WO2017001907A1 - Biocatalytic processes for the preparation of vilanterol - Google Patents

Biocatalytic processes for the preparation of vilanterol Download PDFInfo

- Publication number

- WO2017001907A1 WO2017001907A1 PCT/IB2016/000615 IB2016000615W WO2017001907A1 WO 2017001907 A1 WO2017001907 A1 WO 2017001907A1 IB 2016000615 W IB2016000615 W IB 2016000615W WO 2017001907 A1 WO2017001907 A1 WO 2017001907A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- vilanterol

- compound

- process according

- salt

- tartrate

- Prior art date

Links

- 0 CC(C)(OC1)Oc2c1cc([C@@](*)CNCCCCCCOCCOCc(c(Cl)ccc1)c1Cl)cc2 Chemical compound CC(C)(OC1)Oc2c1cc([C@@](*)CNCCCCCCOCCOCc(c(Cl)ccc1)c1Cl)cc2 0.000 description 1

- OWOCWBVFWIFQCF-VWLOTQADSA-N CC(C)(OC1)Oc2c1cc([C@H](CNCCCCCCOCCOCc(c(Cl)ccc1)c1Cl)O)cc2 Chemical compound CC(C)(OC1)Oc2c1cc([C@H](CNCCCCCCOCCOCc(c(Cl)ccc1)c1Cl)O)cc2 OWOCWBVFWIFQCF-VWLOTQADSA-N 0.000 description 1

- UQBUOFMNRQTQCM-UHFFFAOYSA-O CC=C(C(COCCOCCCCCC[NH3+])=C)Cl Chemical compound CC=C(C(COCCOCCCCCC[NH3+])=C)Cl UQBUOFMNRQTQCM-UHFFFAOYSA-O 0.000 description 1

- KHDUONKKQTXFDZ-KWKHWOPJSA-N CCCOCCOC/C(/C(/Cl)=C\CC)=C(/C)\Cl Chemical compound CCCOCCOC/C(/C(/Cl)=C\CC)=C(/C)\Cl KHDUONKKQTXFDZ-KWKHWOPJSA-N 0.000 description 1

- VQIDLHATGFNDLK-NSHDSACASA-O CCNC[C@@H](c(cc1)nc2c1OC(C)(C)[OH+]C2)O Chemical compound CCNC[C@@H](c(cc1)nc2c1OC(C)(C)[OH+]C2)O VQIDLHATGFNDLK-NSHDSACASA-O 0.000 description 1

Classifications

-

- C—CHEMISTRY; METALLURGY

- C12—BIOCHEMISTRY; BEER; SPIRITS; WINE; VINEGAR; MICROBIOLOGY; ENZYMOLOGY; MUTATION OR GENETIC ENGINEERING

- C12P—FERMENTATION OR ENZYME-USING PROCESSES TO SYNTHESISE A DESIRED CHEMICAL COMPOUND OR COMPOSITION OR TO SEPARATE OPTICAL ISOMERS FROM A RACEMIC MIXTURE

- C12P7/00—Preparation of oxygen-containing organic compounds

- C12P7/02—Preparation of oxygen-containing organic compounds containing a hydroxy group

-

- C—CHEMISTRY; METALLURGY

- C07—ORGANIC CHEMISTRY

- C07C—ACYCLIC OR CARBOCYCLIC COMPOUNDS

- C07C41/00—Preparation of ethers; Preparation of compounds having groups, groups or groups

-

- C—CHEMISTRY; METALLURGY

- C07—ORGANIC CHEMISTRY

- C07C—ACYCLIC OR CARBOCYCLIC COMPOUNDS

- C07C43/00—Ethers; Compounds having groups, groups or groups

- C07C43/02—Ethers

- C07C43/03—Ethers having all ether-oxygen atoms bound to acyclic carbon atoms

- C07C43/14—Unsaturated ethers

- C07C43/178—Unsaturated ethers containing hydroxy or O-metal groups

- C07C43/1786—Unsaturated ethers containing hydroxy or O-metal groups containing halogen

-

- C—CHEMISTRY; METALLURGY

- C12—BIOCHEMISTRY; BEER; SPIRITS; WINE; VINEGAR; MICROBIOLOGY; ENZYMOLOGY; MUTATION OR GENETIC ENGINEERING

- C12P—FERMENTATION OR ENZYME-USING PROCESSES TO SYNTHESISE A DESIRED CHEMICAL COMPOUND OR COMPOSITION OR TO SEPARATE OPTICAL ISOMERS FROM A RACEMIC MIXTURE

- C12P41/00—Processes using enzymes or microorganisms to separate optical isomers from a racemic mixture

Definitions

- This invention relates to highly efficient biocatalytic processes for the

- WO2014041565 describes a similar process to the process described in

- WO2003024439 for the preparation of Vilanterol and pharmaceutical acceptable salts thereof, by a process comprising reduction of ketone with borane.

- WO2010/025085 describes engineered ketoreductase enzymes allegedly

- WO 2004/022547 and US 2005/0075394 describe other synthetic approaches 5 which use 2-azido- or 2-(N-Boc)-amino moieties instead of the 2-bromo moiety.

- the reduction in the described processes is done with borane dimethylsulfide complex and CBS-borane catalyst.

- Use of borane and derivatives thereof requires stoichiometric amounts and borane is known to be toxic and not environmentally friendly.

- the desired process comprises a high substrate concentration, allowing high space-time yields (defined as product amount produced per volume and per time, g/l/day or g/l/h).

- the enzyme (catalyst) concentration should be kept low to allow a commercially competitive process.

- the present invention relates to a process for preparing Vilanterol, which

- the present invention relates to methods of using polypeptides for the biocatalytic conversion of the Ketone Substrate, as described herein below, to the corresponding alcohol, preferably wherein the Ketone Substrate is 2-bromo-l-(2,2- dimethyl-4H- l,3-benzodioxin-6-yl)ethanone and it is converted to enantiopure

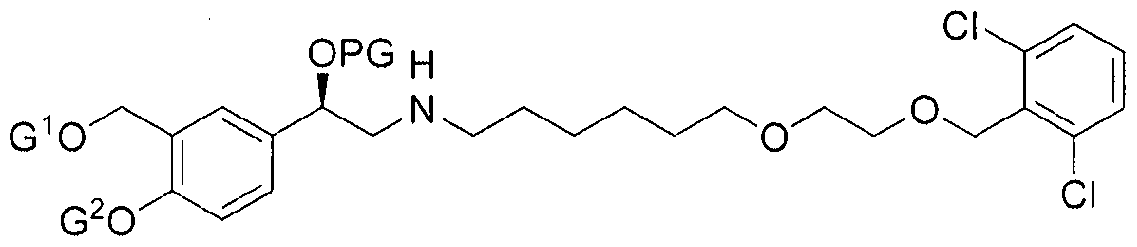

- the present invention provides use of compound of formula V, VI and VII and salts thereof of the following formula:

- the present invention provides preparation of Vilanterol in the form of L-tartaric acid salt.

- the present invention also encompasses the vilanterol tartrate and solid state forms 20 thereof for the preparation of other vilanterol salts, or of vilanterol, solid state

- the present invention also encompasses the vilanterol tartrate and solid state forms thereof described herein for use as medicaments, particularly sole product or as a combination therapy with an inhaled corticosteroid for COPD and asthma. 25

- the present invention also encompasses a process for the preparation of

- compositions comprising combining vilanterol tartrate and solid state forms thereof, or a pharmaceutical composition comprising said vilanterol tartrate and solid state forms thereof and at least one pharmaceutically acceptable

- the present invention also encompasses a method of treating a person suffering from COPD and asthma, comprising administering a therapeutically effective amount of any one or a combination vilanterol tartrate and solid state forms

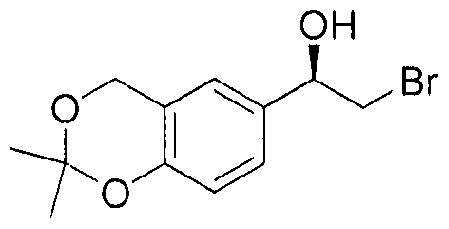

- Figure 1 shows a powder X-ray diffraction pattern ("powder XRD” or "PXRD”) of 5 (R)- 2-bromo-l-(2,2-dimethyl-4H-l,3-benzodioxin-6-yl)ethanol (Compound II).

- Figure 2 shows a powder X-ray diffraction pattern of 6-(2-((2,6- dichlorobenzyl)oxy)ethoxy)hexan-l-amine L-tartaric acid salt (V L-tartrate).

- Figure 3 shows a powder X-ray diffraction pattern of (R)-N-(2-((tert- butyldimethylsilyl)oxy)-2-(2,2-dimethyl-4H-l,3-benzodioxin-6-yl)ethyl)-6-(2-((2,6- 10 dichlorobenzyl)oxy)ethoxy)hexan-l-amine fumarate salt (Via fumarate).

- Figure 4 shows a powder X-ray diffraction pattern of (R)-2-((6-(2-((2,6- dichlorobenzyl)oxy)ethoxy)hexyl)amino)-l-(2,2-dimethyl-4H-l,3-benzodioxin-6- yl)ethan-l-ol L-Tartaric acid salt (VII L-tartrate)

- Figure 5 shows a powder X-ray diffraction pattern of Vilanterol L-tartrate.

- the present invention relates to highly efficient biocatalytic processes for the preparation of Vilanterol and Vilanterol intermediates.

- the present invention provides an improved, safe process with increased

- the present invention offers a desirable, well-controlled biocatalytic process, that may be adapted to a large industrial scale, and allows high substrate loadings (e.g ., > 50 g/L), high percent conversion (e.g., > 90% in 24 h), high 25 enantiomeric excess (e.g., at least about 99% ee) and low enzyme loading (e.g., less than 5 w/w%).

- the process provided in the present invention eliminates the need for an additional co-factor regenerating enzyme other than the ketoreductase enzyme/polypeptide or engineered ketoreductase polypeptide.

- the present invention encompasses crystalline salts of compounds V, VI and VII 30 which are used as intermediates of Vilanterol synthesis.

- the present invention encompasses vilanterol tartrate, solid state forms thereof and pharmaceutical compositions comprising one or more of the vilanterol salts and/or solid state forms thereof.

- the present invention also encompasses vilanterol tartrate and solid state forms thereof for use in the preparation and purification of Vilanterol and Vilanterol salt, such as Vilanterol trifenatate.

- ketooreductase refers to an enzyme/polypeptide that can

- Ketoreductase enzymes include, for example, those classified under the E.C. (or IUBMB - International 5 Union of Biochemistry and Molecular Biology) no. 1.1.1 (i.e. 1.1.1.x) (see

- ketoreductase are given various names in addition to ketoreductase, including, but not

- NADPH-dependent ketoreductases are classified under the IUBMB number of 1.1.1.2 and the CAS number of 9028-12-0.

- ketoreductases are classified under the IUBMB number of 1.1.1.1 and the CAS number 15 of 9031 -72-5.

- the ketoreductases useful for the processes of the present invention comprise enzymes from IUBMB or E.C. 1.1.1.1 and E.C. 1.1.1.2, more

- co-factor refers to a non-protein compound that operates in 20 combination with an enzyme which catalyzes the reaction of interest.

- nicotinamide co-factors such as nicotinamide adenine dinucleotide ('TSfAD”) or a salt thereof, reduced nicotinamide adenine dinucleotide ("NADH”) or a salt thereof, nicotinamide adenine dinucleotide phosphate ("NADP ⁇ + >”), reduced

- NADPH nicotinamide adenine dinucleotide phosphate

- oxidized cofactors function as intermediate hydrogen acceptors in the catalytic mechanism of the enzymes.

- salts of the co- factors include NAD tetra(cyclohexyl ammonium) salt, NAD tetrasodium salt, NAD

- the co-factor is NADP or NADPH.

- the term “isolated” in reference to compounds described in the invention corresponds to a compound that is physically separated from the reaction mixture in which it is formed.

- the term “isolated” in reference to polypeptides/enzymes refers to polypeptides/enzymes at least partially separated from the environment in which they are formed, for example from the natural environment, e.g., from bacteria.

- use of the term “isolated” indicates that a naturally occurring or recombinant enzyme has been at least partially removed from its normal cellular or natural environment, 5 e.g . from bacterial cells.

- the isolated enzyme is in a cell-free system.

- the isolated enzyme can be crude or highly purified.

- isolated does not

- the term "synthesized” or “engineered” refers to 10 an enzyme that is prepared by chemical synthesis, recombinant means, or the

- the term "purified” refers to an enzyme that is essentially free (at least about 90-95% pure) of non- enzymatic material or other enzymes.

- the isolated enzyme can be a lysate or an

- enzyme powder obtained by lyophilization of cell lysates, which can contain isolated, 15 but unpurified enzymes.

- ketoreductase is isolated.

- the ketoreductase can be separated from any host, such as mammals, filamentous fungi, yeasts, and bacteria. The isolation, purification, and

- ketoreductase is synthesized or engineered.

- the ketoreductase can be synthesized chemically or using recombinant means.

- the chemical and recombinant production of ketoreductases is described in, 25 for example, in US2016/0083759, WO2010025085, WO2011022548, and

- the ketoreductase is purified, preferably with a purity of about 90% or more, more preferably with a purity of about 95% or more, Preferably, the ketoreductase is substantially cell-free.

- a thing e.g., a reaction mixture

- room temperature often abbreviated "RT.” This means that the temperature of the thing is close to, or the same as, that of the space, e.g ., the room or fume hood, in which the thing is located.

- room temperature is from about 20°C to about 30°C, or about 22°C to about 27°C, or about 25°C.

- a process or step may be referred to herein as being carried out “overnight.”

- This time interval is from about 8 to about 20 hours, or about 10- 18 hours, typically about 16 hours.

- reduced pressure refers to a pressure of about 10 5 mbar to about 50 mbar.

- vol. or "volume” can be used to refer to ml per gram of the corresponding Vilanterol salts.

- volume can be used to refer to ml per gram of the corresponding Vilanterol salts.

- a statement that 0.5 g of Vilanterol is d issolved in ten volumes of a Solvent X would be u nderstood to mean that the 0.5 g of Vilanterol was dissolved in 5 ml of Solvent X . 10

- a crystal form may be referred to herein as being characterized by graphical data "substantially as depicted in" a Figure.

- Such data include, for example, powder X-ray diffractograms and solid state NMR spectra.

- the graphical data potentially provides additional technical information to fu rther define the 15 respective solid state form (a so-called "fingerprint") which can not necessarily be described by reference to numerical values or peak positions alone.

- the skilled person will understand that such graphical representations of data may be

- the XRPD measurements are taken 30 using copper a radiation wavelength ( 1.5418 A).

- solvate refers to a crystal form that incorporates a solvent in the crystal structure.

- the solvent is water, the solvate is often referred to as a "hydrate.

- the solvent in a solvate may be present in either a stoichiometric or in a non-stoichiometric amount. 35

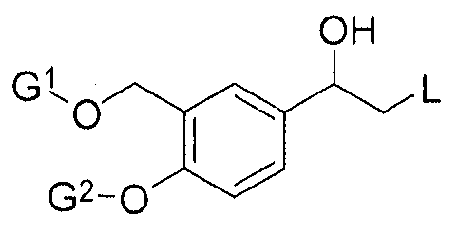

- the present invention relates to polypeptides having

- ketoreductase activity and to methods of using the polypeptides for the biocatalytic conversion of the Ketone Substrate of the following structure:

- L is a leaving group, that may be selected for example from halogen containing groups, typically a chloro, bromo or iodo group; or a sulphonate group such as an 10 alkylsulphonate (particularly d. 6 alkylsulphonates), typically methane sulphonate; or an aryl sulphonate (particularly C 6 . 10 arylsulfonate) group, typically a toluenesulphonate group (e.g. para-toluenesulphonate) ;

- G ⁇ nd G 2 may each independently be a hydroxyl- protecting group or a hydrogen.

- Suitable hydroxyl-protecting protecting groups can be silyl-type protecting 15 groups according to the formula -SiR ⁇ R 3 , wherein R 1 , R 2 and R 3 are independently selected from : a C1-C15 straight or branched alkyl group, a C1-C10 cycloalkyl (preferably C3- 10 cycloalkyl or C 5 - 8 cycloalkyl) group, an optionally substituted C 6 -Ci 0 aryl group and an optionally substituted C 7 -Ci 2 arylalkyl group.

- R 1 , R 2 and R 3 are independently selected from : a C1-C15 straight or branched alkyl group, a C1-C10 cycloalkyl (preferably C3- 10 cycloalkyl or C 5 - 8 cycloalkyl) group, an optionally substituted C 6 -Ci 0 aryl group and an optionally substituted C 7 -Ci 2 arylal

- the hydroxyl- protecting groups G 1 , G 2 may be independently selected from: ether groups (e.g. Ci- 10 alkyl or C 5 - i 0 cyclic ethers, preferably C 5 .s cyclic ethers, methyl ethers or ethyl ethers) or ester groups (e.g. Ci- i 0 alkyl esters, preferably Ch alky! esters, or Cs- io aryl esters, or C7.11 araalkyl esters).

- the hydroxyl protecting groups G 1 , G 2 may be 25 independently selected from methyl or substituted methyl groups, typically

- substituted ethyl groups typically ethoxyethyl, benzyl or tert-butyl ; or ester groups, typically acetate, or aryl substituted acetate groups, for example benzoate or

- Additional hydroxyl-protecting groups can be selected 30 from those described in Greene and Wuts "Greene's Protective Groups in Organic Synthesis", 4th Edition, publ. Wiley, 2006.

- hydroxyl-protecting groups G 1 and G 2 may together represent an group suitable for protection of 1,3 diols, for example cyclic acetal or ketal, typically methylene acetal, ethylidene acetal, isopropylidene acetal (acetonide).

- G 1 , G 2 is isopropylidene acetal (acetonide).

- G 1 and G 2 of the Ketone Substrate together represent isopropylidene acetal (acetonide), and the Ketone Substrate is 2-bromo-l-(2,2-dimethyl-4H-l,3- benzodioxin-6-yl)ethanone, which is referred to as Substrate I.

- Substrate I is converted to enantiopure alcohol : (R)-2-bromo-l-(2,2- dimethyl-4H-l,3-benzodioxin-6-yl)ethanol, which is referred to herein as Compound II.

- the compound has an optical purity of : ⁇ 85%, > 90%, > 92%, > 94%, 96%, ⁇ 98%, > 99%, > 99.5%, or > 99.8%, and more preferably an optical purity of ⁇ 99%, > 99.5%, or > 99.8%.

- Compound II may be isolated, preferably it is crystalline.

- the invention also comprises crystalline Compound II, as described herein below.

- G 1 , G 2 and L are as defined above.

- the present invention comprises a process for biocatalytic reduction of the Ketone Substrate, as described above, to the corresponding alcohol, as described above, preferably wherein the Ketone Substrate is Substrate I and it is converted to enantiomerically pure alcohol, Compound II.

- This process is done by using an isolated enzyme capable of keto-reductase activity.

- ketoreductase polypeptides such as those disclosed in US2016/0083759, 5 WO2010025085, WO2011022548, and WO2009046153, herein incorporated by

- suitable enzymes may be the commercially available enzymes such as: Codexis CDX-005 or Codexis KRED-P1-H01, or an equivalent enzyme thereof.

- equivalent enzyme refers to an enzyme with similar or identical enzymatic activity, which produces the product in the desired enantiomeric 10 access and optical purity, as described in this invention.

- the effective amount of an enzyme or

- combination of enzymes may be any amount of the enzyme that is sufficient to

- a desired degree of conversion of a substrate for example, at least 90%, preferably at least 95%, more preferably at least 98% conversion of a substrate, 15 during 24 hours of reaction time,

- the above process typically allows utilizing substrate in a concentration of at least 20 g/l, preferably at least 40 g/l, more preferably at least 100 g/l .

- NADPH NADPH

- the enzyme and substrate pair used for 20 the regeneration of the co-factor e.g. glucose dehydrogenase and glucose; formate dehydrogenase and sodium formate; phosphite dehydrogenase and sodium phosphite

- glucose dehydrogenase and glucose e.g. glucose dehydrogenase and glucose

- formate dehydrogenase and sodium formate e.g. glucose dehydrogenase and glucose

- phosphite dehydrogenase and sodium phosphite e.g. glucose dehydrogenase and glucose

- formate dehydrogenase and sodium formate phosphite dehydrogenase and sodium phosphite

- the substrate (2-bromo-l-(2,2-dimethyl-4H-l,3-benzodioxin-6- yl)ethanol

- a non- 25 ionic tensioactive agent (surfactant) (preferably Triton ® X- 100) is dissolved in the substrate

- the solution of the substrate in organic solvent may be slowly added to the aqueous solution containing the enzyme and the co-factor under vigorous stirring.

- the pH of the reaction system may be kept constant during the enzymatic reaction by

- the process may be done with a biphasic solvent system, i.e., comprising an aqueous buffer and a water immiscible solvent.

- a biphasic solvent system i.e., comprising an aqueous buffer and a water immiscible solvent.

- the enzyme is dissolved in aqueous buffer.

- aqueous buffer includes potassium or sodium phosphate, hydrochloride or sulfate salts of tertiary amines, triethanolamine, TRIS

- water immiscible organic solvents include ethers, esters, aromatic and aliphatic hydrocarbons or their mixtures, preferably diisopropyl ether, methyl tert-butyl ether, ethyl acetate, isobutyl acetate, butyl acetate, ethyl butanoate, toluene, hexane, 5 heptane or mixtures thereof.

- the process can be done with a monophasic solvent system

- water miscible solvents include alcohols, aprotic polar solvents or mixtures thereof, preferably isopropanol, ethanol, isobutanol, dimethyl sulfoxide, dimethyl formamide, dimethyl 10 acetamide, acetonitrile or mixtures thereof.

- the amount of solvent utilized is an amount necessary to dissolve the enzyme and substrate.

- the amount of water immiscible organic solvent may be from about 20 to about 75 v/v%, from about 30 to about 65v/v% or from about 45 to about 55 v/v%.

- the amount of water miscible solvent may be from about 10 to 15 about 75 v/v%, from about 25 to about 65 v/v%, or from about 50 to about 55v/v%.

- the process is typically performed in the presence of a suitable co-factor as

- the reaction mixture further comprises a co-factor regenerating/recycling system.

- the co-factor regenerating/recycling 20 system comprises a substrate and a dehydrogenase.

- the co-factor recycling system can comprise an additional enzyme and its substrate in more than 1 equivalent amount relative to Ketone Substrate I.

- the co-factor recycling system can comprise, for

- glucose dehydrogenase and glucose the following pairs of enzymes and substrates: glucose dehydrogenase and glucose, formate dehydrogenase and sodium formate or phosphite dehydrogenase and 25 sodium phosphite, alcohol dehydrogenase and a secondary alcohol (e.g. isopropanol).

- a secondary alcohol e.g. isopropanol

- ketoreductase In some of the examples subject to the scope of this invention the ketoreductase

- polypeptide (enzyme) can regenerate the co-factor itself, in the presence of

- the present invention comprises a process for

- Such process may comprise:

- step a) is preferably done by using an isolated enzyme capable of ketoreductase activity.

- an isolated enzyme capable of ketoreductase activity Such enzyme may be as described above.

- the amount of enzyme is typically as described above.

- the above process typically allows utilizing substrate in the above described concentration.

- the process is done with a biphasic solvent system, i.e., comprising an aqueous buffer and a water immiscible solvent.

- a biphasic solvent system i.e., comprising an aqueous buffer and a water immiscible solvent.

- the enzyme is dissolved in the aqueous buffer. Examples of aqueous buffers and of water immiscible solvents are described above.

- the process can be done with a monophasic solvent system comprising an aqueous buffer and a water miscible organic solvent. Examples of water miscible solvent are described above.

- the amount of solvent(s) utilized and their ratio is the amount necessary to dissolve the enzyme and substrate, as described above.

- step al) is preferably done by introduction of protecting group (PG) and preparation of O-protected compound III and compound VI.

- PG protecting group

- Suitable PGs are as described above.

- the present invention comprises crystalline Compound II.

- the crystalline form can be characterized by data selected from one or more of the following : an X-ray powder diffraction pattern having peaks at 9.8, 14.9, 15.9, 18.2 and 19.9 degrees two theta ⁇ 0.2 degrees two theta; an X-ray powder diffraction pattern substantially as depicted in Figure 1 ; and combinations thereof.

- the crystalline form of Compound II may be further characterized by an X-ray powder diffraction pattern having any one, two, three, four or five additional peaks selected from peaks at 8.0, 18.7, 21.9, 24,0 and 25.6 degrees two theta ⁇ 0.2 degrees two theta.

- Table 1 The full peak list of Compound II is presented in the following table (Table 1) :

- the crystalline form of Compound II may alternatively be characterized by the peaks presented in Table 1 above, optionally with the relative intensities.

- the present invention comprises the preparation of compound V from compound IV by reaction with ammonia.

- Compound V may be used in the process of the invention as free base or in the form of a salt.

- Suitable salts may include but are not limited to inorganic acid salts, for example hydrochloride, hydrobromide, phosphate or sulphate, or organic acid salts.

- a suitable organic acid can be selected from acetic acid and its derivatives, benzoic acid or substituted benzoic acids, methanesulfonic acid, benzenesulfonic acid or substituted benzenesulfonic acid, citric acid, maleic acid, malic acid, maleic acid, malonic acid, mandelic acid, succinic acid, fumaric acid, pyroglutamic acid, oxalic acid, tartaric acid or derivatives thereof. More preferably the suitable acid can be selected from tartaric acid, preferably in its optically pure form (preferably L-tartaric acid). 5

- the present invention comprises the preparation of compound VI by reaction of compound III and compound V.

- Compound VI may be used in the process of the invention as free base or in the form of a salt.

- Suitable salts may include but are not limited to inorganic acid salts, for example hydrochloride, hydrobromide, phosphate or sulphate, or organic acid salts.

- a suitable organic acid can 10 be selected from acetic acid and its derivatives, benzoic acid or substituted benzoic acids, methanesulfonic acid, benzenesulfonic acid or substituted benzenesulfonic acid, citric acid, maleic acid, malic acid, maleic acid, malonic acid, mandelic acid, succinic acid, fumaric acid, pyroglutamic acid, oxalic acid, tartaric acid or derivatives thereof.

- the suitable acid can be selected from fumaric acid or tartaric acid, 15 preferably in its optically pure form (preferably L-tartaric acid), more preferably fumaric acid.

- the present invention comprises the preparation of compound VII from compound VI by selective deprotection of PG.

- Compound VII may be used in the process of the invention as free base or in the form of a salt. 20

- Suitable salts may include but are not limited to inorganic acid salts, for

- a suitable organic acid can be selected from acetic acid and its derivatives, benzoic acid or substituted benzoic acids, methanesulfonic acid, benzenesulfonic acid or substituted benzenesulfonic acid, citric acid, maleic acid, malic acid, maleic acid, malonic acid, 25 mandelic acid, succinic acid, fumaric acid, pyroglutamic acid, oxalic acid, tartaric acid or derivatives thereof. More preferably the suitable acid can be selected from tartaric acid, preferably in its optically pure form (preferably L-tartaric acid).

- compound V is in the form of L-tartaric acid salt as crystalline compound

- compound VI is in the form of fumaric acid salt as crystalline 30 compound

- compound VII is in a form of L-tartaric acid salt as crystalline compound.

- the present invention provides Vilanterol tartrate and solid state forms thereof, preferably in substantially pure form.

- the present invention comprises Vilanterol tartrate salt, particularly wherein the molar ratio between Vilanterol and tartaric acid can be 1.5 : 1 to 1 : 1, 35 preferably about 1 : 1, respectively.

- the above salts can be isolated.

- the above salts can be in a solid form, more preferably in a crystalline form.

- the Vilanterol tartrate may be in a crystalline form. According to one

- the present invention comprises a crystalline form of Vilanterol

- the crystalline form of Vilanterol tartrate can be characterized by data 5 selected from one or more of the following : an X-ray powder diffraction pattern substantially as depicted in Figure 2; an X-ray powder diffraction pattern having broad peaks at 7.6, 9.8, 12.1, 20.2 and 28.9 degrees two theta ⁇ 1.0 degree two theta; and combinations thereof.

- the above described Vilanterol tartrate and solid state form thereof can be used to prepare Vilanterol or other different salts of Vilanterol, as well as solid state forms thereof and/or pharmaceutical formulations comprising one or more of the salts and /or solid state forms thereof.

- the above described Vilanterol tartrate and solid state form thereof can be used to prepare Vilanterol 20 triphenylacetate (trifenatate) or Vilanterol tosylate.

- Vilanterol tartrate and solid state forms thereof can be used to purify the API Vilanterol.

- the present invention also encompasses a process for preparing other Vilanterol salts.

- the process comprises preparing Vilanterol tartrate and solid state form

- the obtained Vilanterol comprising basifying Vilanterol tartrate and solid state form thereof, and reacting the obtained Vilanterol with a suitable acid, to obtain the corresponding salt of vilanterol .

- the obtained Vilanterol and subsequently the obtained

- Vilanterol salt such as trifenatate salt

- current invention provides a process for preparation of Vilanterol substantially free from impurity A of the following

- the obtained Vilanterol and subsequently the obtained Vilanterol salt are chemically pure, i.e. having content of impurity A at amount of not more than 0.25%, preferably not more than 0.15%, 5 more preferably not more than 0.10%.

- the Vilanterol prepared by the processes of any aspect or embodiment of the present invention can achieve these chemical purities without requiring chromatographic procedures.

- the processes for preparing the Vilanterol salt such as L-tartrate salt or trifenatate salt

- the Vilanterol tartrate and solid state form thereof of the present invention can also be used as a medicament, preferably for the treatment of a person suffering from

- COPD COPD or asthma as a sole product or in a combination therapy with an inhaled 15 corticosteroid .

- the present invention further encompasses 1) a pharmaceutical composition comprising Vilanterol tartrate and solid state form thereof, as described herein; 2) a pharmaceutical formulation comprising Vilanterol tartrate and solid state form

- Powder X-ray diffraction pattern (“powder XRD” or "PXRD”) method

- Powder X-ray Diffraction was performed on an X- ay powder diffractometer

- the study of enzymatic reactions was carried out with enzyme preparations purchased from different commercial sources.

- the enzymatic reactions were studied in biphasic systems (methyl-tert-butyl ether/water and toluene/water, tested in parallel ), in 1200 microliter reaction volumes.

- the substrate 2-bromo-l-(2,2-di methyl-4H-l,3- benzodioxin-6-yl)ethanone was d issolved in the organic solvents (methyl-tert-butyl 15 ether or toluene) in 20 g/l concentration (70.1 mmol/l).

- the aqueous phase consisted of buffered solutions of nicotinamide adenine dinucleotide (NAD, oxidized form, 5

- NADP nicotinamide adeni ne dinucleotide phosphate

- aqueous phase in 4: 1 v/v ratio.

- the enzymatic reactions were set up by mixing 600 25 microliter of substrate solution (in methyl-tert-butyl ether or toluene) with 600

- Substrate 2-brorno-l-(2,2-dimethyl-4H-l,3-benzodioxin-6-yl)ethanone (5 .00 g), having 84 Area% chromatographic purity, was dissolved in 125 ml diisopropyl ether (DIPE), Triton ® X- 100 emulsifier was added to the solution in 625 mg amount.

- DIPE diisopropyl ether

- reaction mixture was worked up by separating the organic phase, and extracting the remaining aqueous phase two times with 50 ml of methyl-tert-butyl ether. The unified 15 organic phases were dried on anhydrous sodium sulfate and the solvent was

- Substrate 2-bromo-l-(2,2-dimethyl-4H-l,3-benzodioxin-6-yl)ethanone (25 ,00 g,), having 84 Area% chromatographic purity, was dissolved in 625 ml diisopropyl ether (DIPE), Triton X-100 emulsifier was added to the solution in 3.125 g amount.

- DIPE diisopropyl ether

- Example 4 (comparative example): synthesis of (R)-2-bromo-l-(2,2-dimethyl- 10 4H-l,3-benzodioxin-6-yl)ethanol, effect of enzyme addition order on the

- Substrate 2-bromo-l-(2,2-dimethyl-4H- l,3-benzodioxin-6-yl)ethanone (1.67 g,), having 84 Area% chromatographic purity, was dissolved in 42 ml of diisopropyl ether (DIPE), Triton X- 100 emuisifier was added to the solution in 208.3 mg amount.

- DIPE diisopropyl ether

- the two solutions (in DIPE and in water) were mixed under vigorous stirring, thereafter the alcohol 20 dehydrogenase identified in Example 1 (CDX-005 enzyme, purchased from Codexis) was added (in solid form - without prior dissolution) to the formed emulsion in 166,7 mg amount.

- reaction was performed at 25 C for 24 hours, the pH was adjusted continuously to 6.75 during the reaction by using a pH-stat equipment. After 24 hours of reaction time the reaction mixture was analyzed by HPLC. Conversion of 6% was 25 obtained by the HPLC analysis of the isolated crude product, the majority of the

- IPA isopropanol

- DMSO dimethyl sulfoxide

- a buffered aqueous solution of 50 ml final volume was prepared, containing MES buffer ( 100 mM concentration, 976.2 mg), caprylic acid ( 10 m 35 concentration, 72.1 mg), beta-nicotinamide adenine dinucleotide phosphate

- IMADP + monosodium salt

- the solution was diluted to the final volume (50 ml) and 32 ml of it was added to the IPA-DMSO solution of the starting material, under stirring.

- the 5 mixture was vigorously mixed by magnetic stirrer at 25 °C for 10 minutes. A slightly yellow suspension was obtained.

- KRED-P1-H01 alcohol dehydrogenase purchased from Codexis (Ketoreductase Codex Panel variant plate 1, version 1, well H01, batch number D12071) was dissolved in 200 mg amount in 10 ml of the remained buffered aqueous solution containing 10 caprylic acid and NADP + .

- the prepared enzyme solution was added under vigorous stirring, in one portion to the suspension containing the starting material, prepared as described above. The mixture was stirred for 24 hours at 25 °C temperature.

- reaction reached 95.3% conversion and it was worked up by partial evaporation of IPA and extraction with toluene.

- the extract was dried over l ⁇ la 2 S0 4 , then the solvent was 15 evaporated.

- the crude product was obtained in 4.83 g as light yellow crystalline mass, having 80.2% assay and 99.6% optical purity.

- Example 6 Scaled up preparative reaction for the synthesis of (/?)-2-bromo-l- (2,2-dimethyl-4H-l,3-benzodioxin-6-yl)ethanol (compound II), catalyzed by alcohol dehydrogenase KRED-P1-H01 from Codexis 20

- a buffered aqueous solution of 500 ml final volume was prepared, 25 containing MES buffer ( 100 mM concentration, 9762 mg), caprylic acid ( 10 mM

- NADP + monosodium salt

- the solution was diluted to the final volume (500 ml) and 360 30 ml of it was added to the IPA-DMSO solution of the starting material, under stirring.

- KRED-P1-H01 alcohol dehydrogenase purchased from Codexis (Ketoreductase Codex Panel variant plate 1, version 1, well H01, batch number D12071) was dissolved 35 in 2.5 g amount in 100 ml of the remained buffered aqueous solution containing

- the prepared enzyme solution was added under vigorous stirring, in one portion to the suspension containing the starting material, prepared as described above. The mixture was stirred for 24 hours at 25 °C temperature.

- reaction reached 98.5% conversion in 18 hours and >99.5% conversion after 24 hours, 5 thereafter it was worked up by partial evaporation of IPA and extraction with toluene.

- the extract was dried over Na 2 S0 4 , then the solvent was evaporated .

- a light yellow crystalline mass was obtained as crude product.

- the crude product was triturated at room temperature with 1.2 volume of toluene: n-hexane 1 : 1 v/v mixture, thereafter filtered and dried in vacuum oven.

- the product was obtained in 31 g amount as off- 10 white crystalline powder, with 89.6% assay and 99.6% optical purity (first crop) .

- the filtrate was partially evaporated under vacuum then let to cool down to room

- the reactor was sealed and the content was heated to temp. 105-110° C and stirred at 20 the same temp, for 1 hour. The mixture was then cooled down to room temp. The solvent was evaporated under reduced pressure at temp. 30-40° C. The residue was partitioned between EtOAc (400 mL) and water (400 mL). Water phase was separated and the organic phase was washed with water (200 mL). Combined water phases were treated with 20 % aqueous K 2 C0 3 solution (280 mL) followed extraction of the product 25 to EtOAc (2 x 400 mL) . The obtained extract was dried over MgS0 4 and evaporated to dryness to give the title product as slightly yellowish oil (30.28 g, 83 %).

- Example 12 (R)-N-(2-((tert-butyIdimethylsiiyi)oxy)-2-(2,2-dimethyl-4H-l,3- 10 benzodioxin-6-yl)ethyl)-6-(2-((2,6-dichlorobenzyl)oxy)ethoxy)hexan-l-amine fumarate salt (Via fumarate)

- reaction mixture was cooled down to 30°C and toluene ( 1 L) and water

- Example 77(iv)) was dissolved in EtOH (50 mL), followed by addition of 1M HCI solution (50 mL). The mixture was stirred at room temperature for 90 minutes.

- the pH of the mixture was adjusted to ⁇ 9 by addition of 20 % K 2 C0 3 25 solution (25 mL).

- the mixture was then extracted to dichloromethane ( 100 mL).

- the organic phase was washed with water (2 x 25 mL), dried over MgS0 4 and evaporated to dryness.

- the crude vilanterol base ( 14.5 g, 90.9 % purity) was dissolved in

- EtOH (700 mL) was mixed with 1 M aq. HCI acid (700 mL), the formed mixture 25 was cooled to 5 °C, followed by addition of compound VII L-tartrate ( 100 g, obtained by procedure in Example 15). The mixture was stirred at 5 °C for 15 hours. Afterwards, DCM (500 mL) was added, the mixture was cooled to 0 °C and aq. Solution of K 2 C0 3 ( 130g of K 2 C0 3 in 200 mL of water) was then added drop wise to the stirred reaction mixture until pH 9 - 9.5 was obtained. Temp, during the addition was kept below 5 °C. 30 The water phase was separated, and extracted with additional DCM (300 mL).

- Example 23 Comparison of different buffers in the enzymatic 25 enantioselective reduction of 2-bromo-l-(2,2-dimethyl-4H-l,3-benzodioxin-6- y!ethanone (compound I) to (R)-2-bromo-l-(2,2-dimethyI-4H-l,3- benzodioxin-6-yl)ethanone (compound II), catalyzed by ketoreductase CDX- 005 from Codexis

- Enzyme solutions were prepared by dissolving 50-50 milligrams of CDX-005 ketoreductase enzyme (purchased from Codexis) in 2.0 milliliters of each buffered cofactor solution prepared above.

- a substrate solution containing 125 g/l 2-bromo-l-(2,2-dimethyl-4H-l,3- benzodioxin-6-yl)ethanone was prepared in a solvent mixture of isopropano dimethyl 10 sulfoxide 4: 1 v/v, by dissolving 3.125 grams of 2-bromo- l-(2,2-dimethyl-4 -/-l,3- benzodioxin-6-yl)ethanone in the solvent mixture and completing it to 25 milliliters with the same.

- Buffer solution was prepared by dissolving 1180.8 grams of 4-(2- hydroxyethyl)morpholine in 75 liters of water (purified by ion exchange) and adjusting the pH of the solution to 6.75 with nitric acid (20 m/v%).

- a buffered cofactor solution of 90 liters was prepared by dissolving 35.432 10 grams of beta-nicotinamide adenine dinucleotide phosphate disodium salt (NADP+-IMa 2 , oxidized form) in the full volume of the buffer prepared above.

- the pH of the solution was adjusted to 6.75 with the aid of 20% nitric acid, thereafter completed to 90 liters with water (purified by ion exchange).

- Enzyme solution of 18 liters containing CDX-005 (ketoreductase purchased from 15 Codexis) was prepared immediately before use, by dissolving 450 grams of CDX-005 in 18 liters of buffered cofactor solution prepared above. The remaining part of the

- buffered cofactor solution ( ⁇ 72 liters) was loaded in a tempered reactor and stored at 25°C.

- Substrate solution was prepared immediately before use, by dissolving 9 20 kilograms of 2-bromo-l-(2,2-dimethyl-4H-l,3-benzodioxin-6-yl)ethanone (94% assay, 29.671 moles) in a solution prepared from 18 liters of dimethyl sulfoxide (DMSO) and 54 liters of isopropanol, by stirring at room temperature. The volume of the solution was completed to 90 liters with isopropanol .

- DMSO dimethyl sulfoxide

- the biocatalytic reaction mixture was prepared by adding the prepared 25 substrate solution (90 liters) to the tempered reactor containing ⁇ 72 liters of buffer solution, under vigorous stirring . After proper homogenization the full volume of the enzyme solution ( 18 liters) was charged in one portion to the content of the reactor.

- reaction temperature was maintained at 25°C and the reaction mixture was stirred for 24 hours. By analysis of the reaction mixture 99.7% conversion to Compound II 30 was achieved .

- the reaction mixture was filtered through Perlite and the filtering layer was washed with 54 liters of toluene. The washing containing toluene was stored at 0- 5°C and used during the extraction step. The filtrate was partially evaporated under vacuum at 35°C to 110 liter volume.

- the evaporation was performed in 3 portions.

- the respective portions were stored at 0- 5°C before or after evaporation.

- the remaining volume obtained after partial evaporation of the filtrate ( ⁇ 110 liters) was extracted with 54 liters of toluene (obtained as filtrate after the washing of 5 Perlite layer). Thereafter the remaining aqueous phase was extracted with 2x 27 liters of toluene.

- the unified organic phases were extracted with 36 liters of 5% NaHC0 3 solution, thereafter with 2x 36 liters of water.

Landscapes

- Chemical & Material Sciences (AREA)

- Organic Chemistry (AREA)

- Wood Science & Technology (AREA)

- Life Sciences & Earth Sciences (AREA)

- Engineering & Computer Science (AREA)

- Zoology (AREA)

- Biotechnology (AREA)

- Microbiology (AREA)

- General Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Health & Medical Sciences (AREA)

- Biochemistry (AREA)

- Bioinformatics & Cheminformatics (AREA)

- General Engineering & Computer Science (AREA)

- General Health & Medical Sciences (AREA)

- Genetics & Genomics (AREA)

- Analytical Chemistry (AREA)

- Organic Low-Molecular-Weight Compounds And Preparation Thereof (AREA)

Abstract

A process for preparing Vilanterol includes a biocatalytic conversion of a ketone substrate to its corresponding alcohol, and then converting the obtained alcohol into Vilanterol. Polypeptides may be used for the biocatalytic conversion of the ketone substrate, such as 2-bromo-l-(2,2-dimethyl-4H-l,3-benzodioxin-6-yl)ethanone, to an enantiopure alcohol, (R)-2-bromo-l-(2,2-dimethyl-4H-l,3-benzodioxin-6-yl)ethanol for the preparation of Vilanterol. Also disclosed is vilanterol tartrate and solid state forms thereof for use as medicaments and for the preparation of other vilanterol salts, or of vilanterol, solid state forms and/or formulations thereof. Also disclosed is a process for the preparation of pharmaceutical formulations including vilanterol tartrate and solid state forms thereof, as well as a method of treating a person suffering from COPD and asthma by administering a therapeutically effective amount of any one or a combination of vilanterol tartrate and solid state forms thereof or a pharmaceutical composition and/or formulation comprising vilanterol tartrate and solid state forms thereof.

Description

BIOCATALYTIC PROCESSES FOR THE PREPARATION OF VILANTEROL

This application is related to, and claims the benefit or priorities of, U.S. Provisional Application No. 62/151,016, entitled BIOCATALYTIC PROCESSES FOR THE PREPARATION OF VILANTEROL, filed on 22 April 2015, and U.S. Provisional Application No. 62/186,005, entitled VILANTEROL TARTRATE, filed on 29 June 2015, all of the 5 contents of which are incorporated herein by reference in their entirety for all purposes.

Field of the Invention

This invention relates to highly efficient biocatalytic processes for the

preparation of Vilanterol and intermediates in the preparation thereof.

Background of the Invention 10

Vilanterol, 4-{( lR)-2-[(6-{2-[(2,6-Dichlorobenzyl)oxy]ethoxy}hexyl)amino]-l- hydrox

is reported to be a long-acting 2-adrenoceptor agonist, administered as a dry powder formulation. Vilanterol trifenatate is available in combination with Umeclidinium 15 bromide or Fluticasone furoate for the treatment of chronic obstructive pulmonary disease (COPD) and asthma

Vilanterol, as well as certain pharmaceutically acceptable salts thereof and

processes for the preparation thereof, are described in WO2003024439 and in J. Med.

Chem. 2010, 53 (4522-4530). 20

WO2014041565 describes a similar process to the process described in

WO2003024439 for the preparation of Vilanterol and pharmaceutical acceptable salts thereof, by a process comprising reduction of ketone with borane.

WO2010/025085 describes engineered ketoreductase enzymes allegedly

capable of reducing 5-((4S)-2-oxo-4-phenyl ( l,3-oxazolidin-3-yl))-l-(4-fluorophenyl) 25 pentane-l,5-dione to (4S)-3-[(5S)-5-(4-fluorophenyl)-5-hydroxypentanoyl]-4-phenyl- l,3-oxazolidin-2-one.

2-Bromo- l-(2,2-dimethyl-4H-l,3-benzodioxin-6-yl)ethanol is an alcohol

intermediate that can be used to make Vilanterol.

Liu et al. ; Tetrahedron : Asymmetry 2008, 19, 1824-2828 discloses an 30 enantioselective catalytic hydrogenation of the ketone - 2-bromo-l-(2,2-dimethyl-4H-

l,3-benzodioxin-6-yl)ethanone via a chiral Rh-complex yielding the enantiopure

alcohol, 2-bromo-l-(2,2-dimethyl-4H-l,3-benzodioxin-6-yl)ethanol. The enantiomeric excess ("ee") of this process is 93%, and can be increased to 98% only when using

PEGylated chiral ligands.

WO 2004/022547 and US 2005/0075394 describe other synthetic approaches 5 which use 2-azido- or 2-(N-Boc)-amino moieties instead of the 2-bromo moiety. The reduction in the described processes is done with borane dimethylsulfide complex and CBS-borane catalyst. Use of borane and derivatives thereof requires stoichiometric amounts and borane is known to be toxic and not environmentally friendly.

Goswami et al.; Tetrahedron : Asymmetry 2000, 11, 3701-3709 and Goswami et 10 al.; Tetrahedron : Asymmetry 2001, 12, 3343-3348 describe a microbial process,

however, carried out under whole cell fermentation conditions. Whole cells (wet

biomass) were used in a 50-fold mass excess over the substrate, thus require a large excess of whole cell while the substrate, 2-bromo-l-(4H- l,3-benzodioxin-6- yl)ethanone was used in 1 g/l concentration, which is considered very low. In these 15 processes, a 4H-l,3-benzodioxin moiety is used, which has low sensitivity to acids;

therefore its conversion to the corresponding diol requires harsh conditions of

concentrated acids. Such conditions may result in water elimination or racemization, which adversely affects the purity and yield of the final product.

A biocatalytic preparation of other compounds such as (R)-2-azido-l-(4H-l,3- 20 benzodioxin-6-yl)ethanol by whole cell reduction was also described in Procopiou et al. ; Tetrahedron : Asymmetry 2001, 12, 2005-2008. These described reactions were also done with a 1 g/l substrate concentration and yielded only moderate R-selectivity:

enantiomeric excess of 88%.

Moreover, the above described processes utilize intermediates that have limited 25 stability and are oily substances with limited scale-up options and difficult to handle in an industrialized process. Further, the above described processes involve column

chromatography for purification of the intermediates. For at least the above reasons, there is a need to have an improved, safe process with increased efficiency, that can be utilized on an industrial scale, for preparing 2-bromo-l-(2,2-dimethyl-4H-l,3- 30 benzodioxin-6-yl)ethanol and subsequently Vilanterol in high enantiomeric excess (>

98% ee). The desired process comprises a high substrate concentration, allowing high space-time yields (defined as product amount produced per volume and per time, g/l/day or g/l/h). The enzyme (catalyst) concentration should be kept low to allow a commercially competitive process. 35

Summary of the Invention

The present invention relates to a process for preparing Vilanterol, which

comprises a biocatalytic conversion of a ketone substrate to its corresponding alcohol, and then converting the obtained alcohol into Vilanterol.

In one aspect the present invention relates to methods of using polypeptides for the biocatalytic conversion of the Ketone Substrate, as described herein below, to the corresponding alcohol, preferably wherein the Ketone Substrate is 2-bromo-l-(2,2- dimethyl-4H- l,3-benzodioxin-6-yl)ethanone and it is converted to enantiopure

alcohol, (R)-2-bromo-l-(2,2-dimethyl-4H-l,3-benzodioxin-6-yl)ethanol. In particular, these methods may be utilized for the preparation of Vilanterol.

In a further aspect, the present invention provides use of compound of formula V, VI and VII and salts thereof of the following formula:

vi vii 15 in the preparation of Vilanterol. The compounds V, VI and VII are used in the solid form as a salt.

In a further aspect, the present invention provides preparation of Vilanterol in the form of L-tartaric acid salt.

The present invention also encompasses the vilanterol tartrate and solid state forms 20 thereof for the preparation of other vilanterol salts, or of vilanterol, solid state

forms and/or formulations thereof.

The present invention also encompasses the vilanterol tartrate and solid state forms thereof described herein for use as medicaments, particularly sole product or as a combination therapy with an inhaled corticosteroid for COPD and asthma. 25

The present invention also encompasses a process for the preparation of

pharmaceutical formulations comprising combining vilanterol tartrate and solid state forms thereof, or a pharmaceutical composition comprising said vilanterol tartrate and solid state forms thereof and at least one pharmaceutically acceptable

excipient. 30

The present invention also encompasses a method of treating a person suffering from COPD and asthma, comprising administering a therapeutically effective

amount of any one or a combination vilanterol tartrate and solid state forms

thereof, or a pharmaceutical composition and/or formulation comprising vilanterol tartrate and solid state forms thereof described herein.

Brief Description of the Drawings

Figure 1 shows a powder X-ray diffraction pattern ("powder XRD" or "PXRD") of 5 (R)- 2-bromo-l-(2,2-dimethyl-4H-l,3-benzodioxin-6-yl)ethanol (Compound II).

Figure 2 shows a powder X-ray diffraction pattern of 6-(2-((2,6- dichlorobenzyl)oxy)ethoxy)hexan-l-amine L-tartaric acid salt (V L-tartrate).

Figure 3 shows a powder X-ray diffraction pattern of (R)-N-(2-((tert- butyldimethylsilyl)oxy)-2-(2,2-dimethyl-4H-l,3-benzodioxin-6-yl)ethyl)-6-(2-((2,6- 10 dichlorobenzyl)oxy)ethoxy)hexan-l-amine fumarate salt (Via fumarate).

Figure 4 shows a powder X-ray diffraction pattern of (R)-2-((6-(2-((2,6- dichlorobenzyl)oxy)ethoxy)hexyl)amino)-l-(2,2-dimethyl-4H-l,3-benzodioxin-6- yl)ethan-l-ol L-Tartaric acid salt (VII L-tartrate)

Figure 5 shows a powder X-ray diffraction pattern of Vilanterol L-tartrate. 15

Detailed Description of the Invention

The present invention relates to highly efficient biocatalytic processes for the preparation of Vilanterol and Vilanterol intermediates.

The present invention provides an improved, safe process with increased

efficiency, that can be utilized on an industrial scale, for preparing 2-bromo-l-(2,2- 20 dimethyl-4H-l,3-benzodioxin-6-yl)ethanol and subsequently Vilanterol, both in high enantiomeric excess (> 98% ee) and/or optical purity ( >99%).

Particularly, the present invention offers a desirable, well-controlled biocatalytic process, that may be adapted to a large industrial scale, and allows high substrate loadings (e.g ., > 50 g/L), high percent conversion (e.g., > 90% in 24 h), high 25 enantiomeric excess (e.g., at least about 99% ee) and low enzyme loading (e.g., less than 5 w/w%). In addition, the process provided in the present invention eliminates the need for an additional co-factor regenerating enzyme other than the ketoreductase enzyme/polypeptide or engineered ketoreductase polypeptide.

The present invention encompasses crystalline salts of compounds V, VI and VII 30 which are used as intermediates of Vilanterol synthesis.

The present invention encompasses vilanterol tartrate, solid state forms thereof and pharmaceutical compositions comprising one or more of the vilanterol salts and/or solid state forms thereof. The present invention also encompasses vilanterol tartrate

and solid state forms thereof for use in the preparation and purification of Vilanterol and Vilanterol salt, such as Vilanterol trifenatate.

As used herein "ketoreductase" refers to an enzyme/polypeptide that can

catalyse the reduction of a ketone to form the corresponding alcohol. Ketoreductase enzymes include, for example, those classified under the E.C. (or IUBMB - International 5 Union of Biochemistry and Molecular Biology) no. 1.1.1 (i.e. 1.1.1.x) (see

http: //www.enzyme-database.org), as well as synthetic or engineered polypeptide variants thereof (i.e. polypeptides having ketoreductase activity. Ketoreductases

(KREDs) are given various names in addition to ketoreductase, including, but not

limited to, alcohol dehydrogenase, carbonyl reductase, lactate dehydrogenase, 10 hydroxyacid dehydrogenase, hydroxyisocaproate dehydrogenase, [beta]- hydroxybutyrate dehydrogenase, steroid dehydrogenase, sorbitol dehydrogenase, aldoreductase, and the like. NADPH-dependent ketoreductases are classified under the IUBMB number of 1.1.1.2 and the CAS number of 9028-12-0. NADH-dependent

ketoreductases are classified under the IUBMB number of 1.1.1.1 and the CAS number 15 of 9031 -72-5. Preferably, the ketoreductases useful for the processes of the present invention comprise enzymes from IUBMB or E.C. 1.1.1.1 and E.C. 1.1.1.2, more

generally all enzymes belonging to E.C. 1.1.1 and engineered polypeptide variants thereof.

As used herein, the term "co-factor" refers to a non-protein compound that operates in 20 combination with an enzyme which catalyzes the reaction of interest. Co-factors

include, for example, nicotinamide co-factors such as nicotinamide adenine dinucleotide ('TSfAD") or a salt thereof, reduced nicotinamide adenine dinucleotide ("NADH") or a salt thereof, nicotinamide adenine dinucleotide phosphate ("NADP< + >"), reduced

nicotinamide adenine dinucleotide phosphate ("NADPH"), and derivatives or analogs 25 thereof. Reduced cofactors as NADPH or NADH function as intermediate hydrogen

donors, and oxidized cofactors (NADP+ or NAD+) function as intermediate hydrogen acceptors in the catalytic mechanism of the enzymes. Examples of salts of the co- factors include NAD tetra(cyclohexyl ammonium) salt, NAD tetrasodium salt, NAD

tetrasodium hydrate, NADP< + > phosphate hydrate, NADP< + > phosphate sodium salt, 30 and NADH dipotassium salt. Preferably, in the processes of the present invention, the co-factor is NADP or NADPH.

As used herein, the term "isolated" in reference to compounds described in the invention corresponds to a compound that is physically separated from the reaction mixture in which it is formed. 35

As used herein, the term "isolated" in reference to polypeptides/enzymes refers to polypeptides/enzymes at least partially separated from the environment in which they are formed, for example from the natural environment, e.g., from bacteria. Thus, use of the term "isolated" indicates that a naturally occurring or recombinant enzyme has been at least partially removed from its normal cellular or natural environment, 5 e.g . from bacterial cells. Preferably, the isolated enzyme is in a cell-free system. The isolated enzyme can be crude or highly purified. The term "isolated" does not

necessarily imply that the enzyme is the only enzyme present, but that it is the

predominant enzyme present (at least 10-20% more than any other enzyme). As used herein, when applied to an enzyme, the term "synthesized" or "engineered" refers to 10 an enzyme that is prepared by chemical synthesis, recombinant means, or the

combination thereof. As used herein, when applied to an enzyme, the term "purified" refers to an enzyme that is essentially free (at least about 90-95% pure) of non- enzymatic material or other enzymes. The isolated enzyme can be a lysate or an

enzyme powder obtained by lyophilization of cell lysates, which can contain isolated, 15 but unpurified enzymes.

Preferably, in any aspect or embodiment of the present invention, the

ketoreductase is isolated. The ketoreductase can be separated from any host, such as mammals, filamentous fungi, yeasts, and bacteria. The isolation, purification, and

characterization of a NADH-dependent ketoreductase is described in, for example, in 20 Kosjek et al, Purification and Characterization of a Chemotolerant Alcohol

Dehydrogenase Applicable to Coupled Redox Reactions, Biotechnology and

Bioengineering, 86 : 55-62 (2004) , Preferably, the ketoreductase is synthesized or engineered. The ketoreductase can be synthesized chemically or using recombinant means. The chemical and recombinant production of ketoreductases is described in, 25 for example, in US2016/0083759, WO2010025085, WO2011022548, and

WO2009046153. Preferably, the ketoreductase is purified, preferably with a purity of about 90% or more, more preferably with a purity of about 95% or more, Preferably, the ketoreductase is substantially cell-free.

A thing, e.g., a reaction mixture, may be characterized herein as being at, or 30 allowed to come to "room temperature, often abbreviated "RT." This means that the temperature of the thing is close to, or the same as, that of the space, e.g ., the room or fume hood, in which the thing is located. Typically, room temperature is from about 20°C to about 30°C, or about 22°C to about 27°C, or about 25°C.

A process or step may be referred to herein as being carried out "overnight."

This refers to a time interval, e.g . , for the process or step, that spans the time during the night, when that process or step may not be actively observed. This time interval is from about 8 to about 20 hours, or about 10- 18 hours, typically about 16 hours.

As used herein, the term "reduced pressure" refers to a pressure of about 10 5 mbar to about 50 mbar.

As used herein, the terms "vol. " or "volume" can be used to refer to ml per gram of the corresponding Vilanterol salts. For example, a statement that 0.5 g of Vilanterol is d issolved in ten volumes of a Solvent X would be u nderstood to mean that the 0.5 g of Vilanterol was dissolved in 5 ml of Solvent X . 10

A crystal form may be referred to herein as being characterized by graphical data "substantially as depicted in" a Figure. Such data include, for example, powder X-ray diffractograms and solid state NMR spectra. As is well-known in the art, the graphical data potentially provides additional technical information to fu rther define the 15 respective solid state form (a so-called "fingerprint") which can not necessarily be described by reference to numerical values or peak positions alone. In any event, the skilled person will understand that such graphical representations of data may be

subject to small variations, e. g., in peak relative intensities and peak positions due to factors such as variations in i nstrument response and variations in sample 20 concentration and purity, which are well known to the skilled person. Nonetheless, the skilled person would readily be capable of comparing the graphical data in the Figures herein with g raphical data generated for an unknown crystal form and confirm whether the two sets of g raphical data are characterizing the same crystal form or two different crystal forms. A crystal form of a Vilanterol salt referred to herein as being 25 characterized by graphical data "substantially as depicted in" a Figure will thus be

understood to include any crystal forms of the Vilanterol salt characterized with the graphical data having such small variations, as are well known to the skilled person, in comparison with the Figure.

As used herein, unless stated otherwise, the XRPD measurements are taken 30 using copper a radiation wavelength ( 1.5418 A).

As used herein and unless indicated otherwise, the term "solvate" refers to a crystal form that incorporates a solvent in the crystal structure. When the solvent is water, the solvate is often referred to as a "hydrate. " The solvent in a solvate may be present in either a stoichiometric or in a non-stoichiometric amount. 35

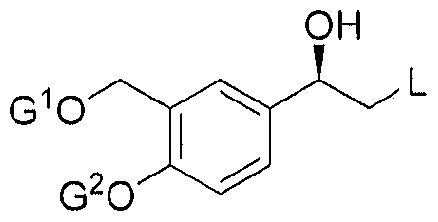

In one embodiment, the present invention relates to polypeptides having

ketoreductase activity, and to methods of using the polypeptides for the biocatalytic conversion of the Ketone Substrate of the following structure:

Alcohol Compound

wherein L is a leaving group, that may be selected for example from halogen containing groups, typically a chloro, bromo or iodo group; or a sulphonate group such as an 10 alkylsulphonate (particularly d.6 alkylsulphonates), typically methane sulphonate; or an aryl sulphonate (particularly C6.10 arylsulfonate) group, typically a toluenesulphonate group (e.g. para-toluenesulphonate) ; G^nd G2 may each independently be a hydroxyl- protecting group or a hydrogen.

Suitable hydroxyl-protecting protecting groups can be silyl-type protecting 15 groups according to the formula -SiR^R3, wherein R1, R2 and R3 are independently selected from : a C1-C15 straight or branched alkyl group, a C1-C10 cycloalkyl (preferably C3- 10 cycloalkyl or C5-8 cycloalkyl) group, an optionally substituted C6-Ci0 aryl group and an optionally substituted C7-Ci2 arylalkyl group. Examples of preferred silyl-type

protecting groups are t-butyldimethylsilyl (TBDMS), triethylsilyl (TES), t- 20 butyldiphenylsilyl (TBDPS), and trimethylsilyl (TMS) . Alternatively, the hydroxyl- protecting groups G1, G2 may be independently selected from: ether groups (e.g. Ci- 10 alkyl or C5- i0 cyclic ethers, preferably C5.s cyclic ethers, methyl ethers or ethyl ethers) or ester groups (e.g. Ci- i0 alkyl esters, preferably Ch alky! esters, or Cs- io aryl esters, or C7.11 araalkyl esters). Particularly, the hydroxyl protecting groups G1, G2 may be 25 independently selected from methyl or substituted methyl groups, typically

tetrahydropyranyl (ΤΉΡ), methoxymethyl (MOM), benzyloxymethyl ; or ethyl or

substituted ethyl groups, typically ethoxyethyl, benzyl or tert-butyl ; or ester groups, typically acetate, or aryl substituted acetate groups, for example benzoate or

substituted benzoate groups. Additional hydroxyl-protecting groups can be selected 30

from those described in Greene and Wuts "Greene's Protective Groups in Organic Synthesis", 4th Edition, publ. Wiley, 2006.

Preferably, hydroxyl-protecting groups G1 and G2 may together represent an group suitable for protection of 1,3 diols, for example cyclic acetal or ketal, typically methylene acetal, ethylidene acetal, isopropylidene acetal (acetonide). Preferably G1, G2 is isopropylidene acetal (acetonide).

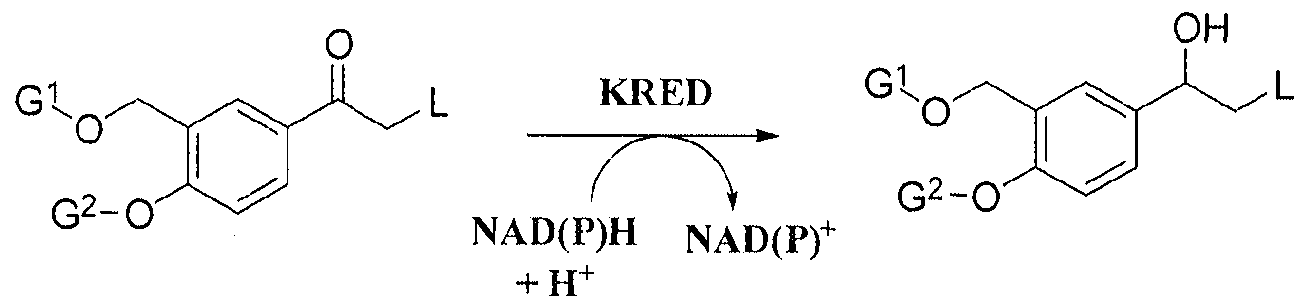

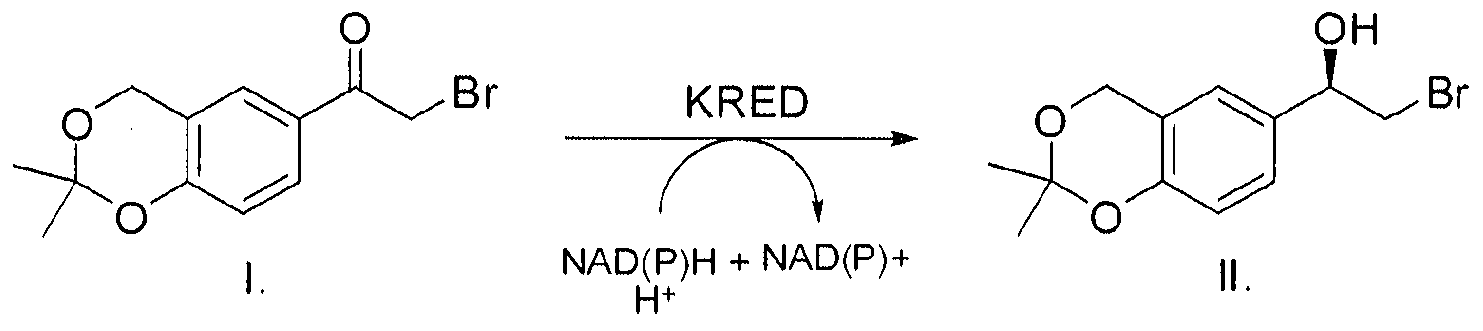

Preferably, G1 and G2 of the Ketone Substrate together represent isopropylidene acetal (acetonide), and the Ketone Substrate is 2-bromo-l-(2,2-dimethyl-4H-l,3- benzodioxin-6-yl)ethanone, which is referred to as Substrate I.

Preferably, Substrate I is converted to enantiopure alcohol : (R)-2-bromo-l-(2,2- dimethyl-4H-l,3-benzodioxin-6-yl)ethanol, which is referred to herein as Compound II.

Preferably, by "enantiopure", it is mean that the compound has an optical purity of : ≥ 85%, > 90%, > 92%, > 94%, 96%,≥ 98%, > 99%, > 99.5%, or > 99.8%, and more preferably an optical purity of ≥ 99%, > 99.5%, or > 99.8%.

Compound II may be isolated, preferably it is crystalline. The invention also comprises crystalline Compound II, as described herein below.

In particular, the above described methods may be utilized for the preparation of Vilanterol .

The process can be illustrated by Scheme 1.

Scheme 1 :

wherein G1, G2 and L are as defined above.

Particularly, when Substrate I is used to produce Compound II, as defined the process can be illustrated by the following scheme:

Scheme 2 :

In another embodiment, the present invention comprises a process for biocatalytic reduction of the Ketone Substrate, as described above, to the

corresponding alcohol, as described above, preferably wherein the Ketone Substrate is Substrate I and it is converted to enantiomerically pure alcohol, Compound II. This process is done by using an isolated enzyme capable of keto-reductase activity.

Examples of enzymes capable of ketoreductase activity are engineered

ketoreductase polypeptides such as those disclosed in US2016/0083759, 5 WO2010025085, WO2011022548, and WO2009046153, herein incorporated by

reference. Examples of suitable enzymes may be the commercially available enzymes such as: Codexis CDX-005 or Codexis KRED-P1-H01, or an equivalent enzyme thereof.

As used herein, the term equivalent enzyme refers to an enzyme with similar or identical enzymatic activity, which produces the product in the desired enantiomeric 10 access and optical purity, as described in this invention.

According to the present invention, the effective amount of an enzyme (or

combination of enzymes) may be any amount of the enzyme that is sufficient to

achieve a desired degree of conversion of a substrate, for example, at least 90%, preferably at least 95%, more preferably at least 98% conversion of a substrate, 15 during 24 hours of reaction time,

The above process typically allows utilizing substrate in a concentration of at least 20 g/l, preferably at least 40 g/l, more preferably at least 100 g/l .

Preferably the required quantities of the enzyme and the co-factor (NADP or

NADPH) are dissolved in an aqueous buffer. The enzyme and substrate pair used for 20 the regeneration of the co-factor (e.g. glucose dehydrogenase and glucose; formate dehydrogenase and sodium formate; phosphite dehydrogenase and sodium phosphite) are dissolved in the same aqueous solution and the pH is adjusted to the required

value. Thereafter the substrate (2-bromo-l-(2,2-dimethyl-4H-l,3-benzodioxin-6- yl)ethanol) is dissolved separately in a water immiscible organic solvent, and a non- 25 ionic tensioactive agent (surfactant) (preferably Triton® X- 100) is dissolved in the

solution. The solution of the substrate in organic solvent may be slowly added to the aqueous solution containing the enzyme and the co-factor under vigorous stirring. The pH of the reaction system may be kept constant during the enzymatic reaction by

addition of an acid or a base if required. 30

The process may be done with a biphasic solvent system, i.e., comprising an aqueous buffer and a water immiscible solvent. Typically, the enzyme is dissolved in aqueous buffer. Examples of aqueous buffer includes potassium or sodium phosphate, hydrochloride or sulfate salts of tertiary amines, triethanolamine, TRIS

(tris(hydroxymethyl)aminomethane), sodium- or potassium salts of MES (2-(N- 35

morpholino)ethanesulfonic acid), HEPES (4-(2-hydroxyethyl)-l- piperazineethanesulfonic acid), MOPS (3-(N-morpholino)propanesulfonic acid), etc.

Examples of water immiscible organic solvents include ethers, esters, aromatic and aliphatic hydrocarbons or their mixtures, preferably diisopropyl ether, methyl tert-butyl ether, ethyl acetate, isobutyl acetate, butyl acetate, ethyl butanoate, toluene, hexane, 5 heptane or mixtures thereof.

Alternatively, the process can be done with a monophasic solvent system

comprising an aqueous buffer and a water miscible organic solvent. Examples of water miscible solvents include alcohols, aprotic polar solvents or mixtures thereof, preferably isopropanol, ethanol, isobutanol, dimethyl sulfoxide, dimethyl formamide, dimethyl 10 acetamide, acetonitrile or mixtures thereof.

Typically the amount of solvent utilized is an amount necessary to dissolve the enzyme and substrate. Typically, the amount of water immiscible organic solvent may be from about 20 to about 75 v/v%, from about 30 to about 65v/v% or from about 45 to about 55 v/v%. The amount of water miscible solvent may be from about 10 to 15 about 75 v/v%, from about 25 to about 65 v/v%, or from about 50 to about 55v/v%.

The process is typically performed in the presence of a suitable co-factor as

NADH or NADPH, and a co-factor regenerating system capable of converting NADP+ to NADPH, or NAD+ to NADH . Optionally, the reaction mixture further comprises a co- factor regenerating/recycling system. Typically, the co-factor regenerating/recycling 20 system comprises a substrate and a dehydrogenase. The co-factor recycling system can comprise an additional enzyme and its substrate in more than 1 equivalent amount relative to Ketone Substrate I. The co-factor recycling system can comprise, for

example, the following pairs of enzymes and substrates: glucose dehydrogenase and glucose, formate dehydrogenase and sodium formate or phosphite dehydrogenase and 25 sodium phosphite, alcohol dehydrogenase and a secondary alcohol (e.g. isopropanol).

In some of the examples subject to the scope of this invention the ketoreductase

polypeptide (enzyme) can regenerate the co-factor itself, in the presence of

isopropanol as water miscible co-solvent, or part of the water-miscible co-solvent

mixture. Reductive equivalents are transferred from the isopropanol to the oxidized co- 30 factor (NAD+ or NADP+), under the effect of the enzyme, while the co-factor is

reduced (to NADH or NADPH) and isopropanol is oxidized to acetone.

In another embodiment, the present invention comprises a process for

preparing Vilanterol, which comprises a biocatalytic conversion of a ketone substrate to its corresponding alcohol, and then converting the obtained alcohol into Vilanterol. 35

Such process may comprise:

a) converting a Ketone Substrate, such as Substrate I, into enantiomerically pure alcohol, preferably Compound II; and

al) converting the formed alcohol, preferably Compound II, to Vilanterol trifenatate, according to the below scheme:

VII L-tait rate

The process of step a) is preferably done by using an isolated enzyme capable of ketoreductase activity. Such enzyme may be as described above.

The amount of enzyme is typically as described above.

The above process typically allows utilizing substrate in the above described concentration.

The order of addition is typically as described above. Preferably, the process is done with a biphasic solvent system, i.e., comprising an aqueous buffer and a water immiscible solvent. Typically, the enzyme is dissolved in the aqueous buffer. Examples of aqueous buffers and of water immiscible solvents are described above. Alternatively the process can be done with a monophasic solvent system comprising an aqueous buffer and a water miscible organic solvent. Examples of water miscible solvent are described above.

Typically the amount of solvent(s) utilized and their ratio is the amount necessary to dissolve the enzyme and substrate, as described above.

The process of step al) is preferably done by introduction of protecting group (PG) and preparation of O-protected compound III and compound VI. Suitable PGs are as described above.

In another embodiment, the present invention comprises crystalline Compound II. The crystalline form can be characterized by data selected from one or more of the following : an X-ray powder diffraction pattern having peaks at 9.8, 14.9, 15.9, 18.2 and 19.9 degrees two theta ± 0.2 degrees two theta; an X-ray powder diffraction pattern substantially as depicted in Figure 1 ; and combinations thereof.

The crystalline form of Compound II may be further characterized by an X-ray powder diffraction pattern having any one, two, three, four or five additional peaks selected from peaks at 8.0, 18.7, 21.9, 24,0 and 25.6 degrees two theta ± 0.2 degrees two theta. The full peak list of Compound II is presented in the following table (Table 1) :

Table 1 :

Pos. Rel. Int.

[°2Θ] [%]

8.0 1

9.8 6

14.9 18

15.9 83

16.4 2

17.9 4

18.2 22

18.7 19

19.9 63

21.6 6

21.9 17

22.6 1

24.0 100

24.3 28

25.3 18

25.6 27

26.9 25

27.1 3

28.2 5

28.9 9

29.5 30

30.3 3

31.5 11

31.8 9

32.2 30

33.6 9

34.2 10

35.5 3

36.5 1

37.2 13

37.5 6

38.3 1

39.0 2

39.8 10

The crystalline form of Compound II may alternatively be characterized by the peaks presented in Table 1 above, optionally with the relative intensities.

In another embodiment, the present invention comprises the preparation of compound V from compound IV by reaction with ammonia. Compound V may be used in the process of the invention as free base or in the form of a salt. Suitable salts may include but are not limited to inorganic acid salts, for example hydrochloride, hydrobromide, phosphate or sulphate, or organic acid salts. A suitable organic acid can be selected from acetic acid and its derivatives, benzoic acid or substituted benzoic

acids, methanesulfonic acid, benzenesulfonic acid or substituted benzenesulfonic acid, citric acid, maleic acid, malic acid, maleic acid, malonic acid, mandelic acid, succinic acid, fumaric acid, pyroglutamic acid, oxalic acid, tartaric acid or derivatives thereof. More preferably the suitable acid can be selected from tartaric acid, preferably in its optically pure form (preferably L-tartaric acid). 5

In another embodiment, the present invention comprises the preparation of compound VI by reaction of compound III and compound V. Compound VI may be used in the process of the invention as free base or in the form of a salt. Suitable salts may include but are not limited to inorganic acid salts, for example hydrochloride, hydrobromide, phosphate or sulphate, or organic acid salts. A suitable organic acid can 10 be selected from acetic acid and its derivatives, benzoic acid or substituted benzoic acids, methanesulfonic acid, benzenesulfonic acid or substituted benzenesulfonic acid, citric acid, maleic acid, malic acid, maleic acid, malonic acid, mandelic acid, succinic acid, fumaric acid, pyroglutamic acid, oxalic acid, tartaric acid or derivatives thereof. Preferably the suitable acid can be selected from fumaric acid or tartaric acid, 15 preferably in its optically pure form (preferably L-tartaric acid), more preferably fumaric acid.

In another embodiment, the present invention comprises the preparation of compound VII from compound VI by selective deprotection of PG. Compound VII may be used in the process of the invention as free base or in the form of a salt. 20

Suitable salts may include but are not limited to inorganic acid salts, for

example hydrochloride, hydrobromide, phosphate or sulphate, or organic acid salts. A suitable organic acid can be selected from acetic acid and its derivatives, benzoic acid or substituted benzoic acids, methanesulfonic acid, benzenesulfonic acid or substituted benzenesulfonic acid, citric acid, maleic acid, malic acid, maleic acid, malonic acid, 25 mandelic acid, succinic acid, fumaric acid, pyroglutamic acid, oxalic acid, tartaric acid or derivatives thereof. More preferably the suitable acid can be selected from tartaric acid, preferably in its optically pure form (preferably L-tartaric acid).

In the preferred embodiment compound V is in the form of L-tartaric acid salt as crystalline compound, compound VI is in the form of fumaric acid salt as crystalline 30 compound, compound VII is in a form of L-tartaric acid salt as crystalline compound.

In another embodiment, the present invention provides Vilanterol tartrate and solid state forms thereof, preferably in substantially pure form. In specific

embodiments, the present invention comprises Vilanterol tartrate salt, particularly wherein the molar ratio between Vilanterol and tartaric acid can be 1.5 : 1 to 1 : 1, 35

preferably about 1 : 1, respectively. The above salts can be isolated. Preferably, the above salts can be in a solid form, more preferably in a crystalline form.

The Vilanterol tartrate may be in a crystalline form. According to one

embodiment, the present invention comprises a crystalline form of Vilanterol

tartrate. The crystalline form of Vilanterol tartrate can be characterized by data 5 selected from one or more of the following : an X-ray powder diffraction pattern substantially as depicted in Figure 2; an X-ray powder diffraction pattern having broad peaks at 7.6, 9.8, 12.1, 20.2 and 28.9 degrees two theta ± 1.0 degree two theta; and combinations thereof.

The above described Vilanterol tartrate and solid state form thereof is 10 particularly advantageous for the purification of the API Vilanterol. In some

embodiments the present invention comprises a process for the purification of

Vilanterol or Vilanterol salt, said process comprising preparing Vilanterol tartrate according to the process of the present invention and converting it to Vilanterol or to Vilanterol salt. 15

The above described Vilanterol tartrate and solid state form thereof can be used to prepare Vilanterol or other different salts of Vilanterol, as well as solid state forms thereof and/or pharmaceutical formulations comprising one or more of the salts and /or solid state forms thereof. Preferably, the above described Vilanterol tartrate and solid state form thereof can be used to prepare Vilanterol 20 triphenylacetate (trifenatate) or Vilanterol tosylate. Particularly, Vilanterol tartrate and solid state forms thereof can be used to purify the API Vilanterol.

The present invention also encompasses a process for preparing other Vilanterol salts. The process comprises preparing Vilanterol tartrate and solid state form

thereof by the processes of the present invention, and converting that salt to said 25 other Vilanterol salt. The conversion can be done, for example, by a process

comprising basifying Vilanterol tartrate and solid state form thereof, and reacting the obtained Vilanterol with a suitable acid, to obtain the corresponding salt of vilanterol . Preferably, the obtained Vilanterol and subsequently the obtained

Vilanterol salt, such as trifenatate salt, are chemically pure, i.e. having total 30 impurity at amount of not more than 10%, preferably not more than 5%, more preferably not more than 0.5%. Specifically, current invention provides a process for preparation of Vilanterol substantially free from impurity A of the following