CN102840407B - Assembling method of composite rubber air channel - Google Patents

Assembling method of composite rubber air channel Download PDFInfo

- Publication number

- CN102840407B CN102840407B CN201210352176.4A CN201210352176A CN102840407B CN 102840407 B CN102840407 B CN 102840407B CN 201210352176 A CN201210352176 A CN 201210352176A CN 102840407 B CN102840407 B CN 102840407B

- Authority

- CN

- China

- Prior art keywords

- air channel

- rubber air

- main body

- steel loop

- mounting hole

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 238000000034 method Methods 0.000 title claims abstract description 12

- 239000002131 composite material Substances 0.000 title abstract description 6

- 229910000831 Steel Inorganic materials 0.000 claims abstract description 64

- 239000010959 steel Substances 0.000 claims abstract description 64

- 238000009423 ventilation Methods 0.000 claims abstract description 21

- 238000007789 sealing Methods 0.000 claims abstract description 7

- 238000004080 punching Methods 0.000 claims description 12

- 238000005987 sulfurization reaction Methods 0.000 claims description 4

- 230000015572 biosynthetic process Effects 0.000 claims description 3

- 238000010276 construction Methods 0.000 claims description 2

- 238000009434 installation Methods 0.000 abstract description 4

- 238000005096 rolling process Methods 0.000 abstract description 3

- 230000001105 regulatory effect Effects 0.000 description 6

- 150000001875 compounds Chemical class 0.000 description 4

- 230000000694 effects Effects 0.000 description 4

- 239000010410 layer Substances 0.000 description 4

- 238000010586 diagram Methods 0.000 description 3

- 238000005516 engineering process Methods 0.000 description 3

- 239000003292 glue Substances 0.000 description 3

- 239000010935 stainless steel Substances 0.000 description 3

- 229910001220 stainless steel Inorganic materials 0.000 description 3

- 239000005030 aluminium foil Substances 0.000 description 2

- 230000007797 corrosion Effects 0.000 description 2

- 238000005260 corrosion Methods 0.000 description 2

- 238000005187 foaming Methods 0.000 description 2

- 239000000463 material Substances 0.000 description 2

- 238000012986 modification Methods 0.000 description 2

- 230000004048 modification Effects 0.000 description 2

- 238000003466 welding Methods 0.000 description 2

- 229910000838 Al alloy Inorganic materials 0.000 description 1

- 229920000742 Cotton Polymers 0.000 description 1

- 239000000956 alloy Substances 0.000 description 1

- 238000013475 authorization Methods 0.000 description 1

- 239000004568 cement Substances 0.000 description 1

- 238000009833 condensation Methods 0.000 description 1

- 230000008602 contraction Effects 0.000 description 1

- 230000007812 deficiency Effects 0.000 description 1

- 238000009826 distribution Methods 0.000 description 1

- 230000008030 elimination Effects 0.000 description 1

- 238000003379 elimination reaction Methods 0.000 description 1

- 230000002708 enhancing effect Effects 0.000 description 1

- 238000009413 insulation Methods 0.000 description 1

- 239000005435 mesosphere Substances 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- 229910052751 metal Inorganic materials 0.000 description 1

- 230000002265 prevention Effects 0.000 description 1

- 239000011241 protective layer Substances 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

Images

Landscapes

- Vibration Prevention Devices (AREA)

Abstract

The invention discloses a composite rubber air channel capable of bearing negative pressure and high pressure and an assembling method thereof. The composite rubber air channel comprises a rubber air channel main body and a support steel ring with an installation hole, wherein the support steel ring is positioned inside and/or outside the rubber air channel main body; the rubber air channel main body is also provided with an installation hole which is aligned with the installation hole on the support steel ring; and the support steel ring is arranged on the rubber air channel main body through a bolt, a gasket and a nut. The assembling method comprises the following steps of: preparing the rubber air channel main body; determining the quantity and positions of the support steel ring(s); installing the bolt and the nut; and screwing, sealing and assembling. The composite rubber air channel is convenient to assemble, can bear negative pressure and high pressure, is mainly applied to flexible connection of air conditioner cabinets of various rolling stocks and vehicle body ventilation pipelines, and can be suitable for any flexible connection and ventilation positions of engineering machinery and the like simultaneously.

Description

Technical field

The present invention relates to a kind of air channel and assembling method thereof, particularly a kind of compounded rubber air channel and assembling method thereof that refers to bear negative pressure and large pressure.

Background technique

Rubber air channel is a kind of ventilation duct for flexibly connecting of commonly using, and can be widely used in the various ventilation occasions that flexibly connect, and especially in the ventilation system of rolling stock, application is very general.Wherein apply most often gum air channel.There are its some advantages in gum air channel, and also having shortcoming, advantage is simultaneously that they can meet the basic demand flexibly connecting with general follow board, shortcoming is, when product bears negative pressure, and the rubber contraction deformation in gum air channel, ventilation-sectional area is reduced, can not meet ventilation requirement; Or during large pressure, the rubber in gum air channel expands outwardly, interfere with parts around, product is destroyed.

Along with the development of rolling stock technology, the particularly development of speed car technology, therefore running velocity is more and more faster, crosses or during access tunnel, car body annex can form powerful subnormal ambient, and the pressure of ventilation system is also increasing at vehicle.Gum air channel can not meet the usage requirement of these environment, and this rubber air channel that can bear negative pressure and large pressure that just need to study a kind of new structure is to meet these requirements.

In prior art, also the compound air duct that has other, if notice of authorization number is the Chinese utility model patent Novel composite air duct of CN 201214421Y, two-layer aluminium foil, the two-layer foaming body inside described aluminium foil and vulcanite five layer materials that are clipped between two-layer foaming body, consist of, two ends, described air channel are respectively provided with the link for being connected with other air channel.Notification number is a kind of air duct used for train of the Chinese utility model patent of CN201362256Y, has air channel housing, and air channel housing adopts aluminum alloy material to make, and is provided with acoustical cotton at the inwall of air channel housing, at outer wall, is coated with anti-condensation material.Notification number is the Chinese patent " inlaid frame compound board air duct " of CN2233059, this compound board air duct is comprised of shell, frame column and air duct joint, shell is to be made by the composite sheet with outer protective layer insulation noise elimination mesosphere and sheath, the outer corner of shell is provided with embedded enhancing rubber cement and solidifies frame column or metal board-coated frame column, shell end is provided with flange or inner sleeve air duct joint, and solidifies and connect as one with frame column.These compound air ducts, or can not bear large pressure, otherwise weight own is heavier, assembles and is not very convenient.Be necessary further to be improved.

Summary of the invention

The technical problem to be solved in the present invention is the deficiency for existing rubber air channel, provides a kind of not only easy to assembly but also can bear negative pressure and compounded rubber air channel and the assembling method thereof of large pressure.

For solving the problems of the technologies described above, the technical solution adopted in the present invention is:

The described compounded rubber air channel that can bear negative pressure and large pressure comprises rubber air channel main body, with the support steel loop of mounting hole, described support steel loop is positioned at inside and or the outside of rubber air channel main body; In the main body of described rubber air channel, be also provided with the mounting hole that can align with the mounting hole supporting on steel loop, described support steel loop is arranged in the main body of rubber air channel by bolt, pad and nut.

Described rubber air channel main body is made by sulfuration by elastic rubbery body.The mounting hole place of rubber air channel main body and support steel loop by applying suitable pretightening force apart from realizing sealing on nut.The size of described compounded rubber air channel diameter during according to normal pressure the size of ventilation determine; When supporting the size of the quantity of steel loop and position ventilation when bearing negative pressure and bearing large pressure, the range of expansion in air channel is determined.Described support steel loop adopts stainless steel, and quantity is one or more and is uniformly distributed; Mounting hole quantity on described support steel loop is more than two or two and is uniformly distributed.During described bolt assembling, on surface, be coated with happy safe fastening glue, described nut adopts lock nut.

The described assembling method that can bear the compounded rubber air channel of negative pressure and large pressure, comprises the following steps:

(1) be ready to rubber air channel main body: during according to normal pressure, the size of ventilation is determined the size of rubber air channel main diameter, elastic rubbery body is made into rubber air channel main body by sulfuration, and identify at rubber air channel body surfaces formation punching position by mould, according to punching position sign, with punching pin made mounting hole in the main body of rubber air channel;

(2) determine to support quantity and the position of steel loop: when bearing negative pressure the size of ventilation and while bearing large pressure the range of expansion in air channel determine quantity and the position of supporting steel loop, the support steel loop that is drilled with the corresponding mounting hole is placed on to inside and or the outside in rubber air channel, and makes the mounting hole in the main body of rubber air channel and support the mounting hole alignment on steel loop;

(3) construction bolt nut a: pad is respectively put at the mounting hole place in supporting steel ring surface and rubber air channel body surfaces, then by bolt ecto-entad through pad, rubber air channel main body, support the mounting hole of steel loop, nut is screwed on bolt;

(4) tighten sealing, complete assembling: on nut, apply suitable pretightening force distance, realize the sealing at rubber air channel and steel loop mounting hole place, complete the assembling in described compounded rubber air channel.

When negative pressure is born in described compounded rubber air channel, can inside recessed distortion under the effect of pressure without the rubber that supports steel loop supporting zone, cause vent area to reduce.When rubber deformation position extends to steel loop Support Position, the rigidity that supports steel loop can stop rubber to continue distortion, keeps ventilation-sectional area constant, guarantees suitable ventilation.When large pressure is born in described compounded rubber air channel, without steel loop supporting zone rubber can be under the effect of pressure outside dilatancy, when rubber deformation position extends to support steel loop Support Position, the rigidity that supports steel loop can stop rubber to continue dilatancy, thereby within the amount of deformation in rubber air channel is limited in to certain scope.

By regulating the size of rubber air channel diameter, the size of ventilation while regulating normal pressure; By adjusting, support quantity and the position of steel loop, the range of expansion in air channel when regulating the size of ventilation while bearing negative pressure and bearing large pressure.

As a further improvement on the present invention, support steel loop and adopt stainless steel, can corrosion protection.

As a further improvement on the present invention, nut adopts lock nut, the inefficacy that comes off of prevention nut.

As a further improvement on the present invention, on bolt, being coated with happy safe solid glue during assembling plays a part fastening and seals.

As a further improvement on the present invention, the quantity that supports steel loop is more than or equal to 1 and be uniformly distributed.

As a further improvement on the present invention, each supports mounting hole on steel loop and is more than or equal to 2 and be uniformly distributed.

Described compounded rubber air channel is easy to assembly, can bear negative pressure and large pressure, be mainly used in various kinds of vehicles vehicle Air conditioner cabinet and the flexibly connecting of car body ventilation duct, especially for the Air conditioner cabinet of bullet train and flexibly connecting of car body ventilation duct, also go for any positions that flexibly connect and ventilate such as engineering machinery simultaneously.

Accompanying drawing explanation

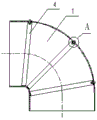

Fig. 1 is for bearing the form structure schematic diagram in the compounded rubber air channel of negative pressure and large pressure;

Fig. 2 is the local structure for amplifying schematic diagram in A place in Fig. 1;

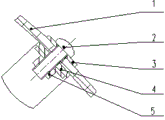

Fig. 3 (a) launches schematic diagram before supporting steel ring welding;

Fig. 3 (b) is the radial section structural representation after supporting steel ring welding forming.

In figure: 1, rubber air channel main body; 2, bolt; 3, pad; 4, support steel loop; 5, nut.

Embodiment

Be a described embodiment that can bear the compounded rubber air channel of negative pressure and large pressure as shown in Figure 1 to Figure 3, comprise rubber air channel main body 1, with the support steel loop 4 of mounting hole, described support steel loop 4 is positioned at the inside of rubber air channel main body 1; In described rubber air channel main body 1, be also provided with the mounting hole that can align with the mounting hole supporting on steel loop 4, described compounded rubber air channel is mainly assembled and is formed by bolt 2, pad 3 and nut 5 by rubber air channel main body 1 and support steel loop 4.

The assembling in described compounded rubber air channel completes in the following manner, and elastic rubbery body is formed to rubber air channel main body 1 by sulfuration, and identifies at rubber air channel main body 1 surface formation punching position by mould, is convenient to punching location; According to home position, use punching pin in rubber covering punching; The support steel loop 4 that is drilled with mounting hole is placed on to the inside of rubber air channel main body 1, and make the mounting hole of rubber air channel main body 1 and support the mounting hole alignment on steel loop 4, then on support steel loop 4 surfaces and rubber air channel main body 1 surperficial mounting hole place, respectively put a pad 3, again bolt 2 ecto-entads passed to pad 3, rubber air channel main body 1, support steel loop 4, last mounting nuts 5, and on nut 5, apply suitable pretightening force distance, realize the sealing of rubber air channel main body 1 and support steel loop 4 installation places.

As other embodiment of the present invention, the places different from above-described embodiment are, on the basis of above-described embodiment, are also included in the outside of rubber air channel main body 1 or externally also install and support steel loop 4 with inside, and concrete assembling method is similar to the above embodiments.

When negative pressure is born in described compounded rubber air channel, can inside recessed distortion under the effect of pressure without supporting steel loop 4 supporting zone rubber, cause vent area to reduce.When rubber deformation position extends to support steel loop Support Position, the rigidity that supports steel loop 4 can stop rubber to continue distortion, keeps ventilation-sectional area constant, guarantees suitable ventilation.When large pressure is born in compounded rubber air channel, without support steel loop 4 supporting zone rubber can be under the effect of pressure outside dilatancy, when rubber deformation position extends to support steel loop 4 Support Position, the rigidity that supports steel loop 4 can stop rubber to continue dilatancy, thereby within the amount of deformation in rubber air channel is limited in to certain scope.By regulating the size of described compounded rubber air channel diameter, the size of ventilation while regulating normal pressure; By adjusting, support quantity and the position of steel loop 4, the range of expansion in air channel when regulating the size of ventilation while bearing negative pressure and bearing large pressure.

The above is only the preferred embodiment of the present invention; it should be pointed out that for those skilled in the art, do not departing under the prerequisite of the principle of the invention and aim; can also make some improvements and modifications, these improvements and modifications also should be considered as protection scope of the present invention.

Claims (1)

1. the assembling method in compounded rubber air channel, described compounded rubber air channel comprises rubber air channel main body (1) and with the support steel loop (4) of mounting hole, described support steel loop be positioned at rubber air channel main body (1) inside and or outside; In described rubber air channel main body (1), be also provided with the mounting hole aliging with the mounting hole supporting on steel loop (4), described support steel loop (4) is arranged in rubber air channel main body (1) by bolt (2), pad (3) and nut (5); It is characterized in that, the assembling method in described compounded rubber air channel comprises the following steps:

(1) be ready to rubber air channel main body: during according to normal pressure, the size of ventilation is determined the size of rubber air channel main diameter, elastic rubbery body is made into rubber air channel main body by sulfuration, and identify at rubber air channel body surfaces formation punching position by mould, according to punching position sign, with punching pin made mounting hole in the main body of rubber air channel;

(2) determine to support quantity and the position of steel loop: when bearing negative pressure the size of ventilation and while bearing large pressure the range of expansion in air channel determine quantity and the position of supporting steel loop, the support steel loop that is drilled with the corresponding mounting hole is placed on to inside and or the outside of rubber air channel main body, and makes the mounting hole of rubber air channel main body and support the mounting hole alignment on steel loop;

(3) construction bolt nut a: pad is respectively put at the mounting hole place in supporting steel ring surface and rubber air channel body surfaces, then by bolt ecto-entad through pad, rubber air channel main body, support the mounting hole of steel loop, nut is screwed on bolt;

(4) tighten sealing, complete assembling: on nut, apply suitable pretightening force distance, realize the sealing at rubber air channel main body and steel loop mounting hole place, complete the assembling in described compounded rubber air channel.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201210352176.4A CN102840407B (en) | 2012-09-21 | 2012-09-21 | Assembling method of composite rubber air channel |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201210352176.4A CN102840407B (en) | 2012-09-21 | 2012-09-21 | Assembling method of composite rubber air channel |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN102840407A CN102840407A (en) | 2012-12-26 |

| CN102840407B true CN102840407B (en) | 2014-03-12 |

Family

ID=47368029

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201210352176.4A Expired - Fee Related CN102840407B (en) | 2012-09-21 | 2012-09-21 | Assembling method of composite rubber air channel |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN102840407B (en) |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103411049A (en) * | 2013-07-22 | 2013-11-27 | 苏州天华有色金属制品有限公司 | Flexible air pipe |

| CN111421733B (en) * | 2020-04-01 | 2021-11-16 | 国际竹藤中心 | Preparation method of winding-formed composite heat-insulation air pipe |

| CN111421852B (en) * | 2020-04-01 | 2021-11-16 | 国际竹藤中心 | Preparation method of multi-wall-layer weather-resistant plant fiber reinforced air pipe |

| CN115711255A (en) * | 2021-08-23 | 2023-02-24 | 中国航天科工飞航技术研究院(中国航天海鹰机电技术研究院) | Sealing connecting piece with gear groove and high-speed flying train |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE4244493A1 (en) * | 1992-01-18 | 1993-07-22 | Eilentropp Hew Kabel | |

| CN201214421Y (en) * | 2008-08-05 | 2009-04-01 | 铁道部运输局 | Novel composite air duct |

| CN201824864U (en) * | 2010-09-13 | 2011-05-11 | 株洲创春科技实业有限责任公司 | Cooling soft air duct for traction motor of electric locomotive |

| CN202368587U (en) * | 2011-12-20 | 2012-08-08 | 扬州华通橡塑有限公司 | Soft connection air channel for train set ventilation system |

-

2012

- 2012-09-21 CN CN201210352176.4A patent/CN102840407B/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| CN102840407A (en) | 2012-12-26 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN102840407B (en) | Assembling method of composite rubber air channel | |

| CN201148897Y (en) | Air discharge system sealing device | |

| CN203067961U (en) | A shock absorber | |

| CN106015780A (en) | Pipeline device for car air conditioning system | |

| CN204704512U (en) | A kind of automobile exhaust system and exhaust flange assembly thereof | |

| CN102888925B (en) | Keel connecting assembly for mounting curtain wall plate | |

| CN103062510B (en) | A kind of for the special-shaped sealing structure through casing | |

| CN201326868Y (en) | Press-fitting pipe orifice packer | |

| CN205013948U (en) | Compensator connection structure | |

| CN204222843U (en) | Brake hose structure after a kind of | |

| CN203835979U (en) | Hub bearing | |

| JP5161758B2 (en) | Waterproof piping equipment in buildings | |

| CN211525743U (en) | Pipeline | |

| CN222067837U (en) | Installation component of send exhaust line | |

| CN207958967U (en) | A kind of fixed sealing device for bridge steel box girder circle duct | |

| CN203272506U (en) | Self-returning ball coupling | |

| CN204648764U (en) | A kind of evaporimeter hermetically-sealed construction | |

| CN223839876U (en) | Hydraulic engineering pipeline protector | |

| CN207527138U (en) | A kind of clutch pipeline assembly with vibration insulation structure | |

| CN213654915U (en) | External channel fixing system for shield tunnel tunnel | |

| CN207146784U (en) | A kind of suspention steel construction ducting system at Novel underground high ferro station | |

| CN203770865U (en) | Metal composite foamed air ducts and connection structure thereof | |

| CN207747848U (en) | A kind of vehicle side ornamental strip assembly | |

| CN218935588U (en) | Petroleum pipeline sealing element | |

| CN217537718U (en) | Butt-joint structural of civil engineering wind channel |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant | ||

| TR01 | Transfer of patent right |

Effective date of registration: 20200608 Address after: 412007 No.301, physical and chemical building, Liyu Industrial Park, no.639, Heilongjiang Road, Tianyuan District, Zhuzhou City, Hunan Province Patentee after: Zhuzhou Times Ruiwei damping equipment Co.,Ltd. Address before: 412007 No. 18 Haitian Road, Tianyuan District, Hunan, Zhuzhou Patentee before: Zhuzhou Times New Material Technology Co.,Ltd. |

|

| TR01 | Transfer of patent right | ||

| CF01 | Termination of patent right due to non-payment of annual fee |

Granted publication date: 20140312 |

|

| CF01 | Termination of patent right due to non-payment of annual fee |