JP3893938B2 - Hybrid vehicle drive structure with transmission - Google Patents

Hybrid vehicle drive structure with transmission Download PDFInfo

- Publication number

- JP3893938B2 JP3893938B2 JP2001323578A JP2001323578A JP3893938B2 JP 3893938 B2 JP3893938 B2 JP 3893938B2 JP 2001323578 A JP2001323578 A JP 2001323578A JP 2001323578 A JP2001323578 A JP 2001323578A JP 3893938 B2 JP3893938 B2 JP 3893938B2

- Authority

- JP

- Japan

- Prior art keywords

- transmission

- motor generator

- vehicle

- internal combustion

- combustion engine

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 230000005540 biological transmission Effects 0.000 title claims abstract description 77

- 238000002485 combustion reaction Methods 0.000 claims abstract description 74

- 230000007246 mechanism Effects 0.000 claims abstract description 35

- 239000000446 fuel Substances 0.000 abstract description 5

- 238000010586 diagram Methods 0.000 description 18

- 230000009467 reduction Effects 0.000 description 9

- 238000010248 power generation Methods 0.000 description 4

- 230000009471 action Effects 0.000 description 3

- 230000008859 change Effects 0.000 description 3

- 230000006872 improvement Effects 0.000 description 3

- 230000000994 depressogenic effect Effects 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- 230000007774 longterm Effects 0.000 description 2

- 239000000969 carrier Substances 0.000 description 1

- 230000003137 locomotive effect Effects 0.000 description 1

- 238000000034 method Methods 0.000 description 1

Images

Classifications

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02T—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO TRANSPORTATION

- Y02T10/00—Road transport of goods or passengers

- Y02T10/60—Other road transportation technologies with climate change mitigation effect

- Y02T10/62—Hybrid vehicles

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02T—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO TRANSPORTATION

- Y02T10/00—Road transport of goods or passengers

- Y02T10/60—Other road transportation technologies with climate change mitigation effect

- Y02T10/7072—Electromobility specific charging systems or methods for batteries, ultracapacitors, supercapacitors or double-layer capacitors

Landscapes

- Arrangement Of Transmissions (AREA)

- Hybrid Electric Vehicles (AREA)

- Retarders (AREA)

- Electric Propulsion And Braking For Vehicles (AREA)

Abstract

Description

【0001】

【発明の属する技術分野】

本発明は、内燃機関と電動機の組合せにより車輪を駆動するハイブリッド車の駆動構造に係る。

【0002】

【従来の技術】

近年、ますます高まりつつある大気環境保全と燃料資源の節約の重要性の認識の下に、内燃機関と電動機の組合せにより車輪が駆動されるハイブリッド車が脚光を浴びてきている。多様な回転数と駆動トルクの組合せが求められる自動車の車輪を内燃機関と電動機により駆動する場合に、その駆動態様をどのようにするかについては、種々の態様が可能であろうが、自動車は元来専ら内燃機関のみによって駆動されてきたものであり、また自動車の分野に於けるハイブリッド車は、従来の内燃機関のみによる駆動の一部を状況が許す限り電動駆動にて置き換えることから出発しているので、ハイブリッド車といえども、内燃機関のみによる駆動が可能となっていることは当然と考えられている。特開平11−198669には、内燃機関のクランク軸に第一の電動発電機を直列に接続して内燃機関または電動機のいずれか一方または両方により駆動される動力軸を構成し、かかる動力軸と第二の電動発電機の出力軸とをそれぞれ遊星歯車機構のリングギヤとサンギヤとに接続して組み合わせ、遊星歯車機構のキャリアを出力軸として、これに変速機を接続してなるハイブリッド車駆動構造が示されている。かかるハイブリッド車駆動構造によれば、内燃機関のみを原動機として働かせても、変速機の変速機能を得て、従来の内燃機関車と同様に自動車に求められる多様な運行態様に対応できる。これは上記の如きハイブリッド車の由来を反映する一つの典型であると思われる。

【0003】

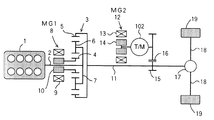

しかし、一方、自動車の原動機として内燃機関と電動機とを組み合わせる機会に、車輪に求められる回転数対駆動トルクと内燃機関より得られる回転数対駆動トルクの間の乖離に起因する内燃機関出力軸と車軸の間の回転数の差を電動機により差動的に吸収し、内燃機関出力軸と車軸の間に従来から必要とされていた変速機を無くすことが本件出願人と同一人により提案された。添付の図1は、そのようなハイブリッド車の駆動構造を示す概略図である。

【0004】

図1に於いて、1は内燃機関であり、図には示されていない車体に取り付けられている。2はその出力軸(クランク軸)である。3は遊星歯車装置であり、4はそのサンギヤ、5はリングギヤ、6はプラネタリピニオン、7はキャリアである。クランク軸2はキャリア7に連結されている。8は第一の電動発電機(MG1)であり、コイル9と回転子10と有し、回転子10はサンギヤ4と連結されている。コイル9は車体より支持されている。リングギヤ5にはプロペラ軸11の一端が連結されている。かくして、遊星歯車装置3は、内燃機関の出力軸2に現れる内燃機関の出力を第一の電動発電機3と車輪駆動軸をなすプロペラ軸11とに分配する動力分配機構を構成している。プロペラ軸11の途中には第二の電動発電機(MG2)12が連結されている。第二の電動発電機12はコイル13と回転子14と有し、コイル13は車体より支持されている。プロペラ軸11に対する回転子14の連結は任意の構造であってよいが、図示の例では、プロペラ軸11に設けられた歯車15に回転子14により支持されて回転する歯車16が噛み合う構造とされている。プロペラ軸11の他端はディファレンシャル装置17を介して一対の車軸18に連結されている。車軸18の各々には車輪19が取り付けられている。

【0005】

図示の駆動構造に於いて、クランク軸2の回転とキャリア7の回転とは同じであり、今この回転数をNcで表すものとする。また第一の電動発電機8の回転とサンギヤ4の回転とは同じであり、今この回転数をNsで表すものとする。一方、リングギヤ5の回転と第二の電動発電機12の回転と車輪19の回転とは互いに対応し、最終的には車速に対応するものであるが、それぞれの回転数は歯車15と16の間の歯数の比、ディファレンシャル装置17に於ける減速比、およびタイヤ径によって異なる。しかし、今ここでは便宜上これらの部分の回転数をリングギヤ5の回転数にて代表するものとし、それをNrとする。そうすると、内燃機関と二つの電動発電機とを遊星歯車装置にて図示の如く組み合わせたハイブリッド車駆動構造に於ける内燃機関と二つの電動発電機MG1、MG2の回転数Nc、Ns、Nrの間の関係は、遊星歯車装置の原理に基づき、図2に示す線図により表される。図にてρはリングギヤの歯数に対するサンギヤの歯数である(ρ<1)。Ncは機関回転数により定まり、Nrは車速により定まるので、Nsは機関回転数と車速の如何により

Ns=(1+1/ρ)Nc−(1/ρ)Nr

として定まる。

【0006】

一方、キャリアとサンギヤとリングギヤのトルクをTc、Ts、Trとすると、これらは

Ts:Tc:Tr=ρ/(1+ρ):1:1/(1+ρ)

の比にて互いに平衡し、従ってまた、これら3要素のいずれかがトルクを発生しあるいは吸収するときには、上記の平衡が成り立つまで相互間にトルクのやりとりが行なわれる。

【0007】

以上の如き駆動構造を備えたハイブリッド車に於いて、内燃機関、MG1、MG2の作動は、図には示されていない車輌運転制御装置により、運転者からの運転指令と車輌の運行状態とに基づいて制御される。即ち、車輌運転制御装置はマイクロコンピュータを備え、運転者からの運転指令と種々のセンサにより検出される車輌の運行状態とに基づいて目標車速および目標車輪駆動トルクを計算すると共に、蓄電装置の充電状態に基づいて蓄電装置に許される電流出力あるいは蓄電装置の充電のために必要な発電量を計算し、これらの計算結果に基づいて、内燃機関を休止を含む如何なる運転状態にて運転すべきか、またMG1およびMG2をいかなる電動状態あるいは発電状態にて運転すべきかを計算し、その計算結果に基づいて内燃機関、MG1、MG2の作動を制御する。

【0008】

【発明が解決しようとする課題】

以上の如く内燃機関の出力軸が動力分配機構を経て第一の電動発電機と車輪駆動軸とに連結され、該車輪駆動軸に第二の電動発電機が連結されたハイブリッド車駆動構造によれば、図2より理解される通り、内燃機関出力軸の回転数Ncと車速に対応する回転数Nrの各々の値およびその間の相対関係は、その変化を第一の電動発電機の回転数Nsにて吸収することにより大幅に変えることができるので、かかるハイブリッド車駆動構造に於いては、これまで変速機は不要とされていた。即ち、動力分配機構の調節次第で、NcとNrの間の関係を自由に変えることができ、また停車中(Nr=0)であっても機関運転(Nc>0)すること、逆に、前進中(Nr>0)であっても機関停止(Nc=0)すること、あるいは機関の運転または停止(Nc≧0)にかかわらず後進(Nr<0)することができる。

【0009】

しかし、MG2の回転数は車速の如何によって左右され、蓄電装置の充電度は車速とは一応無関係であるため、MG2が蓄電装置の充電のための発電機として作動するには大きな制約がある。そこで蓄電装置の充電は専らMG1に頼ることとなり、逆に車輪の電動駆動は専らMG2に頼ることとなる。そのため変速機を備えない上記の如きハイブリッド車駆動構造に於いて、低車速領域にても必要に応じて高い車輪駆動トルクを得ることができる車輌運転性能を確保しておくためには、畢竟MG2は大型化せざるを得ない。

【0010】

これを車速に対する車軸トルクの能力特性線図で示せば、図3の通りである。即ち、今、車輌の内燃機関を広い車速域に亙って高燃費にて運転し、しかも車輌の車速対車軸トルク性能として望まれる限界性能として線Aにて示す如き性能を車輌に持たせようとすれば、高燃費を得る内燃機関の車速対車軸トルク性能は領域Bの如くほぼ平らになるので、残りを専らMG2にて補わなければならず、その車速対車軸トルク性能は領域Cを賄うものでなければなない。そのためMG2は低回転速度にて高トルクを発生することができるよう、それ相当の大型のものとされなければならない。

【0011】

しかし、図3を吟味すれば、領域Cの深さは領域Bの深さに対比して些か深すぎるのではないかとの疑問がもたれる。これは、観点を変えれば、内燃機関と第一および第二の電動発電機なる三つの原動装置の大きさの相対的釣合い、特に内燃機関と第二の電動発電機の大きさの釣合いの問題である。本発明は、かかる疑問に端を発し、この点に関し上記の如きハイブリッド車輌駆動構造を更に改良することを課題としている。

【0012】

【課題を解決するための手段】

かかる課題を解決するものとして、本発明は、内燃機関の出力軸が動力分配機構を経て第一の電動発電機と車輪駆動軸とに連結され、該車輪駆動軸に第二の電動発電機が連結されたハイブリッド車駆動構造に於いて、前記車輪駆動軸への前記第二の電動発電機の連結の途中に変速機を設け、該変速機の入力軸が前記第二の電動発電機のみに連結されており、前記変速機は後進段を含んでおり、前記変速機の後進段による車輌後進駆動と前記動力分配機構の調節による車輌後進駆動との間の選択を行う手段を含んでいること、または前記車輪駆動軸は一端にて前記動力分配機構に連結されまた他端にてディファレンシャル装置に連結されており、前記車輪駆動軸への前記第二の電動発電機の連結の途中に変速機を設け、前記変速機は後進段を含んでおり、前記変速機の後進段による車輌後進駆動と前記動力分配機構の調節による車輌後進駆動との間の選択を行う手段を含んでいること、または前記車輪駆動軸への前記第二の電動発電機の連結の途中に後進段を含む変速機を設け、前記変速機の後進段による車輌後進駆動と前記動力分配機構の調節による車輌後進駆動との間の選択を行う手段を含んでいること、または前記車輪駆動軸の途中または該車輪駆動軸への前記第二の電動発電機の連結の途中の少なくとも一方に後進段を含む変速機を設け、前記変速機の後進段による車輌後進駆動と前記動力分配機構の調節による車輌後進駆動との間の選択を行う手段を含んでいることを特徴とするハイブリッド車駆動構造を提案するものである。

【0013】

尚、電動発電機なる語は、電動機および発電機の両機能を有する手段を指すが、本願発明は、内燃機関の出力軸が動力分配機構を経て第一の電動発電機と車輪駆動軸とに連結され、該車輪駆動軸に第二の電動発電機が連結されたハイブリッド車駆動構造の、短期的車輌駆動性能に関するものであり、換言すれば、車輌のハイブリッド駆動における内燃機関駆動と、電動駆動と、蓄電装置に対する自己充電作用の相互関係が関与する長期的車輌駆動性能に関するものではないので、本願発明の作用および効果に関する限り、第一および第二の電動発電機は、いずれも単なる電動機であってよいものである。確かに、実働する車輌駆動装置としては、既に記した通り、第二の電動発電機は専ら電動機として作動せざるを得ず(しかし発電機として作動することも可能)、従って長期的に作動可能な車輌駆動装置を構成するためには、第一の電動発電機は発電機能を有している必要があるが、この必要性は本願発明の技術的思想とは関係ないことである。従って、本発明の構成に於いて、電動発電機と記載された手段は、発電機能を有しない電動機をその均等物として含むものとする。

【0014】

上記の如きハイブリッド車駆動構造に於いて、前記変速機は前記車輪駆動軸の途中に前記第二の電動発電機の連結部より前記内燃機関の側に設けられてよい。

【0015】

あるいはまた、上記の如きハイブリッド車駆動構造に於いて、前記変速機は前記車輪駆動軸の途中に前記第二の電動発電機の連結部より前記内燃機関とは隔たる側に設けられてよい。

【0016】

更に、上記の如きハイブリッド車駆動構造に於いて、前記変速機は後進段を含んでいてよい。この場合、ハイブリッド車駆動構造は、更に、前記変速機の後進段による車輌後進駆動と前記動力分配機構の調節による車輌後進駆動との間の選択を行う手段を含んでいてよい。

【0017】

【発明の作用及び効果】

上記の如く内燃機関の出力軸が動力分配機構を経て第一の電動発電機と車輪駆動軸とに連結され、該車輪駆動軸に第二の電動発電機が連結されたハイブリッド車駆動構造に於いて、前記車輪駆動軸の途中または該車輪駆動軸への前記第二の電動発電機の連結の途中の少なくとも一方に変速機が設けられれば、低車速にて高車軸トルクが求められたとき、該変速機が前記車輪駆動軸の途中であって前記第二の電動発電機の連結部より内燃機関の側に設けられていれば、前記動力分配機構を調節して内燃機関の回転数を車速に対比して高め、該変速機の減速比を高めることにより、求められた高車軸トルクのより多くを内燃機関により賄い、前記第二の電動発電機に求めるトルクを減じてこの要求に応ずることができ、また該変速機が前記車輪駆動軸の途中であって前記第二の電動発電機の連結部より内燃機関とは隔たる側に設けられていれば、前記動力分配機構を調節して内燃機関の回転数を車速に対比して高め、該変速機の減速比を高めることにより、この高められた減速比にて車輪を内燃機関と前記第二の電動発電機との共働により駆動し、第二の電動発電機に求めるトルクを減じてこの要求に応ずることができ、また該変速機が前記第二の電動発電機の連結の途中に設けられれば、前記動力分配機構の調節の如何に拘らず前記第二の電動発電機より得られる車輪駆動トルクを該変速機の減速比を高めることにより増大し、前記第二の電動発電機を程々の大きさにしておいてもこの要求に応ずることができ、かくして内燃機関と第一および第二の電動発電機の三者の相対的大きさに好ましい釣合いを保ち、内燃機関を常に高燃費にて運転しつつ、図3の線Aにより示されている如き車速対車軸トルク性能を得ることができ、更に変速機が後進段を含み、変速機の後進段による車輌後進駆動と動力分配機構の調節による車輌後進駆動との間の選択を行う手段が設けられていれば、車輌後進駆動に要する駆動トルクの大きさに応じて適宜両者間の選択を行ってより適切な車輌運転を行うことができる。

【0018】

更に、上記の如きハイブリッド車駆動構造に於いて、変速機が後進段を含むよう構成されていれば、車輌の後進に際して、動力分配機構を調節しなくても、変速機を後進段に切り替えることにより容易に車輌の後進が可能となる。この場合、更に変速機の後進段による車輌後進駆動と動力分配機構の調節による車輌後進駆動との間の選択を行う手段が設けられていれば、特に坂道での登り後進や駆動輪が窪みに陥没したときのように高い車軸トルクによる車輌後進が必要なときには、変速機の後進段による車輌後進駆動を選択することにより十分な駆動トルクにてそれに対処し、通常の平地での車輌後進のように左程の車軸トルクが必要とされないときには、動力分配機構の調節による車輌後進駆動を選択することにより変速機切換え操作のない速やかな後進を達成することができる。

【0019】

更にまた、上記の変速機はそれ自身既に種々の態様にて公知のオーバドライブ段を最高速段とするものであってもよく、それによってハイブリッド車に於いても車輌高速運転に対し内燃機関の運転を従来のオーバドライブ付き内燃機関車に於けると同様に最適化することができる。

【0020】

【発明の実施の形態】

図4、図5、図6は、図1に示す如く内燃機関の出力軸が動力分配機構を経て第一の電動発電機と車輪駆動軸とに連結され、該車輪駆動軸に第二の電動発電機が連結されたハイブリッド車駆動構造に、本発明により変速機を組み込む三つの実施例を示す図1と同様の概略図である。図4、図5、図6に於いて、図1に示す部分に対応する部分は対応する符号により示されている。

【0021】

図4に示す第一の実施例に於いては、変速機100は車輪駆動軸の途中であって第二の電動発電機MG2の連結部より内燃機関の側に設けられており、図1についての説明の文言でいえば、車輪駆動軸の一部をなすプロペラ軸11の一部であってMG2の連結部をなす歯車15よりも内燃機関の側に設けられている。変速機100は2段ないし3段のものであってよく、更に後進段を含むものであってよい。そのような変速機は既に公知の技術により種々の態様にて得られるが、前進3段と後進段を有するものについてその一例を解図的に示せば、図7の通りである。

【0022】

図7に於いて、20、22、24、26は一つの遊星歯車機構を構成するサンギヤ、リングギヤ、プラネタリピニオン、キャリアであり、また21、23、25、27は他の一つの遊星歯車機構を構成するサンギヤ、リングギヤ、プラネタリピニオン、キャリアであり、28(C1)、29(C2)はクラッチであり、30(B1)、31(B2)はブレーキであり、32(F1)はワンウェイクラッチである。そしてこれらの回転要素が、33を入力軸とし、34を出力軸として、その間に図示の如く組み合わされていると、クラッチC1が係合されることにより減速比が最も大きい第1速段が達成され、クラッチC1とブレーキB1とが係合されることにより減速比が中程の第2速段が達成され、クラッチC1とC2とが係合されることにより減速比が最も小さい(減速比=1)第3速段が達成され、クラッチC2とブレーキB2とが係合されることにより後進段が達成される。

【0023】

図4の実施例に於いて、変速機100が3段の変速を与えるようになっているとすると、車速対車軸トルクの能力特性線図は、かかる変速機がない場合の図3に対比して、図8の如く変更される。この線図に於いて、領域B1、B2、B3が、それぞれ変速機を第1速段、第2速段、第3速段にすることにより主として内燃機関(場合によって内燃機関およびMG1)によって賄われる領域であり、残る領域Cが第二の電動発電機MG2によって賄われる領域である。図8より、MG2に求められる最大トルクが、図3の場合に比して大幅に低減されることが理解されよう。

【0024】

図5に示す第二の実施例に於いては、変速機101は車輪駆動軸の途中であって第二の電動発電機MG2の連結部より内燃機関とは隔たる側に設けられており、図1についての説明の文言でいえば、車輪駆動軸の一部をなすプロペラ軸11の一部であってMG2の連結部をなす歯車15よりも内燃機関とは隔たる側に設けられている。変速機101もまた2段ないし3段のものであってよく、更に後進段を含むものであってよく、図7に示す如きものであってよい。

【0025】

図5の実施例に於いて、変速機101が3段の変速を与えるようになっているとすると、車速対車軸トルクの能力特性線図は、かかる変速機がない場合の図3に比して、図9の如く変更される。この線図に於いては、領域B1+C1、B2+C2、B3+C3が、それぞれ変速機を第1速段、第2速段、第3速段にすることにより主として内燃機関(場合によって内燃機関およびMG1)およびMG2によって賄われる領域である。この場合にも、図9より分かる通り、MG2に求められる最大トルクは、図3の場合に比して大幅に低減される。

【0026】

図6に示す第3の実施例に於いては、変速機102は車輪駆動軸への第二の電動発電機MG2の連結の途中に設けられており、図1についての説明の文言でいえば、車輪駆動軸の一部をなすプロペラ軸11へのMG2の連結部に設けられている。変速機102もまた2段ないし3段のものであってよい。この場合、MG2の逆転駆動は電気回路の切換えにより簡単に行なえるので、変速機102には後進段はなくてもよい。しかし、変速機102もまた後進段を備えていてもよく、図7に示す如きものであってよい。

【0027】

図6の実施例に於いて、変速機102が3段の変速を与えるようになっているとすると、車速対車軸トルクの能力特性線図は、かかる変速機がない場合の図3に比して、図10の如く変更される。この線図に於いては、領域Bが主として内燃機関(場合によって内燃機関およびMG1)によって賄われる領域であり、領域C1、C2、C3が、それぞれ変速機を第1速段、第2速段、第3速段にすることによりMG2によって賄われる領域である。図10に於いて、領域C1は内燃機関により領域Bに相当するトルクを得た上でMG2の出力トルクを第1速段の変速機により増大したトルクを加算することにより賄えるトルク領域を示す。領域C2、C3も同様のことを示す。図10より分かる通り、MG2自身に求められる最大トルクは、図3の場合に比して大幅に低減される。

【0028】

尚、図8〜図10は、上記の通り車速対車軸トルクの座標系で見て主として内燃機関(場合によって内燃機関およびMG1)および第二の電動発電機MG2により賄うことができるトルクの大きさを車速に対して示す能力特性線図であり、かかる変速機付きハイブリッド車駆動構造に於いては変速線図でない。即ち、図4および図5の実施例に於いて、車軸トルクに対する要求が低い場合にも、車速が低車速から高車速へと増大するにつれて、変速機は必ず第1速段から第2速段、第3速段へと切り換えられることを意味するものではない。これらの実施例に於いて、平地での通常の車輌発進時の如くさしたる高車軸トルクが必要とされないときには、変速機を第3速段に設定したままとして動力分配機構の制御により図3の領域Bを用い、第2速段、第1速段は、それぞれ要求車軸トルクが増大したときあるいはシフトレバーが2位置、L位置へ切り換えられることに応じて使用されるようにしてよい。

【0029】

また、以上のいずれの実施例においても、車輌を後進駆動することは、図2で見てNrを負の値にすることであり、それには内燃機関が運転されているか(Nc>0)いないか(Nc=0)にかかわらず、MG2の回転数Nrが所望の負の値になるよう、内燃機関回転数Ncに応じてMG1の回転数NsおよびMG2の回転数Nrを調整することにより達成される。かかるMG1およびMG2の回転数の調整制御は、無段で迅速に行なえるが、この場合、車輌を後進駆動するトルクは電動発電機のみによってしか賄えないので、得られる後進駆動トルクの大きさは限られる。これに対し、変速機が図4または5に示す実施例における如く車輪駆動軸の途中に設けられていて後進段を備えているときには、これを後進段に切り換えて内燃機関により車輪を後進駆動するようにすれば、変速機の切換えに幾分かの時間を要するが、大きな駆動トルクにて車輌を後進駆動することができる。そこで、図には示されていないが、変速機の後進段による車輌後進駆動と動力分配機構の調節による車輌後進駆動との間の選択を行う手段が設けられていれば、車輌後進駆動に要する駆動トルクの大きさに応じて適宜両者間の選択を行ってより適切な車輌運転を行うことができる。かかる選択を行う手段は、現今のコンピュータを備えた車輌運転制御装置によれば、ほとんどソフトウェア的に達成される。

【0030】

以上に於いては本発明をいくつかの実施例について詳細に説明したが、本発明がこれらの実施例にのみ限られるものではなく、本発明の範囲内にて他に種々の実施例が可能であることは当業者にとって明らかであろう。

【図面の簡単な説明】

【図1】本発明による改良の対象となるハイブリッド車の駆動構造を示す概略図。

【図2】図1に示すハイブリッド車駆動構造に於ける内燃機関と二つの電動発電機MG1、MG2の回転数Nc、Ns、Nrの間の関係を示す線図。

【図3】図1に示すハイブリッド車駆動構造に於いて内燃機関および電動発電機MG2の各々により分担されるべき車軸トルクを車速に対し示す線図。

【図4】図1に示すハイブリッド車駆動構造について本発明によりなされる改良の第一の実施例を示す概略図。

【図5】図1に示すハイブリッド車駆動構造について本発明によりなされる改良の第二の実施例を示す概略図。

【図6】図1に示すハイブリッド車駆動構造について本発明によりなされる改良の第三の実施例を示す概略図。

【図7】三つの変速段と後進段とを提供する変速機の一例を示す概略図。

【図8】図4に示すハイブリッド車駆動構造に於いて内燃機関および電動発電機MG2の各々により分担されるべき車軸トルクを車速に対し示す線図。

【図9】図5に示すハイブリッド車駆動構造に於いて内燃機関および電動発電機MG2の各々により分担されるべき車軸トルクを車速に対し示す線図。

【図10】図6に示すハイブリッド車駆動構造に於いて内燃機関および電動発電機MG2の各々により分担されるべき車軸トルクを車速に対し示す線図。

【符号の説明】

1…内燃機関

2…内燃機関の出力軸

3…遊星歯車装置

4…サンギヤ

5…リングギヤ

6…プラネタリピニオン

7…キャリア

8…第一の電動発電機(MG1)

9…コイル

10…回転子

11…プロペラ軸

12…第二の電動発電機(MG2)

13…コイル

14…回転子

15,16…歯車

17…ディファレンシャル装置

18…車軸

19…車輪

20…サンギヤ

22…リングギヤ

24…プラネタリピニオン

26…キャリア

21…サンギヤ

23…リングギヤ

25…プラネタリピニオン

27…キャリア

28,29…クラッチ

28,29…ブレーキ

32…ワンウェイクラッチ

100,101,102…変速機[0001]

BACKGROUND OF THE INVENTION

The present invention relates to a drive structure of a hybrid vehicle that drives wheels by a combination of an internal combustion engine and an electric motor.

[0002]

[Prior art]

In recent years, under the recognition of the increasing importance of conservation of the air environment and saving of fuel resources, hybrid vehicles in which wheels are driven by a combination of an internal combustion engine and an electric motor have been in the spotlight. When driving an automobile wheel that requires various combinations of rotational speeds and driving torques with an internal combustion engine and an electric motor, various modes will be possible as to how to drive the vehicle. It was originally driven exclusively by internal combustion engines, and hybrid vehicles in the field of automobiles started by replacing part of the drive by conventional internal combustion engines only with electric drive as the situation allows. Therefore, it is natural that even a hybrid vehicle can be driven only by an internal combustion engine. In JP-A-11-198669, a power shaft driven by one or both of an internal combustion engine and an electric motor is configured by connecting a first motor generator in series to a crankshaft of the internal combustion engine, A hybrid vehicle drive structure in which the output shaft of the second motor generator is connected to the ring gear and sun gear of the planetary gear mechanism, combined, and the carrier of the planetary gear mechanism is used as the output shaft to which the transmission is connected. It is shown. According to such a hybrid vehicle drive structure, even if only the internal combustion engine is operated as a prime mover, the transmission function of the transmission can be obtained and the various operation modes required for the automobile can be dealt with in the same manner as the conventional internal combustion engine vehicle. This seems to be a typical example that reflects the origin of the hybrid vehicle as described above.

[0003]

However, on the other hand, on the occasion of combining an internal combustion engine and an electric motor as a motor for an automobile, the internal combustion engine output shaft resulting from the difference between the rotational speed required for wheels and the driving torque obtained from the internal combustion engine, and It was proposed by the same applicant as the present applicant to differentially absorb the difference in rotational speed between the axles by the electric motor and eliminate the conventionally required transmission between the output shaft of the internal combustion engine and the axle. . FIG. 1 attached herewith is a schematic diagram showing the driving structure of such a hybrid vehicle.

[0004]

In FIG. 1,

[0005]

In the illustrated driving structure, the rotation of the crankshaft 2 and the rotation of the

Determined as

[0006]

On the other hand, assuming that the torques of the carrier, the sun gear, and the ring gear are Tc, Ts, and Tr, these are Ts: Tc: Tr = ρ / (1 + ρ): 1: 1 / (1 + ρ)

Therefore, when any of these three elements generate or absorb torque, torque is exchanged between them until the above equilibrium is established.

[0007]

In the hybrid vehicle having the drive structure as described above, the operation of the internal combustion engine, MG1, and MG2 is performed by the vehicle operation control device (not shown in the figure) according to the operation command from the driver and the operation state of the vehicle. Controlled based on. That is, the vehicle operation control device includes a microcomputer, calculates the target vehicle speed and the target wheel drive torque based on the operation command from the driver and the operation state of the vehicle detected by various sensors, and charges the power storage device. Calculate the current output allowed for the power storage device based on the state or the amount of power generation required for charging the power storage device, and on the basis of these calculation results, what operating state should be operated including the shutdown, Further, it is calculated in which electric state or power generation state the MG1 and MG2 should be operated, and the operation of the internal combustion engine, MG1, MG2 is controlled based on the calculation result.

[0008]

[Problems to be solved by the invention]

As described above, according to the hybrid vehicle drive structure in which the output shaft of the internal combustion engine is connected to the first motor generator and the wheel drive shaft through the power distribution mechanism, and the second motor generator is connected to the wheel drive shaft. For example, as can be understood from FIG. 2, the values of the rotational speed Nc of the output shaft of the internal combustion engine and the rotational speed Nr corresponding to the vehicle speed and the relative relationship therebetween change the rotational speed Ns of the first motor generator. Therefore, in such a hybrid vehicle drive structure, a transmission has been made unnecessary. That is, depending on the adjustment of the power distribution mechanism, the relationship between Nc and Nr can be freely changed, and even when the vehicle is stopped (Nr = 0), the engine is operated (Nc> 0). Even when the vehicle is moving forward (Nr> 0), the engine can be stopped (Nc = 0), or the vehicle can move backward (Nr <0) regardless of whether the engine is operating or stopped (Nc ≧ 0).

[0009]

However, since the rotational speed of MG2 depends on the speed of the vehicle, and the degree of charge of the power storage device is irrelevant to the vehicle speed, there is a great restriction on the operation of MG2 as a generator for charging the power storage device. Therefore, charging of the power storage device depends exclusively on MG1, and conversely, electric driving of the wheels depends exclusively on MG2. Therefore, in the hybrid vehicle drive structure as described above that does not include a transmission, in order to ensure vehicle driving performance that can obtain high wheel drive torque as required even in the low vehicle speed region, 畢竟 MG2 Must be enlarged.

[0010]

This is shown in FIG. 3 as an ability characteristic diagram of axle torque with respect to vehicle speed. That is, now, the internal combustion engine of the vehicle is operated with high fuel efficiency over a wide vehicle speed range, and the vehicle has the performance shown by the line A as the limit performance desired as the vehicle speed vs. axle torque performance of the vehicle. If this is the case, the vehicle speed vs. axle torque performance of the internal combustion engine that obtains high fuel efficiency becomes almost flat as in region B, so the rest must be supplemented exclusively by MG2, and the vehicle speed vs. axle torque performance covers region C. Must be a thing. Therefore, MG2 must be made large in size so that high torque can be generated at a low rotational speed.

[0011]

However, if FIG. 3 is examined, it will be questioned that the depth of the area | region C may be a little too deep compared with the depth of the area | region B. FIG. From a different point of view, this is a problem of the relative balance of the sizes of the three prime movers, the internal combustion engine and the first and second motor generators, particularly the balance of the sizes of the internal combustion engine and the second motor generator. It is. The present invention originates from such a question, and an object of the present invention is to further improve the hybrid vehicle drive structure as described above.

[0012]

[Means for Solving the Problems]

In order to solve such a problem, in the present invention, an output shaft of an internal combustion engine is connected to a first motor generator and a wheel drive shaft through a power distribution mechanism, and a second motor generator is connected to the wheel drive shaft. In the connected hybrid vehicle drive structure, a transmission is provided in the middle of the connection of the second motor generator to the wheel drive shaft, and the input shaft of the transmission is provided only for the second motor generator. Connected , the transmission includes a reverse gear, and includes means for selecting between vehicle reverse drive by the reverse gear of the transmission and vehicle reverse drive by adjustment of the power distribution mechanism. Or the wheel drive shaft is connected to the power distribution mechanism at one end and to the differential device at the other end, and the transmission is in the middle of the connection of the second motor generator to the wheel drive shaft. The transmission includes a reverse gear. And means for selecting between vehicle reverse drive by the reverse gear of the transmission and vehicle reverse drive by adjustment of the power distribution mechanism, or the second electric drive to the wheel drive shaft A transmission including a reverse gear is provided in the middle of the generator connection, and includes means for selecting between vehicle reverse drive by the reverse gear of the transmission and vehicle reverse drive by adjustment of the power distribution mechanism. Or at least one of the wheel drive shaft or the connection of the second motor generator to the wheel drive shaft is provided with a transmission including a reverse gear, and the vehicle reverse drive by the reverse gear of the transmission; The present invention proposes a hybrid vehicle drive structure including means for selecting between vehicle reverse drive by adjusting the power distribution mechanism .

[0013]

The term “motor generator” refers to a means having both functions of an electric motor and a generator. However, in the present invention, the output shaft of the internal combustion engine passes through a power distribution mechanism into the first motor generator and the wheel drive shaft. The present invention relates to a short-term vehicle drive performance of a hybrid vehicle drive structure in which a second motor generator is connected to the wheel drive shaft. In other words, the internal combustion engine drive and the electric drive in the hybrid drive of the vehicle And the long-term vehicle drive performance that involves the interrelationship of the self-charging action with respect to the power storage device, the first and second motor generators are simply electric motors as far as the actions and effects of the present invention are concerned. It can be. Certainly, as already mentioned, as the actual vehicle drive system, the second motor generator must operate exclusively as an electric motor (but can also operate as a generator), so it can operate in the long term. In order to construct a simple vehicle drive device, the first motor generator needs to have a power generation function, but this necessity is not related to the technical idea of the present invention. Therefore, in the structure of this invention, the means described as a motor generator shall include the motor which does not have a power generation function as the equivalent.

[0014]

In the hybrid vehicle drive structure as described above, the transmission may be provided in the middle of the wheel drive shaft and closer to the internal combustion engine than the connecting portion of the second motor generator.

[0015]

Alternatively, in the hybrid vehicle drive structure as described above, the transmission may be provided on the side away from the internal combustion engine from the connecting portion of the second motor generator in the middle of the wheel drive shaft.

[0016]

Furthermore, in the hybrid vehicle drive structure as described above, the transmission may include a reverse gear. In this case, the hybrid vehicle drive structure may further include means for selecting between vehicle reverse drive by the reverse gear of the transmission and vehicle reverse drive by adjustment of the power distribution mechanism.

[0017]

[Action and effect of the invention]

As described above, in the hybrid vehicle drive structure in which the output shaft of the internal combustion engine is connected to the first motor generator and the wheel drive shaft through the power distribution mechanism, and the second motor generator is connected to the wheel drive shaft. If a transmission is provided in at least one of the wheel drive shaft or the connection of the second motor generator to the wheel drive shaft, when high axle torque is obtained at low vehicle speed, If the transmission is provided in the middle of the wheel drive shaft and closer to the internal combustion engine than the connecting portion of the second motor generator, the power distribution mechanism is adjusted to adjust the rotational speed of the internal combustion engine to the vehicle speed. To meet the demand by increasing the reduction ratio of the transmission to cover the required high axle torque by the internal combustion engine and reducing the torque required for the second motor generator. And the transmission can be used for the wheel drive. If it is provided in the middle of the shaft and on the side separated from the internal combustion engine from the connecting portion of the second motor generator, the power distribution mechanism is adjusted to compare the rotational speed of the internal combustion engine with the vehicle speed. The torque required for the second motor generator is increased by increasing the reduction ratio of the transmission so that the wheels are driven by the cooperation of the internal combustion engine and the second motor generator at the increased reduction ratio. can of meeting this demand by subtracting, also if we provided in the middle speed change machine of the connection of the second motor generator, irrespective the second motor generator of the regulation of the power distribution mechanism The wheel drive torque obtained from the machine can be increased by increasing the speed reduction ratio of the transmission, and this requirement can be met even if the second motor generator is moderately sized. The relative size of the first and second motor generators Maintaining the balance preferred, while operating an internal combustion engine always at high fuel efficiency, it can be obtained which such vehicle speed versus axle torque performance is indicated by line A in FIG. 3, further comprising a transmission reverse gear, the transmission If there is a means to select between the vehicle reverse drive by the reverse gear and the vehicle reverse drive by adjusting the power distribution mechanism, the selection between the two is appropriately performed according to the magnitude of the drive torque required for the vehicle reverse drive Ru can do a more appropriate vehicle operation carried out.

[0018]

Furthermore, in the hybrid vehicle drive structure as described above, if the transmission is configured to include a reverse gear, the transmission can be switched to the reverse gear without adjusting the power distribution mechanism when the vehicle moves backward. This makes it possible to easily reverse the vehicle. In this case, if there is further provided a means for selecting between the vehicle reverse drive by the reverse gear of the transmission and the vehicle reverse drive by adjusting the power distribution mechanism, the reverse of the climb on the slope and the drive wheel are depressed. When it is necessary to reverse the vehicle with a high axle torque, such as when it is depressed, it is possible to cope with it with a sufficient driving torque by selecting the vehicle reverse drive with the reverse gear of the transmission, so that the vehicle reverses on a normal flat ground. When the left-hand axle torque is not required, it is possible to achieve rapid reverse without a transmission switching operation by selecting vehicle reverse drive by adjusting the power distribution mechanism.

[0019]

Furthermore, the above-described transmission itself may be the one with the known overdrive stage having the highest speed stage in various aspects, so that even in a hybrid vehicle, the internal combustion engine can be used for high-speed driving. Operation can be optimized as in a conventional overdrive internal combustion locomotive.

[0020]

DETAILED DESCRIPTION OF THE INVENTION

4, 5, and 6, the output shaft of the internal combustion engine is connected to the first motor generator and the wheel drive shaft through the power distribution mechanism as shown in FIG. 1, and the second electric motor is connected to the wheel drive shaft. FIG. 2 is a schematic view similar to FIG. 1 showing three embodiments incorporating a transmission according to the present invention in a hybrid vehicle drive structure to which a generator is connected. 4, 5, and 6, portions corresponding to the portions shown in FIG. 1 are indicated by the corresponding reference numerals.

[0021]

In the first embodiment shown in FIG. 4, the

[0022]

In FIG. 7, 20, 22, 24 and 26 are sun gears, ring gears, planetary pinions and carriers constituting one planetary gear mechanism, and 21, 23, 25 and 27 are other planetary gear mechanisms. The sun gear, the ring gear, the planetary pinion, and the carrier are configured, 28 (C1) and 29 (C2) are clutches, 30 (B1) and 31 (B2) are brakes, and 32 (F1) is a one-way clutch. . When these rotating elements are combined as shown in the figure with 33 as an input shaft and 34 as an output shaft, the first speed stage having the largest reduction ratio is achieved by engaging the clutch C1. When the clutch C1 and the brake B1 are engaged, the second speed with a medium reduction ratio is achieved, and when the clutches C1 and C2 are engaged, the reduction ratio is the smallest (reduction ratio = 1) The third speed is achieved, and the reverse speed is achieved by engaging the clutch C2 and the brake B2.

[0023]

In the embodiment of FIG. 4, if the

[0024]

In the second embodiment shown in FIG. 5, the

[0025]

In the embodiment of FIG. 5, if the

[0026]

In the third embodiment shown in FIG. 6, the

[0027]

In the embodiment of FIG. 6, assuming that the

[0028]

8 to 10 show the magnitude of torque that can be provided mainly by the internal combustion engine (in some cases, the internal combustion engine and MG1) and the second motor generator MG2 in the coordinate system of vehicle speed versus axle torque as described above. Is a performance characteristic diagram showing the speed with respect to the vehicle speed, and is not a shift diagram in such a hybrid vehicle drive structure with a transmission. That is, in the embodiment shown in FIGS. 4 and 5, even when the demand for the axle torque is low, the transmission always shifts from the first speed to the second speed as the vehicle speed increases from the low vehicle speed to the high vehicle speed. It does not mean that the vehicle can be switched to the third gear. In these embodiments, when the high axle torque, which is the same as when starting a normal vehicle on a flat ground, is not required, the transmission is maintained at the third speed stage, and the region shown in FIG. Using B, the second speed and the first speed may be used when the required axle torque increases or when the shift lever is switched to the 2 position or the L position, respectively.

[0029]

Further, in any of the above embodiments, driving the vehicle in reverse means that Nr is set to a negative value as seen in FIG. 2, which is whether the internal combustion engine is operated (Nc> 0). This is achieved by adjusting the rotation speed Ns of MG1 and the rotation speed Nr of MG2 according to the internal combustion engine rotation speed Nc so that the rotation speed Nr of MG2 becomes a desired negative value regardless of (Nc = 0). Is done. Such control for adjusting the rotational speeds of MG1 and MG2 can be performed quickly and continuously. In this case, the torque for driving the vehicle backward can be provided only by the motor generator, and therefore the magnitude of the reverse drive torque obtained is large. Is limited. In contrast, when the transmission is provided with a reverse gear be provided in the middle of the wheel drive shaft as in the embodiment shown in FIG. 4 or 5, the the Rikuruma wheels by the internal combustion engine is switched to the reverse gear which If the vehicle is driven backward, it takes some time to switch the transmission, but the vehicle can be driven backward with a large driving torque. Therefore, although not shown in the figure, if a means for selecting between vehicle reverse drive by the reverse gear of the transmission and vehicle reverse drive by adjustment of the power distribution mechanism is provided, the vehicle reverse drive is required. More appropriate vehicle operation can be performed by appropriately selecting between the two according to the magnitude of the driving torque. The means for making such a selection is achieved almost by software according to a vehicle operation control apparatus equipped with a current computer.

[0030]

Although the present invention has been described in detail with respect to several embodiments, the present invention is not limited to these embodiments, and various other embodiments are possible within the scope of the present invention. It will be apparent to those skilled in the art.

[Brief description of the drawings]

FIG. 1 is a schematic diagram showing a drive structure of a hybrid vehicle to be improved by the present invention.

2 is a diagram showing the relationship between the internal combustion engine and the rotational speeds Nc, Ns, Nr of two motor generators MG1, MG2 in the hybrid vehicle drive structure shown in FIG.

3 is a diagram showing an axle torque to be shared by an internal combustion engine and a motor generator MG2 with respect to vehicle speed in the hybrid vehicle drive structure shown in FIG.

FIG. 4 is a schematic view showing a first embodiment of the improvement made by the present invention with respect to the hybrid vehicle drive structure shown in FIG. 1;

FIG. 5 is a schematic view showing a second embodiment of the improvement made by the present invention with respect to the hybrid vehicle drive structure shown in FIG. 1;

FIG. 6 is a schematic diagram showing a third embodiment of the improvement made by the present invention with respect to the hybrid vehicle drive structure shown in FIG. 1;

FIG. 7 is a schematic view showing an example of a transmission that provides three shift speeds and a reverse speed.

8 is a diagram showing an axle torque to be shared by each of the internal combustion engine and the motor generator MG2 with respect to the vehicle speed in the hybrid vehicle drive structure shown in FIG.

9 is a diagram showing an axle torque to be shared by an internal combustion engine and a motor generator MG2 with respect to vehicle speed in the hybrid vehicle drive structure shown in FIG.

10 is a diagram showing axle torque with respect to vehicle speed to be shared by the internal combustion engine and the motor generator MG2 in the hybrid vehicle drive structure shown in FIG. 6;

[Explanation of symbols]

DESCRIPTION OF

9 ...

DESCRIPTION OF

Claims (6)

Priority Applications (19)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2001323578A JP3893938B2 (en) | 2001-10-22 | 2001-10-22 | Hybrid vehicle drive structure with transmission |

| US10/261,411 US7223200B2 (en) | 2001-10-22 | 2002-10-02 | Hybrid-vehicle drive system and operation method with a transmission |

| CA2704802A CA2704802C (en) | 2001-10-22 | 2002-10-08 | Hybrid-vehicle drive system with a transmission |

| CA2632448A CA2632448C (en) | 2001-10-22 | 2002-10-08 | Operation method of a hybrid-vehicle drive system with a transmission |

| CA2704805A CA2704805A1 (en) | 2001-10-22 | 2002-10-08 | Hybrid-vehicle drive system with a transmission |

| CA2704804A CA2704804C (en) | 2001-10-22 | 2002-10-08 | Hybrid-vehicle drive system with a transmission |

| CA002406817A CA2406817C (en) | 2001-10-22 | 2002-10-08 | Hybrid-vehicle drive system and operation method with a transmission |

| CA002548815A CA2548815C (en) | 2001-10-22 | 2002-10-08 | Hybrid-vehicle drive system and operation method with a transmission |

| ES04028725T ES2294422T3 (en) | 2001-10-22 | 2002-10-21 | METHOD OF OPERATION OF A TRACTION SYSTEM FOR HYBRID VEHICLE. |

| ES02023460T ES2269583T3 (en) | 2001-10-22 | 2002-10-21 | HYBRID TRANSMISSION SYSTEM OF A VEHICLE AND METHOD OF OPERATION WITH A TRANSMISSION. |

| DE60223850T DE60223850T2 (en) | 2001-10-22 | 2002-10-21 | Method for operating a drive system of a hybrid vehicle |

| EP04028726A EP1520743B1 (en) | 2001-10-22 | 2002-10-21 | Method of operating a hybrid-vehicle drive system |

| DE60227711T DE60227711D1 (en) | 2001-10-22 | 2002-10-21 | Method for operating a drive system of a hybrid vehicle |

| ES04028726T ES2308093T3 (en) | 2001-10-22 | 2002-10-21 | METHOD OF OPERATION OF A MOTOR SYSTEM OF A HYBRID VEHICLE. |

| DE60214104T DE60214104T2 (en) | 2001-10-22 | 2002-10-21 | Drive system for hybrid vehicle and method of operation with a transmission |

| EP02023460A EP1304248B1 (en) | 2001-10-22 | 2002-10-21 | Hybrid-vehicle drive system and operation method with a transmission |

| EP04028725A EP1514716B1 (en) | 2001-10-22 | 2002-10-21 | Method of operating a hybrid-vehicle drive system |

| KR10-2002-0064574A KR100501062B1 (en) | 2001-10-22 | 2002-10-22 | Hybrid-vehicle drive system and operation method with a transmission |

| CNB021471347A CN1286681C (en) | 2001-10-22 | 2002-10-22 | Mixed power vehicle drive system with speed changing box and operating method |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2001323578A JP3893938B2 (en) | 2001-10-22 | 2001-10-22 | Hybrid vehicle drive structure with transmission |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2003127681A JP2003127681A (en) | 2003-05-08 |

| JP2003127681A5 JP2003127681A5 (en) | 2005-06-23 |

| JP3893938B2 true JP3893938B2 (en) | 2007-03-14 |

Family

ID=19140447

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2001323578A Expired - Lifetime JP3893938B2 (en) | 2001-10-22 | 2001-10-22 | Hybrid vehicle drive structure with transmission |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP3893938B2 (en) |

Families Citing this family (41)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP3650089B2 (en) | 2002-08-02 | 2005-05-18 | トヨタ自動車株式会社 | Hybrid drive device and automobile equipped with the same |

| JP4130154B2 (en) | 2003-05-29 | 2008-08-06 | トヨタ自動車株式会社 | Vehicle drive device |

| JP3845400B2 (en) | 2003-08-18 | 2006-11-15 | 本田技研工業株式会社 | Hybrid vehicle |

| US7822524B2 (en) | 2003-12-26 | 2010-10-26 | Toyota Jidosha Kabushiki Kaisha | Vehicular drive system |

| JP3783716B2 (en) | 2004-01-22 | 2006-06-07 | トヨタ自動車株式会社 | Control device for hybrid vehicle |

| JP4306597B2 (en) | 2004-02-25 | 2009-08-05 | トヨタ自動車株式会社 | Control device for vehicle drive device |

| JP4168954B2 (en) * | 2004-02-26 | 2008-10-22 | トヨタ自動車株式会社 | Control device for vehicle drive device |

| DE602005026646D1 (en) | 2004-04-27 | 2011-04-14 | Toyota Motor Co Ltd | VEHICLE CONTROL SPEED STEPS |

| US7322902B2 (en) | 2004-05-10 | 2008-01-29 | Toyota Jidosha Kabushiki Kaisha | Control device for vehicular transmission mechanism |

| JP4155230B2 (en) | 2004-06-03 | 2008-09-24 | トヨタ自動車株式会社 | Control device for vehicle drive device |

| JP4046103B2 (en) * | 2004-06-07 | 2008-02-13 | トヨタ自動車株式会社 | Control device for vehicle drive device |

| JP4315087B2 (en) * | 2004-09-27 | 2009-08-19 | トヨタ自動車株式会社 | Vehicle drive device |

| JP3860593B2 (en) * | 2004-12-20 | 2006-12-20 | トヨタ自動車株式会社 | Hybrid drive device and automobile equipped with the same |

| JP4549923B2 (en) | 2005-05-20 | 2010-09-22 | トヨタ自動車株式会社 | Load driving device and electric vehicle equipped with the same |

| KR100704788B1 (en) | 2005-08-18 | 2007-04-10 | 현대자동차주식회사 | Hybrid vehicles |

| JP4358178B2 (en) * | 2005-10-26 | 2009-11-04 | トヨタ自動車株式会社 | Engine start control device |

| JP4216843B2 (en) | 2005-10-26 | 2009-01-28 | トヨタ自動車株式会社 | Electric vehicle drive control device and control method thereof |

| JP2007120586A (en) * | 2005-10-26 | 2007-05-17 | Toyota Motor Corp | Control device for automatic transmission for vehicle |

| JP4063294B2 (en) | 2005-10-26 | 2008-03-19 | トヨタ自動車株式会社 | Control device for vehicle drive device |

| US7976428B2 (en) | 2005-10-26 | 2011-07-12 | Toyota Jidosha Kabushiki Kaisha | Control system for drive unit of vehicle |

| JP4052329B2 (en) | 2005-10-26 | 2008-02-27 | トヨタ自動車株式会社 | Shift control device for automatic transmission |

| JP4069941B2 (en) | 2005-10-26 | 2008-04-02 | トヨタ自動車株式会社 | Control device for vehicle drive device |

| JP4063295B2 (en) * | 2005-10-26 | 2008-03-19 | トヨタ自動車株式会社 | Control device for drive device for hybrid vehicle |

| JP4200999B2 (en) | 2005-10-26 | 2008-12-24 | トヨタ自動車株式会社 | Control device for vehicle drive device |

| JP4077003B2 (en) | 2005-10-26 | 2008-04-16 | トヨタ自動車株式会社 | Electric vehicle drive control device and control method thereof |

| JP4234710B2 (en) | 2005-10-26 | 2009-03-04 | トヨタ自動車株式会社 | Electric vehicle drive control device and control method thereof |

| JP4371099B2 (en) * | 2005-10-26 | 2009-11-25 | トヨタ自動車株式会社 | Power transmission control device |

| JP4525613B2 (en) | 2006-02-28 | 2010-08-18 | トヨタ自動車株式会社 | Control device for vehicle power transmission device |

| JP4297918B2 (en) | 2006-03-23 | 2009-07-15 | トヨタ自動車株式会社 | Power transmission device and assembly method thereof |

| JP4584171B2 (en) | 2006-03-23 | 2010-11-17 | トヨタ自動車株式会社 | Power transmission device and assembly method thereof |

| JP4059276B2 (en) | 2006-03-24 | 2008-03-12 | トヨタ自動車株式会社 | Power transmission device and assembly method thereof |

| JP4192967B2 (en) * | 2006-06-15 | 2008-12-10 | トヨタ自動車株式会社 | Vehicle drive device |

| JP4957104B2 (en) * | 2006-07-19 | 2012-06-20 | 株式会社豊田中央研究所 | Starting device |

| JP5066905B2 (en) * | 2006-12-04 | 2012-11-07 | トヨタ自動車株式会社 | Control device for vehicle drive device |

| JP2008155802A (en) | 2006-12-25 | 2008-07-10 | Toyota Motor Corp | Control device of vehicle driving device |

| JP4339374B2 (en) | 2007-04-27 | 2009-10-07 | 本田技研工業株式会社 | Power equipment |

| JP2009227268A (en) * | 2008-02-26 | 2009-10-08 | Nissan Motor Co Ltd | Vehicular drive apparatus |

| WO2009106941A1 (en) * | 2008-02-26 | 2009-09-03 | Nissan Motor Co., Ltd. | Vehicle drive apparatus |

| JP4610654B2 (en) * | 2009-02-09 | 2011-01-12 | 本田技研工業株式会社 | Power transmission device |

| JP5874335B2 (en) * | 2011-11-15 | 2016-03-02 | トヨタ自動車株式会社 | Drive device for hybrid vehicle |

| CN102922981B (en) * | 2012-10-29 | 2015-06-03 | 长城汽车股份有限公司 | Hybrid power drive device and vehicle |

-

2001

- 2001-10-22 JP JP2001323578A patent/JP3893938B2/en not_active Expired - Lifetime

Also Published As

| Publication number | Publication date |

|---|---|

| JP2003127681A (en) | 2003-05-08 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP3893938B2 (en) | Hybrid vehicle drive structure with transmission | |

| JP3852321B2 (en) | HV drive structure and method with cranking support torque increasing means | |

| CA2632448C (en) | Operation method of a hybrid-vehicle drive system with a transmission | |

| US8177004B2 (en) | Control system for drive unit of hybrid vehicle | |

| US7108630B2 (en) | Control system for hybrid drive unit | |

| US10315507B2 (en) | Hybrid vehicle | |

| JP3757845B2 (en) | Driving method of hybrid vehicle drive structure with transmission | |

| JP3852322B2 (en) | Driving method of hybrid vehicle drive structure with transmission | |

| CN109720333B (en) | Control device for hybrid vehicle | |

| US20050252703A1 (en) | Hybrid powertrain | |

| JP2003269596A (en) | Speed control device for hybrid transmission | |

| US10759413B2 (en) | Control system for hybrid vehicle | |

| JP2008120233A (en) | Hybrid driving device | |

| JP2007198438A (en) | Vehicle control device and vehicle | |

| US20160214598A1 (en) | Driving force control system for a vehicle | |

| JPH11227476A (en) | Driving device for automobile | |

| JP3861803B2 (en) | Power transmission device for vehicle | |

| JP3758650B2 (en) | Control device for hybrid drive | |

| JP2000220731A (en) | Electro-motive vehicle | |

| JP3747842B2 (en) | Driving method of hybrid vehicle drive structure equipped with transmission | |

| JP3646963B2 (en) | Hybrid car | |

| JP4005589B2 (en) | Power output device, automobile equipped with the same, and power transmission device | |

| CA2548815C (en) | Hybrid-vehicle drive system and operation method with a transmission | |

| JP3648720B2 (en) | Hybrid car | |

| JP2003166633A (en) | Method of operating hybrid vehicle driving structure with transmission |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20041005 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20041012 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20050405 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20050606 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20051122 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20060120 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20060815 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20061013 |

|

| A911 | Transfer to examiner for re-examination before appeal (zenchi) |

Free format text: JAPANESE INTERMEDIATE CODE: A911 Effective date: 20061020 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20061121 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20061204 |

|

| R151 | Written notification of patent or utility model registration |

Ref document number: 3893938 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R151 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20101222 Year of fee payment: 4 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20101222 Year of fee payment: 4 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20111222 Year of fee payment: 5 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20111222 Year of fee payment: 5 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20121222 Year of fee payment: 6 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20131222 Year of fee payment: 7 |

|

| EXPY | Cancellation because of completion of term |