CN103603662A - Coal cutter for thin coal layer - Google Patents

Coal cutter for thin coal layer Download PDFInfo

- Publication number

- CN103603662A CN103603662A CN201310456149.6A CN201310456149A CN103603662A CN 103603662 A CN103603662 A CN 103603662A CN 201310456149 A CN201310456149 A CN 201310456149A CN 103603662 A CN103603662 A CN 103603662A

- Authority

- CN

- China

- Prior art keywords

- control cabinet

- cutting

- rocking arm

- tractive unit

- traction

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Landscapes

- Fluid-Pressure Circuits (AREA)

Abstract

The invention discloses a coal cutter for a thin coal layer. The coal cutter comprises a machine body. A control cabinet is disposed in the machine body. A PLC electric control system used for controlling the whole machine is disposed in the control cabinet. A group of a traction motion mechanism and a cutting part is disposed at the right side of the control cabinet and a same group of the traction motion mechanism and the cutting part is disposed at the right side of the control cabinet. The traction motion mechanisms comprise traction parts and motion parts. The cutting parts comprise rocker arms and cutting drums. Cutting motors on the rocker arms drive the cutting drums. An independent pump station is disposed between the control cabinet and the right traction motion mechanism. The independent pump station adjusts the height of the rocker arms through connecting a reversing valve with a left heightening oil cylinder and a right heightening oil cylinder. The control cabinet, the left traction part, the independent pump station and the right traction part are connected into a whole body through high-strength hydraulic nuts, and move in a scraper conveyer pin rail through the traction motion mechanisms. The whole body is compact in structure and low in machine surface height. When necessary, the independent pump station can be demounted, the control cabinet and the right traction motion mechanism are connected, and the left heightening oil cylinder and the right heightening oil cylinder are controlled by a working surface emulsion pump station, thus reducing the length of the machine body and improving adaptability.

Description

Technical field

The invention belongs to coal-cutting machinery field, concrete is a kind of coal-winning machine that is applicable to exploit girdle.

Background technology

From national coal storage total amount, thin and ultra-thin coal seam is widely distributed in China.In the 95Ge emphasis mineral bureau of the whole nation, have more than 80 office to compose and deposit thin and ultra-thin coal seam, in the State owned coal mine in the whole nation thin with ultra-thin coal seam reserves up to 25.29 hundred million tons.In recent years the exploitation dynamics of girdle is being strengthened gradually, thinner seam gradually becomes main mining coal seam.Therefore, coal mining industry is to thin seam mining also pay attention to day by day.

But at present the mechanization degree of thin seam mining is also lower,, therefore there is number of drawbacks and the deficiency such as yield poorly, accident is many, workman's work under bad environment, potential safety hazard are very large in the mining type that mostly adopts big gun to adopt in actual recovery process.The cry of the high-power low seam electric traction coal mining machine of coal enterprise's this geological conditions of demand adaptation is more and more higher.But existing coal-winning machine all exists in thin seam mining process that power is less, the long compliance of fuselage is low, production efficiency is low, result of use is poor, have a strong impact on the multiple practical problems such as China's girdle complicated geological coal mining work to some extent.

Summary of the invention

The technical problem solving: for the deficiencies in the prior art, the invention provides a kind of low seam mining machinery, solve in prior art, utilize the big gun mode of adopting to cause to yield poorly, the defect such as accident is many, work under bad environment and the defect such as existing coal-winning machine power is little, fuselage length compliance is low, production efficiency is low.

Technical scheme: for solving the problems of the technologies described above, the present invention by the following technical solutions:

A kind of low seam mining machinery, comprise fuselage, described fuselage interior is provided with control cabinet, in described control cabinet, be provided with PLC electrical control system, left and right sides at control cabinet is respectively provided with one group of identical traction walking mechanism and cutting units, described traction walking mechanism comprises tractive unit and running part, and described cutting units comprises rocking arm and cutting drum.

In fuselage interior, the left side of described control cabinet is provided with left tractive unit, and the right side of control cabinet is provided with independent pumping plant and right tractive unit successively, between above-mentioned control cabinet, left tractive unit, independent pumping plant and right tractive unit, all by several High Performance Hydraulic Nut, connects respectively; Described independent pumping plant is connected with left and right adjust high cylinder respectively and common formed rocking arm and heighten hydraulic means by fluid pressure line and reversal valve; One end of described left tractive unit and left adjust high cylinder is hinged, and one end of described right tractive unit and right adjust high cylinder is hinged.

Left and right sides lower position in control cabinet old man side is respectively provided with identical left running part and right running part, described left running part and right running gear tractive unit other and respective side is bolted, and left and right tractive unit drives left and right running part to walk on drag conveyor pin rail by traction electric machine.

Outside at fuselage, the end of the rocking arm of cutting units becomes swallow-tail form, an angle of rocking arm dovetail respectively with the tractive unit of respective side on side plate hinged, another angle of rocking arm dovetail is hinged with the other end of the adjust high cylinder of respective side respectively.

On described rocking arm, be equipped with cutting motor and rocker-arm driving device, and cutting motor is bi-motor series connection form, described rocking arm front end is all provided with described cutting drum, and between rocking arm and cutting drum, by square feather joint, cutting motor drives cutting drum to work by rocker-arm driving device.Realize the requirement that has larger cutting power on small size rocking arm, can realize the exploitation of the hard more difficult mining coal seam of cut.

Also comprise work plane emulsion power pack, the feed pipe of work plane emulsion power pack is connected in the distributing valve at control cabinet rear portion, by distributing valve and then be connected to described reversal valve.Can choice for use independence pumping plant or work plane emulsion power pack separately left and right adjust high cylinder is controlled or is controlled simultaneously; In the situation that conditions down-hole allows, also dismountable independent pumping plant, is directly connected control cabinet with right tractive unit, utilizes separately work plane emulsion power pack left and right adjust high cylinder to be carried out to the control of height, shorten fuselage length, be more suitable for the exploitation requirement of girdle.

Further, in the present invention, described traction electric machine is connected with female splined shaft gear by external splines output shaft, after two-stage spur gear slows down, passing to two-stage planetary reduction mechanism exports by planet carrier, by spline, be connected with running part driving wheel, running part drive wheel road wheel is walked on drag conveyor pin rail.

Further, in the present invention, the cutting motor in described rocking arm drives cutting drum to rotate by square flange after slowing down by three grades of spur gears again after primary planet pinion slows down.

Further, in the present invention, described traction electric machine is alternating-current variable frequency motor.By changing the speed of output frequency change traction electric machine, realizing the speed of coal-winning machine motion adjusts.

Beneficial effect: a kind of low seam mining machinery of the present invention has adopted compact design method, make control cabinet, independent pumping plant, traction walking mechanism and cutting units form an integral body, by traction walking mechanism, be positioned on drag conveyor, make this equipment machine height extremely low, can meet the mining operations to girdle and dirt band girdle under the condition of not loosening moving big gun, improve the utilization rate of coal resources, reduce work plane excavation cost;

Take the design of full electric traction simultaneously, utilize PLC electrical control system to control complete machine, simple in structure, internal construction modularization, be convenient to safeguard and use, save personnel cost, improve coal mining personnel's labour intensity and working environment, reduced cost of ton coal;

On rocking arm, use the cutting motor of bi-motor series connection form to control cutting drum motion, realized the requirement that has larger cutting power on small size rocking arm, can meet the mining requirement of the hard more difficult mining coal seam of cut;

Affected by down-hole geological conditions, when fuselage need to be shortened at small space place, can remove independent pumping plant, control cabinet is directly connected with right tractive unit, and directly rocking arm is heightened to control up and down by work plane emulsion power pack, give full play to the effect of work plane emulsion power pack, shortened fuselage length, strengthened the compliance of complete machine.

