The cooling tower noise elimination structure

Technical field

The present invention relates to the technical field that Cooling Tower for Air conditioning System is eliminated the noise, particularly relate to a kind of noise elimination structure that can eliminate the cooling tower buzz airborne noise.

Background technology

Cooling tower is widely used in commercial production and the commercial field as exchange heat equipment.In recent years, along with the construction of a large amount of skyscrapers in city, the annex of skyscraper is often as the mechanical floor of cooling tower; The noise of cooling tower does not add obstruct; The architecture storey on through next door, to the life of resident family, having a rest makes a big impact, the cooling tower buzz incident that disturbs residents frequently takes place.

The cooling tower main noise is that Low Medium Frequency is main circulating fan ventilation noise, wherein comprises the air power noise of air-flow generation and the mechanical noise that driving mechanism produces again.Higher and low-frequency noise penetrates, diffracting power is strong because of its sounding position, spread scope is far away, and the most outstanding to the influence of surrounding environment.Because the axial flow fan in cooling tower blast is low; Its air quantity and integral heat sink effect are very responsive to the drag losses of sound-attenuating system; So the difficult point that the cooling tower noise reduction is administered just is the contradiction between loud value, wide band noise elimination requirement and cooling tower self the ventilation and heat performance, its noise abatement must take into account a series of correlative factors such as thermal property, structural manufacturing process, ordinary maintenance, improvement expenses.

Existing cooling tower buzz control measures mainly is; In the axial flow fan in cooling tower outlet guiding airduct is set, built-in resistive garden shape anechoic sheet, effective air-out area of anechoic sheet is an axial flow blower upright projection area; Its shortcoming is, and is bigger to blast, the wind loss of axial flow blower.The cooling tower filler district directly is provided with air intake noise elimination louver, and its shortcoming is that noise elimination louver cost is high, sound deadening capacity is not enough.

Summary of the invention

The object of the present invention is to provide a kind of easy for installationly, can effectively eliminate the cooling tower airborne noise transmission, prevent to produce the blast of blower fan of cooling tower, the noise control method of wind loss, meet the cooling tower noise elimination structure of silencer acoustics standard.

The technical solution adopted for the present invention to solve the technical problems is: on cooling tower top the air-out silencer is set; The air outlet of air-out silencer is the main noise sensitive spot dorsad, prevents noise radiation, and air-out silencer external form is the moulding of arc water conservancy diversion; Form the noise elimination breathing space between axial flow blower and the moulding of arc water conservancy diversion; The air-out silencer exports the resistance noise reduction inserted sheet that laterally arranges, and forms resistance noise reduction inserted sheet structure, and the air-out silencer is up 30 ° of oblique angle moulding at axial flow blower with exterior portions; Meet the air force code requirement; The hot gas that prevents air outlet gets into the packing area again, and the vertical sound insulation baffle plate under the air-out silencer is on top, packing area, to avoid hindering the maintenance of cooling tower.Structure is sound insulating layer between cooling tower two side elevations and two side elevations and the cooling tower upper brace, in establish the absorbent treatment peripheral hardware and decorate armour layer, between use the sound insulating layer sealing at interval, in establish absorbent treatment, peripheral hardware is decorated armour layer.

The cooling tower bottom is provided with the air intake silencer, and the air inlet of air intake silencer is towards the noise-sensitive point, in the cooling tower filler district with the lower part; Air intake silencer superstructure is down 30 ° of oblique angle moulding; Outer is vertical moulding, and vertical moulding and packing area distance are the height of packing area, is the sound insulation baffle plate in the middle of vertical sound insulating layer and the packing area; In the middle of the sound insulation baffle plate is sound insulating layer; Two limits are absorbent treatment, form the labyrinth type noise elimination structure of air intake silencer, and vertical moulding and ground distance are that 1/2 of packing area height is established the air intake louver.Incoming air area satisfies the code requirement of the ratio of GB/T50392-2006 " mechanical-draft cooling tower production engineering specifications " 6.3 air inlet 6.3.2 air inlets area in the packing area.

The invention has the beneficial effects as follows that the air-out blast of axial flow fan in cooling tower, wind loss are little, the incoming air area of packing area satisfies code requirement, and the effect of eliminating the cooling tower airborne noise transmission is remarkable.

Below in conjunction with accompanying drawing and embodiment the present invention is further explained.

Description of drawings

Fig. 1 is the embodiments of the invention front views.

Fig. 2 is an embodiments of the invention texture edge cutaway view.

Fig. 3 is an embodiments of the invention structure A partial enlarged drawing.

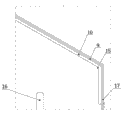

1. cooling towers among the figure, 2. air outlet, 3. air inlet, 4. main noise sensitive spot, 5. air-out silencer; 6. air intake silencer, 7. arc water conservancy diversion moulding, 8. resistance noise reduction inserted sheet structure, 9. sound insulating layer, 10. absorbent treatment; 11. axial flow blower, 12. noise elimination breathing spaces, 13. packing areas, 14. air intake louvers, 15.30 ° of oblique angles; 16. the sound insulation baffle plate, 17. decorate armour layer, 18. labyrinth type noise elimination structures, 19. upper braces, 20. 2 side elevations.

The specific embodiment

In Fig. 1, air-out silencer (5) is on cooling tower (1) axial flow blower (11) top, and two side elevations (20) are in cooling tower (1) left and right sides, and is sound insulating layer (9) between cooling tower (1) upper brace (19).

In Fig. 2, the embodiment shown in 3; Resistance noise reduction inserted sheet structure (8) part of air-out silencer (5) is upper and lower to be 30 ° of oblique angle moulding (15); Be noise elimination breathing space (12) between arc water conservancy diversion moulding (7) and the axial flow blower (11); Air intake silencer (6) top is 30 ° of oblique angle moulding (15); Vertical sound insulating layer (9) and packing area (13), the centre is sound insulation baffle plate (16), is that sound insulating layer (9) two limits are absorbent treatment (10) in the middle of the sound insulation baffle plate (16); Form the labyrinth type noise elimination structure (18) of air intake silencer (6); Air inlet (3) uses air intake louver (14), and the structure between air-out silencer (5), air intake silencer (6), cooling tower (1) two side elevation (20) and two side elevations (20) and the cooling tower upper brace (19) is establishes absorbent treatment (10) in the sound insulating layer (9), and peripheral hardware is decorated armour layer (17).