EP0141992A2 - Multi-part piston for internal-combustion engines, having a partly isolated cooling oil conduit - Google Patents

Multi-part piston for internal-combustion engines, having a partly isolated cooling oil conduit Download PDFInfo

- Publication number

- EP0141992A2 EP0141992A2 EP84111624A EP84111624A EP0141992A2 EP 0141992 A2 EP0141992 A2 EP 0141992A2 EP 84111624 A EP84111624 A EP 84111624A EP 84111624 A EP84111624 A EP 84111624A EP 0141992 A2 EP0141992 A2 EP 0141992A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- piston

- ring

- cooling oil

- combustion engines

- internal

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02F—CYLINDERS, PISTONS OR CASINGS, FOR COMBUSTION ENGINES; ARRANGEMENTS OF SEALINGS IN COMBUSTION ENGINES

- F02F3/00—Pistons

- F02F3/0015—Multi-part pistons

- F02F3/003—Multi-part pistons the parts being connected by casting, brazing, welding or clamping

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02F—CYLINDERS, PISTONS OR CASINGS, FOR COMBUSTION ENGINES; ARRANGEMENTS OF SEALINGS IN COMBUSTION ENGINES

- F02F3/00—Pistons

- F02F3/16—Pistons having cooling means

- F02F3/18—Pistons having cooling means the means being a liquid or solid coolant, e.g. sodium, in a closed chamber in piston

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02F—CYLINDERS, PISTONS OR CASINGS, FOR COMBUSTION ENGINES; ARRANGEMENTS OF SEALINGS IN COMBUSTION ENGINES

- F02F3/00—Pistons

- F02F3/16—Pistons having cooling means

- F02F3/20—Pistons having cooling means the means being a fluid flowing through or along piston

- F02F3/22—Pistons having cooling means the means being a fluid flowing through or along piston the fluid being liquid

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F05—INDEXING SCHEMES RELATING TO ENGINES OR PUMPS IN VARIOUS SUBCLASSES OF CLASSES F01-F04

- F05C—INDEXING SCHEME RELATING TO MATERIALS, MATERIAL PROPERTIES OR MATERIAL CHARACTERISTICS FOR MACHINES, ENGINES OR PUMPS OTHER THAN NON-POSITIVE-DISPLACEMENT MACHINES OR ENGINES

- F05C2201/00—Metals

- F05C2201/02—Light metals

- F05C2201/021—Aluminium

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F05—INDEXING SCHEMES RELATING TO ENGINES OR PUMPS IN VARIOUS SUBCLASSES OF CLASSES F01-F04

- F05C—INDEXING SCHEME RELATING TO MATERIALS, MATERIAL PROPERTIES OR MATERIAL CHARACTERISTICS FOR MACHINES, ENGINES OR PUMPS OTHER THAN NON-POSITIVE-DISPLACEMENT MACHINES OR ENGINES

- F05C2201/00—Metals

- F05C2201/04—Heavy metals

- F05C2201/0433—Iron group; Ferrous alloys, e.g. steel

- F05C2201/0448—Steel

Definitions

- the invention relates to a multi-part piston for internal combustion engines according to the preamble of the claim.

- the object of the invention is to find a reliable and simple fixation within the piston parts to be connected for a sheet metal ring to be inserted for the isolation of certain partial areas, in which neither the material properties of the piston part in question nor its material properties due to the type of connection of the ring to be introduced can be negatively influenced.

- a suitable type of connection can, for. B. can be achieved in that the ring to be introduced is attached to the intermediate ring with screws. The screws are then screwed in on the side of the intermediate ring which faces outwards as seen from the inside of the cooling oil duct.

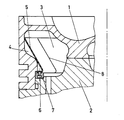

- FIG. 1 An embodiment is shown in the drawing, which shows a cooling oil channel in longitudinal section through a two-part piston.

- a steel piston crown 1 is attached to an aluminum piston lower part 2 by fastening means, not shown. Cooling oil flows through the annular space 3.

- a slotted flexible ring 5 is introduced to shield a partial area 4 of the annular space 3. This ring 5 is via screws 6 on an intermediate ring 7 from z. B. steel fit between the piston crown 1 and the lower piston part 2.

- the parting line 8 of the slotted ring 5 can be welded subsequently.

- the ring 5 is preformed in such a way that after its assembly, it rests firmly against the piston wall region to be covered at its upper free end.

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Fluid Mechanics (AREA)

- Pistons, Piston Rings, And Cylinders (AREA)

Abstract

Description

Die Erfindung betrifft einen mehrteiligen Kolben für Verbrennungsmotoren nach dem Oberbegriff des Patentanspruchs.The invention relates to a multi-part piston for internal combustion engines according to the preamble of the claim.

Mit Kühlöl beaufschlagte Flächen in dem Kühlölkanal eines Kolbens lokal gegen die Wirkung des Kühlöls zu isolieren ist z. B. aus DE-OS 29 30 079 und DE-G 81 32 778 bekannt. In beiden Fällen wird die Isolierung durch die Ausbildung eines Hohlraumes mit Hilfe eines zusätzlich in den Kolben einzubringenden Blechringes erreicht. Dabei ist die Ausführung nach dem DE-G 81 32 778 auf Fälle ausgerichtet, in denen die abzudeckende Fläche in einem hinterschnittenen Ringraum liegt. In diesem Fall muß nämlich der einzubringende Blechring während der Montage verformbar sein, da er sonst in die Hinterschnitträume nicht eingebracht werden kann. Die Verformbarkeit kann dabei z. B. durch ein achsiales Schlitzen des Ringes erfolgen. Bei der Lösung nach dem genannten Gebrauchsmuster besteht eine Schwierigkeit jedoch darin, den eingebrachten Blechring an dem entsprechenden Kolbenteil betriebssicher zu fixieren, ohne durch die Art der Fixierung das mechanische Verhalten des betreffenden Kolbenteiles unter Betriebslast negativ zu beeinflussen. Eine solche negative Beeinflussung ergibt sich z. B. durch ein Anschweißen des Blechringes an das betreffende Kolbenteil. Durch eine an dem oberen und unteren Ende des einzubringenden Blechringes vorgenommene feste Verbindung mit dem betreffenden Kolbenteil kann auch das rechnerisch vorbestimmte elastische Verhalten dieses Kolbenteiles unter Betriebsbedingungen negativ beeinflußt werden.Areas that are acted upon by cooling oil in the cooling oil channel of a piston are to be isolated locally against the action of the cooling oil. B. from DE-OS 29 30 079 and DE-G 81 32 778 known. In both cases, the insulation is achieved by forming a cavity with the aid of a sheet metal ring which is also to be inserted into the piston. The design according to DE-G 81 32 778 is aimed at cases in which the area to be covered lies in an undercut annular space. In this case, the sheet metal ring to be inserted must be deformable during assembly, since otherwise it cannot be inserted into the undercut spaces. The deformability can z. B. by axial slitting of the ring. In the solution according to the utility model mentioned, however, there is a difficulty in securely fixing the introduced sheet metal ring to the corresponding piston part without adversely affecting the mechanical behavior of the piston part in question under operating load due to the type of fixation. Such a negative Influence arises e.g. B. by welding the sheet metal ring to the relevant piston part. The arithmetically predetermined elastic behavior of this piston part under operating conditions can also be negatively influenced by a firm connection made to the piston part in question at the upper and lower ends of the sheet metal ring to be introduced.

Hiervon ausgehend liegt der Erfindung die Aufgabe zugrunde, für einen zur Isolierung bestimmter Teilbereiche einzubringenden Blechring eine in jeder Hinsicht betriebssichere und einfache Fixierung innerhalb der zu verbindenden Kolbenteile zu finden, bei der weder die Werkstoffeigenschaften des betreffenden Kolbenteiles, noch dessen Materialeigenschaften durch die Art der Verbindung des einzubringenden Ringes negativ beeinflußt werden können.Proceeding from this, the object of the invention is to find a reliable and simple fixation within the piston parts to be connected for a sheet metal ring to be inserted for the isolation of certain partial areas, in which neither the material properties of the piston part in question nor its material properties due to the type of connection of the ring to be introduced can be negatively influenced.

Gelöst wird diese Aufgabe gemäß den Merkmalen des Patentanspruchs durch die Verwendung eines zusätzlichen Zwischenringes, der zwischen den zu verbindenden Kolbenteilen im Kühl- ölkanalbereich eingeklemmt ist und an den der in den Kühlölkanal einzubringende Ring zerstörungsfrei lösbar angebunden werden kann.This object is achieved according to the features of the patent claim by the use of an additional intermediate ring which is clamped between the piston parts to be connected in the cooling oil duct area and to which the ring to be introduced into the cooling oil duct can be detachably connected in a non-destructive manner.

Eine zweckmäßige Art der Verbindung kann z. B. dadurch erreicht werden, daß der einzubringende Ring an dem Zwischenring mit Schrauben befestigt ist. Die Schrauben werden dann an der Seite des Zwischenringes eingeschraubt, die von dem Inneren des Kühlölkanals aus gesehen nach außen weist.A suitable type of connection can, for. B. can be achieved in that the ring to be introduced is attached to the intermediate ring with screws. The screws are then screwed in on the side of the intermediate ring which faces outwards as seen from the inside of the cooling oil duct.

Ein Ausführungsbeispiel ist in der Zeichnung dargestellt, die einen Kühlölkanal im Längsschnitt durch einen zweiteiligen Kolben zeigt.An embodiment is shown in the drawing, which shows a cooling oil channel in longitudinal section through a two-part piston.

Ein Stahl-Kolbenboden 1 ist durch nicht dargestellte Befestiqunqsmittel auf einem Aluminiumkolbenunterteil 2 angebracht. Durch den Ringraum 3 strömt Kühlöl. Zur Abschirmung eines Teilbereiches 4 des Ringraumes 3 ist ein geschlitzter biegsamer Ring 5 eingebracht. Dieser Ring 5 ist über Schrauben 6 an einem Zwischenring 7 aus z. B. Stahl passungsgenau zwischen dem Kolbenboden 1 und dem Kolbenunterteil 2 eingeklemmt. Die Trennfuge 8 des geschlitzten Ringes 5 kann nachträglich verschweißt werden. Der Ring 5 ist so vorgeformt, daß er nach seiner Montage an seinem oberen freien Ende fest an dem abzudeckenden Kolbenwandbereich anliegt.A steel piston crown 1 is attached to an aluminum piston

Claims (1)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE3338809 | 1983-10-26 | ||

| DE3338809 | 1983-10-26 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0141992A2 true EP0141992A2 (en) | 1985-05-22 |

| EP0141992A3 EP0141992A3 (en) | 1986-05-21 |

| EP0141992B1 EP0141992B1 (en) | 1988-05-04 |

Family

ID=6212749

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP84111624A Expired EP0141992B1 (en) | 1983-10-26 | 1984-09-28 | Multi-part piston for internal-combustion engines, having a partly isolated cooling oil conduit |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP0141992B1 (en) |

| JP (1) | JPS60111048A (en) |

| DE (1) | DE3470908D1 (en) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1288464A3 (en) * | 2001-08-30 | 2003-08-20 | Caterpillar Inc. | Piston assembly for free piston internal combustion engine |

| WO2013156442A1 (en) * | 2012-04-18 | 2013-10-24 | Mahle International Gmbh | Piston for an internal combustion engine |

| WO2017087433A1 (en) * | 2015-11-18 | 2017-05-26 | Federal-Mogul Corporation | Piston providing for reduced heat loss using cooling media |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB348084A (en) * | 1928-11-09 | 1931-04-28 | Hugo Junkers | Improvements in and relating to pistons for engines |

| DE1905029A1 (en) * | 1969-02-01 | 1970-08-06 | Augsburg Nuernberg Ag Zweignie | Pistons for direct injection internal combustion engines |

| DE3017787A1 (en) * | 1980-05-09 | 1981-11-12 | Klöckner-Humboldt-Deutz AG, 5000 Köln | IC engine piston with ceramic crown - has sheet metal discs interposed between skirt and crown to form piston ring recess |

-

1984

- 1984-09-28 DE DE8484111624T patent/DE3470908D1/en not_active Expired

- 1984-09-28 EP EP84111624A patent/EP0141992B1/en not_active Expired

- 1984-10-25 JP JP59223132A patent/JPS60111048A/en active Pending

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB348084A (en) * | 1928-11-09 | 1931-04-28 | Hugo Junkers | Improvements in and relating to pistons for engines |

| DE1905029A1 (en) * | 1969-02-01 | 1970-08-06 | Augsburg Nuernberg Ag Zweignie | Pistons for direct injection internal combustion engines |

| DE3017787A1 (en) * | 1980-05-09 | 1981-11-12 | Klöckner-Humboldt-Deutz AG, 5000 Köln | IC engine piston with ceramic crown - has sheet metal discs interposed between skirt and crown to form piston ring recess |

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1288464A3 (en) * | 2001-08-30 | 2003-08-20 | Caterpillar Inc. | Piston assembly for free piston internal combustion engine |

| WO2013156442A1 (en) * | 2012-04-18 | 2013-10-24 | Mahle International Gmbh | Piston for an internal combustion engine |

| US9726109B2 (en) | 2012-04-18 | 2017-08-08 | Mahle International Gmbh | Piston for an internal combustion engine |

| WO2017087433A1 (en) * | 2015-11-18 | 2017-05-26 | Federal-Mogul Corporation | Piston providing for reduced heat loss using cooling media |

| US10294887B2 (en) | 2015-11-18 | 2019-05-21 | Tenneco Inc. | Piston providing for reduced heat loss using cooling media |

Also Published As

| Publication number | Publication date |

|---|---|

| EP0141992A3 (en) | 1986-05-21 |

| EP0141992B1 (en) | 1988-05-04 |

| JPS60111048A (en) | 1985-06-17 |

| DE3470908D1 (en) | 1988-06-09 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE1914162A1 (en) | Air-cooled internal combustion engine | |

| DE2106923A1 (en) | Internal combustion engine pistons | |

| EP0268988B1 (en) | Diesel engine | |

| EP0099873A2 (en) | Cylindrical rotary valve with seal for piston engines | |

| DE2850816A1 (en) | COMBUSTION MACHINE | |

| DE2644661A1 (en) | PISTON | |

| DE10325914B4 (en) | Piston for an internal combustion engine | |

| CH615980A5 (en) | ||

| EP0204687B1 (en) | Two-stroke internal-combustion engine | |

| EP0141992B1 (en) | Multi-part piston for internal-combustion engines, having a partly isolated cooling oil conduit | |

| DE2200818A1 (en) | Inlet and outlet lines for an internal combustion engine and their flow ducts | |

| DE3107461A1 (en) | HOUSING BLOCK FOR PISTON PISTON COMBUSTION ENGINES, IN PARTICULAR DIESEL ENGINES | |

| DE2726089A1 (en) | Refrigeration system compressor valve plate - has low resistance suction flow path defined by annular corrugated element between planar members | |

| DE8330717U1 (en) | MULTI-PIECE PISTON FOR COMBUSTION ENGINES WITH PARTLY INSULATED COOLING OIL CHANNEL | |

| EP0297253B1 (en) | Arrangement of the fuel injection valve in a reciprocating piston type internal combustion engine | |

| DE19740229B4 (en) | Internal combustion engine cylinder head with intake duct and additional air duct | |

| EP0935061B1 (en) | Stationary gas engine | |

| DE10225573B4 (en) | Two-stroke engine and method for its production | |

| DE2733302A1 (en) | EXHAUST BASE FOR MULTI-CYLINDER COMBUSTION MACHINERY, IN PARTICULAR FOR MOTOR VEHICLES | |

| DE3335983C2 (en) | Internal combustion engine | |

| DE600604C (en) | Longitudinally split cylinder with exchangeable liner for air-cooled two-stroke internal combustion engines | |

| DE3742611C2 (en) | Liquid-cooled cylinder liner of a reciprocating piston internal combustion engine | |

| DE962945C (en) | Air-cooled, slot-controlled two-stroke internal combustion engine | |

| DE3331664C2 (en) | ||

| DE2718162A1 (en) | Single cylinder two stroke engine - has one piece cast head and cylinder with two part crankcase with cast transfer channels |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): DE FR GB IT |

|

| RTI1 | Title (correction) | ||

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): DE FR GB IT |

|

| 17P | Request for examination filed |

Effective date: 19861004 |

|

| 17Q | First examination report despatched |

Effective date: 19870429 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): DE FR GB IT |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 19880504 Ref country code: FR Free format text: THE PATENT HAS BEEN ANNULLED BY A DECISION OF A NATIONAL AUTHORITY Effective date: 19880504 |

|

| REF | Corresponds to: |

Ref document number: 3470908 Country of ref document: DE Date of ref document: 19880609 |

|

| EN | Fr: translation not filed | ||

| GBV | Gb: ep patent (uk) treated as always having been void in accordance with gb section 77(7)/1977 [no translation filed] | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19881123 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19911017 Year of fee payment: 8 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19930602 |