US1853916A - Sash weight - Google Patents

Sash weight Download PDFInfo

- Publication number

- US1853916A US1853916A US414765A US41476529A US1853916A US 1853916 A US1853916 A US 1853916A US 414765 A US414765 A US 414765A US 41476529 A US41476529 A US 41476529A US 1853916 A US1853916 A US 1853916A

- Authority

- US

- United States

- Prior art keywords

- opening

- plate

- plates

- sash

- sash weight

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- E—FIXED CONSTRUCTIONS

- E05—LOCKS; KEYS; WINDOW OR DOOR FITTINGS; SAFES

- E05D—HINGES OR SUSPENSION DEVICES FOR DOORS, WINDOWS OR WINGS

- E05D13/00—Accessories for sliding or lifting wings, e.g. pulleys, safety catches

- E05D13/10—Counterbalance devices

- E05D13/14—Counterbalance devices with weights

Definitions

- one of the objects of the present invention is to provide aV means for successfully using some of this Waste and atk the same time lprovide a counterweight for Window sash and the like, which is not only practicable, but is actually advantageous over the Well-known cast Weights in. that it is not apt to be broken and is relative- ⁇ ly heavy in comparison to itssize, or bulk.

- a further and importantobject is ltopro- Vide a novel structure in which portions or sections can be readily removed to vary the Weight.

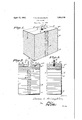

- Figure l is a perspective view of a form of the invention that is at present considered preferable.

- Figure 2 is a side elevation with the upper portion in section, on the line 2 2 of Figure 1.

- the invention ⁇ as disclosed consists of a stack of metal plates el, which are shown as rectangular and of equal size. These plates may be cut from Waste or scrap steel bars and are therefore relatively heavy. Though independent pieces, they are permanently held together by lines 5 of electric Welding, the Welding tools being passed along the opposite sides of the stack and causing the metal of the different plates to flovv together and unite in a manner vvell understood.

- the topmost sheet of the pile, designated 4a is provided with an opening 6 that is preferably elongated, and the plate below it, designated 1lb, is provided With a slot 7 alined With the opening or slot 6, but longer than the same so as to extend beneath the plate 4a atthe opposite ends of the opening 6, as clearly shown in Figure 2.

- FIG. 8 This affords an anchoring means for a hanger eye member which is preferably in the form of a staple 8, the closed or looped Figure 8 is a sectional view. onthe line most plate, and anchored in the opening of end of which projects abovethe stack and has its shanks 9 extending dovvnvvardlythrough the opening 6 with the terminals l0 ⁇ offset and lying in the end portions of the slot 7 beneath the plate 4a.

- a simple, but very effective eye is therefore provided in which the cable or other hanger canfbe engaged.

- a trim and very compact countervveight is thus provided, the Weight of which is rela-I tively great for its size, making it particu-v larly usefulV for metallic sash in metal Win- Y dow-frames.

- the structure furthermore perp e mits a variation in Weight. That is to say, ⁇ by employinga cold chisel and hammer, one or more of the lovvermost plates can be removed by cutting the Welded portions. 5

- a countervveight for sashes and the like comprising a stack of metal plates securedl together, Vthe uppermost plate having an opening .therethrough and aplate beneath also having an opening, and an eye member projecting through the opening of the upper the lovver plate.

- a countervveight for sashes and the like having Shanks passing downwardly through the opening with their terminals utstanding in the ends of the slots, and lines of Welding connecting opposite edges of the plates and securing them together.

