged in the dust barrel and mainly used for enabling the dust barrel to generate cyclone with a rotating direction, when a driving air suction motor is electrified to generate suction, external air flows into the dust barrel along an air inlet, the air rotates along the cyclone barrel and forms cyclone through the guiding action of the air guide block and the curved surface, the lower cover can separate most dust particles, the cyclone can not only accelerate the filtering speed, but also can avoid the blockage of a stainless steel mesh caused by large-particle objects, the cyclone respectively passes through the first filter sponge and the HEPA assembly along through holes in the upper cover after being filtered by the stainless steel mesh, and the filtering effect is better; the air spills over from the air outlet again after the sponge is filtered to the second, and the most dust particle that the one-level filtration left over in further separation goes out to promote the air quality of discharge shell, the heat dissipation lug be provided with do benefit to the area of contact of increase shell and air, can lead away the heat that the motor produced that induced drafts of drive rapidly, guarantee that the drive motor that induced drafts is in normal temperature within range work.

Drawings

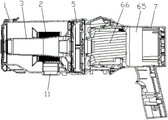

Fig. 1 is an exploded view of the present invention.

Fig. 2 is an assembly view of the present invention.

Fig. 3 is a cross-sectional view of the present invention.

Fig. 4 is a schematic structural diagram of the motor assembly of the present invention.

FIG. 5 is a schematic view of a cyclone assembly (with stainless steel mesh) of the present invention.

FIG. 6 is a schematic view of a cyclone cartridge assembly of the present invention (without stainless steel mesh).

In the figure: 1-a dust bucket; 2-stainless steel mesh; 3-a cyclone cylinder assembly; 4-a first filter sponge; 5-a HEPA component; 6-a motor assembly; 7-a second filter sponge; 11-an air inlet; 31-a cyclone; 32-lower cover; 33-upper cover; 34-a curved surface; 35-an air guide block; 36-a stop; 61-a housing; 62-heat dissipating bumps; 63-air outlet; 64-a handle; 65-a cavity; 66-drive the suction motor.

Detailed Description

The present invention will now be described in further detail with reference to the accompanying drawings. These drawings are simplified schematic views illustrating only the basic structure of the present invention in a schematic manner, and thus show only the constitution related to the present invention.

In the present invention, it should be noted that the terms "upper", "lower", "inner", "outer", etc. indicate orientations or positional relationships based on those shown in the drawings, which are merely for convenience of describing the present invention and simplifying the description, but do not indicate or imply that the referred device or element must have a specific orientation, be constructed in a specific orientation, and be operated, and thus should not be construed as limiting the present invention; the terms "first", "second" and "first" are used for descriptive purposes only and are not to be construed as indicating or implying relative importance; furthermore, unless expressly stated or limited otherwise, the terms "mounted," "connected," and "connected" are to be construed broadly, as they may be fixedly connected, detachably connected, or integrally connected, for example; can be mechanically or electrically connected; the two elements can be directly connected or indirectly connected through an intermediate medium, and the two elements can be communicated with each other, wherein the 'detachable connection' can be a threaded connection, can be clamped with each other, and can also be indirectly connected through the intermediate medium. The specific meanings of the above terms in the present invention can be understood in specific cases to those skilled in the art.

Example 1

Referring to fig. 1 to 6, the present invention provides a detachable classification filtering apparatus for a handheld vacuum cleaner, including a motor assembly 6; the motor assembly 6 comprises a housing 61; a cavity 65 is arranged in the shell 61; a driving suction motor 66 is arranged on one side of the cavity 65; also comprises a dust barrel 1; the side wall of the dust barrel 1 is provided with an air inlet 11; the dust barrel 1 is detachably connected with the shell 61; a cyclone barrel component 3 is arranged in the dust barrel 1; a HEPA component 5 is arranged between the cyclone cylinder component 3 and the driving air suction motor 66; dust bucket 1 installs in complete machine upper portion front end, the main effect is the dust accumulation and forms the whirlwind die cavity with other parts, constitute first order filtration, can isolate most dust particle, whirlwind section of thick bamboo subassembly 3 is installed inside the dust bucket, the main effect is that let dust bucket 1 produce the whirlwind that has the direction of rotation, produce suction after the drive induced draft motor 66 circular telegram, outside air flows into in dust bucket 1 along air intake 11, through whirlwind section of thick bamboo subassembly 3 effect formation whirlwind, filterable speed can be accelerated on the one hand, on the other hand can avoid large granule thing to cause the jam.

