CN109630894B - Automatic air supplement and exhaust device for long-distance pipeline and operation method - Google Patents

Automatic air supplement and exhaust device for long-distance pipeline and operation method Download PDFInfo

- Publication number

- CN109630894B CN109630894B CN201811572912.0A CN201811572912A CN109630894B CN 109630894 B CN109630894 B CN 109630894B CN 201811572912 A CN201811572912 A CN 201811572912A CN 109630894 B CN109630894 B CN 109630894B

- Authority

- CN

- China

- Prior art keywords

- pipeline

- water

- shaped pipeline

- exhaust

- air supplement

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F17—STORING OR DISTRIBUTING GASES OR LIQUIDS

- F17D—PIPE-LINE SYSTEMS; PIPE-LINES

- F17D1/00—Pipe-line systems

- F17D1/08—Pipe-line systems for liquids or viscous products

- F17D1/14—Conveying liquids or viscous products by pumping

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F17—STORING OR DISTRIBUTING GASES OR LIQUIDS

- F17D—PIPE-LINE SYSTEMS; PIPE-LINES

- F17D3/00—Arrangements for supervising or controlling working operations

- F17D3/01—Arrangements for supervising or controlling working operations for controlling, signalling, or supervising the conveyance of a product

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F17—STORING OR DISTRIBUTING GASES OR LIQUIDS

- F17D—PIPE-LINE SYSTEMS; PIPE-LINES

- F17D5/00—Protection or supervision of installations

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Health & Medical Sciences (AREA)

- Public Health (AREA)

- Water Supply & Treatment (AREA)

- Sewage (AREA)

- Pipe Accessories (AREA)

Abstract

The invention discloses an automatic air supplement and exhaust device for a long-distance pipeline and an operation method thereof, and aims to effectively solve the technical problem of air supplement and exhaust in the pipeline in a long-distance large-diameter high-lift water delivery and transfer system. Aiming at the problems existing in the prior art, the invention arranges the exhaust supplementing devices at the high points and the secondary high points in the pipelines of the water delivery and transfer system, thereby effectively solving the exhaust supplementing problem of the long-distance water delivery pipeline with complex terrains, effectively protecting the pipeline and improving the working efficiency and the economic benefit of pipeline transportation.

Description

Technical Field

The invention relates to the technical field of pipeline water delivery, in particular to an automatic air supplementing and exhausting device for a long-distance pipeline and an operation method.

Background

In a water delivery and transfer system, a long-distance, large-diameter and high-lift water delivery and transfer system has more U-shaped pipelines due to complex and large fluctuation of the terrain, and the safety of the pipelines is particularly important, but pipe explosion accidents caused by air explosion type water hammers due to the problem of air supplement and exhaust occur sometimes, so the problem of air supplement and exhaust of a pressure delivery and transfer pipeline has important significance for the safe use of the water delivery pipeline, and necessary measures are taken for ensuring the safety of the pipeline water delivery system. In addition, road transportation is an energy-saving emission-reducing environment-friendly project actively popularized by the state at present, meets the national sustainable development requirement, and is a project supported by the national industrial policy. The pipeline transportation expense is reduced than the highway transportation expense by a wide margin, except the self operation cost expense of the pipeline transportation system, other expenses are not produced, the pipeline transportation system implements the automatic control of the pipeline transportation system through a monitoring system, and the pipeline transportation is adopted, thereby improving the economic benefit of enterprises and reducing the important measures of expense cost.

Disclosure of Invention

The invention aims to provide an automatic air supplement and exhaust device for a long-distance pipeline and an operation method, and solves the problem of pipe explosion caused by an air explosion type water hammer due to the problem of air supplement and exhaust of a long-distance water pipeline in a complex terrain.

In order to solve the technical problems, the invention adopts the following technical scheme:

the automatic air supplementing and exhausting device comprises a water inlet pool, a water outlet pool, a water demand point and an air supplementing and exhausting device, wherein the water inlet pool, the water outlet pool and the water demand point are communicated through a pipeline, the air supplementing and exhausting device comprises an air supplementing and exhausting valve, a manual ball valve and a U-shaped pipeline, the U-shaped pipeline is arranged at the joint of the two adjacent pipelines, one end of the manual ball valve is arranged at the U-shaped pipeline, and the air supplementing and exhausting valve is connected and arranged at one end of the manual ball valve.

Furthermore, the air supply and exhaust device is arranged in more than 2 groups.

Furthermore, the air supply and exhaust device between the water inlet pool and the water outlet pool adopts the following operation method:

1) the method comprises the steps that a starting pump station is pressurized to lift water from a water inlet pool, when water flows to the top end position of a first U-shaped pipeline, a first air supplement and exhaust valve starts to exhaust, a first manual ball valve and a second manual ball valve are in a fully opened state in the operation of a pipeline system, when the water reaches the top end position of the first U-shaped pipeline, the water starts to flow to a second U-shaped pipeline and a third U-shaped pipeline, in the process, due to the fact that the pipeline is large in diameter, the first air supplement and exhaust valve is in a state of alternately working for air supplement, and when the water level is higher than the top end position of the first U-shaped pipeline, the first air supplement and exhaust valve is in a fully;

2) when water is pumped to the top end of the third U-shaped pipeline, the second air supplement and exhaust valve is in an exhaust state and begins to flow to the fourth U-shaped pipeline and the water outlet pool, and in the process, due to the fact that the pipeline is large in diameter, the second air supplement and exhaust valve is in a state of air supplement and exhaust alternate work until the water level is higher than the top end position of the third U-shaped pipeline, and the second air supplement and exhaust valve is in a complete closing state.

Further, the following operation method is used for the air supply and exhaust device of the water outlet pool and the water demand point 20:

1) when water flows from the water outlet pool by gravity, flows to the top end position of a fifth U-shaped pipeline and flows to the top end position of a sixth U-shaped pipeline, a third air supplement and exhaust valve and a fourth air supplement and exhaust valve start to exhaust, the third manual ball valve, the fourth manual ball valve and the fifth manual ball valve are in a fully open state in the operation of a pipeline system, when the water reaches the top end position of the sixth U-shaped pipeline, the water flows to the seventh U-shaped pipeline and the eighth U-shaped pipeline, in the process, the fourth air supplement and exhaust valve is in an air supplement and exhaust alternate working state, the fifth air supplement and exhaust valve is in an air exhaust state, and when the water level is higher than the top end position of the sixth U-shaped pipeline, the fourth air supplement and exhaust valve is in a fully closed state;

2) when water is pumped to the top end of the eighth U-shaped pipeline, the fifth air supplement and exhaust valve is in an exhaust state and begins to flow to the ninth U-shaped pipeline and the water demand point, and the fifth air supplement and exhaust valve is in a state of air supplement and exhaust alternate work in the process until water reaches the water demand point and the pipe flow is full, and the fifth air supplement and exhaust valve is in a complete closing state.

Furthermore, a water hammer prevention valve is arranged on the outlet main pipe of the starting pump station.

Compared with the prior art, the invention has at least one of the following beneficial effects:

1. the technical problems of air supplement and exhaust in the pipeline are effectively solved, and automatic air suction and exhaust are realized;

2. the pipe-explosion accident and the collapse of the pipeline of the water delivery and transfer system are effectively prevented, and the safety of a pipe network system is effectively ensured;

3. the stability of the pipeline water delivery and transfer system and the working efficiency of pipeline delivery are improved, the service life of the pipeline is prolonged, and the pipeline water delivery and transfer system is improved

The economic benefit of water delivery and adjustment is improved.

Drawings

FIG. 1 is a first schematic structural diagram of an exhaust and gas supplementing device according to the present invention.

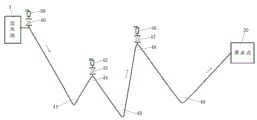

FIG. 2 is a schematic structural diagram of an exhaust and gas supplementing device according to the present invention.

Detailed Description

In order to make the objects, technical solutions and advantages of the present invention more apparent, the present invention is described in further detail below with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are merely illustrative of the invention and are not intended to limit the invention.

Example 1:

as shown in fig. 1 and 2, the automatic exhaust device and the operation method for long-distance pipeline exhaust compensation include a water inlet tank 6, a water outlet tank 1, a water demand point 20 and an exhaust compensation device, wherein the water inlet tank 6, the water outlet tank 1 and the water demand point 20 are communicated through pipelines, the exhaust compensation device includes an exhaust compensation valve, a manual ball valve and a U-shaped pipeline, the U-shaped pipeline is arranged at the joint of two adjacent pipelines, one end of the manual ball valve is arranged at the U-shaped pipeline, the exhaust compensation valve is connected to one end of the manual ball valve, and the exhaust compensation device is arranged in groups larger than 2 for better drainage, wherein:

referring to fig. 1, the air supplement and exhaust of the long-distance water pipeline with complex terrains comprises a water lifting part: 6-a water inlet pool, a first supplement and exhaust valve 31, a first manual ball valve 32, a first U-shaped pipeline 33, a second U-shaped pipeline 34, a second supplement and exhaust valve 35, a second manual ball valve 36, a third U-shaped pipeline 37, a fourth U-shaped pipeline 38 and a water outlet pool 30;

the water lifting part solves the technical scheme explanation of the air supplement and exhaust problem of the complex-terrain long-distance water conveying pipeline, only a representative example is provided, and a plurality of groups of air supplement and exhaust valves are arranged in the actual complex-terrain long-distance water conveying pipeline and are mainly arranged at high points and secondary high points with complex terrain fluctuation. For example, 2 sets of air supply and exhaust valves are provided, namely a first air supply and exhaust valve 31 and a second air supply and exhaust valve 35. When the water lifting part of the pipeline is a newly-built pipeline or is repaired and maintained, a large amount of or full-pipe air enters the pipeline, and the air in the pipeline must be removed before the pump is started next time.

In addition, under two conditions, the air supply and exhaust valve works, one is that when a pipe network system suddenly breaks down, such as power failure and equipment failure, water rapidly flows to an initial pump station from a low point when the faults happen, so that a water hammer is generated, therefore, according to the statement of the complaint, a water hammer prevention valve is arranged on a main pipe at the outlet of the initial pump station, the water hammer is effectively eliminated, but in the process, part of water is discharged to a water inlet pool, and at the moment, the first air supply and exhaust valve 31 and the second air supply and exhaust valve 35 at the high point start to work; the second is in the pipe network system, because the quality or ageing of construction quality, valve and mounting lead to the trouble on the pipeline, the pipeline conspires one to begin to leak, and the valve of mending on the pipeline begins to work, has prevented the enlarged change of trouble, has effectively solved the flat of pipeline and has collapsed and the pipe explosion, has effectively ensured pipe network system's safety.

The process operation of the water lifting part is as follows: when the initial pump station is used for pumping water from the 6-inlet basin, water flows to the top end position of the first U-shaped pipeline 33, the first air supplement and exhaust valve 31 starts to exhaust, the first manual ball valve 32 and the second manual ball valve 36 are in a fully opened state in the operation of the pipeline system, when the water reaches the top end position of the first U-shaped pipeline 33, the water starts to flow to the second U-shaped pipeline 34 and the third U-shaped pipeline 37, in the process, due to the fact that the pipeline is large in diameter, the first air supplement and exhaust valve 31 is in a state of alternately working air supplement and exhaust, and when the water level is higher than the top end position of the first U-shaped pipeline 33, the first air supplement and exhaust valve 31 is in a fully closed state, the fact that air in the pipeline is completely exhausted is indicated, and the pipeline is effectively protected. When water is pumped to the top end of the third U-shaped pipeline 37, the second air supply and exhaust valve 35 is in an exhaust state, and the water starts to flow to the fourth U-shaped pipeline 38 and the water outlet pool 1, in the process, due to the fact that the pipeline is large in diameter, the second air supply and exhaust valve 35 is in a state of air supply and exhaust alternate work, and when the water level is higher than the top end of the third U-shaped pipeline 37, the second air supply and exhaust valve 35 is in a completely closed state, which indicates that air in the pipeline is completely exhausted, effectively protects the pipeline, and ensures safe and stable operation of a pipe network system;

see fig. 2, the exhaust of mending of complicated topography long distance water pipeline, the water delivery part includes: 1-a water outlet pool, a third air supplement and exhaust valve, a third manual ball valve 40, a fifth U-shaped pipeline 41, a fourth air supplement and exhaust valve 42, a fourth manual ball valve 43, a sixth U-shaped pipeline 44, a seventh U-shaped pipeline 45, a fifth air supplement and exhaust valve 46, a fifth manual ball valve 47, an eighth U-shaped pipeline 48, a ninth U-shaped pipeline 49 and a water demand point 20;

the water delivery part solves the technical scheme explanation of the problem of air supplement and exhaust of a long-distance water delivery pipeline with a complex terrain, and the working principle of an air supplement and exhaust valve of the water delivery part and the working principle of a water lifting part are different, and only exist in water delivery from a high point to a place and water lifting from a low point to the high point. The water supply and exhaust valve is mainly arranged at a high point, a secondary high point and a starting point of complex terrain with large fluctuation. 3 groups of air supplement and exhaust valves, namely a third air supplement and exhaust valve, a fourth air supplement and exhaust valve 42 and a fifth air supplement and exhaust valve 46 are arranged, so that a large amount of or full pipe air enters the pipeline when the pipeline of the water delivery part is a newly-built pipeline or is maintained;

in addition under the other condition, the valve that mends can work, be in pipe network system, because construction quality, valve and the quality of mounting or ageing lead to the trouble on the pipeline, the pipeline conspires one to begin to leak, and the valve that mends on the pipeline, fourth valve 42 and the valve 46 that mends start working of valve, has prevented the enlargement of trouble, has effectively solved the shrivelled of pipeline and has collapsed and the pipe explosion, has effectively ensured pipe network system's safety.

The process operation of the water delivery system is as follows: when water flows from the water outlet pool 1 by gravity flow and flows to the top end position of the fifth U-shaped pipeline 41 and the top end position of the sixth U-shaped pipeline 44, the third air supplement and exhaust valve and the fourth air supplement and exhaust valve 42 start to exhaust, the third manual ball valve 40, the fourth manual ball valve 43 and the fifth manual ball valve 47 are in a fully open state in the operation of the pipeline system, when the water reaches the top end position of the sixth U-shaped pipeline 44, the water starts to flow to the seventh U-shaped pipeline 45 and the eighth U-shaped pipeline 48, in the process, the fourth air supplement and exhaust valve 42 has a state of alternately working with air supplement and exhaust, the fifth air supplement and exhaust valve 46 is in an exhaust state, and when the water level is higher than the top end position of the second U-shaped pipeline 34, the fourth air supplement and exhaust valve 42 is in a fully closed state, which indicates that the air in the pipeline is completely exhausted, and the pipeline is effectively protected. When water is pumped to the top end of the eighth U-shaped pipeline 48, the fifth air supply and exhaust valve 46 is in an exhaust state, and the water starts to flow to the ninth U-shaped pipeline 49 and the water demand point 20, in the process, the fifth air supply and exhaust valve 46 has a state of alternately working of air supply and exhaust, and until the water reaches the water demand point 201 and is in a full-pipe flow state, the fifth air supply and exhaust valve 46 is in a completely closed state, which indicates that the air in the pipeline at the section is completely exhausted, effectively protects the pipeline, and ensures the safe and stable operation of a pipe network system.

Through the technical scheme, the technical problems of in-pipe air supply and exhaust of the water lifting pipeline system and the water conveying pipeline system are effectively solved, the safety of the whole pipe network system and equipment is ensured, and the pipe network system is enabled to operate safely, stably, economically and efficiently.

Although the invention has been described herein with reference to a number of illustrative embodiments thereof, it should be understood that numerous other modifications and embodiments can be devised by those skilled in the art that will fall within the spirit and scope of the principles of this disclosure. More specifically, various variations and modifications are possible in the component parts and/or arrangements of the subject combination arrangement within the scope of the disclosure, the drawings and the appended claims. In addition to variations and modifications in the component parts and/or arrangements, other uses will also be apparent to those skilled in the art.

Claims (4)

1. The utility model provides an automatic exhaust apparatus that mends of long distance pipeline, includes intake pool (6), play pond (1), water demand point (20), mends exhaust apparatus, its characterized in that: the water inlet pool (6), the water outlet pool (1) and the water demand point (20) are communicated through pipelines, the air supplementing and exhausting device comprises an air supplementing and exhausting valve, a manual ball valve and a U-shaped pipeline, the U-shaped pipeline is arranged at the joint of two adjacent pipelines, one end of the manual ball valve is arranged at the U-shaped pipeline, and the other end of the manual ball valve is connected with the air supplementing and exhausting valve, and the operation method of the automatic air supplementing and exhausting device for the long-distance pipeline comprises the following steps: 1) when the initial pump station pumps water from the water inlet pool (6) under pressure and the water flows to the top end position of the first U-shaped pipeline (33), a first air supplement and exhaust valve (31) arranged at the first U-shaped pipeline (33) starts to exhaust air, in the operation of the pipeline system, a first manual ball valve (32) arranged at a first U-shaped pipeline (33) and a second manual ball valve (36) arranged at a third U-shaped pipeline (37) are in a fully opened state, when the water reaches the top end position of the first U-shaped pipeline (33), the water starts to flow to the second U-shaped pipeline (34) and the third U-shaped pipeline (37), in the process, as the pipeline is a large-diameter pipeline, the first air supplement and exhaust valve (31) arranged at the first U-shaped pipeline (33) has the state of alternately working air supplement and exhaust until the water level is higher than the top end position of the first U-shaped pipeline (33), the first air supplement and exhaust valve (31) arranged at the first U-shaped pipeline (33) is in a completely closed state;

2) when water is pumped to the top end of the third U-shaped pipeline (37), the second air supplement and exhaust valve (35) arranged at the third U-shaped pipeline (37) is in an exhaust state, and the water starts to flow to the fourth U-shaped pipeline (38) and the water outlet pool (1), in the process, due to the large-diameter pipeline, the second air supplement and exhaust valve (35) has a state of alternately working of air supplement and exhaust, and when the water level is higher than the top end position of the third U-shaped pipeline (37), the second air supplement and exhaust valve (35) arranged at the third U-shaped pipeline (37) is in a completely closed state.

2. The automatic air replenishing and discharging device for the long-distance pipeline according to claim 1, wherein: the arrangement groups of the air supply and exhaust devices between the water inlet pool (6) and the water outlet pool (1) and between the water outlet pool (1) and the water demand point (20) are more than 2.

3. The automatic air replenishing and discharging device for the long-distance pipeline according to claim 1, wherein: the air supply and exhaust device of the water outlet pool (1) and the water demand point (20) adopts the following operation method:

1) when water flows automatically from the water outlet pool (1) by gravity, flows to the fifth U-shaped pipeline (41) and flows to the top end position of the sixth U-shaped pipeline (44), a third air supplement and exhaust valve (39) arranged at the water outlet pool and a fourth air supplement and exhaust valve (42) arranged at the sixth U-shaped pipeline (44) start to exhaust, a third manual ball valve (40) arranged at the water outlet pool, a fourth manual ball valve (43) arranged at the sixth U-shaped pipeline (44) and a fifth manual ball valve (47) arranged at the eighth U-shaped pipeline (48) are in a fully opened state in the operation of the pipeline system, when the water reaches the top end position of the sixth U-shaped pipeline (44), the water flows to the seventh U-shaped pipeline (45) and the eighth U-shaped pipeline (48) start to flow, and in the process, the fourth air supplement and exhaust valve (42) arranged at the sixth U-shaped pipeline (44) has a state of alternately working of air supplement and exhaust, a fifth air supplement and exhaust valve (46) arranged at the eighth U-shaped pipeline (48) is in an exhaust state, and a fourth air supplement and exhaust valve (42) arranged at the sixth U-shaped pipeline (44) is in a completely closed state until the water level is higher than the top position of the sixth U-shaped pipeline (44);

2) when water is pumped to the top end of the eighth U-shaped pipeline (48), the fifth air supplement and exhaust valve (46) arranged on the eighth U-shaped pipeline (48) is in an exhaust state, and the water starts to flow to the ninth U-shaped pipeline (49) and the water demand point (20), in the process, the fifth air supplement and exhaust valve (46) arranged on the eighth U-shaped pipeline (48) has a state of alternately working of air supplement and exhaust, and when the water reaches the water demand point (20) and is in full pipe flow, the fifth air supplement and exhaust valve (46) arranged on the eighth U-shaped pipeline (48) is in a complete closing state.