- a CounterWeight for sash and the like comprising a stack of plates, the uppermost having an opening therein, an underlying plate having a slot that alines with the opening and extends on opposite sides of the same beneath the overlying plate, an eye member for suspending the counterweight compris-V ing a staple having shanks passing throughv the opening and offset terminals lying in the l5 end portions of the slot beneath the overlying plate, and means securing'together ,the

Description

April 172, 1932 T. E. MCLAUGHLIN 1,853,916

SASH WEIGHT Filed Dec. 17, 1929 30mm-nto@ lPatentedV Apr. 12, 1932 il i i? 'rHoMAs n. MCLAUGHLIN, oFYCLEVELAND,oi'eirdAssrGivoR'To TRUscoN struinenY ooM-f,

PANY, or CLEVELAND, onro, A CoRPoRArroNoF MICHIGAN sAsH WEiG'HT Application mea Deeember 17; 132,9. Yserieu No. 414,765. i

In the cutting, shearing, punching and forming of metal sheets "and bars, particularly those of the heavier grades, there is considerable Waste material, and one of the objects of the present invention is to provide aV means for successfully using some of this Waste and atk the same time lprovide a counterweight for Window sash and the like, Which is not only practicable, but is actually advantageous over the Well-known cast Weights in. that it is not apt to be broken and is relative-` ly heavy in comparison to itssize, or bulk.

A further and importantobject is ltopro- Vide a novel structure in which portions or sections can be readily removed to vary the Weight.

While the invention is primarily intended for userin countervveighting Window sash, it is obviously not restricted to such employment.

In the accompanying drawings:

Figure l is a perspective view of a form of the invention that is at present considered preferable. A

Figure 2 is a side elevation with the upper portion in section, on the line 2 2 of Figure 1.

3;-3 of Figure 2.

The invention `as disclosed consists of a stack of metal plates el, Which are shown as rectangular and of equal size. These plates may be cut from Waste or scrap steel bars and are therefore relatively heavy. Though independent pieces, they are permanently held together by lines 5 of electric Welding, the Welding tools being passed along the opposite sides of the stack and causing the metal of the different plates to flovv together and unite in a manner vvell understood. The topmost sheet of the pile, designated 4a, is provided with an opening 6 that is preferably elongated, and the plate below it, designated 1lb, is provided With a slot 7 alined With the opening or slot 6, but longer than the same so as to extend beneath the plate 4a atthe opposite ends of the opening 6, as clearly shown in Figure 2. This affords an anchoring means for a hanger eye member which is preferably in the form of a staple 8, the closed or looped Figure 8 is a sectional view. onthe line most plate, and anchored in the opening of end of which projects abovethe stack and has its shanks 9 extending dovvnvvardlythrough the opening 6 with the terminals l0 `offset and lying in the end portions of the slot 7 beneath the plate 4a. A simple, but very effective eye is therefore provided in which the cable or other hanger canfbe engaged.

A trim and very compact countervveight is thus provided, the Weight of which is rela-I tively great for its size, making it particu-v larly usefulV for metallic sash in metal Win- Y dow-frames. The structure furthermore perp e mits a variation in Weight. That is to say,`by employinga cold chisel and hammer, one or more of the lovvermost plates can be removed by cutting the Welded portions. 5

From the foregoing, it is thought that the construction, operation and many advantages of the herein described invention vvill be ap-A parent to those skilled in the art Without further description andit Will be understood that various changes in the size, shape, proe portion and minor details of construction may be resorted to Without departing from the spiritl or sacrificing any of the advan-IV tages Aof the invention.

That I claim is: Y

l. A countervveight for sashes and the like comprising a stack of metal plates securedl together, Vthe uppermost plate having an opening .therethrough and aplate beneath also having an opening, and an eye member projecting through the opening of the upper the lovver plate.

uppermost having yan yopening therethrough, y

and an underlying plate havingA a slot of greater length than the opening, an eye staple extending above the top of the stackv and SQ l 2; A countervveight for sashes and the like having Shanks passing downwardly through the opening with their terminals utstanding in the ends of the slots, and lines of Welding connecting opposite edges of the plates and securing them together.

4. A CounterWeight for sash and the like comprising a stack of plates, the uppermost having an opening therein, an underlying plate having a slot that alines with the opening and extends on opposite sides of the same beneath the overlying plate, an eye member for suspending the counterweight compris-V ing a staple having shanks passing throughv the opening and offset terminals lying in the l5 end portions of the slot beneath the overlying plate, and means securing'together ,the

opposite sides of the plates.

In testimony whereof, I ax my signature.

THOMAS E. MGLAUGHLIN.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US414765A US1853916A (en) | 1929-12-17 | 1929-12-17 | Sash weight |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US414765A US1853916A (en) | 1929-12-17 | 1929-12-17 | Sash weight |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US1853916A true US1853916A (en) | 1932-04-12 |

Family

ID=23642860

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US414765A Expired - Lifetime US1853916A (en) | 1929-12-17 | 1929-12-17 | Sash weight |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US1853916A (en) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20060211550A1 (en) * | 2002-06-07 | 2006-09-21 | Nautilus, Inc. | Adjustable dumbbell system |

| US20070087918A1 (en) * | 2005-10-05 | 2007-04-19 | Intellbell Ventures, Inc. | Selectorized dumbbell weight with weight plates formed by a pair of welded weight subplates and method of manufacture thereof |

| US20090186748A1 (en) * | 2008-01-23 | 2009-07-23 | Nautilus, Inc. | Adjustable dumbbell with an orientation feature |

-

1929

- 1929-12-17 US US414765A patent/US1853916A/en not_active Expired - Lifetime

Cited By (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20060211550A1 (en) * | 2002-06-07 | 2006-09-21 | Nautilus, Inc. | Adjustable dumbbell system |

| US7553265B2 (en) * | 2002-06-07 | 2009-06-30 | Nautilus, Inc. | Adjustable dumbbell system |

| US20100035736A1 (en) * | 2002-06-07 | 2010-02-11 | Nautilus, Inc. | Adjustable dumbbell system |

| US7794373B2 (en) | 2002-06-07 | 2010-09-14 | Nautilus, Inc. | Adjustable dumbbell system |

| US20110003668A1 (en) * | 2002-06-07 | 2011-01-06 | Nautilus, Inc. | Adjustable dumbbell system |

| US8002680B2 (en) | 2002-06-07 | 2011-08-23 | Nautilus, Inc. | Adjustable dumbbell system |

| US20070087918A1 (en) * | 2005-10-05 | 2007-04-19 | Intellbell Ventures, Inc. | Selectorized dumbbell weight with weight plates formed by a pair of welded weight subplates and method of manufacture thereof |

| US7335142B2 (en) * | 2005-10-05 | 2008-02-26 | Intellex, Inc. | Selectorized dumbbell weight with weight plates formed by a pair of welded weight subplates and method of manufacture thereof |

| US20090186748A1 (en) * | 2008-01-23 | 2009-07-23 | Nautilus, Inc. | Adjustable dumbbell with an orientation feature |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US2994114A (en) | Fire proof fire block | |

| US1853916A (en) | Sash weight | |

| US1737214A (en) | Pipe fastening | |

| US2490018A (en) | Fastener for window screens, storm windows, and the like | |

| US2061304A (en) | Sectional garage door | |

| US2098676A (en) | Beam and the like for building construction | |

| GB471258A (en) | Improvements in steel doors | |

| US2129625A (en) | Stud and rafter | |

| US1653716A (en) | Automobile operating gate | |

| US1860571A (en) | Cattle guard | |

| US1734410A (en) | Fastening device | |

| US396404A (en) | Chain-link | |

| US1425570A (en) | Sash weight | |

| US1105791A (en) | Means for fastening floor and sidewalk grating. | |

| US2016032A (en) | Dipper door control | |

| US1515159A (en) | Studding | |

| US1431849A (en) | Hollow metal window | |

| AT235720B (en) | Device for opening and closing skylight windows | |

| DE83181C (en) | ||

| US835863A (en) | Window-sash. | |

| DE136795C (en) | ||

| US1888752A (en) | Sheet piling | |

| US670309A (en) | Girder construction. | |

| GB261213A (en) | Improvements in or relating to buffer-bars for motor vehicles | |

| US1761155A (en) | Belt splice |