In the present embodiment, the cyclone assembly 3 comprises a cyclone 31; an upper cover 33 is arranged at one end of the cyclone cylinder 31; a through hole (not shown) for communicating the dust barrel 1 and the cavity 65 is arranged in the middle of the upper cover 33; the middle part of the cyclone cylinder 31 is provided with a lower cover 32; the stainless steel net 2 is sleeved between the lower cover 32 and the upper cover 33; a first filtering sponge 4 is arranged between the upper cover 33 and the HEPA component 5; the upper cover 33 is provided with an air guide block 35; the air guide block 35 is arranged corresponding to the air inlet 11; a stop block 36 is arranged at the air outlet end of the air guide block 35; the stop block 36 and the air guide block 35 are rotatably arranged; the other end of the air guide block 35 is provided with a curved surface 34; the curved surface 34 is spirally arranged along the outer wall of the stainless steel net 2; after the drive induced draft motor 66 circular telegram produced suction, outside air flows into in the dirt bucket 1 along air intake 11, through the guide effect of air guide block 35 and curved surface 34, make the air rotatory and form whirlwind along a whirlwind section of thick bamboo 31, lower cover 32 can isolate most dust particles, and whirlwind not only can accelerate filterable speed, can also avoid large granule thing to cause stainless steel mesh 2 to block up, whirlwind passes first filter sponge 4 and sea handkerchief subassembly 5 respectively along the through-hole on the upper cover 33 after stainless steel mesh 2 filters, the filter effect is better.

In this embodiment, the motor assembly 6 further comprises a second filter sponge 7; the second filtering sponge 7 is arranged in an inverted U shape; the second filter sponge 7 is arranged at one end of the cavity 65 far away from the driving suction motor 66; the side wall of the shell 61 is symmetrically provided with air outlets 63; the air outlet 63 corresponds to the second filtering sponge 7; the outer side wall of the shell 61 is provided with a heat dissipation lug 62; the heat dissipation protrusions 62 are arranged around the circumferential direction of the housing 61; the air spills over from air outlet 62 again after second filter sponge 7, and the most dust particle that the one-level filtration left over in the further separation was gone up to promote the air quality of discharge shell 61, the heat dissipation lug 62 be provided with do benefit to the area of contact of increase shell 61 and air, can lead away the heat that the drive induced draft motor 66 produced rapidly, guarantees that the drive induced draft motor 66 is in normal temperature range and works.

As shown in fig. 1 to 6, the present invention is driven by a motor to generate suction and form cyclone, air passes through a specific path with various filtering devices, dust particles are placed at the bottom of a dust barrel 1 to realize complete isolation of the dust particles from clean air, and finally a cleaning effect is achieved, the passing filtering devices are mainly divided into five stages, namely, cyclone filtration, steel mesh filtration, front-section sponge filtration, middle-section sea handkerchief filtration and tail-end sponge filtration of the dust barrel, and in the using process:

the suction motor 66 is driven to be electrified to generate suction force, external air flows into the dust barrel 1 along the air inlet 11, and is guided by the air guide block 35 and the curved surface 34, so that the air rotates along the cyclone cylinder 31 to form cyclone, the lower cover 32 can separate most dust particles, and the most dust particles are screwed at the bottom of the dust barrel 1 to complete first-stage filtration;

in the dust collection process, the primary unfiltered dust particles are blocked outside the stainless steel mesh 2 through the small pores on the outer surface of the stainless steel mesh 2 and are screwed at the bottom of the dust barrel 1 under the action of the cyclone, so that secondary filtration is completed;

in the dust collection process, the second-stage unfiltered dust particles are blocked and adsorbed on the surface of the first filtering sponge 4 through the filtering of the first filtering sponge 4, so that the third-stage filtering is completed;

in the dust collection process, the dust particles left after the third-stage unfiltered are blocked and adsorbed on the surface of the HEPA component 5 through the filtration of the HEPA component 5, so that the four-stage filtration is completed;

in the dust absorption process, through the filtration of second filter sponge 7, the dust granule separation that leaves behind the level four unfiltered is adsorbed on second filter sponge 7 surface, accomplishes five levels and filters.

While there have been shown and described what are at present considered the fundamental principles and essential features of the invention and its advantages, it will be apparent to those skilled in the art that the invention is not limited to the details of the foregoing exemplary embodiments, but is capable of other specific forms without departing from the spirit or essential characteristics thereof. The present embodiments are therefore to be considered in all respects as illustrative and not restrictive, the scope of the invention being indicated by the appended claims rather than by the foregoing description, and all changes which come within the meaning and range of equivalency of the claims are therefore intended to be embraced therein. Any reference sign in a claim should not be construed as limiting the claim concerned.

Furthermore, it should be understood that although the present description refers to embodiments, not every embodiment may contain only a single embodiment, and such description is for clarity only, and those skilled in the art should integrate the description, and the embodiments may be combined as appropriate to form other embodiments understood by those skilled in the art.

Claims (10)

1. The utility model provides a hierarchical filter equipment of hand-held type dust catcher detachable which characterized in that: comprises that

A motor assembly including a housing; a cavity is arranged in the shell; a driving air suction motor is arranged on one side of the cavity;

the side wall of the dust barrel is provided with an air inlet; the dust barrel is detachably connected with the shell; a cyclone cylinder assembly is arranged in the dust barrel; and a HEPA component is arranged between the cyclone cylinder component and the driving air suction motor.

2. The detachable graded filtering apparatus of claim 1, wherein the cyclone cylinder assembly comprises a cyclone cylinder; one end of the cyclone cylinder is provided with an upper cover; and the middle part of the upper cover is provided with a through hole for communicating the dust barrel with the cavity.

3. The detachable graded filtering device of claim 2, wherein a lower cover is provided in the middle of the cyclone cylinder; and a stainless steel mesh is sleeved between the lower cover and the upper cover.

4. The detachable graded filtering device of claim 3, wherein a first filtering sponge is arranged between the upper cover and the HEPA component.

5. The detachable graded filtering device of the handheld dust collector as claimed in claim 4, wherein the upper cover is provided with an air guide block; the air guide block is arranged corresponding to the air inlet.

6. The detachable graded filtering device of the handheld dust collector as claimed in claim 5, wherein a stop block is arranged at the air outlet end of the air guide block; the stop block and the air guide block are rotatably installed.

7. The detachable graded filtering device of the handheld dust collector as claimed in claim 6, wherein the other end of the air guide block is provided with a curved surface; the curved surface is spirally arranged along the outer wall of the stainless steel net.

8. The detachable graded filter device of claim 1, wherein the motor assembly further comprises a second filter sponge; the second filtering sponge is arranged in an inverted U shape; the second filter sponge is arranged at one end, far away from the driving air suction motor, of the cavity.

9. The detachable graded filtering device of claim 8, wherein the side wall of the housing is symmetrically provided with air outlets; the air outlet corresponds to the position of the second filtering sponge.

10. The detachable graded filtering device of claim 9, wherein the outer side wall of the housing is provided with a heat dissipating protrusion; the heat dissipation projection is arranged around the circumferential direction of the housing.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010265972.9A CN111358335A (en) | 2020-04-07 | 2020-04-07 | Detachable grading and filtering device of handheld dust collector |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010265972.9A CN111358335A (en) | 2020-04-07 | 2020-04-07 | Detachable grading and filtering device of handheld dust collector |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN111358335A true CN111358335A (en) | 2020-07-03 |

Family

ID=71199163

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202010265972.9A Pending CN111358335A (en) | 2020-04-07 | 2020-04-07 | Detachable grading and filtering device of handheld dust collector |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN111358335A (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN112971587A (en) * | 2021-04-14 | 2021-06-18 | 深圳市杉川机器人有限公司 | Portable dust collector |

Citations (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN2453827Y (en) * | 2000-12-27 | 2001-10-17 | 倪祖根 | Split wirlwind dust-filtering device of cleaner |

| CN201529089U (en) * | 2009-10-16 | 2010-07-21 | 江苏美的春花电器股份有限公司 | Cyclone separation device of dust collector |

| CN106618374A (en) * | 2017-02-24 | 2017-05-10 | 江苏美的清洁电器股份有限公司 | Handheld dust collector |

| CN107280580A (en) * | 2017-08-23 | 2017-10-24 | 小狗电器互联网科技(北京)股份有限公司 | Dust cup assembly and dust catcher |

| CN107453530A (en) * | 2017-09-25 | 2017-12-08 | 湖州鸿远电机有限公司 | A kind of noise reduction, radiating motor |

| CN206807198U (en) * | 2017-03-31 | 2017-12-26 | 温岭市精仁机械有限公司 | the radiating shell of motor |

| CN209805580U (en) * | 2019-05-14 | 2019-12-17 | 浙江四福机电有限公司 | Noise-reduction motor shell |

| CN110613399A (en) * | 2019-11-08 | 2019-12-27 | 珠海格力电器股份有限公司 | Dust collector, dust cup device and separating cone thereof |

| CN210240114U (en) * | 2019-08-14 | 2020-04-03 | 广州市柏理通电机有限公司 | Heat radiator for water-cooled water pump |

-

2020

- 2020-04-07 CN CN202010265972.9A patent/CN111358335A/en active Pending

Patent Citations (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN2453827Y (en) * | 2000-12-27 | 2001-10-17 | 倪祖根 | Split wirlwind dust-filtering device of cleaner |

| CN201529089U (en) * | 2009-10-16 | 2010-07-21 | 江苏美的春花电器股份有限公司 | Cyclone separation device of dust collector |

| CN106618374A (en) * | 2017-02-24 | 2017-05-10 | 江苏美的清洁电器股份有限公司 | Handheld dust collector |

| CN206807198U (en) * | 2017-03-31 | 2017-12-26 | 温岭市精仁机械有限公司 | the radiating shell of motor |

| CN107280580A (en) * | 2017-08-23 | 2017-10-24 | 小狗电器互联网科技(北京)股份有限公司 | Dust cup assembly and dust catcher |

| CN107453530A (en) * | 2017-09-25 | 2017-12-08 | 湖州鸿远电机有限公司 | A kind of noise reduction, radiating motor |

| CN209805580U (en) * | 2019-05-14 | 2019-12-17 | 浙江四福机电有限公司 | Noise-reduction motor shell |

| CN210240114U (en) * | 2019-08-14 | 2020-04-03 | 广州市柏理通电机有限公司 | Heat radiator for water-cooled water pump |

| CN110613399A (en) * | 2019-11-08 | 2019-12-27 | 珠海格力电器股份有限公司 | Dust collector, dust cup device and separating cone thereof |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN112971587A (en) * | 2021-04-14 | 2021-06-18 | 深圳市杉川机器人有限公司 | Portable dust collector |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN110064637B (en) | Prevent weaving dust remover of jam | |

| CN101313833B (en) | Cyclone dust-separating apparatus of vacuum cleaner | |

| CN1985747A (en) | Compact automatic vacuum cleaner | |

| CA2448342A1 (en) | Filter assembly for a cyclone-type dust collecting apparatus of vacuum cleaner | |

| AU2005202601B1 (en) | Cyclone dust collecting apparatus having contaminants counterflow prevention member | |

| CN102283613B (en) | Cyclone separation device | |

| CN102920395A (en) | Double-side self-cleaning linkage structure for filter cartridge of dust collector | |

| US7260867B2 (en) | Bagless dust box for vacuum cleaner | |

| CN210541365U (en) | Dust collecting box of floor cleaning robot | |

| CN112220414A (en) | Double-vortex air dust box structure and sweeping robot | |

| CN111358335A (en) | Detachable grading and filtering device of handheld dust collector | |

| CN216149257U (en) | Compressed air filtering device | |

| CN108201414B (en) | Dust cup for dust collector and dust collector | |

| CN211722972U (en) | Dust collector assembly and convenient suction device | |

| CN105996903A (en) | Dust remover easy to clean | |

| CN110893081A (en) | Dust collector assembly and convenient suction device | |

| CN207065729U (en) | A kind of air cleaning unit of the filter screen with double medium filtration circle | |

| CN213993418U (en) | Dust collector with rotary filter screen | |

| CN213696722U (en) | Double-cavity dust-gas separation device and mite removing instrument with same | |

| JP2005279503A (en) | Filter unit and vacuum cleaner using the same | |

| CN208680128U (en) | A kind of carbon black finished powder dust-extraction unit | |

| CN107212809B (en) | Garbage can type dust collector | |

| CN215820766U (en) | Cleaning equipment with simple ash scraping operation | |

| CN213993429U (en) | Vacuum cleaner with pre-filter assembly | |

| CN213993428U (en) | Dust collector |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination |