Swing type small concrete mixer

Technical Field

The invention relates to the field of construction equipment, in particular to a swing type small concrete mixer.

Background

Concrete is a powdered hydraulic inorganic cementitious material. The concrete mixer is a machine for mixing and mixing concrete, gravel aggregate and water into a concrete mixture, mainly comprises a mixing cylinder, a feeding and discharging mechanism, a water supply system, a prime motor, a transmission mechanism, a frame, a supporting device and the like, and the existing concrete mixer is poor in mixing effect, not uniform enough in mixing, low in mixing efficiency and difficult to meet daily production requirements of people.

Disclosure of Invention

The invention aims to provide a swing type small concrete mixer to solve the problems in the background technology.

In order to achieve the purpose, the invention provides the following technical scheme:

a swing type small concrete mixer comprises a base, support legs, a first motor, a driving shaft and a discharge hole, wherein the left end and the right end of the upper surface of the base are respectively and fixedly connected with a left fixing plate and a right fixing plate, an agitator tank is arranged between the left fixing plate and the right fixing plate, the bottom of the agitator tank is suspended, the left side wall of the agitator tank is fixedly connected with a left swing shaft, the left end of the left swing shaft is rotatably connected with the left fixing plate, the right end of the agitator tank is fixedly connected with a right swing shaft, the right end of the right swing shaft is rotatably connected with the right fixing plate, the upper surface of the agitator tank is fixedly connected with a feed inlet, the right end of the feed inlet is fixedly connected with the first motor, the shaft extension end of the first motor is fixedly connected with the driving shaft, the lower end of the driving shaft extends into the agitator tank, the, driven gear and driving shaft meshing, driven gear inlays in the tooth's socket, driven gear's lower fixed surface is connected with the (mixing) shaft, the last fixed surface of base is connected with the second motor, the below of right side oscillating axle is equipped with half bevel gear, the axle extension end and the half bevel gear fixed connection of second motor, the left and right sides of half bevel gear is equipped with left bevel gear, right bevel gear respectively, left bevel gear and right bevel gear overlap respectively and establish on right oscillating axle, half bevel gear respectively with left bevel gear, right bevel gear intermittent type meshing.

As a further scheme of the invention: the lower surface of the base is fixedly connected with a supporting leg.

As a still further scheme of the invention: the central lines of the left swinging shaft and the right swinging shaft are positioned on the same straight line.

As a still further scheme of the invention: the right side of first motor is equipped with the inlet tube, inlet tube and agitator tank intercommunication install the valve on the inlet tube.

As a still further scheme of the invention: stirring rods are distributed on the stirring shaft.

As a still further scheme of the invention: the lower end of the stirring shaft is fixedly connected with a stirring blade.

As a still further scheme of the invention: the lower fixed surface of agitator tank is connected with the bin outlet, installs the valve on the bin outlet.

Compared with the prior art, the invention has the beneficial effects that: in the stirring process, the driven gear drives the stirring shaft to revolve when passing by automatically, the stirring rod is used for stirring the concrete, the stirring range is enlarged, the stirring dead angle is greatly reduced, the stirring effect is improved, the stirring efficiency is improved, and when the stirring is carried out, the stirring tank is shaken from front to back to drive the concrete slurry to shake in the stirring tank, so that the concrete slurry is mixed more uniformly, and the stirring effect is further improved.

Drawings

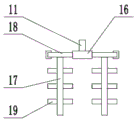

FIG. 1 is a schematic view of a swing type small concrete mixer;

FIG. 2 is a schematic view showing the structure of a stirring shaft in the swing type small concrete mixer.

In the figure: 1-a base; 2-a leg; 3-left fixed plate; 4-right fixed plate; 5-a left oscillating shaft; 6-right oscillating shaft; 7-stirring tank; 8-a feed inlet; 9-a water inlet pipe; 10-a first electric machine; 11-a drive shaft; 12-a second electric machine; 13-half bevel gear; 14-left bevel gear; 15-right bevel gear; 16-a drive gear; 17-a stirring shaft; 18-a driven gear; 19-a stirring rod; 20-discharge opening.

Detailed Description

The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the drawings in the embodiments of the present invention, and it is obvious that the described embodiments are only a part of the embodiments of the present invention, and not all of the embodiments. All other embodiments, which can be derived by a person skilled in the art from the embodiments given herein without making any creative effort, shall fall within the protection scope of the present invention.

