WO2024079968A1 - Capacitor - Google Patents

Capacitor Download PDFInfo

- Publication number

- WO2024079968A1 WO2024079968A1 PCT/JP2023/028668 JP2023028668W WO2024079968A1 WO 2024079968 A1 WO2024079968 A1 WO 2024079968A1 JP 2023028668 W JP2023028668 W JP 2023028668W WO 2024079968 A1 WO2024079968 A1 WO 2024079968A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- out terminal

- pull

- claw

- capacitor

- lead

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01G—CAPACITORS; CAPACITORS, RECTIFIERS, DETECTORS, SWITCHING DEVICES, LIGHT-SENSITIVE OR TEMPERATURE-SENSITIVE DEVICES OF THE ELECTROLYTIC TYPE

- H01G2/00—Details of capacitors not covered by a single one of groups H01G4/00-H01G11/00

- H01G2/14—Protection against electric or thermal overload

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01G—CAPACITORS; CAPACITORS, RECTIFIERS, DETECTORS, SWITCHING DEVICES, LIGHT-SENSITIVE OR TEMPERATURE-SENSITIVE DEVICES OF THE ELECTROLYTIC TYPE

- H01G4/00—Fixed capacitors; Processes of their manufacture

- H01G4/002—Details

- H01G4/228—Terminals

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01G—CAPACITORS; CAPACITORS, RECTIFIERS, DETECTORS, SWITCHING DEVICES, LIGHT-SENSITIVE OR TEMPERATURE-SENSITIVE DEVICES OF THE ELECTROLYTIC TYPE

- H01G4/00—Fixed capacitors; Processes of their manufacture

- H01G4/32—Wound capacitors

Definitions

- the present invention relates to a capacitor.

- Patent Document 1 discloses a capacitor in which a capacitor element (10) having electrodes (10a) on its end faces is connected by a bus bar (20) and housed in a case (50), which is filled with resin (60) and has external connection terminals (32) (42) drawn out in a direction approximately perpendicular to the case opening (53), and further includes a terminal block (70), one side of which is embedded in the resin (60) without contacting the case (50), and a screw portion (73a) provided on the other side faces the mounting holes (32b) (42b) of the external connection terminals (32) (42).

- the CP wire connected to the electrode portion of the capacitor element and the bus bar are connected by soldering.

- the heat generated during the soldering connection tends to escape to the outside through the bus bar, so the temperature of the solder is likely to drop. Therefore, in the capacitor described in Patent Document 1, it is difficult to connect the CP wire and the bus bar by soldering.

- the present invention was made to solve the above problems, and aims to provide a capacitor that can improve the connectivity between the lead-out terminals without using joining materials such as solder.

- the capacitor of the present invention comprises a capacitor element having a body and an external electrode provided on an end face of the body, a pull-out terminal electrically connected to the external electrode, an exterior case in which the capacitor element is housed so that the pull-out terminal protrudes outward, and a filling resin filled inside the exterior case so as to embed the capacitor element, the pull-out terminal having a first pull-out terminal and a second pull-out terminal electrically connected to the external electrode via the first pull-out terminal, and the first pull-out terminal and the second pull-out terminal are engaged so as to make surface contact.

- the present invention provides a capacitor that can improve the connectivity between lead terminals without using joining materials such as solder.

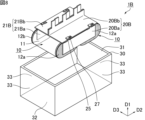

- FIG. 1 is a schematic perspective view showing an example of a capacitor according to a first embodiment of the present invention.

- FIG. 2 is a schematic perspective view showing an example of the capacitor shown in FIG. 1 (excluding the filled resin) in an exploded state.

- FIG. 3 is a schematic perspective view showing an example of the capacitor element shown in FIGS.

- FIG. 4 is a schematic cross-sectional view showing an example of a cross section of the capacitor element shown in FIG. 3 taken along line a1-a2.

- FIG. 5 is a schematic perspective view showing a state before the first lead terminal and the second lead terminal shown in FIG. 2 are locked.

- FIG. 6 is a schematic perspective view showing a state after the first lead terminal and the second lead terminal shown in FIG. 5 have been locked.

- FIG. 5 is a schematic perspective view showing a state before the first lead terminal and the second lead terminal shown in FIG. 2 are locked.

- FIG. 7 is a schematic perspective view showing an example of a capacitor according to the second embodiment of the present invention.

- FIG. 8 is a schematic perspective view showing an example of the capacitor shown in FIG. 7 (excluding the filled resin) in an exploded state.

- FIG. 9 is a schematic perspective view showing a state before the first lead terminal and the second lead terminal shown in FIG. 8 are locked.

- FIG. 10 is a schematic perspective view showing a state in which the first lead terminal and the second lead terminal shown in FIG. 9 are being locked.

- FIG. 11 is a schematic perspective view showing a state after the first lead terminal and the second lead terminal shown in FIG. 10 have been locked.

- a film capacitor is shown as an example of a capacitor of the present invention.

- the capacitor of the present invention can also be applied to capacitors other than film capacitors.

- the capacitor of the present invention comprises a capacitor element having a body and an external electrode provided on an end face of the body, a pull-out terminal electrically connected to the external electrode, an exterior case in which the capacitor element is housed so that the pull-out terminal protrudes outward, and a filling resin filled inside the exterior case so as to embed the capacitor element, the pull-out terminal having a first pull-out terminal and a second pull-out terminal electrically connected to the external electrode via the first pull-out terminal, and the first pull-out terminal and the second pull-out terminal are engaged so as to make surface contact.

- one of the first and second pull-out terminals has a first claw-shaped portion and a second claw-shaped portion located at a different height than the first claw-shaped portion in the first direction, and the other of the first and second pull-out terminals is sandwiched between the first and second claw-shaped portion in the first direction.

- FIG. 1 is a schematic perspective view showing an example of a capacitor according to a first embodiment of the present invention.

- FIG. 2 is a schematic perspective view showing an example of the capacitor shown in FIG. 1 (excluding the filled resin) in a disassembled state.

- the capacitor 1A shown in Figures 1 and 2 has a capacitor element 10 (see Figure 3 described later), a pull-out terminal 20A, a pull-out terminal 21A, an exterior case 30, and a filling resin 40.

- the first direction D1, the second direction D2, and the third direction D3 are perpendicular to each other.

- FIG. 3 is a schematic perspective view showing an example of the capacitor element shown in FIGS. 1 and 2.

- FIG. 4 is a schematic cross-sectional view showing an example of a cross-section along line a1-a2 of the capacitor element shown in FIG. 3.

- the capacitor element 10 shown in Figures 3 and 4 has a body 11, a first external electrode 12a, and a second external electrode 12b.

- the element body 11 is a wound body in which the first metallized film 13a and the second metallized film 13b are wound in a stacked state in the first direction D1.

- the capacitor 1A or more specifically, the capacitor element 10 is a wound-type film capacitor in which the metallized films are stacked and wound.

- capacitor 1A or more specifically, capacitor element 10

- capacitor element 10 may be a laminated film capacitor in which metallized films are laminated.

- element body 11 has a flat cross-sectional shape when viewed in a cross section perpendicular to the winding axis direction of element body 11 (third direction D3 in FIG. 3). More specifically, it is preferable that element body 11 has a cross-sectional shape pressed into a flat shape such as an ellipse or oval, and that the cross-sectional shape of element body 11 is thinner than when it is a perfect circle.

- Whether the base body has been pressed to have a flat cross-sectional shape can be confirmed, for example, by checking whether or not there are press marks on the base body.

- the capacitor element 10 may have a cylindrical winding axis.

- the winding axis is disposed on the central axis of the first metallized film 13a and the second metallized film 13b in the wound state, and serves as the winding axis when winding the first metallized film 13a and the second metallized film 13b.

- the first metallized film 13a has a first dielectric film 14a and a first metal layer 15a.

- the first dielectric film 14a has a first principal surface 14aa and a second principal surface 14ab that face each other in the first direction D1.

- the first metal layer 15a is provided on the first main surface 14aa of the first dielectric film 14a. More specifically, the first metal layer 15a is provided on the first main surface 14aa of the first dielectric film 14a so as to reach one side edge of the first dielectric film 14a in the third direction D3, but not to reach the other side edge of the first dielectric film 14a.

- the second metallized film 13b has a second dielectric film 14b and a second metal layer 15b.

- the second dielectric film 14b has a first main surface 14ba and a second main surface 14bb that face each other in the first direction D1.

- the second metal layer 15b is provided on the first main surface 14ba of the second dielectric film 14b. More specifically, the second metal layer 15b is provided on the first main surface 14ba of the second dielectric film 14b so as not to reach one side edge of the second dielectric film 14b in the third direction D3, but to reach the other side edge of the second dielectric film 14b.

- the adjacent first metallized films 13a and second metallized films 13b are shifted in the third direction D3 so that the end of the first metal layer 15a that reaches the side edge of the first dielectric film 14a is exposed on one end surface of the element body 11, and the end of the second metal layer 15b that reaches the side edge of the second dielectric film 14b is exposed on the other end surface of the element body 11.

- the first metallized film 13a protrudes toward the first external electrode 12a relative to the second metallized film 13b.

- the second metallized film 13b protrudes toward the second external electrode 12b relative to the first metallized film 13a.

- the first metal layer 15a is connected to the first external electrode 12a and is not connected to the second external electrode 12b.

- the second metal layer 15b is connected to the second external electrode 12b and is not connected to the first external electrode 12a.

- the adjacent first metallized film 13a and second metallized film 13b are shifted in the third direction D3 as described above, so that in the adjacent first dielectric film 14a and second dielectric film 14b, the first dielectric film 14a having the first metal layer 15a on the first main surface 14aa protrudes toward the first external electrode 12a relative to the second dielectric film 14b having the first metal layer 15a not provided on its main surface.

- the second dielectric film 14b having the second metal layer 15b on the first main surface 14ba protrudes toward the second external electrode 12b relative to the first dielectric film 14a having the second metal layer 15b not provided on its main surface.

- the element body 11 is formed by winding the first metallized film 13a and the second metallized film 13b in a stacked state in the first direction D1, and therefore can be said to include the first dielectric film 14a, the first metal layer 15a, the second dielectric film 14b, and the second metal layer 15b in the first direction D1. It can also be said that the element body 11 is a wound body formed by winding the first dielectric film 14a, the first metal layer 15a, the second dielectric film 14b, and the second metal layer 15b in the first direction D1.

- the first main surface 14aa of the first dielectric film 14a and the second main surface 14bb of the second dielectric film 14b face each other in the first direction D1

- the second main surface 14ab of the first dielectric film 14a and the first main surface 14ba of the second dielectric film 14b face each other in the first direction D1.

- the first metallized film 13a and the second metallized film 13b are wound in a state in which they are stacked in the first direction D1.

- the first metallized film 13a and the second metallized film 13b are wound in a state in which they are stacked in the first direction D1, so that the second metallized film 13b is on the inside of the first metallized film 13a, and more specifically, the first metal layer 15a is on the inside of the first dielectric film 14a, and the second metal layer 15b is on the inside of the second dielectric film 14b. That is, in the element body 11, the first metal layer 15a and the second metal layer 15b face each other with the first dielectric film 14a or the second dielectric film 14b sandwiched between them.

- the first metal layer 15a may be provided with a fuse portion.

- the fuse portion provided in the first metal layer 15a is, for example, a portion of the first metal layer 15a that connects a divided electrode portion in which the portion facing the second metal layer 15b is divided into multiple portions, and an electrode portion that does not face the second metal layer 15b.

- Examples of electrode patterns of the first metal layer 15a provided with a fuse portion include the electrode patterns disclosed in JP 2004-363431 A and JP 5-251266 A.

- the second metal layer 15b may also be provided with a fuse portion, similar to the first metal layer 15a.

- the first dielectric film 14a may contain a curable resin as a main component.

- the main component means the component with the highest weight percentage, preferably the component with a weight percentage greater than 50% by weight.

- the curable resin may be a thermosetting resin or a photocurable resin.

- thermosetting resin means a resin that can be cured by heat, but the curing method is not limited. Therefore, thermosetting resin also includes resins that can be cured by methods other than heat (for example, light, electron beam, etc.) so long as they are heat-curable. Also, depending on the material, a reaction may be initiated due to the reactivity of the material itself, and resins that proceed to cure without necessarily being subjected to heat from the outside are also considered to be thermosetting resins. The same applies to photocurable resins, and so long as they are light-curable, they also include resins that can be cured by methods other than light (for example, heat, etc.).

- the curable resin is preferably made of a cured product of a first organic material having a hydroxyl group (OH group) and a second organic material having an isocyanate group (NCO group).

- the curable resin is made of a cured product having a urethane bond obtained by reacting the hydroxyl group of the first organic material with the isocyanate group of the second organic material.

- FT-IR Fourier transform infrared spectrophotometer

- the first dielectric film 14a may contain at least one of a hydroxyl group and an isocyanate group.

- the first dielectric film 14a may contain either a hydroxyl group or an isocyanate group, or may contain both a hydroxyl group and an isocyanate group.

- Examples of the first organic material include phenoxy resin, polyvinyl acetoacetal resin, polyvinyl butyral resin, etc.

- the second organic material examples include aromatic polyisocyanates such as diphenylmethane diisocyanate (MDI) and tolylene diisocyanate (TDI), and aliphatic polyisocyanates such as hexamethylene diisocyanate (HDI).

- aromatic polyisocyanates such as diphenylmethane diisocyanate (MDI) and tolylene diisocyanate (TDI)

- aliphatic polyisocyanates such as hexamethylene diisocyanate (HDI).

- HDI hexamethylene diisocyanate

- the second organic material multiple types of organic materials may be used in combination.

- the first dielectric film 14a may contain a thermoplastic resin as a main component.

- thermoplastic resins examples include polypropylene, polyethersulfone, polyetherimide, polyarylate, etc.

- the first dielectric film 14a may contain additives to impart various functions.

- Additives include, for example, leveling agents to impart smoothness.

- the additive preferably has a functional group that reacts with a hydroxyl group and/or an isocyanate group and forms part of the crosslinked structure of the cured product.

- examples of such additives include resins having at least one functional group selected from the group consisting of a hydroxyl group, an epoxy group, a silanol group, and a carboxyl group.

- the second dielectric film 14b may contain a thermosetting resin as a main component, a photocurable resin as a main component, or a thermoplastic resin as a main component.

- the second dielectric film 14b may also contain an additive, like the first dielectric film 14a.

- compositions of the first dielectric film 14a and the second dielectric film 14b may be different from each other, but are preferably the same.

- the thickness of the first dielectric film 14a and the second dielectric film 14b is preferably 1 ⁇ m or more and 10 ⁇ m or less, and more preferably 3 ⁇ m or more and 5 ⁇ m or less.

- the thicknesses of the first dielectric film 14a and the second dielectric film 14b may be different from each other, but it is preferable that they are the same.

- the thickness of the dielectric film is measured using an optical thickness gauge.

- the first dielectric film 14a and the second dielectric film 14b are each preferably produced by forming a resin solution containing the resin material as described above into a film and then curing it by heat treatment.

- Examples of materials that can be used to form the first metal layer 15a and the second metal layer 15b include metals such as aluminum, zinc, titanium, magnesium, tin, and nickel.

- compositions of the first metal layer 15a and the second metal layer 15b may be different from each other, but are preferably the same.

- the thickness of the first metal layer 15a and the second metal layer 15b is preferably 5 nm or more and 40 nm or less.

- the thicknesses of the first metal layer 15a and the second metal layer 15b may be different from each other, but are preferably the same.

- the thickness of the metal layer is measured by observing a cross section of the metallized film along the first direction using a transmission electron microscope (TEM).

- TEM transmission electron microscope

- the first metal layer 15a and the second metal layer 15b are preferably formed by depositing a metal such as that described above onto the main surfaces of the first dielectric film 14a and the second dielectric film 14b, respectively.

- the first external electrode 12a is provided on one end surface of the element body 11. More specifically, the first external electrode 12a is connected to the first metal layer 15a by contacting the end of the first metal layer 15a exposed on one end surface of the element body 11. On the other hand, the first external electrode 12a is not connected to the second metal layer 15b.

- the second external electrode 12b is provided on the other end surface of the element body 11. More specifically, the second external electrode 12b is connected to the second metal layer 15b by contacting the end of the second metal layer 15b exposed on the other end surface of the element body 11. On the other hand, the second external electrode 12b is not connected to the first metal layer 15a.

- the constituent materials of the first external electrode 12a and the second external electrode 12b include metals such as zinc, aluminum, tin, and zinc-aluminum alloys.

- compositions of the first external electrode 12a and the second external electrode 12b may be different from each other, but are preferably the same.

- the first external electrode 12a and the second external electrode 12b are preferably formed by spraying a metal such as that described above onto one end face and the other end face of the body 11, respectively.

- the draw-out terminal 20A is electrically connected to the first external electrode 12a.

- the draw-out terminal 20A is electrically connected to the first external electrode 12a via a joining member such as solder.

- the pull-out terminal 20A has a first pull-out terminal 20Aa and a second pull-out terminal 20Ab.

- the first pull-out terminal 20Aa may be electrically located closest to the first external electrode 12a in the pull-out terminal 20A.

- the first pull-out terminal 20Aa may be located closest to the first external electrode 12a in the electrical path extending from the first external electrode 12a to the pull-out terminal 20A.

- the first pull-out terminal 20Aa does not have to be located electrically closest to the first external electrode 12a in the pull-out terminal 20A. In other words, the first pull-out terminal 20Aa does not have to be located closest to the first external electrode 12a in the electrical path between the first external electrode 12a and the pull-out terminal 20A. In other words, the pull-out terminal 20A may have another pull-out terminal that is electrically closer to the first external electrode 12a than the first pull-out terminal 20Aa.

- the second pull-out terminal 20Ab is electrically connected to the first external electrode 12a via the first pull-out terminal 20Aa.

- the second pull-out terminal 20Ab is provided at a position electrically farther away from the first external electrode 12a than the first pull-out terminal 20Aa.

- the second pull-out terminal 20Ab may be located on the side of the pull-out terminal 20A that is electrically opposite the first external electrode 12a.

- the second pull-out terminal 20Ab may be located on the side of the electrical path between the first external electrode 12a and the pull-out terminal 20A that is closest to the first external electrode 12a.

- the second pull-out terminal 20Ab does not have to be located on the most electrically opposite side of the pull-out terminal 20A from the first external electrode 12a.

- the second pull-out terminal 20Ab does not have to be located on the most opposite side of the first external electrode 12a in the electrical path between the first external electrode 12a and the pull-out terminal 20A.

- the pull-out terminal 20A may have another pull-out terminal that is provided at a position electrically farther away from the first external electrode 12a than the second pull-out terminal 20Ab.

- the first pull-out terminal 20Aa and the second pull-out terminal 20Ab are engaged so as to make surface contact.

- FIG. 5 is a schematic perspective view showing the state before the first and second pull-out terminals shown in FIG. 2 are locked.

- FIG. 6 is a schematic perspective view showing the state after the first and second pull-out terminals shown in FIG. 5 are locked. Note that in FIGS. 5 and 6, other components such as the capacitor element are omitted to make it easier to focus on the locking state of the first and second pull-out terminals.

- the first pull-out terminal 20Aa has a first claw portion 25a and a second claw portion 25b.

- the second claw portion 25b is located at a different height than the first claw portion 25a in the first direction D1.

- the second claw portion 25b may be located lower than the first claw portion 25a in the first direction D1, i.e., closer to the capacitor element 10 (see FIG. 2) than the first claw portion 25a in the first direction D1.

- the second claw portion 25b may be located higher than the first claw portion 25a in the first direction D1, i.e., farther from the capacitor element 10 (see FIG. 2) than the first claw portion 25a in the first direction D1.

- two claw-shaped portions located at different heights in the same direction means that at least the tips of the two claw-shaped portions are located at different heights in the same direction (first direction D1 in Figure 5).

- the first claw portion 25a and the second claw portion 25b do not have to overlap when viewed from the first direction D1.

- the first claw portion 25a and the second claw portion 25b may overlap when viewed from the first direction D1.

- the first pull-out terminal 20Aa may further include a third claw portion 25c.

- the third claw portion 25c may be located at the same height as the second claw portion 25b in the first direction D1. In other words, as shown in FIG. 5, the third claw portion 25c may be located at a different height than the first claw portion 25a in the first direction D1, similar to the second claw portion 25b.

- the third claw portion 25c may be located lower than the first claw portion 25a in the first direction D1, i.e., closer to the capacitor element 10 (see FIG. 2) than the first claw portion 25a in the first direction D1.

- the third claw portion 25c may be located at the same height as the first claw portion 25a or the same height as the second claw portion 25b in the first direction D1.

- two claw-shaped portions are located at the same height in the same direction (first direction D1 in Figure 5) means that at least the tips of the two claw-shaped portions are located at the same height in the same direction (first direction D1 in Figure 5).

- the first claw portion 25a and the third claw portion 25c do not have to overlap when viewed from the first direction D1.

- the first claw portion 25a and the third claw portion 25c may overlap when viewed from the first direction D1.

- the first claw portion 25a may be located between the second claw portion 25b and the third claw portion 25c in the second direction D2 perpendicular to the first direction D1 when viewed from the first direction D1.

- first claw portion 25a does not have to be located between the second claw portion 25b and the third claw portion 25c in the second direction D2 when viewed from the first direction D1.

- the second pull-out terminal 20Ab is sandwiched between the first claw portion 25a and the second claw portion 25b in the first direction D1. More specifically, the second pull-out terminal 20Ab is sandwiched by the elastic force of the first claw portion 25a and the second claw portion 25b in the first direction D1. Furthermore, as shown in FIG. 6, if the first pull-out terminal 20Aa further has a third claw portion 25c, the second pull-out terminal 20Ab is sandwiched between the first claw portion 25a and the third claw portion 25c in the first direction D1. More specifically, the second pull-out terminal 20Ab is sandwiched by the elastic force of the first claw portion 25a and the third claw portion 25c in the first direction D1.

- the first pull-out terminal 20Aa has the first claw portion 25a, the second claw portion 25b, and the third claw portion 25c, but instead of the first pull-out terminal 20Aa, the second pull-out terminal 20Ab may have the first claw portion 25a, the second claw portion 25b, and the third claw portion 25c. In this case, instead of the second pull-out terminal 20Ab, the first pull-out terminal 20Aa may be sandwiched between the first claw portion 25a and the second claw portion 25b and also between the first claw portion 25a and the third claw portion 25c in the first direction D1.

- the first pull-out terminal 20Aa has three claw-shaped portions, the first claw-shaped portion 25a, the second claw-shaped portion 25b, and the third claw-shaped portion 25c, but the number of claw-shaped portions is not particularly limited as long as it has at least two, the first claw-shaped portion 25a and the second claw-shaped portion 25b. The same applies when the second pull-out terminal 20Ab has claw-shaped portions.

- the first pull-out terminal 20Aa and the second pull-out terminal 20Ab are sandwiched between the multiple claw-shaped portions of one of the first pull-out terminal 20Aa and the second pull-out terminal 20Ab.

- the first pull-out terminal 20Aa and the second pull-out terminal 20Ab are engaged so as to be in surface contact.

- the first pull-out terminal 20Aa and the second pull-out terminal 20Ab are engaged, so that the first pull-out terminal 20Aa and the second pull-out terminal 20Ab can be mechanically (physically) connected without using a joining material such as solder. Therefore, in the capacitor 1A, the connectivity between the first pull-out terminal 20Aa and the second pull-out terminal 20Ab can be improved without using a joining material such as solder.

- connection points of the first and second pull-out terminals 20Aa and 20Ab can be held firmly without using a joining material such as solder, improving handling (assembly workability) when assembling the capacitor 1A, for example, when storing the capacitor element 10 connected to the pull-out terminal 20A in the exterior case 30.

- the first and second pull-out terminals 20Aa and 20Ab are in surface contact when connected as described above, so it is easy to weld the first and second pull-out terminals 20Aa and 20Ab. For this reason, it is preferable that the first and second pull-out terminals 20Aa and 20Ab are welded at points where they are engaged so as to be in surface contact.

- the second pull-out terminal 20Ab may be provided with a notch 26.

- the second pull-out terminal 20Ab has a notch 26, it is preferable that the first claw-shaped portion 25a is fitted into the notch 26. In this case, the first claw-shaped portion 25a is prevented from shifting in the second direction D2 by the notch 26, so that the first pull-out terminal 20Aa and the second pull-out terminal 20Ab are sufficiently firmly locked.

- the second pull-out terminal 20Ab has a notch 26, but if the second pull-out terminal 20Ab has a first claw-shaped portion 25a instead of the first pull-out terminal 20Aa, the first pull-out terminal 20Aa may have a notch 26 instead of the second pull-out terminal 20Ab, and the first claw-shaped portion 25a of the second pull-out terminal 20Ab may be fitted into the notch 26 provided in the first pull-out terminal 20Aa.

- the timing at which the first pull-out terminal 20Aa and the first external electrode 12a are connected as shown in Figure 2 may be before the first pull-out terminal 20Aa and the second pull-out terminal 20Ab are locked, or may be after the first pull-out terminal 20Aa and the second pull-out terminal 20Ab are locked.

- the draw-out terminal 21A is electrically connected to the second external electrode 12b.

- the draw-out terminal 21A is electrically connected to the second external electrode 12b via a joining member such as solder.

- the pull-out terminal 21A has a first pull-out terminal 21Aa and a second pull-out terminal 21Ab.

- the first pull-out terminal 21Aa may be electrically located closest to the second external electrode 12b in the pull-out terminal 21A.

- the first pull-out terminal 21Aa may be located closest to the second external electrode 12b in the electrical path extending from the second external electrode 12b to the pull-out terminal 21A.

- the first pull-out terminal 21Aa does not have to be electrically located closest to the second external electrode 12b in the pull-out terminal 21A. In other words, the first pull-out terminal 21Aa does not have to be located closest to the second external electrode 12b in the electrical path between the second external electrode 12b and the pull-out terminal 21A. In other words, the pull-out terminal 21A may have another pull-out terminal that is electrically closer to the second external electrode 12b than the first pull-out terminal 21Aa.

- the second pull-out terminal 21Ab is electrically connected to the second external electrode 12b via the first pull-out terminal 21Aa.

- the second pull-out terminal 21Ab is provided at a position electrically farther away from the second external electrode 12b than the first pull-out terminal 21Aa.

- the second pull-out terminal 21Ab may be located on the side of the pull-out terminal 21A that is electrically opposite the second external electrode 12b.

- the second pull-out terminal 21Ab may be located on the side of the electrical path between the second external electrode 12b and the pull-out terminal 21A that is closest to the second external electrode 12b.

- the second pull-out terminal 21Ab does not have to be located on the most electrically opposite side of the second external electrode 12b in the pull-out terminal 21A.

- the second pull-out terminal 21Ab does not have to be located on the most opposite side of the second external electrode 12b in the electrical path between the second external electrode 12b and the pull-out terminal 21A.

- the pull-out terminal 21A may have another pull-out terminal that is provided at a position electrically farther away from the second external electrode 12b than the second pull-out terminal 21Ab.

- first pull-out terminal 21Aa and the second pull-out terminal 21Ab are engaged so as to make surface contact.

- the first pull-out terminal 21Aa and the second pull-out terminal 21Ab when the first pull-out terminal 21Aa and the second pull-out terminal 21Ab are engaged, the first pull-out terminal 21Aa and the second pull-out terminal 21Ab can be mechanically (physically) connected without using a joining material such as solder.

- the connectivity between the first pull-out terminal 21Aa and the second pull-out terminal 21Ab can be improved without using a joining material such as solder.

- connection points of the first and second pull-out terminals 21Aa and 21Ab can be held firmly without using a joining material such as solder, improving handling (assembly workability) when assembling the capacitor 1A, for example, when storing the capacitor element 10 to which the pull-out terminals 21A are connected in the exterior case 30.

- first and second pull-out terminals 21Aa and 21Ab when welding the first and second pull-out terminals 21Aa and 21Ab to further strengthen the connection points of the first and second pull-out terminals 21Aa and 21Ab, if the first and second pull-out terminals 21Aa and 21Ab are in surface contact when connected as described above, it is easier to weld the first and second pull-out terminals 21Aa and 21Ab. For this reason, it is preferable that the first and second pull-out terminals 21Aa and 21Ab are welded at points where they are engaged so as to make surface contact.

- the capacitor 1A it is sufficient that at least the first pull-out terminal 20Aa and the second pull-out terminal 20Ab are engaged so as to make surface contact, and it is preferable that the first pull-out terminal 21Aa and the second pull-out terminal 21Ab are engaged so as to make surface contact, but they do not have to be engaged so as to make surface contact.

- the engaging manner of the first and second drawn-out terminals 21Aa and 21Ab is preferably the same as the engaging manner of the first and second drawn-out terminals 20Aa and 20Ab described above, but may be different from the engaging manner of the first and second drawn-out terminals 20Aa and 20Ab.

- the shape of the pull-out terminal 20A may be, for example, plate-like or linear (rod-like). That is, the shape of the first pull-out terminal 20Aa and the second pull-out terminal 20Ab may each be, for example, plate-like or linear (rod-like). In this case, the first pull-out terminal 20Aa and the second pull-out terminal 20Ab may each have a shape with a partially bent portion.

- the shape of the drawer terminal 21A may be, for example, plate-like or linear (rod-like). That is, the shape of the first drawer terminal 21Aa and the second drawer terminal 21Ab may each be, for example, plate-like or linear (rod-like). In this case, the first drawer terminal 21Aa and the second drawer terminal 21Ab may each have a shape with a partially bent portion.

- the first pull-out terminal 20Aa, the second pull-out terminal 20Ab, the first pull-out terminal 21Aa, and the second pull-out terminal 21Ab are each also called a bus bar.

- the pull-out terminal 20A and the pull-out terminal 21A are each used as terminals for electrically connecting the capacitor element 10 to an object to be mounted, for example, when mounting the capacitor 1A to the object to be mounted.

- the capacitor element 10 is housed inside the exterior case 30 so that the pull-out terminals 20A and 21A protrude toward the outside.

- the capacitor element 10 be stored in the center of the interior of the outer case 30, away from the inner surface of the outer case 30.

- one capacitor element 10 is stored inside one exterior case 30, but multiple capacitor elements 10 may be stored inside one exterior case 30.

- the shape of the exterior case 30 is, for example, a cylindrical shape with a bottom and an opening 31 at one end in the first direction D1, as shown in Figures 1 and 2.

- the outer surface of the exterior case 30 includes a first outer surface 32 facing the opening 31 in the first direction D1, and a second outer surface 33 (in the example shown in Figures 1 and 2, four outer surfaces are included) extending from the first outer surface 32 toward the opening 31 in the first direction D1.

- Examples of the exterior case 30 include a resin case, a metal case, etc.

- the exterior case 30 is a resin case

- the resin that constitutes the resin case include liquid crystal polymer (LCP), polyphenylene sulfide, polybutylene terephthalate, etc.

- LCP liquid crystal polymer

- the resin case contains a liquid crystal polymer.

- the liquid crystal polymer contained in the resin case may be, for example, a liquid crystal polymer having p-hydroxybenzoic acid and 6-hydroxy-2-naphthoic acid groups in its skeleton.

- liquid crystal polymers formed from polycondensates using various components such as phenol, phthalic acid, and ethylene terephthalate can also be used.

- Liquid crystal polymers can also be classified into types I, II, and III, but the material used is the same as the liquid crystal polymer formed from the above-mentioned components.

- the resin case preferably further contains an inorganic filler in addition to the liquid crystal polymer.

- the inorganic filler contained in the resin case can be a material that is stronger than the liquid crystal polymer.

- the inorganic filler is preferably a material that has a higher melting point than the liquid crystal polymer, and more preferably a material with a melting point of 680°C or higher.

- the shape of the inorganic filler is not particularly limited, and examples include a shape having a longitudinal direction such as a fiber shape or a plate shape.

- As an inorganic filler of such a shape multiple types of inorganic materials may be used in combination.

- the resin case contains at least one of a fibrous inorganic material and a plate-shaped inorganic material as the inorganic filler.

- a filler being fibrous means that the relationship between the longitudinal dimension in the longitudinal direction and the cross-sectional diameter in a cross section perpendicular to the longitudinal direction is longitudinal dimension/cross-sectional diameter ⁇ 5 (i.e., the aspect ratio is 5:1 or more).

- the cross-sectional diameter is the longest distance between two points on the circumference of the cross section. If the cross-sectional diameter varies in the longitudinal direction, the measurement is taken at the point where the cross-sectional diameter is largest.

- a filler being plate-like means that the relationship between the cross-sectional diameter of the face with the largest projected area and the maximum height in the direction perpendicular to this cross section is cross-sectional diameter/maximum height ⁇ 3.

- the inorganic filler has a portion oriented from the first outer surface 32 toward the opening 31 on the second outer surface 33 of the exterior case 30 and a portion oriented toward the adjacent second outer surface 33, and is dispersed inside the exterior case 30.

- the size of the inorganic filler is preferably 5 ⁇ m or more in diameter and 50 ⁇ m or more in length.

- the inorganic filler be dispersed throughout the exterior case 30 without agglomerating.

- inorganic fillers examples include inorganic materials such as fibrous glass filler, plate-like talc or mica. Of these, it is preferable for the inorganic filler to contain fibrous glass filler as the main component.

- the resin case contains another resin (e.g., polyphenylene sulfide) instead of the liquid crystal polymer, it is preferable that the resin case further contains an inorganic filler as described above.

- another resin e.g., polyphenylene sulfide

- the resin case is manufactured by a method such as injection molding.

- the exterior case 30 is a metal case

- the metal that constitutes the metal case include simple metals such as aluminum, magnesium, iron, stainless steel, and copper, and alloys that contain at least one of these simple metals. Of these, it is preferable that the metal case contains aluminum or an aluminum alloy.

- the metal case is manufactured by a method such as impact molding.

- the filled resin 40 is filled inside the exterior case 30 so as to embed the capacitor element 10.

- the capacitor element 10 is held inside the exterior case 30.

- the filling resin 40 is filled between the capacitor element 10 and the exterior case 30, more specifically, between the outer surface of the capacitor element 10 and the inner surface of the exterior case 30. Furthermore, inside the exterior case 30, the filling resin 40 is filled not only between the capacitor element 10 and the exterior case 30, but also in the area from the opening 31 of the exterior case 30 to the capacitor element 10.

- the filling resin 40 it is preferable to appropriately select a resin with low moisture permeability from the viewpoint of suppressing the infiltration of moisture into the capacitor element 10, and examples thereof include epoxy resin, silicone resin, urethane resin, etc.

- examples of the hardener for the epoxy resin include an amine hardener, an imidazole hardener, etc.

- the filling resin 40 only the above-mentioned resin may be used, but in order to improve strength, a resin to which a reinforcing agent has been added may also be used.

- reinforcing agents include silica and alumina.

- the thickness of the filling resin 40 at the opening 31 of the exterior case 30 is large.

- the thickness of the filling resin 40 at the opening 31 of the exterior case 30 is preferably sufficiently large within the range that allows for the volume (physical size) of the entire capacitor 1A, and specifically, is preferably 2 mm or more, and more preferably 4 mm or more.

- the thickness of the filling resin 40 for the capacitor element 10 is made larger on the opening 31 side of the exterior case 30 than on the first outer surface 32 side by arranging the capacitor element 10 on the opening 31 side of the exterior case 30 inside the exterior case 30.

- the thickness of the filling resin 40 is measured, for example, using a soft X-ray device if it is in a non-destructive state, and using a length measuring device such as a caliper if it is in a destructive state.

- the relationship between the height of the outer case 30 and the height of the filled resin 40 in the first direction D1 is such that the thickness of the filled resin 40 at the opening 31 of the outer case 30 is as large as possible, and may be up to a position on the inside of the outer case 30, may be nearly to the top, or may overflow slightly due to surface tension.

- the pull-out terminal 20A in the pull-out terminal 20A, at least a portion of the first pull-out terminal 20Aa (see FIG. 2) may be embedded in the filling resin 40. In the example shown in FIG. 1, the entire first pull-out terminal 20Aa is embedded in the filling resin 40.

- the pull-out terminal 21A in the pull-out terminal 21A, at least a portion of the first pull-out terminal 21Aa (see FIG. 2) may be embedded in the filling resin 40. In the example shown in FIG. 1, the entire first pull-out terminal 21Aa is embedded in the filling resin 40.

- the second pull-out terminal 20Ab may protrude from the filling resin 40.

- a portion (end) of the second pull-out terminal 20Ab protrudes from the filling resin 40.

- the second pull-out terminal 21Ab may protrude from the filling resin 40.

- a portion (end) of the second pull-out terminal 21Ab protrudes from the filling resin 40.

- one of the first and second lead-out terminals has a claw-shaped portion

- the other of the first and second lead-out terminals has a slit portion penetrating in a first direction

- the claw-shaped portion is inserted through the slit portion in the first direction and hooked onto an edge of the slit portion.

- the capacitor of the second embodiment of the present invention is otherwise similar to the capacitor of the first embodiment of the present invention.

- FIG. 7 is a schematic perspective view showing an example of a capacitor according to embodiment 2 of the present invention.

- FIG. 8 is a schematic perspective view showing an example of the capacitor shown in FIG. 7 (excluding the filled resin) in a disassembled state.

- the capacitor 1B shown in Figures 7 and 8 has two capacitor elements 10 (see Figure 3 above), a pull-out terminal 20B, a pull-out terminal 21B, an exterior case 30, and a filling resin 40.

- two capacitor elements 10 are housed inside one exterior case 30, but one capacitor element 10 may be housed inside one exterior case 30, or three or more capacitor elements 10 may be housed inside one exterior case 30.

- the pull-out terminal 20B is electrically connected to each of the first external electrodes 12a of the two capacitor elements 10.

- the pull-out terminal 20B is electrically connected to each of the first external electrodes 12a of the two capacitor elements 10 via a joining member such as solder.

- the pull-out terminal 20B has a first pull-out terminal 20Ba and a second pull-out terminal 20Bb.

- the first pull-out terminal 20Ba and the second pull-out terminal 20Bb are engaged so as to make surface contact.

- the following describes the locking manner of the first pull-out terminal 20Ba and the second pull-out terminal 20Bb.

- FIG. 9 is a schematic perspective view showing the state before the first and second pull-out terminals shown in FIG. 8 are engaged.

- FIG. 10 is a schematic perspective view showing the state in which the first and second pull-out terminals shown in FIG. 9 are in the process of being engaged.

- FIG. 11 is a schematic perspective view showing the state after the first and second pull-out terminals shown in FIG. 10 have been engaged. Note that in FIGS. 9, 10, and 11, other components such as a capacitor element are omitted to make it easier to focus on the manner in which the first and second pull-out terminals are engaged.

- the first pull-out terminal 20Ba has a claw-shaped portion 25.

- the second pull-out terminal 20Bb has a slit portion 27.

- the slit portion 27 penetrates the second pull-out terminal 20Bb in the first direction D1.

- the slit portion 27 may include a first slit portion 27a and a second slit portion 27b.

- the second slit portion 27b is connected to the first slit portion 27a in a second direction D2 that is perpendicular to the first direction D1.

- the first slit portion 27a is capable of containing the claw-shaped portion 25.

- the slit portion when the slit portion is capable of containing the claw-shaped portion when viewed from the same direction (first direction D1 in FIG. 9), this means that when the claw-shaped portion and the slit portion are overlapped while viewed from the same direction (first direction D1 in FIG. 9), the claw-shaped portion does not protrude from the slit portion, or more specifically, the outer edge of the claw-shaped portion is not positioned outside the outer edge of the slit portion.

- the second slit portion 27b cannot contain the claw-shaped portion 25.

- the slit portion being unable to contain the claw portion when viewed from the same direction means that when the claw portion and the slit portion are overlapped while viewed from the same direction (first direction D1 in FIG. 9), the claw portion protrudes from the slit portion, or more specifically, the outer edge of the claw portion is positioned outside the outer edge of the slit portion.

- first slit portion 27a can contain the claw-shaped portion 25 when viewed from the first direction D1, the claw-shaped portion 25 can be directly inserted into the first slit portion 27a in the first direction D1, as shown in FIG. 10.

- the claw-shaped portion 25 cannot be directly inserted into the second slit portion 27b in the first direction D1.

- the claw-shaped portion 25 is capable of sliding in the second direction D2 between the first slit portion 27a and the second slit portion 27b when inserted into the slit portion 27 in the first direction D1.

- the dimension in the third direction D3 of the base side portion (portion extending in the first direction D1) located on the opposite side to the tip of the claw-shaped portion 25 is equal to or smaller than the dimension in the third direction D3 of the second slit portion 27b

- the claw-shaped portion 25 can slide in the second direction D2 between the first slit portion 27a and the second slit portion 27b when inserted into the first slit portion 27a in the first direction D1.

- the claw-shaped portion 25 When the claw-shaped portion 25 is slid in the second direction D2 toward the second slit portion 27b from the state shown in FIG. 10 in which the claw-shaped portion 25 is inserted into the first slit portion 27a in the first direction D1, as shown in FIG. 11, the claw-shaped portion 25 is hooked onto the edge of the slit portion 27 while being inserted into the slit portion 27 in the first direction D1. More specifically, as shown in FIG. 11, it is preferable that the claw-shaped portion 25 is hooked onto the edge of the second slit portion 27b. In this case, the claw-shaped portion 25 is positioned in the third direction D3 by the second slit portion 27b.

- the first pull-out terminal 20Ba has a claw-shaped portion 25, but instead of the first pull-out terminal 20Ba, the second pull-out terminal 20Bb may have the claw-shaped portion 25.

- the first pull-out terminal 20Ba may have a slit portion 27, and the claw-shaped portion 25 of the second pull-out terminal 20Bb may be inserted into the slit portion 27 provided in the first pull-out terminal 20Ba in the first direction D1 and hooked onto the edge of the slit portion 27.

- the claw-shaped portion 25 of one of the first and second pull-out terminals 20Ba and 20Bb is inserted in the first direction D1 through the slit portion 27 provided on the other of the first and second pull-out terminals 20Ba and 20Bb, and hooked onto the edge of the slit portion 27.

- the first and second pull-out terminals 20Ba and 20Bb are engaged so as to make surface contact.

- the first pull-out terminal 20Ba and the second pull-out terminal 20Bb are engaged, so that the first pull-out terminal 20Ba and the second pull-out terminal 20Bb can be mechanically (physically) connected without using a joining material such as solder. Therefore, in the capacitor 1B, the connectivity between the first pull-out terminal 20Ba and the second pull-out terminal 20Bb can be improved without using a joining material such as solder.

- connection points of the first pull-out terminal 20Ba and the second pull-out terminal 20Bb can be held firmly without using a joining material such as solder, improving handling (assembly workability) when assembling the capacitor 1B, for example, when storing the capacitor element 10 connected to the pull-out terminal 20B in the exterior case 30.

- the first and second pull-out terminals 20Ba and 20Bb are in surface contact when connected, and therefore it is easy to weld the first and second pull-out terminals 20Ba and 20Bb.

- the first and second pull-out terminals 20Ba and 20Bb are welded at points where they are engaged so as to make surface contact.

- the first pull-out terminal 20Ba and the second pull-out terminal 20Bb are engaged at two locations, but the number of locations at which the first pull-out terminal 20Ba and the second pull-out terminal 20Bb are engaged is not particularly limited.

- the first pull-out terminal 20Ba may further include a claw-shaped portion 25'.

- the claw-shaped portion 25' may be located at a different height than the claw-shaped portion 25 in the first direction D1.

- the claw-shaped portion 25' may be located lower than the claw-shaped portion 25 in the first direction D1, i.e., closer to the capacitor element 10 (see FIG. 8) than the claw-shaped portion 25 in the first direction D1.

- claw portion 25 and claw portion 25' do not have to overlap when viewed from the first direction D1.

- the second pull-out terminal 20Bb is sandwiched between the claw-shaped portions 25 and 25' in the first direction D1 as shown in FIG. 11.

- the second pull-out terminal 20Bb is less likely to shift in the first direction D1 when sandwiched between the claw-shaped portions 25 and 25', so that the first pull-out terminal 20Ba and the second pull-out terminal 20Bb are sufficiently firmly locked.

- the first pull-out terminal 20Ba has a claw-shaped portion 25 and a claw-shaped portion 25', but if the second pull-out terminal 20Bb has a claw-shaped portion 25 instead of the first pull-out terminal 20Ba, the second pull-out terminal 20Bb may further have a claw-shaped portion 25', and instead of the second pull-out terminal 20Bb, the first pull-out terminal 20Ba may be sandwiched between the claw-shaped portion 25 and the claw-shaped portion 25' of the second pull-out terminal 20Bb in the first direction D1.

- the first slit portion 27a and the second slit portion 27b are connected in the second direction D2, but they may be connected in the third direction D3 instead of the second direction D2.

- the claw-shaped portion 25 may be slidable in the third direction D3 between the first slit portion 27a and the second slit portion 27b while being inserted into the slit portion 27 in the first direction D1.

- the timing at which the first pull-out terminal 20Ba and the first external electrode 12a are connected as shown in Figure 8 may be before the first pull-out terminal 20Ba and the second pull-out terminal 20Bb are locked, or may be after the first pull-out terminal 20Ba and the second pull-out terminal 20Bb are locked.

- the pull-out terminal 21B is electrically connected to each of the second external electrodes 12b of the two capacitor elements 10.

- the pull-out terminal 21B is electrically connected to each of the second external electrodes 12b of the two capacitor elements 10 via a joining member such as solder.

- the lead-out terminal 20B is electrically connected to each of the first external electrodes 12a of the two capacitor elements 10 and the lead-out terminal 21B is electrically connected to each of the second external electrodes 12b of the two capacitor elements 10, the two capacitor elements 10 are connected in parallel.

- the pull-out terminal 21B has a first pull-out terminal 21Ba and a second pull-out terminal 21Bb.

- first pull-out terminal 21Ba and the second pull-out terminal 21Bb are engaged so as to make surface contact.

- the first pull-out terminal 21Ba and the second pull-out terminal 21Bb when the first pull-out terminal 21Ba and the second pull-out terminal 21Bb are engaged, the first pull-out terminal 21Ba and the second pull-out terminal 21Bb can be mechanically (physically) connected without using a joining material such as solder.

- the connectivity between the first pull-out terminal 21Ba and the second pull-out terminal 21Bb can be improved without using a joining material such as solder.

- connection points of the first pull-out terminal 21Ba and the second pull-out terminal 21Bb can be held firmly without using a joining material such as solder, improving handling (assembly workability) when assembling the capacitor 1B, for example, when storing the capacitor element 10 to which the pull-out terminal 21B is connected in the exterior case 30.

- first and second pull-out terminals 21Ba and 21Bb when welding the first and second pull-out terminals 21Ba and 21Bb to strengthen the connection points of the first and second pull-out terminals 21Ba and 21Bb, if the first and second pull-out terminals 21Ba and 21Bb are in surface contact when connected as described above, it is easier to weld the first and second pull-out terminals 21Ba and 21Bb. For this reason, it is preferable that the first and second pull-out terminals 21Ba and 21Bb are welded at points where they are engaged so as to make surface contact.

- the capacitor 1B it is sufficient that at least the first pull-out terminal 20Ba and the second pull-out terminal 20Bb are engaged so as to make surface contact, and it is preferable that the first pull-out terminal 21Ba and the second pull-out terminal 21Bb are engaged so as to make surface contact, but they do not have to be engaged so as to make surface contact.

- the engaging manner of the first and second drawn-out terminals 21Ba and 21Bb is preferably the same as the engaging manner of the first and second drawn-out terminals 20Ba and 20Bb described above, but may be different from the engaging manner of the first and second drawn-out terminals 20Ba and 20Bb.

- the engaging manner of the first and second drawn-out terminals 21Ba and 21Bb may be the same as the engaging manner of the first and second drawn-out terminals 20Aa and 20Ab described above.

- the capacitor of the present invention is useful, for example, as a smoothing capacitor that constitutes a power conversion device (e.g., an inverter) for in-vehicle use.

- a power conversion device e.g., an inverter

- a capacitor element having an element body and external electrodes provided on end faces of the element body; A lead terminal electrically connected to the external electrode; an exterior case in which the capacitor element is housed so that the lead-out terminal protrudes outward; a filling resin filled inside the exterior case so as to embed the capacitor element, the lead-out terminal includes a first lead-out terminal and a second lead-out terminal electrically connected to the external electrode via the first lead-out terminal,

- the capacitor is characterized in that the first lead-out terminal and the second lead-out terminal are engaged so as to be in surface contact with each other.

- one of the first and second lead-out terminals has a first claw-shaped portion and a second claw-shaped portion located at a different height from the first claw-shaped portion in a first direction;

- one of the first and second lead terminals further includes a third claw portion located at the same height as the second claw portion in the first direction;

- a notch portion is provided in the other of the first lead terminal and the second lead terminal,

- one of the first lead terminal and the second lead terminal has a claw-shaped portion, the other of the first and second drawn-out terminals is provided with a slit portion penetrating in a first direction,

- the capacitor according to any one of ⁇ 1> to ⁇ 8>, wherein the claw-shaped portion is inserted into the slit portion in the first direction and hooked onto an edge of the slit portion.

- the slit portion includes a first slit portion and a second slit portion connected to the first slit portion in a second direction perpendicular to the first direction,

- the capacitor described in ⁇ 9> wherein, when viewed from the first direction, the first slit portion is capable of containing the claw-shaped portion, and the second slit portion is not capable of containing the claw-shaped portion.

- Reference Signs List 1A, 1B Capacitor 10 Capacitor element 11 Body 12a First external electrode 12b Second external electrode 13a First metallized film 13b Second metallized film 14a First dielectric film 14aa First main surface 14ab of first dielectric film Second main surface 14b of first dielectric film Second dielectric film 14ba First main surface 14bb of second dielectric film Second main surface 15a of second dielectric film First metal layer 15b Second metal layer 20A, 20B, 21A, 21B Lead terminals 20Aa, 20Ba, 21Aa, 21Ba First lead terminals 20Ab, 20Bb, 21Ab, 21Bb Second lead terminals 25, 25' Claw-shaped portion 25a First claw-shaped portion 25b Second claw-shaped portion 25c Third claw-shaped portion 26 Notch portion 27 Slit portion 27a First slit portion 27b Second slit portion 30 Exterior case 31 Opening 32 First outer surface 33 Second outer surface 40 Filling resin D1 First direction D2 Second direction D3 Third direction

Landscapes

- Engineering & Computer Science (AREA)

- Power Engineering (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Manufacturing & Machinery (AREA)

- Fixed Capacitors And Capacitor Manufacturing Machines (AREA)

Abstract

Description

本発明は、コンデンサに関する。 The present invention relates to a capacitor.

特許文献1には、端面に電極部(10a)を有するコンデンサ素子(10)をバスバー(20)で接続しケース(50)に収納するとともに樹脂(60)を充填し外部接続用端子(32)(42)をケース開口部(53)と略直交する方向に向かって引き出したコンデンサであって、該コンデンサは、さらに、端子台(70)を備えており、端子台(70)は、ケース(50)と接することなく、一方側が樹脂(60)に埋設されているとともに、他方側に設けられたネジ部(73a)が外部接続用端子(32)(42)の取付孔(32b)(42b)と対向していることを特徴とするコンデンサが開示されている。 Patent Document 1 discloses a capacitor in which a capacitor element (10) having electrodes (10a) on its end faces is connected by a bus bar (20) and housed in a case (50), which is filled with resin (60) and has external connection terminals (32) (42) drawn out in a direction approximately perpendicular to the case opening (53), and further includes a terminal block (70), one side of which is embedded in the resin (60) without contacting the case (50), and a screw portion (73a) provided on the other side faces the mounting holes (32b) (42b) of the external connection terminals (32) (42).

特許文献1に記載のコンデンサでは、コンデンサ素子の電極部に接続されたCP線とバスバーとがはんだによって接続される、とされている。しかしながら、特許文献1に記載のコンデンサでは、CP線とバスバーとをはんだによって接続しようとしても、はんだ接続時の熱がバスバーを介して外部に逃げやすくなるため、はんだの温度が下がりやすくなる。よって、特許文献1に記載のコンデンサでは、CP線とバスバーとをはんだによって接続することが困難である。 In the capacitor described in Patent Document 1, the CP wire connected to the electrode portion of the capacitor element and the bus bar are connected by soldering. However, in the capacitor described in Patent Document 1, even if you try to connect the CP wire and the bus bar by soldering, the heat generated during the soldering connection tends to escape to the outside through the bus bar, so the temperature of the solder is likely to drop. Therefore, in the capacitor described in Patent Document 1, it is difficult to connect the CP wire and the bus bar by soldering.

これに対して、特許文献1に記載のコンデンサにおいて、CP線とバスバーとを、はんだ接続ではなく溶接することが考えられる。しかしながら、特許文献1に記載のコンデンサにおいて、CP線とバスバーとを溶接しようとしても、特許文献1の図1等に記載の構造、コンデンサ素子のサイズのばらつき等によって、CP線とバスバーとを充分に面接触させることができない。よって、特許文献1に記載のコンデンサでは、CP線とバスバーとを溶接することが困難である。 In response to this, in the capacitor described in Patent Document 1, it is possible to weld the CP wire and the bus bar together rather than soldering them together. However, even if one attempts to weld the CP wire and the bus bar together in the capacitor described in Patent Document 1, the structure described in Figure 1 of Patent Document 1, variations in the size of the capacitor elements, and other factors make it impossible to achieve sufficient surface contact between the CP wire and the bus bar. Therefore, in the capacitor described in Patent Document 1, it is difficult to weld the CP wire and the bus bar together.

以上のように、従来のコンデンサでは、コンデンサ素子の電極部を外部に引き出すために複数の引出端子(特許文献1に記載のコンデンサでは、CP線及びバスバー)が接続された構造を用いる場合、はんだ等の接合部材を用いずに引出端子間(特許文献1に記載のコンデンサでは、CP線とバスバーとの間)の接続性を向上する点で改善の余地がある。 As described above, in conventional capacitors, when a structure is used in which multiple lead-out terminals (CP wires and bus bars in the capacitor described in Patent Document 1) are connected to lead out the electrodes of the capacitor element, there is room for improvement in terms of improving the connectivity between the lead-out terminals (between the CP wires and bus bars in the capacitor described in Patent Document 1) without using a joining material such as solder.

本発明は、上記の問題を解決するためになされたものであり、はんだ等の接合部材を用いずに引出端子間の接続性を向上可能なコンデンサを提供することを目的とするものである。 The present invention was made to solve the above problems, and aims to provide a capacitor that can improve the connectivity between the lead-out terminals without using joining materials such as solder.

本発明のコンデンサは、素体と、上記素体の端面上に設けられた外部電極と、を有するコンデンサ素子と、上記外部電極に電気的に接続された引出端子と、上記引出端子が外部に向かって突出するように上記コンデンサ素子が内部に収納された外装ケースと、上記コンデンサ素子を埋設させるように上記外装ケースの内部に充填された充填樹脂と、を備え、上記引出端子は、第1引出端子と、上記第1引出端子を介して上記外部電極に電気的に接続された第2引出端子と、を有し、上記第1引出端子及び上記第2引出端子は、面接触するように係止されている、ことを特徴とする。 The capacitor of the present invention comprises a capacitor element having a body and an external electrode provided on an end face of the body, a pull-out terminal electrically connected to the external electrode, an exterior case in which the capacitor element is housed so that the pull-out terminal protrudes outward, and a filling resin filled inside the exterior case so as to embed the capacitor element, the pull-out terminal having a first pull-out terminal and a second pull-out terminal electrically connected to the external electrode via the first pull-out terminal, and the first pull-out terminal and the second pull-out terminal are engaged so as to make surface contact.

本発明によれば、はんだ等の接合部材を用いずに引出端子間の接続性を向上可能なコンデンサを提供できる。 The present invention provides a capacitor that can improve the connectivity between lead terminals without using joining materials such as solder.

以下、本発明のコンデンサについて説明する。なお、本発明は、以下の構成に限定されるものではなく、本発明の要旨を逸脱しない範囲において適宜変更されてもよい。また、以下において記載する個々の好ましい構成を複数組み合わせたものもまた本発明である。 The capacitor of the present invention will be described below. Note that the present invention is not limited to the configuration below, and may be modified as appropriate without departing from the spirit of the present invention. In addition, a combination of multiple individual preferred configurations described below also constitutes the present invention.

以下に示す各実施形態は例示であり、異なる実施形態で示す構成の部分的な置換又は組み合わせが可能であることは言うまでもない。実施形態2以降では、実施形態1と共通の事項についての記載は省略し、異なる点を主に説明する。特に、同様の構成による同様の作用効果については、実施形態毎に逐次言及しない。 The embodiments shown below are merely examples, and it goes without saying that partial substitution or combination of the configurations shown in different embodiments is possible. From embodiment 2 onwards, descriptions of matters common to embodiment 1 will be omitted, and differences will be mainly explained. In particular, similar effects resulting from similar configurations will not be mentioned one by one for each embodiment.

以下の説明において、各実施形態を特に区別しない場合、単に「本発明のコンデンサ」と言う。 In the following description, unless otherwise specified, each embodiment will simply be referred to as the "capacitor of the present invention."

以下では、本発明のコンデンサの一例として、フィルムコンデンサを示す。本発明のコンデンサは、フィルムコンデンサ以外のコンデンサにも適用可能である。 Below, a film capacitor is shown as an example of a capacitor of the present invention. The capacitor of the present invention can also be applied to capacitors other than film capacitors.

以下に示す図面は模式図であり、その寸法、縦横比の縮尺等は実際の製品と異なる場合がある。 The drawings shown below are schematic diagrams, and the dimensions, aspect ratio, and other scales may differ from those of the actual product.

本明細書中、要素間の関係性を示す用語(例えば、「平行」、「直交」等)及び要素の形状を示す用語は、文字通りの厳密な態様のみを意味するだけではなく、実質的に同等な範囲、例えば、数%程度の差異を含む範囲も意味する。 In this specification, terms indicating the relationship between elements (e.g., "parallel," "orthogonal," etc.) and terms indicating the shapes of elements do not only mean the literal, strict form, but also mean a range that is substantially equivalent, for example, a range that includes a difference of about a few percent.

本発明のコンデンサは、素体と、上記素体の端面上に設けられた外部電極と、を有するコンデンサ素子と、上記外部電極に電気的に接続された引出端子と、上記引出端子が外部に向かって突出するように上記コンデンサ素子が内部に収納された外装ケースと、上記コンデンサ素子を埋設させるように上記外装ケースの内部に充填された充填樹脂と、を備え、上記引出端子は、第1引出端子と、上記第1引出端子を介して上記外部電極に電気的に接続された第2引出端子と、を有し、上記第1引出端子及び上記第2引出端子は、面接触するように係止されている、ことを特徴とする。 The capacitor of the present invention comprises a capacitor element having a body and an external electrode provided on an end face of the body, a pull-out terminal electrically connected to the external electrode, an exterior case in which the capacitor element is housed so that the pull-out terminal protrudes outward, and a filling resin filled inside the exterior case so as to embed the capacitor element, the pull-out terminal having a first pull-out terminal and a second pull-out terminal electrically connected to the external electrode via the first pull-out terminal, and the first pull-out terminal and the second pull-out terminal are engaged so as to make surface contact.

[実施形態1]

本発明の実施形態1のコンデンサにおいて、第1引出端子及び第2引出端子の一方は、第1爪状部と、第1方向において第1爪状部と異なる高さに位置する第2爪状部と、を有し、第1引出端子及び第2引出端子の他方は、第1方向において第1爪状部及び第2爪状部に挟み込まれている。

[Embodiment 1]

In the capacitor of embodiment 1 of the present invention, one of the first and second pull-out terminals has a first claw-shaped portion and a second claw-shaped portion located at a different height than the first claw-shaped portion in the first direction, and the other of the first and second pull-out terminals is sandwiched between the first and second claw-shaped portion in the first direction.

図1は、本発明の実施形態1のコンデンサの一例を示す斜視模式図である。図2は、図1に示すコンデンサ(ただし、充填樹脂を除く)が分解された状態の一例を示す斜視模式図である。 FIG. 1 is a schematic perspective view showing an example of a capacitor according to a first embodiment of the present invention. FIG. 2 is a schematic perspective view showing an example of the capacitor shown in FIG. 1 (excluding the filled resin) in a disassembled state.

図1及び図2に示すコンデンサ1Aは、コンデンサ素子10(後述する図3参照)と、引出端子20Aと、引出端子21Aと、外装ケース30と、充填樹脂40と、を有している。

The

図1等において、第1方向D1と第2方向D2と第3方向D3とは、互いに直交している。 In FIG. 1 etc., the first direction D1, the second direction D2, and the third direction D3 are perpendicular to each other.

図3は、図1及び図2に示すコンデンサ素子の一例を示す斜視模式図である。図4は、図3に示すコンデンサ素子の線分a1-a2に沿う断面の一例を示す断面模式図である。 FIG. 3 is a schematic perspective view showing an example of the capacitor element shown in FIGS. 1 and 2. FIG. 4 is a schematic cross-sectional view showing an example of a cross-section along line a1-a2 of the capacitor element shown in FIG. 3.

図3及び図4に示すコンデンサ素子10は、素体11と、第1外部電極12aと、第2外部電極12bと、を有している。

The

素体11は、第1金属化フィルム13aと第2金属化フィルム13bとが第1方向D1に積層された状態で巻回されてなる巻回体である。つまり、コンデンサ1A、より具体的には、コンデンサ素子10は、金属化フィルムが積層された状態で巻回された巻回型のフィルムコンデンサである。

The

なお、コンデンサ1A、より具体的には、コンデンサ素子10は、金属化フィルムが積層された積層型のフィルムコンデンサであってもよい。

In addition,

コンデンサ素子10では、低背化の観点から、素体11の巻軸方向(図3では、第3方向D3)に直交する断面を見たときに、素体11の断面形状が扁平形状であることが好ましい。より具体的には、素体11の断面形状が楕円又は長円のような扁平形状にプレスされ、素体11の断面形状が真円であるときよりも厚みが小さい形状とされることが好ましい。

In terms of reducing the height of

素体の断面形状が扁平形状となるようにプレスされたかどうかについては、例えば、素体にプレス痕が存在するかどうかで確認できる。 Whether the base body has been pressed to have a flat cross-sectional shape can be confirmed, for example, by checking whether or not there are press marks on the base body.

コンデンサ素子10は、円柱状の巻回軸を有していてもよい。巻回軸は、巻回状態の第1金属化フィルム13a及び第2金属化フィルム13bの中心軸上に配置されるものであり、第1金属化フィルム13a及び第2金属化フィルム13bを巻回する際の巻軸となるものである。

The

第1金属化フィルム13aは、第1誘電体フィルム14aと、第1金属層15aと、を有している。

The first

第1誘電体フィルム14aは、第1方向D1に相対する第1主面14aa及び第2主面14abを有している。

The first

第1金属層15aは、第1誘電体フィルム14aの第1主面14aa上に設けられている。より具体的には、第1金属層15aは、第1誘電体フィルム14aの第1主面14aa上で、第3方向D3において、第1誘電体フィルム14aの一方の側縁に届き、第1誘電体フィルム14aの他方の側縁に届かないように設けられている。

The

第2金属化フィルム13bは、第2誘電体フィルム14bと、第2金属層15bと、を有している。

The second

第2誘電体フィルム14bは、第1方向D1に相対する第1主面14ba及び第2主面14bbを有している。

The second

第2金属層15bは、第2誘電体フィルム14bの第1主面14ba上に設けられている。より具体的には、第2金属層15bは、第2誘電体フィルム14bの第1主面14ba上で、第3方向D3において、第2誘電体フィルム14bの一方の側縁に届かず、第2誘電体フィルム14bの他方の側縁に届くように設けられている。

The

素体11では、第1金属層15aにおける第1誘電体フィルム14aの側縁に届いている側の端部が素体11の一方の端面に露出し、第2金属層15bにおける第2誘電体フィルム14bの側縁に届いている側の端部が素体11の他方の端面に露出するように、隣り合う第1金属化フィルム13a及び第2金属化フィルム13bが第3方向D3にずれている。つまり、隣り合う第1金属化フィルム13a及び第2金属化フィルム13bにおいて、第1金属化フィルム13aは、第2金属化フィルム13bに対して第1外部電極12a側に突出している。また、隣り合う第1金属化フィルム13a及び第2金属化フィルム13bにおいて、第2金属化フィルム13bは、第1金属化フィルム13aに対して第2外部電極12b側に突出している。このような状態で、第1金属層15aは、第1外部電極12aに接続され、かつ、第2外部電極12bに接続されていない。また、第2金属層15bは、第2外部電極12bに接続され、かつ、第1外部電極12aに接続されていない。

In the

素体11では、隣り合う第1金属化フィルム13a及び第2金属化フィルム13bが上述したように第3方向D3にずれていることから、隣り合う第1誘電体フィルム14a及び第2誘電体フィルム14bにおいて、第1金属層15aが第1主面14aa上に設けられている第1誘電体フィルム14aは、第1金属層15aが主面上に設けられていない第2誘電体フィルム14bに対して第1外部電極12a側に突出している。また、隣り合う第1誘電体フィルム14a及び第2誘電体フィルム14bにおいて、第2金属層15bが第1主面14ba上に設けられている第2誘電体フィルム14bは、第2金属層15bが主面上に設けられていない第1誘電体フィルム14aに対して第2外部電極12b側に突出している。

In the

素体11は、第1金属化フィルム13aと第2金属化フィルム13bとが第1方向D1に積層された状態で巻回されてなることから、第1誘電体フィルム14a、第1金属層15a、第2誘電体フィルム14b、及び、第2金属層15bを第1方向D1に順に含んでいる、と言える。また、素体11は、第1誘電体フィルム14a、第1金属層15a、第2誘電体フィルム14b、及び、第2金属層15bが第1方向D1に順に積層された状態で巻回されてなる巻回体である、とも言える。

The

素体11では、第1誘電体フィルム14aの第1主面14aaと第2誘電体フィルム14bの第2主面14bbとが第1方向D1に対向し、かつ、第1誘電体フィルム14aの第2主面14abと第2誘電体フィルム14bの第1主面14baとが第1方向D1に対向している。このように、素体11では、第1金属化フィルム13aと第2金属化フィルム13bとが第1方向D1に積層された状態で巻回されている。言い換えれば、素体11では、第2金属化フィルム13bが第1金属化フィルム13aの内側となり、より具体的には、第1金属層15aが第1誘電体フィルム14aの内側となり、かつ、第2金属層15bが第2誘電体フィルム14bの内側となるように、第1金属化フィルム13aと第2金属化フィルム13bとが第1方向D1に積層された状態で巻回されている。つまり、素体11では、第1金属層15aと第2金属層15bとは、第1誘電体フィルム14a又は第2誘電体フィルム14bを挟んで互いに対向している。

In the

第1金属層15aには、ヒューズ部が設けられていてもよい。第1金属層15aに設けられるヒューズ部は、例えば、第1金属層15aにおいて、第2金属層15bに対向する部分が複数に分割された分割電極部と、第2金属層15bに対向しない部分である電極部とを接続する部分である。ヒューズ部が設けられた第1金属層15aの電極パターンとしては、例えば、特開2004-363431号公報、特開平5-251266号公報等に開示された電極パターンが挙げられる。

The

第2金属層15bにも、第1金属層15aと同様に、ヒューズ部が設けられていてもよい。

The

第1誘電体フィルム14aは、硬化性樹脂を主成分として含んでいてもよい。

The

本明細書中、主成分は、重量百分率が最も高い成分を意味し、好ましくは、重量百分率が50重量%よりも高い成分を意味する。 In this specification, the main component means the component with the highest weight percentage, preferably the component with a weight percentage greater than 50% by weight.

硬化性樹脂は、熱硬化性樹脂であってもよいし、光硬化性樹脂であってもよい。 The curable resin may be a thermosetting resin or a photocurable resin.

本明細書中、熱硬化性樹脂は、熱で硬化し得る樹脂を意味しているが、その硬化方法を限定するものではない。したがって、熱硬化性樹脂には、熱で硬化し得る樹脂である限り、熱以外の方法(例えば、光、電子ビーム等)でも硬化し得る樹脂も含まれる。また、材料によっては、材料自体が有する反応性によって反応が開始する場合があり、必ずしも外部から熱等を与えなくても硬化が進む樹脂についても、熱硬化性樹脂とする。光硬化性樹脂についても同様であり、光で硬化し得る樹脂である限り、光以外の方法(例えば、熱等)でも硬化し得る樹脂も含まれる。 In this specification, thermosetting resin means a resin that can be cured by heat, but the curing method is not limited. Therefore, thermosetting resin also includes resins that can be cured by methods other than heat (for example, light, electron beam, etc.) so long as they are heat-curable. Also, depending on the material, a reaction may be initiated due to the reactivity of the material itself, and resins that proceed to cure without necessarily being subjected to heat from the outside are also considered to be thermosetting resins. The same applies to photocurable resins, and so long as they are light-curable, they also include resins that can be cured by methods other than light (for example, heat, etc.).

硬化性樹脂は、水酸基(OH基)を有する第1有機材料と、イソシアネート基(NCO基)を有する第2有機材料との硬化物からなることが好ましい。この場合、硬化性樹脂は、第1有機材料の水酸基と第2有機材料のイソシアネート基とが反応して得られるウレタン結合を有する硬化物からなる。 The curable resin is preferably made of a cured product of a first organic material having a hydroxyl group (OH group) and a second organic material having an isocyanate group (NCO group). In this case, the curable resin is made of a cured product having a urethane bond obtained by reacting the hydroxyl group of the first organic material with the isocyanate group of the second organic material.

誘電体フィルムにおけるウレタン結合の存在については、フーリエ変換赤外分光光度計(FT-IR)で分析することにより確認できる。 The presence of urethane bonds in the dielectric film can be confirmed by analysis using a Fourier transform infrared spectrophotometer (FT-IR).

硬化性樹脂が上述した反応により得られる場合、出発材料の未硬化部分が第1誘電体フィルム14a中に残留する場合がある。例えば、第1誘電体フィルム14aは、水酸基及びイソシアネート基の少なくとも一方を含んでいてもよい。この場合、第1誘電体フィルム14aは、水酸基及びイソシアネート基の一方を含んでいてもよいし、水酸基及びイソシアネート基の両方を含んでいてもよい。

When the curable resin is obtained by the above-mentioned reaction, uncured portions of the starting material may remain in the

誘電体フィルムにおける水酸基及び/又はイソシアネート基の存在については、FT-IRで分析することにより確認できる。 The presence of hydroxyl groups and/or isocyanate groups in the dielectric film can be confirmed by FT-IR analysis.

第1有機材料としては、例えば、フェノキシ樹脂、ポリビニルアセトアセタール樹脂、ポリビニルブチラール樹脂等が挙げられる。 Examples of the first organic material include phenoxy resin, polyvinyl acetoacetal resin, polyvinyl butyral resin, etc.

第1有機材料としては、複数種類の有機材料が併用されてもよい。 Multiple types of organic materials may be used in combination as the first organic material.

第2有機材料としては、例えば、ジフェニルメタンジイソシアネート(MDI)、トリレンジイソシアネート(TDI)等の芳香族ポリイソシアネート、ヘキサメチレンジイソシアネート(HDI)等の脂肪族ポリイソシアネート等が挙げられる。第2有機材料としては、これらのポリイソシアネートの少なくとも1種の変性体が用いられてもよいし、これらのポリイソシアネートの少なくとも1種とその変性体との混合物が用いられてもよい。 Examples of the second organic material include aromatic polyisocyanates such as diphenylmethane diisocyanate (MDI) and tolylene diisocyanate (TDI), and aliphatic polyisocyanates such as hexamethylene diisocyanate (HDI). As the second organic material, at least one modified product of these polyisocyanates may be used, or a mixture of at least one of these polyisocyanates and its modified product may be used.

第2有機材料としては、複数種類の有機材料が併用されてもよい。 As the second organic material, multiple types of organic materials may be used in combination.