Accompanying drawing explanation

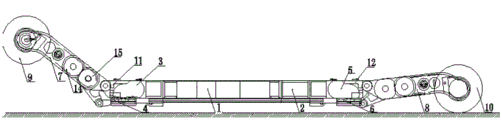

Fig. 1 is complete machine front view of the present invention;

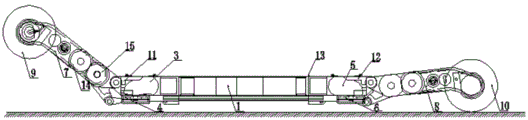

Fig. 2 is the syndeton front view of independent pump station part of the present invention;

Fig. 3 is the top view of Fig. 2;

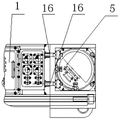

Fig. 4 is for removing the complete machine front view after independent pumping plant;

Fig. 5 is for removing control cabinet after independent pumping plant and the front view of right tractive unit syndeton;

Fig. 6 is the top view of Fig. 5.

The specific embodiment

Below in conjunction with accompanying drawing, the present invention is further described.

As shown in Figures 1 to 4, a kind of low seam mining machinery, comprise fuselage, described fuselage interior is provided with control cabinet 1, in described control cabinet 1, is provided with PLC electrical control system, at the left and right sides of control cabinet 1, is respectively provided with one group of identical traction walking mechanism and cutting units, described traction walking mechanism comprises tractive unit and running part, specifically comprise left and right tractive unit and left and right running part, described cutting units comprises rocking arm and cutting drum, specifically comprises left and right rocking arm and left and right cutting drum.

In fuselage interior, the left side of described control cabinet 1 is provided with left tractive unit 3, the right side of control cabinet 1 is provided with independent pumping plant 2 and right tractive unit 5 successively, above-mentioned control cabinet 1, left tractive unit 3, between independent pumping plant 2 and right tractive unit 2, all by several High Performance Hydraulic Nut 16, connect respectively, the High Performance Hydraulic Nut 16 showing in Fig. 3 is in old man's side, the High Performance Hydraulic Nut 16 showing in Fig. 4 is in rib side, because High Performance Hydraulic Nut 16 is applicable to narrow space, heavy load oscillating machinery fastening, the connection that has guaranteed this machine is firm, make control cabinet, independent pumping plant, traction walking mechanism and cutting units form an integral body.Described independent pumping plant 2 is connected with left and right adjust high cylinder respectively and common formed rocking arm and heighten hydraulic means by fluid pressure line and reversal valve; Described left tractive unit 3 is hinged with one end of left adjust high cylinder 11, and described right tractive unit 5 is hinged with one end of right adjust high cylinder 12.In independent pumping plant 2, comprise pump box, heighten motor, heighten pump and electromagnetic valve, heighten driven by motor and heighten pump liquid draw force feed and deliver to left and right adjust high cylinder for controlling the lifting of rocking arm by fluid pressure line and reversal valve.

Left and right sides lower position in control cabinet 1 old man's side is respectively provided with identical left running part 4 and right running part 6, described left running part 4 is bolted with the tractive unit of respective side respectively with right running part 6, and left and right tractive unit drives left and right running part to walk on drag conveyor pin rail by traction electric machine; Concrete, described traction electric machine is connected with female splined shaft gear by external splines output shaft, after two-stage spur gear slows down, passing to two-stage planetary reduction mechanism exports by planet carrier, by spline, be connected with running part driving wheel, running part drive wheel road wheel is walked on drag conveyor pin rail.This traction electric machine is selected alternating-current variable frequency motor simultaneously, by frequency converter, changes frequency of supply, thereby changes the rotating speed of traction electric machine, changes the hauling speed of coal-winning machine, realizes the adjustment to coal-winning machine motion speed.

Outside at fuselage, the left rocking arm 7 of cutting units becomes swallow-tail form with the end of right rocking arm 8, an angle of rocking arm dovetail respectively with the tractive unit of respective side on side plate hinged, another angle of rocking arm dovetail is hinged with the other end of the adjust high cylinder of respective side respectively;

On described rocking arm, be equipped with cutting motor and rocker-arm driving device, and cutting motor is bi-motor series connection form, be that one-level cutting motor 15 is connected with secondary cutting motor 14, described left rocking arm 7 front ends are provided with left cutting drum 9, and right rocking arm 8 front ends are provided with right cutting drum 10.Between rocking arm and cutting drum, by square feather joint, described rocker-arm driving device comprises three grades of spur gears and primary planet pinion, and the cutting motor in described rocking arm drives cutting drum to rotate by square flange after slowing down by rocker-arm driving device.

The present invention also comprises work plane emulsion power pack, has two cover pumping plants, and a set of is described independent pumping plant 2, and also having a set of is work plane emulsion power pack.Can choice for use independence pumping plant 2 or work plane emulsion power pack is controlled left and right adjust high cylinder separately or two cover pumping plants are controlled simultaneously; When space, down-hole is narrower and small, detachable described independent pumping plant 2, control cabinet 1 right side is directly connected with right tractive unit 5, High Performance Hydraulic Nut 16 is as shown in Figure 6 in old man's side, High Performance Hydraulic Nut 16 is as shown in Figure 5 in rib side, High Performance Hydraulic Nut 16 easy accessibility, are applicable to often need the occasion of dismounting.Being utilized as whole working surface hydraulic support or individual prop provides the work plane emulsion power pack of power to realize voltage supply, the feed pipe of work plane emulsion power pack is connected in the distributing valve at control cabinet 1 rear portion by the space 13 between control cabinet 1 and right tractive unit 5, by distributing valve and then be connected to reversal valve, utilize the voltage supply of work plane emulsion power pack, left and right adjust high cylinder is controlled, and then changed rocking arm height and the height of mining.Because fixing the position of work plane emulsion power pack,, in the working space in underground mining, therefore can greatly reduce the length of fuselage, do not improved the compliance of coal-winning machine.

The above is only the preferred embodiment of the present invention; be noted that for those skilled in the art; under the premise without departing from the principles of the invention, can also make some improvements and modifications, these improvements and modifications also should be considered as protection scope of the present invention.

Claims (4)

1. a low seam mining machinery, it is characterized in that: comprise fuselage, described fuselage interior is provided with control cabinet (1), described control cabinet is provided with PLC electrical control system in (1), left and right sides at control cabinet (1) is respectively provided with one group of identical traction walking mechanism and cutting units, described traction walking mechanism comprises tractive unit and running part, and described cutting units comprises rocking arm and cutting drum;

In fuselage interior, the left side of described control cabinet (1) is provided with left tractive unit (3), the right side of control cabinet (1) is provided with independent pumping plant (2) and right tractive unit (5) successively, between above-mentioned control cabinet (1), left tractive unit (3), independent pumping plant (2) and right tractive unit (2), all by several High Performance Hydraulic Nut (16), connects respectively; Described independent pumping plant (2) is connected with left and right adjust high cylinder respectively and common formed rocking arm and heighten hydraulic means by fluid pressure line and reversal valve; Described left tractive unit (3) is hinged with one end of left adjust high cylinder (11), and one end of described right tractive unit and right adjust high cylinder (12) is hinged;

Left and right sides lower position in control cabinet (1) old man's side is respectively provided with identical left running part (4) and right running part (6), described left running part (4) is bolted with the tractive unit of respective side respectively with right running part (6), and left and right tractive unit drives left and right running part to walk on drag conveyor pin rail by traction electric machine;

Outside at fuselage, the end of the rocking arm of cutting units becomes swallow-tail form, an angle of rocking arm dovetail respectively with the tractive unit of respective side on side plate hinged, another angle of rocking arm dovetail is hinged with the other end of the adjust high cylinder of respective side respectively;

On described rocking arm, be equipped with cutting motor and rocker-arm driving device, and cutting motor is bi-motor series connection form, described rocking arm front end is all provided with described cutting drum, and between rocking arm and cutting drum, by square feather joint, cutting motor drives cutting drum to work by rocker-arm driving device.

Also comprise work plane emulsion power pack, the feed pipe of work plane emulsion power pack is connected in the special distribution valve at control cabinet (1) rear portion, by distributing valve and then be connected to described reversal valve.

2. a kind of low seam mining machinery according to claim 1, it is characterized in that: described traction electric machine is connected with female splined shaft gear by external splines output shaft, after two-stage spur gear slows down, passing to two-stage planetary reduction mechanism exports by planet carrier, by spline, be connected with running part driving wheel, running part drive wheel road wheel is walked on drag conveyor pin rail.

3. a kind of low seam mining machinery according to claim 1, is characterized in that: the cutting motor in described rocking arm drives cutting drum to rotate by square flange after slowing down by three grades of spur gears again after primary planet pinion slows down.

4. a kind of low seam mining machinery according to claim 1, is characterized in that: described traction electric machine is alternating-current variable frequency motor.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201310456149.6A CN103603662A (en) | 2013-09-29 | 2013-09-29 | Coal cutter for thin coal layer |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201310456149.6A CN103603662A (en) | 2013-09-29 | 2013-09-29 | Coal cutter for thin coal layer |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN103603662A true CN103603662A (en) | 2014-02-26 |

Family

ID=50121914

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201310456149.6A Pending CN103603662A (en) | 2013-09-29 | 2013-09-29 | Coal cutter for thin coal layer |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN103603662A (en) |

Cited By (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN104695953A (en) * | 2015-02-15 | 2015-06-10 | 山东科技大学 | Coal cutter realizing automatic height adjustment of barrel and working method of coal cutter |

| CN105804743A (en) * | 2016-04-11 | 2016-07-27 | 中南大学 | Continuous rotating and vibrating cutting equipment realizing pregrooving and used for hard rock ore body and construction process of equipment |

| CN106640069A (en) * | 2017-01-17 | 2017-05-10 | 太原理工大学 | Coal mining machine and transmission system thereof |

| CN108612527A (en) * | 2018-04-13 | 2018-10-02 | 山东里能鲁西矿业有限公司 | A kind of low seam mining machinery |

| CN108661636A (en) * | 2018-03-24 | 2018-10-16 | 山东里能鲁西矿业有限公司 | A kind of low seam mining machinery rocking arm |

| CN109372808A (en) * | 2018-10-10 | 2019-02-22 | 三重型装备有限公司 | Height-adjustment hydraulic system for coal mining machine, coalcutter and complete set of equipments system |

| CN111608655A (en) * | 2020-05-22 | 2020-09-01 | 张世利 | Hydraulic drive thin coal seam coal mining machine |

| CN115949405A (en) * | 2023-03-14 | 2023-04-11 | 三一重型装备有限公司 | Coal mining machine control method and system, coal mining machine, electronic equipment and computer medium |

| CN117569804A (en) * | 2024-01-16 | 2024-02-20 | 山西启创达矿山设备制造有限责任公司 | Double-cutting-part coal mining machine rocker arm and use method thereof |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB1481917A (en) * | 1974-05-28 | 1977-08-03 | Eickhoff Geb | Drum cutter loader mining machines |

| CN201053320Y (en) * | 2007-03-29 | 2008-04-30 | 辽源煤矿机械厂 | Low coal seam hydraulic drag coal cutter |

| CN201326417Y (en) * | 2008-12-12 | 2009-10-14 | 浦国树 | Airborne electric traction coal mining machine for ultra-thin coal seams |

| CN202187761U (en) * | 2011-07-16 | 2012-04-11 | 西安煤矿机械有限公司 | High-power heavy type low seam mining machine |

| CN202926325U (en) * | 2012-11-10 | 2013-05-08 | 山东先河悦新机电股份有限公司 | Alternative-current traction coal mining machine of thin coal seam |

| CN203603898U (en) * | 2013-09-29 | 2014-05-21 | 江苏中机矿山设备有限公司 | Thin coal seam coal mining machine |

-

2013

- 2013-09-29 CN CN201310456149.6A patent/CN103603662A/en active Pending

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB1481917A (en) * | 1974-05-28 | 1977-08-03 | Eickhoff Geb | Drum cutter loader mining machines |

| CN201053320Y (en) * | 2007-03-29 | 2008-04-30 | 辽源煤矿机械厂 | Low coal seam hydraulic drag coal cutter |

| CN201326417Y (en) * | 2008-12-12 | 2009-10-14 | 浦国树 | Airborne electric traction coal mining machine for ultra-thin coal seams |

| CN202187761U (en) * | 2011-07-16 | 2012-04-11 | 西安煤矿机械有限公司 | High-power heavy type low seam mining machine |

| CN202926325U (en) * | 2012-11-10 | 2013-05-08 | 山东先河悦新机电股份有限公司 | Alternative-current traction coal mining machine of thin coal seam |

| CN203603898U (en) * | 2013-09-29 | 2014-05-21 | 江苏中机矿山设备有限公司 | Thin coal seam coal mining machine |

Cited By (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN104695953A (en) * | 2015-02-15 | 2015-06-10 | 山东科技大学 | Coal cutter realizing automatic height adjustment of barrel and working method of coal cutter |

| CN105804743A (en) * | 2016-04-11 | 2016-07-27 | 中南大学 | Continuous rotating and vibrating cutting equipment realizing pregrooving and used for hard rock ore body and construction process of equipment |

| CN106640069A (en) * | 2017-01-17 | 2017-05-10 | 太原理工大学 | Coal mining machine and transmission system thereof |

| CN108661636A (en) * | 2018-03-24 | 2018-10-16 | 山东里能鲁西矿业有限公司 | A kind of low seam mining machinery rocking arm |

| CN108612527A (en) * | 2018-04-13 | 2018-10-02 | 山东里能鲁西矿业有限公司 | A kind of low seam mining machinery |

| CN109372808A (en) * | 2018-10-10 | 2019-02-22 | 三重型装备有限公司 | Height-adjustment hydraulic system for coal mining machine, coalcutter and complete set of equipments system |

| CN111608655A (en) * | 2020-05-22 | 2020-09-01 | 张世利 | Hydraulic drive thin coal seam coal mining machine |

| CN115949405A (en) * | 2023-03-14 | 2023-04-11 | 三一重型装备有限公司 | Coal mining machine control method and system, coal mining machine, electronic equipment and computer medium |

| CN115949405B (en) * | 2023-03-14 | 2023-06-02 | 三一重型装备有限公司 | Coal mining machine control method, system, coal mining machine, electronic equipment and computer medium |

| CN117569804A (en) * | 2024-01-16 | 2024-02-20 | 山西启创达矿山设备制造有限责任公司 | Double-cutting-part coal mining machine rocker arm and use method thereof |

| CN117569804B (en) * | 2024-01-16 | 2024-03-19 | 山西启创达矿山设备制造有限责任公司 | Double-cutting-part coal mining machine rocker arm and use method thereof |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN103603662A (en) | Coal cutter for thin coal layer | |

| CN203603898U (en) | Thin coal seam coal mining machine | |

| CN203476332U (en) | Crawler type coal mining machine | |

| CN201560761U (en) | Open-driving hydraulic traction coal mining machine | |

| CN203612840U (en) | Mining hydraulic monorail hoist | |

| CN102979521B (en) | Rocker-type transverse shearer | |

| CN104709152B (en) | Middle trough moving van | |

| CN202064948U (en) | Ultra-low surface full hydraulic drilling type coal mining machine | |

| CN103982182B (en) | Cutting part of heading machine hybrid power transmission system | |

| CN107165662B (en) | Crushing anchor protector | |

| CN203050701U (en) | Traction part with bridge-type structure for low-seam coal-mining machine | |

| CN202265845U (en) | Mine crawler loader | |

| CN105197626B (en) | A kind of material Loosen machine | |

| CN203856422U (en) | Guy line-free sand washing workover rig | |

| CN103174416B (en) | Multi-point drive electric traction coal mining machine | |

| CN202810650U (en) | Crawler-type double-arm full-hydraulic drilling rig | |

| CN102733807B (en) | Diesel-power full-hydraulic continuous stripping machine | |

| CN201722715U (en) | Tilt-shovel hydraulic rock shoveling machine | |

| CN203097891U (en) | Rocker type transverse drum shearer | |

| CN104564076A (en) | Caterpillar band walking type double-barrel coal cutter for strip mine | |

| CN201896617U (en) | Coal charging machinery used on blasting driving face of coal mine | |

| CN201326417Y (en) | Airborne electric traction coal mining machine for ultra-thin coal seams | |

| CN204371343U (en) | A kind of opencut caterpillar track travelling double-ended shearer | |

| CN102889080A (en) | Dragging part of torque shunting thin coal layer mining machine | |

| CN102530571A (en) | All-hydraulic tracked reclaimer and charger |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C02 | Deemed withdrawal of patent application after publication (patent law 2001) | ||

| WD01 | Invention patent application deemed withdrawn after publication |

Application publication date: 20140226 |