Referring to fig. 1 and 2, in the embodiment of the present invention, a swing type small concrete mixer includes a base 1, a support leg 2, a first motor 10, a driving shaft 11 and a discharge port 20, the support leg 2 is fixedly connected to a lower surface of the base 1, a left fixing plate 3 and a right fixing plate 4 are respectively fixedly connected to left and right ends of an upper surface of the base 1, a mixing tank 7 is disposed between the left fixing plate 3 and the right fixing plate 4, a bottom of the mixing tank 7 is suspended, a left swing shaft 5 is fixedly connected to a left sidewall of the mixing tank 7, a left end of the left swing shaft 5 is rotatably connected to the left fixing plate 3, a right swing shaft 6 is fixedly connected to a right end of the mixing tank 7, a right end of the right swing shaft 6 is rotatably connected to the right fixing plate 4, center lines of the left swing shaft 5 and the right swing shaft 6 are located on a same straight line, the mixing tank 7 can swing back and, the right end of the feed inlet 8 is fixedly connected with a first motor 10, the right side of the first motor 10 is provided with a water inlet pipe 9, the water inlet pipe 9 is communicated with a stirring tank 7, a valve is arranged on the water inlet pipe 9, the shaft extension end of the first motor 10 is fixedly connected with a driving shaft 11, the lower end of the driving shaft 11 extends into the stirring tank 7, the lower end of the driving shaft 11 is sleeved with a driving gear 16, the inner wall of the stirring tank 7 is provided with tooth grooves, the left side and the right side of the driving shaft 11 are respectively provided with a driven gear 18, the driven gear 18 is meshed with the driving shaft 11, the driven gear 18 is embedded in the tooth grooves, the driving shaft 11 is driven to rotate when the first motor 10 runs, and then the driving gear 16 is driven to rotate, so as to drive the driven gear 18 to revolve along the tooth grooves while transmitting, the driven gear 18 drives the stirring shaft 17 to revolve while rotating, the stirring rod 19 is used for stirring concrete, the stirring range is expanded, and the stirring effect is greatly improved, the upper surface of the base 1 is fixedly connected with the second motor 12, the lower part of the right swinging shaft 6 is provided with the half bevel gear 13, the shaft extension end of the second motor 12 is fixedly connected with the half bevel gear 13, the left side and the right side of the half bevel gear 13 are respectively provided with the left bevel gear 14 and the right bevel gear 15, the left bevel gear 14 and the right bevel gear 15 are respectively sleeved on the right swinging shaft 6, the half bevel gear 13 is respectively and intermittently meshed with the left bevel gear 14 and the right bevel gear 15, the second motor 12 drives the half bevel gear 13 to rotate when in operation, when the half bevel gear 13 is meshed with the left bevel gear 14, the right swinging shaft 6 is driven to rotate, when the half bevel gear 13 is separated from the left bevel gear 14 and meshed with the right bevel gear 15, so relapse, drive right swing axle 6 just reversing to rocking around driving agitator tank 7, making the concrete thick liquid mix more evenly, further improving stirring effect, agitator tank 7's lower fixed surface is connected with bin outlet 20, installs the valve on the bin outlet 20, and the concrete thick liquid after the stirring is accomplished passes through bin outlet 20 and discharges.

It should be particularly noted that, the stirring rod in this application is the application of prior art, and revolution when the (mixing) shaft is autobiography, stirring while agitator tank back and forth swing are the innovation point of this application, and it has effectively solved the concrete mixing problem not enough even, and stirring efficiency is low.

It will be evident to those skilled in the art that the invention is not limited to the details of the foregoing illustrative embodiments, and that the present invention may be embodied in other specific forms without departing from the spirit or essential attributes thereof. The present embodiments are therefore to be considered in all respects as illustrative and not restrictive, the scope of the invention being indicated by the appended claims rather than by the foregoing description, and all changes which come within the meaning and range of equivalency of the claims are therefore intended to be embraced therein. Any reference sign in a claim should not be construed as limiting the claim concerned.

Furthermore, it should be understood that although the present description refers to embodiments, not every embodiment may contain only a single embodiment, and such description is for clarity only, and those skilled in the art should integrate the description, and the embodiments may be combined as appropriate to form other embodiments understood by those skilled in the art.