4. The automatic air replenishing and discharging device for the long-distance pipeline according to claim 1, wherein: a water hammer prevention valve is arranged on the main pipe at the outlet of the starting pump station.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201811572912.0A CN109630894B (en) | 2018-12-21 | 2018-12-21 | Automatic air supplement and exhaust device for long-distance pipeline and operation method |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201811572912.0A CN109630894B (en) | 2018-12-21 | 2018-12-21 | Automatic air supplement and exhaust device for long-distance pipeline and operation method |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN109630894A CN109630894A (en) | 2019-04-16 |

| CN109630894B true CN109630894B (en) | 2020-06-26 |

Family

ID=66076270

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201811572912.0A Active CN109630894B (en) | 2018-12-21 | 2018-12-21 | Automatic air supplement and exhaust device for long-distance pipeline and operation method |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN109630894B (en) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN110820670A (en) * | 2019-11-14 | 2020-02-21 | 云南大红山管道有限公司 | Pipeline emptying device and method for complex-terrain long-distance pipeline water delivery and transfer system |

| CN112856237B (en) * | 2019-11-26 | 2022-10-04 | 中国石油天然气股份有限公司 | Method and device for positioning gas column in gathering and transportation pipeline and storage medium |

| CN115493092A (en) * | 2022-09-01 | 2022-12-20 | 云南大红山管道有限公司 | Long-distance large-pipe-diameter water delivery and transfer anti-leakage explosion-proof pipe monitoring system and method |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6024113A (en) * | 1997-09-05 | 2000-02-15 | Komiya; Keinosuke | Method of preventing external contamination in multiple tank fluid systems |

| DE19947197A1 (en) * | 1999-10-01 | 2001-04-12 | Bosch Gmbh Robert | Device and method for dosing a reducing agent |

| CN203023801U (en) * | 2012-12-28 | 2013-06-26 | 建滔(连州)铜箔有限公司 | Liquid replenishment system |

| CN105113579A (en) * | 2015-09-28 | 2015-12-02 | 云南大红山管道有限公司 | Long-distance large-diameter high-altitude pipeline water conveying system and operating method |

| CN106400882B (en) * | 2016-11-23 | 2023-10-20 | 特技阀门集团有限公司 | Device for protecting water hammer of long-distance pump water supply system |

-

2018

- 2018-12-21 CN CN201811572912.0A patent/CN109630894B/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| CN109630894A (en) | 2019-04-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN109630894B (en) | Automatic air supplement and exhaust device for long-distance pipeline and operation method | |

| CN202284572U (en) | Dual-purpose pump pipe with pumping and siphoning functions | |

| CN106400882B (en) | Device for protecting water hammer of long-distance pump water supply system | |

| CN200999960Y (en) | Natural gas vehicle air entraining substation system | |

| CN206846172U (en) | A kind of elastic membrane protecting water hammer device | |

| CN105972672A (en) | Circulating pump pipeline | |

| CN110219610B (en) | Shale gas horizontal well high-pressure pumping bridge plug device | |

| CN110820670A (en) | Pipeline emptying device and method for complex-terrain long-distance pipeline water delivery and transfer system | |

| CN204283897U (en) | A kind of Pontoon pump station | |

| CN207277418U (en) | A kind of new subregion intelligent water supply system and water supply installation | |

| CN109162930A (en) | A kind of paint spray booth's water supply self-priming apparatus | |

| CN206458583U (en) | One kind linkage startup-shutdown control device | |

| CN204590163U (en) | Buried self filling type integration fire pump station | |

| CN107586906A (en) | A kind of method that leakage detection apparatus progress cooling wall leak detection is suppressed using self-control | |

| CN208688720U (en) | A kind of pumping plant water lift pipeline water-filling pressure testing multifunction system | |

| CN209238619U (en) | The circulation oil flushing equipment of hydraulic system pipeline | |

| CN205779192U (en) | A kind of vehicle water circulation system | |

| CN112112136A (en) | Force-eliminating discharge device of long-distance water conveying and transferring system and operation method | |

| CN220015637U (en) | Hydraulic valve station of withdrawal and straightening machine for maintenance safety | |

| CN115899577A (en) | Long-distance water conveying and transferring system for complex terrain and anti-cavitation device and method | |

| CN216713199U (en) | Automatic protection system of water hammer of U-shaped water supply engineering with pressurized middle part | |

| CN221275210U (en) | Ammonia water unloading pump station | |

| CN115355650B (en) | Water hammer preventing system and method for circulating cooling water of power plant and design method | |

| CN209012079U (en) | A kind of paint spray booth's water supply self-priming apparatus | |

| CN214249162U (en) | Device for effectively controlling water hammer prevention valve to be closed |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |