US20010040446A1 - Apparatus and method for the measurement and monitoring of electrical power generation and transmission - Google Patents

Apparatus and method for the measurement and monitoring of electrical power generation and transmission Download PDFInfo

- Publication number

- US20010040446A1 US20010040446A1 US09/835,250 US83525001A US2001040446A1 US 20010040446 A1 US20010040446 A1 US 20010040446A1 US 83525001 A US83525001 A US 83525001A US 2001040446 A1 US2001040446 A1 US 2001040446A1

- Authority

- US

- United States

- Prior art keywords

- transmission line

- magnetic flux

- flux density

- recited

- sensor

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Abandoned

Links

Images

Classifications

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01R—MEASURING ELECTRIC VARIABLES; MEASURING MAGNETIC VARIABLES

- G01R15/00—Details of measuring arrangements of the types provided for in groups G01R17/00 - G01R29/00, G01R33/00 - G01R33/26 or G01R35/00

- G01R15/14—Adaptations providing voltage or current isolation, e.g. for high-voltage or high-current networks

- G01R15/142—Arrangements for simultaneous measurements of several parameters employing techniques covered by groups G01R15/14 - G01R15/26

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01R—MEASURING ELECTRIC VARIABLES; MEASURING MAGNETIC VARIABLES

- G01R19/00—Arrangements for measuring currents or voltages or for indicating presence or sign thereof

- G01R19/25—Arrangements for measuring currents or voltages or for indicating presence or sign thereof using digital measurement techniques

- G01R19/2513—Arrangements for monitoring electric power systems, e.g. power lines or loads; Logging

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01R—MEASURING ELECTRIC VARIABLES; MEASURING MAGNETIC VARIABLES

- G01R21/00—Arrangements for measuring electric power or power factor

- G01R21/133—Arrangements for measuring electric power or power factor by using digital technique

Definitions

- SCADA Supervisory Control and Data Acquisition

- Each substation connected to the transmission grid is equipped with several potential transformers (PT) and current transformers (CT) to measure the voltage, current, and electric power flow on each line and bus.

- PT potential transformers

- CT current transformers

- the PT and CT data is monitored in real time and transmitted back to a central computer from each substation through a Remote Terminal Unit (RTU) using various wired and wireless communication methods.

- RTU Remote Terminal Unit

- the present invention is an apparatus and method for the measurement and monitoring of electric power generation and transmission associated with one or more power generating plants. Specifically, the apparatus and method of the present invention allows for a determination of the amount and direction of electric power flowing over a particular high-voltage electric power transmission line, allows for a determination of the real and reactive components of the electric power, and further allows for a determination of the amount of electric power being produced by any particular electric power generation plant connected to an electric power transmission grid.

- the apparatus of the present invention is comprised primarily of one or more monitoring devices that collect the information necessary to determine the electric power flow on any particular transmission line being monitored.

- a monitoring device in accordance with the present invention is installed in a fixed location near a high-voltage electric power transmission line. During the installation process, appropriate measurements are made to establish the spatial relationship between the monitoring device and the multiple phase conductors of the transmission line.

- the monitoring device is primarily comprised of sensing elements responsive to the electric potential and the magnetic flux densities associated with the transmission line, therefore allowing for periodic or continuous measurements of the electric potential and magnetic flux densities associated with the transmission line.

- the method of the present invention relates not only to the collection of information, but also the transmission and processing of the collected information.

- the method of the present invention contemplates discreet or continuous data transmissions of collected information from remote monitoring devices, each of which monitors a particular transmission line or lines, to a central processing facility where a computational analysis is conducted to calculate the amount and direction of both real and reactive electric power flowing on each monitored set of transmission lines.

- the resulting power data can be further analyzed and compiled to determine the net electric power output of any electric power generating facility connected to the monitored transmission lines.

- FIG. 1 is a perspective view of a preferred embodiment of the apparatus for the measurement and monitoring of electric power generation and transmission in accordance with the present invention

- FIG. 2 is a plan view of the interior of the first weatherproof housing of the apparatus of FIG. 1, which contains the electric and magnetic field measurement components necessary to carry out the function of the present invention, with the door of the housing in the open position;

- FIG. 3 is a block diagram depicting the preferred method for the measurement and monitoring of electric power generation and transmission in accordance with the present invention

- FIG. 4 is a block diagram depicting the preferred method of communicating information associated with the measured electric power generation and transmission in accordance with the present invention

- FIG. 5 is a schematic circuit diagram of a preferred amplification and filtration circuit for the magnetic field measurements associated with the apparatus and method of the present invention

- FIG. 6 is a schematic circuit diagram of a preferred amplification and filtration circuit for the electric potential measurements associated with the apparatus and method of the present invention

- FIG. 7 is a schematic representation of magnetic flux associated with a conductor through which current passes

- FIG. 8 is a schematic representation showing the phasor relationship between the unit phasor components present in an infinitely long, three-phase electric power transmission line;

- FIG. 9 is a schematic representation of an exemplary three-phase electric power transmission line geometry with a pair of magnetic field sensors located at ground level for measuring the magnetic flux density associated with the transmission line;

- FIG. 10 is a schematic representation of the three conductors of a three-phase electric power transmission line, with an electric potential sensor located a predetermined distance above ground level for measuring the electric potential associated with the transmission line;

- FIG. 11 is a schematic representation showing the capacitances resulting from the interaction between the conductors of a three-phase electric power transmission line and an electric potential sensor;

- FIG. 12 is a typical circuit diagram explaining the relationship of the capacitances shown in FIG. 11.

- FIG. 13 depicts a common arrangement of electric power transmission lines in which independent parallel circuits are disposed on opposite sides of a supporting tower.

- the present invention is an apparatus and method for the measurement and monitoring of electric power generation and transmission associated with one or more electric power generating plants. This is preferably accomplished through measurement and collection of data related to the amount of electric power flowing over one or more transmission lines operably connected to a particular electric power grid and operably connected to said one or more electric power generating plants. Computational analysis of this data allows for a determination of the specific amount of electric power being generated by these electric power plants connected to the transmission and distribution grid.

- Electric power is distributed over most public transmission grids in three-phase form, each of said phases being carried over a separate conductor.

- transmission line is used to refer to the three separate conductors.

- Each of these separate phases generates its own time-varying magnetic and electric field.

- the three phases are out of phase with each other by one third of a cycle, such that the sum of the fields generated by these three phases would essentially be zero if all three phases were transmitted over conductors that were closely packed.

- the physics of electric power transmission dictates that the three phases maintain physical separation, the distances for which are determined by factors such as line voltage, insulator effectiveness, etc. This physical separation means that the electric and magnetic fields produced by each phase do not completely cancel each other.

- any point in space around these three phases will contain an electric potential and a magnetic field that are determined by a known set of factors. These factors include: line voltage, amount of current, direction of current, spatial arrangement of the three conductors with respect to each other and to the measurement point, and the electromagnetic properties of the surrounding environment.

- the present invention employs sensors to measure the electric potential and the various vector components of the magnetic field surrounding the transmission lines.

- the equipment which is located remotely but within the general proximity of the transmission lines is referred to as the “monitoring device.”

- the monitoring device 10 consists of (1) a first weatherproof housing (generally indicated by reference numeral 12 ) containing the electric potential and magnetic field measurement components necessary to carry out the function of the present invention (the “sensor unit”), and (2) a second weatherproof housing (generally indicated by reference numeral 14 ) containing the necessary processing and communications components, including a power supply and data transmission equipment.

- a first weatherproof housing generally indicated by reference numeral 12

- a second weatherproof housing generally indicated by reference numeral 14

- all components could be combined in a single housing without departing from the spirit and scope of the present invention.

- FIG. 2 is a plan view of the sensor unit with the door 12 a of the weatherproof housing 12 in the open position and the measurement components generally shown.

- electric potential measurement is accomplished by the use of a conducting plate 16 which is oriented vertically with respect to the ground, although other geometrical arrangements may also be used.

- the conducting plate is mounted on the inside door 12 a of the weatherproof housing 12 and is isolated from the grounded door by means of a plurality of insulator bushings (indicated in phantom at the corners of the conducting plate 16 ).

- the conducting plate 16 together with the input capacitance of an operational amplifier circuit, create a capacitive voltage divider whose output voltage, an AC voltage at line frequency, is proportional to the net electric potential created by the voltages of the phases of the transmission lines.

- a conducting plate 16 is used as the electric potential sensor 16 in this preferred embodiment, other sensors, including a wire grid sensor or a wire cage sensor, could also be used without departing from the spirit and scope of the present invention.

- the output measurement from the conducting plate 16 is applied to an amplification and filtration circuit for the purpose of removing extraneous noise from the readings.

- the preferred amplification and filtration circuit is discussed in further detail below with reference to FIG. 6.

- Magnetic flux density measurement is accomplished by the use of coils 18 and 20 , as shown in FIG. 2. Although what is actually being measured is the magnetic flux density, for purposes of the description herein, the generic term “magnetic field sensor” is used as a reference to the sensor measuring magnetic flux density.

- the first magnetic field sensor 18 is preferably a coil that measures the horizontal component of the magnetic field and is mounted such that the axis of the coil is both oriented in the direction of the magnetic field component desired to be measured, i.e. horizontal, and oriented normally to the generally parallel planes defined by the conductors of the transmission line being monitored.

- the second magnetic field sensor 20 is a coil that preferably measures the vertical component, and is therefore vertically oriented with respect to underlying ground surface.

- each magnetic field sensor 18 , 20 (an AC voltage at line frequency) is directly proportional to the time rate of change of the net magnetic flux density created by the currents flowing through the three conductors of the transmission line.

- coils are the preferred magnetic field sensors 18 , 20 , other means for sensing the magnetic flux density may also be employed, e.g., Hall Effect sensors, without departing from the spirit and scope of the present invention.

- three coils may be utilized to improve accuracy or aid in alignment of the other two coils.

- the third coil could potentially improve accuracy in situations in which the conductors are sagging significantly.

- the addition of the third coil would be oriented such that the sensitive axes of the three sensors are mutually perpendicular.

- this third axis of measurement would necessitate modification of the computational analysis to include a third coordinate accordingly.

- the output measurements from the magnetic field sensors 18 , 20 are also respectively applied to amplification and filtration circuits (indicated generally by reference numerals 22 and 24 ) for the purpose of removing extraneous noise from the readings.

- amplification and filtration circuits are discussed in further detail below with reference to FIG. 5.

- the monitoring device 10 and specifically the sensor unit 12 , is governed by practical concerns such as access to property in close proximity to the transmission lines to be measured.

- the sensor unit 12 should be sufficiently close to the transmission line such that the sensors 16 , 18 , 20 are able to accurately measure the particular field being monitored.

- the magnetic field sensors 18 , 20 and the electric potential sensor 16 are housed in close proximity to one another so that they are measuring fields at essentially the same point in space.

- An alternative arrangement is to locate the sensors at different locations, i.e., positioning the electric field sensor closer to the transmission lines than the magnetic field sensors.

- One particular advantage of such an alternative arrangement is to provide improved accuracy in situations of sagging and swaying transmission lines; specifically, increased accuracy is achieved in the electric potential measurement without creating the possibility for interference with the magnetic field sensors. In other words, in some circumstances, it might be advisable to place the electric potential sensor in a housing or enclosure near the transmission line, whereas the magnetic sensors are contained in a separate housing or enclosure located farther away from the transmission line.

- FIG. 3 is a block diagram of the external, field-installed portion of the invention—the monitoring device 10 .

- the monitoring device 10 generally consists of the electric potential and magnetic field sensors 16 , 18 , 20 ; memory and data storage elements; programmable data processing elements; hard-wired or wireless communication elements; and a power supply.

- the monitoring device 10 is programmed such that it periodically collects data from various sensors, processes it into a form suitable for transmission, and transmits the information to a central processing facility where various processing routines are performed on the data to determine the amount and direction of electric power flowing over any particular electric power transmission line.

- the preferred monitoring device 10 includes at least two magnetic field sensors 18 , 20 , as described above with reference to FIG. 2 and which are oriented to respond to the horizontal (B H ) and vertical (B V ) components of the magnetic field, each sensor specifically measuring the time rate of change of the net magnetic flux density.

- the monitoring device of the present invention also includes an electric potential sensor 16 , which is also described above with reference to FIG. 2.

- the output voltage of the first magnetic field sensor 18 is applied to an amplification and filtration circuit 22 which has a dual function.

- the primary function of the amplification and filtration circuit 22 is to amplify the relatively small output voltage of the first magnetic field sensor 22 to a level that will be suitable as an input to an analog-to-digital converter.

- the secondary function of the circuit 22 is to serve as a low-pass filter, removing extraneous noise from the output voltage of the magnetic field sensor 18 .

- the output voltage of the second magnetic field sensor 20 is applied to another amplification and filtration circuit 24 to amplify the voltage and remove extraneous noise.

- the output voltage of the electric field sensor 16 is applied to yet another amplification and filtration circuit 26 to amplify the voltage and remove extraneous noise.

- the input impedances of the amplification and filtration circuits 22 , 24 , 26 affect the frequency responses and phase shifts of the respective sensors 16 , 18 , 20 so that, in fact, each sensor and associated amplification and filtration circuit combination functions as an integrated sensor. This is particularly important in the case of the electric potential sensor 16 as the input impedance of the amplification and filtration 26 must be very high in order to have the sensor/amplifier combination function at frequencies as low as 60 Hz.

- FIG. 5 depicts preferred amplification and filtration circuits 22 , 24 for the magnetic fields sensors 18 , 20 , as mentioned above with respect to FIG. 2.

- the output from each magnetic field sensor 18 , 20 is loaded by a capacitor 75 a, 75 b and a resistor 76 a, 76 b, whose respective values are selected to result in zero phase shift and a scale factor of 1.0 mv/milligauss for each sensor 18 , 20 , although it is understood that other capacitors may be used and the phase shifts corrected for computationally.

- Each output of the loaded sensors 18 , 20 is then passed through a two-section RC lowpass filter 77 a, 77 b to provide a measure of radio frequency interference rejection.

- the outputs from the RC lowpass filters 77 a, 77 b are applied to the input terminals of a standard instrumentation amplifier 78 a, 78 b (e.g., a differential amplifier), the resulting output voltages being proportional to vector components of the magnetic flux density as measured by the magnetic field sensors 18 , 20 .

- FIG. 6 depicts a preferred amplification and filtration circuit 26 for the electric potential sensor 16 , as mentioned above with respect to FIG. 2.

- the electric potential sensor 16 is connected through a capacitor 79 that functions as a DC block to a capacitor 80 connected to ground.

- This second capacitor 80 is referred to as “Ci” in the computational analysis that follows.

- the voltage across the second capacitor 80 is the input voltage to a standard operational amplifier active lowpass filter 81 , which inverts the signal and filters out high frequency noise with the resulting output voltage being proportional to electric potential density as measured by the electric potential sensor 16 .

- the output voltages are then applied to the inputs of an analog multiplexer (MUX) 56 .

- MUX analog multiplexer

- an apparatus in accordance with the present invention include a sample-and-hold amplifier for the output of each filtered coil sensor.

- the output voltages of the respective amplification and filtration circuits 22 , 24 , 26 would be applied to the inputs of such sample-and-hold amplifiers before such output voltages are applied to the MUX 56 in order to avoid time-skew in the subsequent conversion of these signals from analog to digital form.

- Sample-and-hold amplifiers are generally known in the art, and any conventional means for performing the sample-and-hold function maybe incorporated into the apparatus of the present invention as contemplated herein.

- the two magnetic flux density signals and the electric potential signal each is separately passed through an analog-to-digital (A/D) converter 58 .

- A/D analog-to-digital

- Which of the three signals is passed through to the analog-to-digital convertor 58 at any given time is determined by a control logic 60 associated with a microprocessor 62 .

- This microprocessor 62 executes software code stored in random access memory (RAM) 64 and read-only memory (ROM) 66 .

- Such software code derives from this digitized data the magnitude of the horizontal component of the magnetic flux density (B H ), the vertical component of the magnetic flux density (B V ), the magnitude of the electric potential signal (E), the phase angle of B H with respect to E (H a ), and the phase angle of B V with respect to E (V a ).

- the converted data now in digital form, is stored in the random access memory 64 of the microprocessor 62 .

- the outputted signal from the microprocessor 62 is then transmitted to one or both of a radio frequency (RF) transceiver 68 with associated transmission antenna 69 and a landline network 70 for subsequent transmission of the signal to a central processing facility.

- RF radio frequency

- the radio frequency (RF) transceiver 68 and any associated data transmission equipment is preferably contained in the second weatherproof housing 14 .

- the individual electronic components of the monitoring device 10 are preferably powered by a battery 72 that may be continuously recharged by a solar panel array 74 .

- the battery 72 is preferably contained in the second weatherproof housing 14 , and solar panel array 74 is external to the housing 14 , yet operably connected to the battery 72 .

- FIG. 4 is a block diagram of preferred communication components and the central processing facility of the apparatus and method of the present invention. These components are not installed in the field with the monitoring device 10 , but rather are located at some remote location. Specifically, the outputted signal from the microprocessor 62 depicted in FIG. 3 is transmitted to the central processing facility via one or both of a radio frequency (RF) transceiver 68 with associated transmission antenna 69 and a landline network 70 .

- RF radio frequency

- a receiving antenna 100 or similar communication component receives this transmitted signal, which is representative of the measurements of the electric potential and magnetic field vectors in digital form.

- the receiving antenna 100 is operably connected to an analog or digital communications network 102 which transmits the signal to the central processing facility 110 .

- Such transmission may be carried out, for example, by a satellite link 104 , a microwave link 106 , and/or a fiber optic link 108 , although other data transmission means may certainly be used without departing from the spirit and scope of the present invention.

- a computational analysis is performed by a digital computer program 112 to determine the magnitude and direction of the real and reactive power flow on the transmission line. Subsequently, for any particular electric power generation facility for which all, or most of, the connected transmission lines are measured and calculated in accordance with the present invention, through a simple summing of the power flows on each transmission line, the net electric power output of the facility can be determined. Then, such electric power generation and transmission data associated with one or more electric power generating plants can then be communicated to third parties.

- Such communication to third parties be through export of the data to an access-controlled Internet web site 114 , which also may maintain an extensive database of physical and electric parameters of various electric power transmission lines.

- the data associated with electric power plants of interest to a particular party are then available to that party through a common Internet browser program 116 , such as Netscape Navigator® or Microsoft Internet Explorer®.

- the communications channel from the microprocessor 62 of the local monitoring device 10 to the central processing facility 110 may be bi-directional so that the information maintained and stored in the microprocessor 62 may be sent out on a scheduled basis or may be polled. Furthermore, through bi-directional communications, the microprocessor 62 is remotely re-programmable.

- the data is used to computationally estimate the amount of electric power being transmitted over the transmission line associated with the collected data. More specifically, for any particular transmission line, certain of the variables that govern the electric potential and magnetic field vectors measured by the sensors are constants, independent of the amount of electric power flowing on the lines. For each transmission line, it is possible to ascertain the line voltage ratings and insulative properties from either direct observation or publicly available information. Simple measurements accomplished with a visual measuring device such as a laser range-finder are used to determine the spatial arrangement of the conductors with respect to each other and with respect to the measurement point.

- measurements may be affected by slight changes in variables, such as temperature and power flow on the transmission lines; however, appropriate corrections can be made computationally.

- the only required variables that are not constants, independent of time, are the amount of current flowing over each of the three conductors and the direction of electric power flow. The data provided by the monitoring device enables these variables to be calculated.

- the magnitude and direction of the electric power flowing through a given transmission line, along with the real and reactive components of that power, can be determined through a computational analysis preferably carried out using a digital computer program.

- the horizontal and vertical magnetic field components calculated in the analysis component depend linearly on the line currents, albeit with complex coefficients. That is, the horizontal magnetic field component can be represented by a complex number (a phasor) that is a linear combination of the horizontal magnetic field contributions caused by each of the three conductors of the three-phase transmission line, with the coefficients of combination being complex numbers determined from the geometrical arrangement of the conductors and the sensor location with respect to the conductors. In other words, there results n complex simultaneous linear equations in n complex unknowns with n squared complex coefficients.

- a complex number a phasor

- Such a set of equations is invertible (i.e., it may be solved by a number of means, such by the use of Cramer's Rule or by Gaussian elimination) and is solved analytically. Given perfect measurements (or actual measurements, perfectly corrected) the real and imaginary components of the electric power on the line are determined exactly.

- the preferred method of computational analysis has two components.

- the first component of the computational analysis is run off-line. It consists of computation of the complex coefficients of the above-referenced set of simultaneous linear equations which define the geometrical arrangement of the conductors and the sensor location with respect to the conductors, followed by inversion of the coefficient matrix. These results are stored in a database.

- This first component of the computational analysis needs to be performed only once for a given installation of a monitoring device with respect to a particular transmission line.

- the second component is run on-line. It corrects the measured phase angle for sensor errors and geometrically induced errors to get actual horizontal and vertical magnetic field values, and multiplies the resulting measurement vector by the inverted coefficient matrix referred to above to determine line current and phase angle.

- the sensed phase angle differs from the phase angle on the transmission line in a very complicated way, being affected by: the geometrical relationships between the conductors of the transmission line and the location of the monitoring device in three-dimensional space; sag of the transmission line; and the inherent minor inaccuracies of the sensors and their associated electronics. Nevertheless, many, if not all, of the resulting errors can be calculated and compensated for, leading to a computational estimate of the power factor on the line. Since the phase angle on the transmission line is calculated, and the real and reactive powers are calculated as signed quantities, the direction of flow of both the real and the imaginary components of the apparent power can be determined as well.

- measurements of the generated magnetic field can be determined, which then allows for a determination of the power on the transmission line in question through careful application of known mathematical algorithms to the field data collected.

- known mathematical algorithms to the field data collected.

- the transmission line is oriented parallel to a flat, perfectly conducting Earth.

- H I 2 ⁇ ⁇ ⁇ ⁇ r ⁇ ⁇ Amp ⁇ / ⁇ m ( 1 )

- I is the current flowing through the conductor

- r is the distance from the conductor to the point at which the magnetic field intensity is being measured. It is somewhat more common to refer to the strength of a magnetic field in terms of the magnetic flux density B.

- the magnetic flux density is defined as:

- this formula can be used to determine the magnetic flux density B in milligauss at a distance r (measured in meters) from an infinitely thin conductor carrying I Amperes of electrical current.

- H is a spatial vector

- B is also a spatial vector.

- the direction of the magnetic flux density B is perpendicular to a line drawn from the measurement point to the nearest point on the conductor.

- the magnetic flux lines are directed counter-clockwise, giving a magnetic flux density vector B directed as shown in FIG. 7.

- the angle ⁇ is the angle between r (the line drawn from the measurement point P and the conductor) and the positive x-axis. Since B is perpendicular to r, the spatial vector B can be resolved into its horizontal and vertical components B X and B Y . For a single conductor carrying direct current (DC), the x and y components are simply determined by:

- a three-phase alternating current (AC) electric power transmission line there are three conductors, carrying currents that are 120° apart in time phase.

- the time relationship between the currents may be represented by phasors, as in standard AC circuit analysis.

- FIG. 8 is a diagram showing the phasor relationship between the unit phasor components present in an infinitely long, three-phase transmission line over the flat Earth.

- Io is the (signed) RMS amplitude of the current on each conductor

- A, B, and C are unit phasors chosen to be 120° apart, as follows:

- the x and y coordinates of the three conductors of a three-phase transmission line may be designated as (x C1 , y C1 ), (x C2 , y C2 ), and (x C3 , y C3 ) respectively.

- the geometric distances and respective angles in equations (17) through (22) may be calculated by:

- r 1 ⁇ square root ⁇ square root over ( ) ⁇ [( x C1 ⁇ x S ) 2 +( y C1 ⁇ y S ) 2 ] (23)

- r 3 ⁇ square root ⁇ square root over ( ) ⁇ [( x C3 ⁇ x S ) 2 +( y C3 ⁇ y S ) 2 ] (25)

- ⁇ 1 tan ⁇ 1 [( y C1 ⁇ y S )/( x C1 ⁇ x s )] (26)

- Equations (29) and (30) have been derived under the assumption that the current on the first conductor line 1 (phase 1 ) is governed by equation (3), that is:

- Io is a scalar element, which may be either positive or negative.

- the current on the first conductor may have any phase relationship. Its phase has meaning only with respect to some well-defined phase reference, which will be defined below as the phase of the voltage on the first conductor.

- Io is not a scalar, but rather is also a phasor and is hereinafter denoted by Io, where

- equation (31) becomes:

- Equations (29) and (30) must be suitably modified as well:

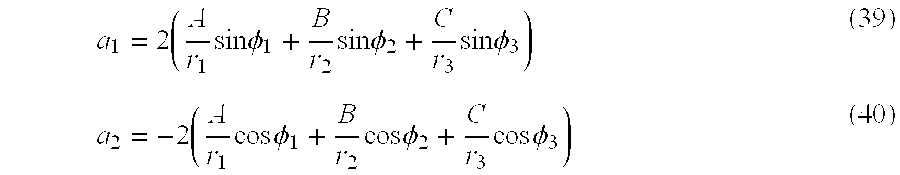

- B H 2 ⁇ Io ⁇ ( A r 1 ⁇ sin ⁇ ⁇ ⁇ 1 + B r 2 ⁇ sin ⁇ ⁇ ⁇ 2 + C r 3 ⁇ sin ⁇ ⁇ ⁇ 3 ) ( 35 )

- B V - 2 ⁇ Io ⁇ ( A r 1 ⁇ cos ⁇ ⁇ ⁇ 1 + B r 2 ⁇ cos ⁇ ⁇ ⁇ 2 + C r 3 ⁇ cos ⁇ ⁇ ⁇ 3 ) ( 36 )

- Equations (35) and (36) can therefore be rewritten as:

- a 1 and a 2 are complex constants depending on the line geometry, and equations (37) and (38) state that the horizontal and vertical magnetic flux densities B H and B V , as phasors, may be obtained by multiplying the complex phasor current Io by a 1 and a 2 , respectively.

- the phasor Io in both magnitude and angle, can be determined from a measurement of the horizontal component of the magnetic flux density B H , or from measurement of the vertical component of the magnetic flux density B V by dividing by the appropriate complex number (a 1 or a 2 ).

- FIG. 9 is an example of a line geometry with a pair of magnetic field sensors 18 ′, 20 ′ located at ground level.

- the sensors 18 ′, 20 ′ are located fifty feet below the level of the power lines, and fifty feet lateral of the first phase of the line. In this example, fifty feet separate the conductors from one another. Solving for the distance and angle parameters:

- Equation (35) 2 ⁇ Io ⁇ ( A ⁇ ( 0.707 ) ( 21.56 ) + B ⁇ ( 0.8944 ) ( 34.09 ) + C ⁇ ( 0.949 ) ( 48.20 ) ) ( 58 )

- B V - 2 ⁇ Io ⁇ ( A ⁇ ( 0.707 ) ( 21.56 ) + B ⁇ ( 0.447 ) ( 34.09 ) + C ⁇ ( 0.316 ) ( 48.20 ) ) ( 59 )

- phase of the measured horizontal magnetic flux density ( ⁇ 29.98°) is approximately the same as the phase of the first conductor (0°), with a rather large 29.98° error.

- the 29.98° error depends only on the geometry of the conductor arrangement, it can be calculated and accounted for.

- V L is the line voltage

- I L is the line current

- ⁇ is the difference between the phase of the line voltage and the phase of the line current. Therefore, the phase of the voltage on the line must be determined as well.

- FIG. 10 shows the three conductors of a three-phase electric power transmission line, with an electric potential sensor 16 ′ located distance y S above the Earth.

- the electric field in the region above the Earth may be determined by adding a set of image conductors symmetrically placed with respect to the x-axis, each with the opposite sign of the voltage when compared to the real conductors above ground.

- the voltage on the first conductor is V 1

- the voltage on its image conductor is ⁇ V 1

- the second and third conductors are imaged in the same manner.

- the electric potential sensor 16 ′ itself is a metal plate oriented roughly perpendicular to the line of sight from the sensor location at coordinates (0, y S ) to the average position of the transmission line conductors. Any given transmission line conductor, together with the metal plate 16 ′, constitute two pieces of conducting material with an insulator (air) in between. In that sense, the transmission line conductor and the metal plate 16 ′ form a capacitor, which is defined as two conducting objects separated by, or immersed in, a dielectric medium. Therefore, there exists a capacitance between each conductor (including the image conductors) and the electric potential sensor 16 ′.

- the electric potential sensor 16 ′ is connected to ground through a conventional electrical capacitor Ci, forming an electrical circuit, an example of which is shown in FIG. 11.

- Equation (70) applies only for two finite area plates of large extent compared to their separation (so that fringing may be neglected), it may be used to approximate the size of the capacitances shown in FIG. 11.

- 34.64 0.0185 ⁇ ⁇ pF ( 87 )

- the capacitive divider output is a highly attenuated linear combination of the line-to-ground voltages appearing on each of the three phases of the electric power transmission line.

- the voltage developed across the capacitor Ci has a magnitude of 55.4 mv, with a phase angle of ⁇ 8.95°.

- the output voltage of the capacitive divider not only provides a voltage whose magnitude is proportional to the magnitude of the line-to-line voltage on the electric power transmission line, but whose phase is approximately the phase of the voltage on the first conductor, the nearest conductor in this example.

- the error in measuring the phase of the line-to-ground voltage on the first conductor ( ⁇ 8.95° in this case) is dependent only on the geometry of the line conductor with respect to the monitoring device 10 ′ location. Therefore, it may be calculated and corrected for if the geometry is known.

- V o 0.0554 ⁇ 8.95 (96)

- the output of the electric potential sensor 16 ′ lags the voltage in the first conductor by 8.95°, and the output voltage of the magnetic field sensor 18 ′ lags the current through the first conductor by 29.98°.

- the phase angle ⁇ L in the transmission line can be obtained by correcting this difference by adding the difference of the two sensor errors—and these may be computed a priori from the geometrical arrangement of the sensors with respect to the transmission line conductors.

- the essential objective of the present invention is to determine by remote sensors, the total power output of an electric power generating plant, accurate determination of the direction of the power flow on a line is as important as determination of the magnitude of the power flow. Specifically, it is necessary to distinguish between the electric power coming out of an electric power generation plant and the power going in.

- MVAR w 1 MVAR H +w 2 MVAR v (106)

- the average of the horizontal and vertical measurements provides a more accurate measurement than that provided by either measurement taken alone.

- weighting factors can be defined as:

- a 11 ⁇ ⁇ ⁇ 2 ⁇ ⁇ ⁇ A r 11 ⁇ sin ⁇ ⁇ ⁇ 11 + B r 12 ⁇ sin ⁇ ⁇ ⁇ 12 + C r 13 ⁇ sin ⁇ ⁇ ⁇ 13 ⁇ ( 118 )

- a 12 ⁇ ⁇ ⁇ 2 ⁇ ⁇ ⁇ A r 14 ⁇ sin ⁇ ⁇ ⁇ 14 + B r 15 ⁇ sin ⁇ ⁇ ⁇ 15 + C r 16 ⁇ sin ⁇ ⁇ ⁇ 16 ⁇ ( 119 )

- a 21 ⁇ ⁇ ⁇ - 2 ⁇ ⁇ ⁇ A r 11 ⁇ cos ⁇ ⁇ ⁇ 11 + B r 12 ⁇ cos ⁇ ⁇ ⁇ 12 + C r 13 ⁇ cos ⁇ ⁇ ⁇ 13 ⁇ ( 120 )

- a 22 ⁇ ⁇ ⁇ - 2 ⁇ ⁇ ⁇ A r 14 ⁇ cos

- r ij is the distance from the sensor location to the j th conductor

- ⁇ 1j is the angle between the line-of-sight to the j th conductor and the positive x-axis.

- Equation (117) may be re-written in vector-matrix form as:

- Equation (123) may be solved in several ways for I:

- equation (123) may be solved by Gaussian elimination.

- I is a 2-vector of complex phasors

- B is a 2-vector of complex phasors

- A is a 2 ⁇ 2 matrix of complex co-efficients.

- the foregoing computational analysis thus allows for calculation of the magnitude and direction of the electric power flowing through a given transmission line from data collected by the monitoring device 10 of the present invention.

- this computational analysis is preferably carried using a digital computer program at the central processing facility.

- computational analysis could also be carried out by the microprocessor associated with the monitoring device itself.

Landscapes

- Physics & Mathematics (AREA)

- General Physics & Mathematics (AREA)

- Engineering & Computer Science (AREA)

- Power Engineering (AREA)

- Measuring Magnetic Variables (AREA)

- Arrangements For Transmission Of Measured Signals (AREA)

- Cable Transmission Systems, Equalization Of Radio And Reduction Of Echo (AREA)

Abstract

An apparatus in accordance with the present invention allows for a determination of the amount and direction of electric power flowing over a particular high-voltage electric power transmission line without proximate access to said transmission line, and further allows for a determination of the amount of electric power being produced by any particular electric power generation plant connected to an electric power transmission grid.

Description

- The present application claims priority from U.S.

provisional application 60/196,720 filed on Apr. 13, 2000 and U.S.provisional application 60/226,130 filed Aug. 18, 2000. This application relates to an apparatus and method for the measurement and monitoring of electric power generation and transmission associated with one or more power generating plants. The entire disclosures contained in U.S.provisional applications 60/196,720 and 60/226,130, including the attachments thereto, are incorporated herein by this reference. - Various apparatus and methods currently exist for measuring and monitoring the amount of electric power generated by any particular electric power generation facility connected to an electric power transmission grid. Common apparatus and methods are also available for measuring and monitoring the amount of electric power flowing over any particular transmission line. Specifically, most electric power plant operators employ a Supervisory Control and Data Acquisition (SCADA) system to monitor their electric power generation and transmission systems. Each substation connected to the transmission grid is equipped with several potential transformers (PT) and current transformers (CT) to measure the voltage, current, and electric power flow on each line and bus. The PT and CT data is monitored in real time and transmitted back to a central computer from each substation through a Remote Terminal Unit (RTU) using various wired and wireless communication methods. Such data is compiled to provide the electric power plant operators with accurate and up-to-date generation and transmission data.

- Of course, implementation of these methods requires proximate access to the physical facilities associated with the generation and transmission of electric power. The owner or manager of these physical facilities is able to control or limit proximate access to said facilities, and thus is able to prevent any particular party that employs current technology from directly measuring and monitoring either the amount of electric power flowing over a particular transmission line or the amount of electric power being generated by a particular electric power generation facility. Information about electric transmission line flows and electric power generation facility output is useful and valuable for companies engaged in the business of buying and selling electricity on the open market, and power plant operators currently do not release this information to other participants in the market.

- It is thus a paramount object of the present invention to provide an apparatus and method for the measurement and monitoring of electric power generation and transmission associated with a plurality of power generation plants without necessity of proximate access to the physical facilities associated with the generation and transmission of electric power.

- It is a further object of the present invention to provide an apparatus and method that is capable of ascertaining both the amount and direction of electric power flowing over transmission lines and the amount of electric power generated by any electric power generation plant connected to those lines without necessity of proximate access to the physical facilities associated with the generation and transmission of electric power.

- These and other objects and advantages of the present invention will become apparent upon a reading of the following description.

- The present invention is an apparatus and method for the measurement and monitoring of electric power generation and transmission associated with one or more power generating plants. Specifically, the apparatus and method of the present invention allows for a determination of the amount and direction of electric power flowing over a particular high-voltage electric power transmission line, allows for a determination of the real and reactive components of the electric power, and further allows for a determination of the amount of electric power being produced by any particular electric power generation plant connected to an electric power transmission grid.

- The apparatus of the present invention is comprised primarily of one or more monitoring devices that collect the information necessary to determine the electric power flow on any particular transmission line being monitored. Specifically, a monitoring device in accordance with the present invention is installed in a fixed location near a high-voltage electric power transmission line. During the installation process, appropriate measurements are made to establish the spatial relationship between the monitoring device and the multiple phase conductors of the transmission line. The monitoring device is primarily comprised of sensing elements responsive to the electric potential and the magnetic flux densities associated with the transmission line, therefore allowing for periodic or continuous measurements of the electric potential and magnetic flux densities associated with the transmission line.

- The method of the present invention relates not only to the collection of information, but also the transmission and processing of the collected information. Specifically, the method of the present invention contemplates discreet or continuous data transmissions of collected information from remote monitoring devices, each of which monitors a particular transmission line or lines, to a central processing facility where a computational analysis is conducted to calculate the amount and direction of both real and reactive electric power flowing on each monitored set of transmission lines. The resulting power data can be further analyzed and compiled to determine the net electric power output of any electric power generating facility connected to the monitored transmission lines.

- FIG. 1 is a perspective view of a preferred embodiment of the apparatus for the measurement and monitoring of electric power generation and transmission in accordance with the present invention;

- FIG. 2 is a plan view of the interior of the first weatherproof housing of the apparatus of FIG. 1, which contains the electric and magnetic field measurement components necessary to carry out the function of the present invention, with the door of the housing in the open position;

- FIG. 3 is a block diagram depicting the preferred method for the measurement and monitoring of electric power generation and transmission in accordance with the present invention;

- FIG. 4 is a block diagram depicting the preferred method of communicating information associated with the measured electric power generation and transmission in accordance with the present invention;

- FIG. 5 is a schematic circuit diagram of a preferred amplification and filtration circuit for the magnetic field measurements associated with the apparatus and method of the present invention;

- FIG. 6 is a schematic circuit diagram of a preferred amplification and filtration circuit for the electric potential measurements associated with the apparatus and method of the present invention;

- FIG. 7 is a schematic representation of magnetic flux associated with a conductor through which current passes;

- FIG. 8 is a schematic representation showing the phasor relationship between the unit phasor components present in an infinitely long, three-phase electric power transmission line;

- FIG. 9 is a schematic representation of an exemplary three-phase electric power transmission line geometry with a pair of magnetic field sensors located at ground level for measuring the magnetic flux density associated with the transmission line;

- FIG. 10 is a schematic representation of the three conductors of a three-phase electric power transmission line, with an electric potential sensor located a predetermined distance above ground level for measuring the electric potential associated with the transmission line;

- FIG. 11 is a schematic representation showing the capacitances resulting from the interaction between the conductors of a three-phase electric power transmission line and an electric potential sensor;

- FIG. 12 is a typical circuit diagram explaining the relationship of the capacitances shown in FIG. 11; and

- FIG. 13 depicts a common arrangement of electric power transmission lines in which independent parallel circuits are disposed on opposite sides of a supporting tower.

- The present invention is an apparatus and method for the measurement and monitoring of electric power generation and transmission associated with one or more electric power generating plants. This is preferably accomplished through measurement and collection of data related to the amount of electric power flowing over one or more transmission lines operably connected to a particular electric power grid and operably connected to said one or more electric power generating plants. Computational analysis of this data allows for a determination of the specific amount of electric power being generated by these electric power plants connected to the transmission and distribution grid.

- Electric power is distributed over most public transmission grids in three-phase form, each of said phases being carried over a separate conductor. For purposes of the present application, the term “transmission line” is used to refer to the three separate conductors. Each of these separate phases generates its own time-varying magnetic and electric field. The three phases are out of phase with each other by one third of a cycle, such that the sum of the fields generated by these three phases would essentially be zero if all three phases were transmitted over conductors that were closely packed. The physics of electric power transmission, however, dictates that the three phases maintain physical separation, the distances for which are determined by factors such as line voltage, insulator effectiveness, etc. This physical separation means that the electric and magnetic fields produced by each phase do not completely cancel each other. In accordance with the Biot-Savart Law of Magnetic Fields and Laplace's Equation, any point in space around these three phases will contain an electric potential and a magnetic field that are determined by a known set of factors. These factors include: line voltage, amount of current, direction of current, spatial arrangement of the three conductors with respect to each other and to the measurement point, and the electromagnetic properties of the surrounding environment.

- The present invention employs sensors to measure the electric potential and the various vector components of the magnetic field surrounding the transmission lines. For purposes of this description, the equipment which is located remotely but within the general proximity of the transmission lines is referred to as the “monitoring device.”

- Referring now to FIG. 1, in the preferred embodiment, the

monitoring device 10 consists of (1) a first weatherproof housing (generally indicated by reference numeral 12) containing the electric potential and magnetic field measurement components necessary to carry out the function of the present invention (the “sensor unit”), and (2) a second weatherproof housing (generally indicated by reference numeral 14) containing the necessary processing and communications components, including a power supply and data transmission equipment. Of course, all components could be combined in a single housing without departing from the spirit and scope of the present invention. - FIG. 2 is a plan view of the sensor unit with the

door 12 a of theweatherproof housing 12 in the open position and the measurement components generally shown. In this preferred embodiment, electric potential measurement is accomplished by the use of a conductingplate 16 which is oriented vertically with respect to the ground, although other geometrical arrangements may also be used. The conducting plate is mounted on theinside door 12 a of theweatherproof housing 12 and is isolated from the grounded door by means of a plurality of insulator bushings (indicated in phantom at the corners of the conducting plate 16). The conductingplate 16, together with the input capacitance of an operational amplifier circuit, create a capacitive voltage divider whose output voltage, an AC voltage at line frequency, is proportional to the net electric potential created by the voltages of the phases of the transmission lines. Of course, although a conductingplate 16 is used as theelectric potential sensor 16 in this preferred embodiment, other sensors, including a wire grid sensor or a wire cage sensor, could also be used without departing from the spirit and scope of the present invention. - Regardless, although not shown in FIG. 2, the output measurement from the conducting

plate 16 is applied to an amplification and filtration circuit for the purpose of removing extraneous noise from the readings. The preferred amplification and filtration circuit is discussed in further detail below with reference to FIG. 6. - Magnetic flux density measurement is accomplished by the use of

coils magnetic field sensor 18 is preferably a coil that measures the horizontal component of the magnetic field and is mounted such that the axis of the coil is both oriented in the direction of the magnetic field component desired to be measured, i.e. horizontal, and oriented normally to the generally parallel planes defined by the conductors of the transmission line being monitored. Likewise, the secondmagnetic field sensor 20 is a coil that preferably measures the vertical component, and is therefore vertically oriented with respect to underlying ground surface. Of course, non-horizontal and/or non-vertical vector components could also be measured without departing from the spirit and scope of the present invention. Furthermore, as will become clear in the computational analysis that follows, only one magnetic sensor is actually required to carry out the requisite magnetic flux density measurement in accordance with the present invention. - The voltage across each

magnetic field sensor 18, 20 (an AC voltage at line frequency) is directly proportional to the time rate of change of the net magnetic flux density created by the currents flowing through the three conductors of the transmission line. Although coils are the preferredmagnetic field sensors - Of further note, three coils may be utilized to improve accuracy or aid in alignment of the other two coils. The third coil could potentially improve accuracy in situations in which the conductors are sagging significantly. The addition of the third coil would be oriented such that the sensitive axes of the three sensors are mutually perpendicular. Of course, the addition of this third axis of measurement would necessitate modification of the computational analysis to include a third coordinate accordingly.

- As further shown in FIG. 2, the output measurements from the

magnetic field sensors reference numerals 22 and 24) for the purpose of removing extraneous noise from the readings. The preferred amplification and filtration circuits are discussed in further detail below with reference to FIG. 5. - Location of the

monitoring device 10, and specifically thesensor unit 12, is governed by practical concerns such as access to property in close proximity to the transmission lines to be measured. In any case, thesensor unit 12 should be sufficiently close to the transmission line such that thesensors magnetic field sensors potential sensor 16 are housed in close proximity to one another so that they are measuring fields at essentially the same point in space. An alternative arrangement is to locate the sensors at different locations, i.e., positioning the electric field sensor closer to the transmission lines than the magnetic field sensors. One particular advantage of such an alternative arrangement is to provide improved accuracy in situations of sagging and swaying transmission lines; specifically, increased accuracy is achieved in the electric potential measurement without creating the possibility for interference with the magnetic field sensors. In other words, in some circumstances, it might be advisable to place the electric potential sensor in a housing or enclosure near the transmission line, whereas the magnetic sensors are contained in a separate housing or enclosure located farther away from the transmission line. - FIG. 3 is a block diagram of the external, field-installed portion of the invention—the

monitoring device 10. As shown, themonitoring device 10 generally consists of the electric potential andmagnetic field sensors monitoring device 10 is programmed such that it periodically collects data from various sensors, processes it into a form suitable for transmission, and transmits the information to a central processing facility where various processing routines are performed on the data to determine the amount and direction of electric power flowing over any particular electric power transmission line. - Specifically, the

preferred monitoring device 10 includes at least twomagnetic field sensors potential sensor 16, which is also described above with reference to FIG. 2. - The output voltage of the first

magnetic field sensor 18 is applied to an amplification andfiltration circuit 22 which has a dual function. The primary function of the amplification andfiltration circuit 22 is to amplify the relatively small output voltage of the firstmagnetic field sensor 22 to a level that will be suitable as an input to an analog-to-digital converter. The secondary function of thecircuit 22 is to serve as a low-pass filter, removing extraneous noise from the output voltage of themagnetic field sensor 18. Similarly, the output voltage of the secondmagnetic field sensor 20 is applied to another amplification andfiltration circuit 24 to amplify the voltage and remove extraneous noise. Finally, the output voltage of theelectric field sensor 16 is applied to yet another amplification andfiltration circuit 26 to amplify the voltage and remove extraneous noise. - The input impedances of the amplification and

filtration circuits respective sensors potential sensor 16 as the input impedance of the amplification andfiltration 26 must be very high in order to have the sensor/amplifier combination function at frequencies as low as 60 Hz. - FIG. 5 depicts preferred amplification and

filtration circuits magnetic fields sensors magnetic field sensor capacitor resistor sensor sensors RC lowpass filter 77 a, 77 b to provide a measure of radio frequency interference rejection. Finally, the outputs from the RC lowpass filters 77 a, 77 b are applied to the input terminals of astandard instrumentation amplifier 78 a, 78 b (e.g., a differential amplifier), the resulting output voltages being proportional to vector components of the magnetic flux density as measured by themagnetic field sensors - FIG. 6 depicts a preferred amplification and

filtration circuit 26 for the electricpotential sensor 16, as mentioned above with respect to FIG. 2. Although various similar circuits could be employed by one of ordinary skill to achieve the same objective, in the preferred circuit of FIG. 6, the electricpotential sensor 16 is connected through acapacitor 79 that functions as a DC block to acapacitor 80 connected to ground. Thissecond capacitor 80 is referred to as “Ci” in the computational analysis that follows. The voltage across thesecond capacitor 80 is the input voltage to a standard operational amplifieractive lowpass filter 81, which inverts the signal and filters out high frequency noise with the resulting output voltage being proportional to electric potential density as measured by the electricpotential sensor 16. - After the amplification and filtration of the respective signals as described above, the output voltages are then applied to the inputs of an analog multiplexer (MUX) 56.

- Before completing the description of the amplification and filtration circuitry, however, it is noteworthy that in an alternate embodiment, it is contemplated that an apparatus in accordance with the present invention include a sample-and-hold amplifier for the output of each filtered coil sensor. The output voltages of the respective amplification and

filtration circuits MUX 56 in order to avoid time-skew in the subsequent conversion of these signals from analog to digital form. Sample-and-hold amplifiers are generally known in the art, and any conventional means for performing the sample-and-hold function maybe incorporated into the apparatus of the present invention as contemplated herein. - From the

MUX 56, the two magnetic flux density signals and the electric potential signal each is separately passed through an analog-to-digital (A/D)converter 58. Which of the three signals is passed through to the analog-to-digital convertor 58 at any given time is determined by acontrol logic 60 associated with amicroprocessor 62. Thismicroprocessor 62 executes software code stored in random access memory (RAM) 64 and read-only memory (ROM) 66. Such software code derives from this digitized data the magnitude of the horizontal component of the magnetic flux density (BH), the vertical component of the magnetic flux density (BV), the magnitude of the electric potential signal (E), the phase angle of BH with respect to E (Ha), and the phase angle of BV with respect to E (Va). - The converted data, now in digital form, is stored in the

random access memory 64 of themicroprocessor 62. The outputted signal from themicroprocessor 62 is then transmitted to one or both of a radio frequency (RF)transceiver 68 with associatedtransmission antenna 69 and alandline network 70 for subsequent transmission of the signal to a central processing facility. Referring back to FIG. 1, the radio frequency (RF)transceiver 68 and any associated data transmission equipment is preferably contained in the secondweatherproof housing 14. - Finally, with respect to FIG. 3, the individual electronic components of the

monitoring device 10 are preferably powered by abattery 72 that may be continuously recharged by asolar panel array 74. Referring again to FIG. 1, thebattery 72 is preferably contained in the secondweatherproof housing 14, andsolar panel array 74 is external to thehousing 14, yet operably connected to thebattery 72. - FIG. 4 is a block diagram of preferred communication components and the central processing facility of the apparatus and method of the present invention. These components are not installed in the field with the

monitoring device 10, but rather are located at some remote location. Specifically, the outputted signal from themicroprocessor 62 depicted in FIG. 3 is transmitted to the central processing facility via one or both of a radio frequency (RF)transceiver 68 with associatedtransmission antenna 69 and alandline network 70. A receivingantenna 100 or similar communication component receives this transmitted signal, which is representative of the measurements of the electric potential and magnetic field vectors in digital form. The receivingantenna 100 is operably connected to an analog ordigital communications network 102 which transmits the signal to thecentral processing facility 110. Such transmission may be carried out, for example, by asatellite link 104, amicrowave link 106, and/or afiber optic link 108, although other data transmission means may certainly be used without departing from the spirit and scope of the present invention. - At the

central processing facility 110, a computational analysis, as will be described in detail below, is performed by adigital computer program 112 to determine the magnitude and direction of the real and reactive power flow on the transmission line. Subsequently, for any particular electric power generation facility for which all, or most of, the connected transmission lines are measured and calculated in accordance with the present invention, through a simple summing of the power flows on each transmission line, the net electric power output of the facility can be determined. Then, such electric power generation and transmission data associated with one or more electric power generating plants can then be communicated to third parties. It is contemplated and preferred that such communication to third parties be through export of the data to an access-controlledInternet web site 114, which also may maintain an extensive database of physical and electric parameters of various electric power transmission lines. The data associated with electric power plants of interest to a particular party are then available to that party through a commonInternet browser program 116, such as Netscape Navigator® or Microsoft Internet Explorer®. - As an additional refinement, the communications channel from the

microprocessor 62 of thelocal monitoring device 10 to thecentral processing facility 110 may be bi-directional so that the information maintained and stored in themicroprocessor 62 may be sent out on a scheduled basis or may be polled. Furthermore, through bi-directional communications, themicroprocessor 62 is remotely re-programmable. - Returning to the computational analysis performed at the

central processing facility 110, once the requisite data has been collected and transmitted to thecentral processing facility 110, the data is used to computationally estimate the amount of electric power being transmitted over the transmission line associated with the collected data. More specifically, for any particular transmission line, certain of the variables that govern the electric potential and magnetic field vectors measured by the sensors are constants, independent of the amount of electric power flowing on the lines. For each transmission line, it is possible to ascertain the line voltage ratings and insulative properties from either direct observation or publicly available information. Simple measurements accomplished with a visual measuring device such as a laser range-finder are used to determine the spatial arrangement of the conductors with respect to each other and with respect to the measurement point. In this regard, it is understood that measurements may be affected by slight changes in variables, such as temperature and power flow on the transmission lines; however, appropriate corrections can be made computationally. The only required variables that are not constants, independent of time, are the amount of current flowing over each of the three conductors and the direction of electric power flow. The data provided by the monitoring device enables these variables to be calculated. - Specifically, with the data provided from the monitoring device, the magnitude and direction of the electric power flowing through a given transmission line, along with the real and reactive components of that power, can be determined through a computational analysis preferably carried out using a digital computer program.

- The horizontal and vertical magnetic field components calculated in the analysis component depend linearly on the line currents, albeit with complex coefficients. That is, the horizontal magnetic field component can be represented by a complex number (a phasor) that is a linear combination of the horizontal magnetic field contributions caused by each of the three conductors of the three-phase transmission line, with the coefficients of combination being complex numbers determined from the geometrical arrangement of the conductors and the sensor location with respect to the conductors. In other words, there results n complex simultaneous linear equations in n complex unknowns with n squared complex coefficients. Such a set of equations is invertible (i.e., it may be solved by a number of means, such by the use of Cramer's Rule or by Gaussian elimination) and is solved analytically. Given perfect measurements (or actual measurements, perfectly corrected) the real and imaginary components of the electric power on the line are determined exactly.

- The preferred method of computational analysis has two components. The first component of the computational analysis is run off-line. It consists of computation of the complex coefficients of the above-referenced set of simultaneous linear equations which define the geometrical arrangement of the conductors and the sensor location with respect to the conductors, followed by inversion of the coefficient matrix. These results are stored in a database. This first component of the computational analysis needs to be performed only once for a given installation of a monitoring device with respect to a particular transmission line.

- The second component is run on-line. It corrects the measured phase angle for sensor errors and geometrically induced errors to get actual horizontal and vertical magnetic field values, and multiplies the resulting measurement vector by the inverted coefficient matrix referred to above to determine line current and phase angle. In this regard, the sensed phase angle differs from the phase angle on the transmission line in a very complicated way, being affected by: the geometrical relationships between the conductors of the transmission line and the location of the monitoring device in three-dimensional space; sag of the transmission line; and the inherent minor inaccuracies of the sensors and their associated electronics. Nevertheless, many, if not all, of the resulting errors can be calculated and compensated for, leading to a computational estimate of the power factor on the line. Since the phase angle on the transmission line is calculated, and the real and reactive powers are calculated as signed quantities, the direction of flow of both the real and the imaginary components of the apparent power can be determined as well.

- Method of Computation

- Using the

monitoring device 10 of the present invention as described above, measurements of the generated magnetic field can be determined, which then allows for a determination of the power on the transmission line in question through careful application of known mathematical algorithms to the field data collected. As an example of the method, consider a typical application consisting of a single transmission line comprised of three conductors (or phases). For purposes of the calculation, it is assumed that the transmission line is oriented parallel to a flat, perfectly conducting Earth. -

- where I is the current flowing through the conductor, and r is the distance from the conductor to the point at which the magnetic field intensity is being measured. It is somewhat more common to refer to the strength of a magnetic field in terms of the magnetic flux density B. The magnetic flux density is defined as:

- B=μ0H Webers/m2 (2)

-

-

- Accordingly, this formula can be used to determine the magnetic flux density B in milligauss at a distance r (measured in meters) from an infinitely thin conductor carrying I Amperes of electrical current.

-

- Since H is a spatial vector, B is also a spatial vector. For this reason, the direction of the magnetic flux density B is perpendicular to a line drawn from the measurement point to the nearest point on the conductor. According to the familiar “right-hand rule” for determining direction, if the current is directed toward the viewer, the magnetic flux lines are directed counter-clockwise, giving a magnetic flux density vector B directed as shown in FIG. 7.

- Also, as shown in FIG. 7, the angle φ is the angle between r (the line drawn from the measurement point P and the conductor) and the positive x-axis. Since B is perpendicular to r, the spatial vector B can be resolved into its horizontal and vertical components B X and BY. For a single conductor carrying direct current (DC), the x and y components are simply determined by:

- BX=B sin φ (6)

- BY=−B cos φ (7)

- For a three-phase alternating current (AC) electric power transmission line, there are three conductors, carrying currents that are 120° apart in time phase. The time relationship between the currents may be represented by phasors, as in standard AC circuit analysis.

- FIG. 8 is a diagram showing the phasor relationship between the unit phasor components present in an infinitely long, three-phase transmission line over the flat Earth. Mathematically:

- I1=Io A (8)

- I2=Io B (9)

- I3=Io C (10)

- where Io is the (signed) RMS amplitude of the current on each conductor, and A, B, and C are unit phasors chosen to be 120° apart, as follows:

- A=1.0+j0.0 (11)

- B=−0.5−j0.866 (12)

- C=−0.5+j0.866 (13)

-

- Each of the three magnetic flux densities calculated in equations (14), (15), and (16) has a horizontal and a vertical component. Accordingly, the horizontal and vertical components of the three-phase transmission line, as shown in FIG. 8 and which are analogous to the vector components of a single phase line as per equations (6) and (7) above, may be calculated as follows:

- Referring again to FIG. 8, the x and y coordinates of the three conductors of a three-phase transmission line may be designated as (x C1, yC1), (xC2, yC2), and (xC3, yC3) respectively. As shown, the geometric distances and respective angles in equations (17) through (22) may be calculated by:

- r 1={square root}{square root over ( )}[(x C1 −x S)2+(y C1 −y S)2] (23)

- r 2={square root}{square root over ( )}[(x C2 −x S)2+(y C2 −y S)2] (24)

- r 3={square root}{square root over ( )}[(x C3 −x S)2+(y C3 −y S)2] (25)

- and

- φ1=tan−1 [(y C1 −y S)/(x C1 −x s)] (26)

- φ2=tan−1 [(y C2 −y S)/(x C2 −x S)] (27)

- φ3=tan−1 [(y C3 −y S)/(x C3 −x S)] (28)

-

- Equations (29) and (30) have been derived under the assumption that the current on the first conductor line 1 (phase 1) is governed by equation (3), that is:

- I1=Io A (31)

- where Io is a scalar element, which may be either positive or negative. In fact, the current on the first conductor may have any phase relationship. Its phase has meaning only with respect to some well-defined phase reference, which will be defined below as the phase of the voltage on the first conductor. In other words, Io is not a scalar, but rather is also a phasor and is hereinafter denoted by Io, where

- Io=Io ∠φ (32)

- Accordingly, equation (31) becomes:

- I1=Io A (33)

- with

- Io=|Io| (34)

-

- Some interpretation is now in order. A, B, C, r 1, r2, r3, φ1, φ2, and φ3 are known constants which are either defined or determined from the geometry of the line arrangement. Equations (35) and (36) can therefore be rewritten as:

- BH=a1 Io (37)

- BV=a2 Io (38)

-

- a 1 and a2 are complex constants depending on the line geometry, and equations (37) and (38) state that the horizontal and vertical magnetic flux densities BH and BV, as phasors, may be obtained by multiplying the complex phasor current Io by a1 and a2, respectively.

- These are linear relationships. Both equations (37) and (38) constitute one equation in one unknown, albeit with a complex given phasor (B H), complex coefficient (a1), and complex unknown phasor (Io).

- With one linear equation in one unknown, the equation is solvable. Solving for Io from (37) and (38):

- Io=B H /a 1 (41)

- Io=B V /a 2 (42)

- The above calculations indicate that, in principle, the phasor Io, in both magnitude and angle, can be determined from a measurement of the horizontal component of the magnetic flux density B H, or from measurement of the vertical component of the magnetic flux density BV by dividing by the appropriate complex number (a1 or a2).

- Accordingly, only one measurement—of either B H or BV—is sufficient to determine Io, to within an arbitrary phase shift. That is, from one measurement, one can determine apparent power, but not the distribution of apparent power between the real power (MW) and the reactive power (MVars). Since real and reactive power are each a signed quantity, the direction of power flow can not be determined unless the phase indeterminacy can be resolved.

- A Numerical Example

- FIG. 9 is an example of a line geometry with a pair of

magnetic field sensors 18′, 20′ located at ground level. Thesensors 18′, 20′ are located fifty feet below the level of the power lines, and fifty feet lateral of the first phase of the line. In this example, fifty feet separate the conductors from one another. Solving for the distance and angle parameters: - r 1={square root}(502+502)=70.7 ft. (43)

- r 2={square root}(1002+502)=111.8 ft (44)

- r 3={square root}(1502+502)=158.1 ft. (45)

- φ1=tan−1 (50/50)=45.0° (46)

- φ2=tan−1 (50/100)=26.56° (47)

- φ3=tan−1 (50/150)=18.43° (48)

- r 1, r2, and r3 must be in meters, therefore:

- r 1=70.7/3.28=21.56 meters (49)

- r 2=111.8/3.28=34.09 meters (50)

- r 3=158/3.28=48.20 meters (51)

- sin φ1=sin (45.0°)=0.707 (52)

- sin φ2=sin (26.56°)=0.447 (53)

- sin φ3=sin (18.43°)=0.316 (54)

- cos φ1=cos (45.0°)=0.707 (55)

- cos φ2=cos (26.56°)=0.8944 (56)

- cos φ3=cos (18.43°)=0.949 (57)

-

- Assuming,

- Io=1000∠0°=1000+j0 Amps (60)

-