US1853816A - Tomato unwrapping machine - Google Patents

Tomato unwrapping machine Download PDFInfo

- Publication number

- US1853816A US1853816A US339163A US33916329A US1853816A US 1853816 A US1853816 A US 1853816A US 339163 A US339163 A US 339163A US 33916329 A US33916329 A US 33916329A US 1853816 A US1853816 A US 1853816A

- Authority

- US

- United States

- Prior art keywords

- tomatoes

- belts

- conveyor

- wrappers

- housing

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B69/00—Unpacking of articles or materials, not otherwise provided for

Definitions

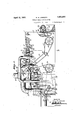

- WllGIBlIl Fig. 1 is a side elevation partly inisection and with part oftheside wallJbroken-away, of an unwrapping machine embodying my invention, and portions of conveying and re.--

- Fig. .2 is-a planwiew of the machine and.

- Fig. 3 1s a vertlcal transverse SGCtlOIlsOIl the line .33, Flg. -1.

- Fig. 4 isaa plan vievwof 'therear end. of a- 39 longitudinal conveyor and storageelements: and a cross sect1on-oa-wall'forsupporting.-

- Fig. 5 is a section oft-transverse conveyor at'the. rearr end of-the machinevand-portions- H of parallel spaced belts 22 snmlar'to: thebelts 853 35 of the. machineadjacent.thereton

- Fig. 6 is-an enlarged perspective fragmentary longitudinal vie-w of the housing,-.con--.- veyorbelts, rollers, and flexible gates adapted to engage wrappedtomatoes moved by the belts.

- l designates generally; a .frame includ-ing-. side walls-2 and 3', a front 'wal-l 4l,cross.1nem- H here 5 and reinforcing andsupporting; angles such as 6 and cornerposts/T.

- the sldesand front end wall. are. formed of'sheetymetal to form. enclosing; walls whereby the frame. may comprise a housing.

- the belts 11" are parall elTand spacedfto I provide openings

- An air conduit 18 communicates with the interior ofthe housing... below the horizontal portionsot'the beltsv anda tanv 19 mounted in a chamber 20fsup-- e.

- the conduit ported by the housing and communicatingwith the conduit is adapted'to draw a current'of air downwardly between-the belts and; wrapped tomatoes supported thereby and through the openings-between the belts into the conduit and'through the chamber 26;

- AI conduit 21 also 'communicating ..withTthe fan chamber 20 conductsair drawnthroughthe conduit 18 into the housin beneaththev inclined path oftlie belts for discharge upwardly between the spaced beltsfor moving; wrappers away from the tomatoes.

- Condni'ts28 and29 are connectedinto the, housing, respectively below the horiz ontal path of'thelast named group of beltsto draw air downwardly therethrongh; and below the inclined. path to blow airu-pwardly the-re througl 1'-,.. and-I communicate with the a n..; chamber 20 similarly to the conduits lS-and- 21, the two setsof conduitshaving acommon inlet to the fan chamber and a common outlet 31 therefrom.

- Hoods 32 and 33 are mounted over the inclined portions of the belt paths and relatively large conduits 34 and 35 connected to the hoods have a common outlet 36 for wrapper-removing air currents moving from the housing.

- a suction fan 37 is mounted at the outlet 36 to draw air from the housing, and supplement the blast from the fan 19.

- a fan housing 38 is preferably provided having a dividing wall 39 to form the chamber 20 communicating with the conduits 18, 28, 21 and 29, and a chamber 40 communicating with the conduits 34 and 35 and containing the fan 37 and having a discharge stack 41.

- the fans 19 and 37 are mounted on a common shaft 42 journaled in the fan housing 38.

- the blasts delivered upwardly through the inclined paths assist the suction currents in moving wrappers that are disengaged from the tomatoes during the passage of the tomatoes rearwardly in the machine, as will be more particularly described.

- the air currents are confined and rendered more effective by provision of walls43 and 44 having edges secured to the side walls of the housing and forming chambers 45 and 46 below the horizontal and inclined portions of the paths respectively.

- the machine is operated by a motor 47 mounted on a shelf 48 within the housing 1 having a driving shaft 49 journaled in the side wall 2 and provided with a pulley 5O keyed thereto and an idler pulley 51, both exterior of the housing.

- a belt 52 is adapted to run on the pulley and a pulley 53 on the fan shaft 42 to operate the fans, or on pulley 51 and an idler pulley 54 on the fan shaft for suspending operation of the shaft by the motor.

- Motion is transmitted from the fan shaft 42 to the conveyors through a belt 55, reducing sets 56 and 57 mounted on parallel spaced shafts 58 journaled in the side walls 2 and 3, a belt 59 connecting the reducing sets, and a belt 60 running on a pulley 61 of the second set and a pulley 62 on the rear shaft 25 of the rearward conveyor.

- the belts 22 transmit motion from the shaft 25 to the roller shafts 24 and 23.

- the rear pulley shaft 14 of the second conveyor is operated by a chain 63 through suitable sprockets from the shaft 23, and the belts 11 transmit motion from the roller shaft 14 to the roller shafts 13 and 12.

- the primary conveyor is operated at slower speed than the belts 11 and 22, by a chain 64 running on a sprocket 65 on the shaft 12 and a larger sprocket 66 on the shaft 9.

- the roller shaft 8 of the primary conveyor is supported by a tightener 67 for adjusting the tension of the endless conveyor.

- the two sets of spaced parallel conveying belts are similar and auxiliary elements associated with the same are alike so that only one group of such auxiliary elements will be described.

- gates 68 and 69 Depending into the path of the tomatoes and at right angles thereto are gates 68 and 69, one at each end of the horizontal portion of the path comprising metal strips 70 and 71 having end flanges 72 secured to the side walls of the housing by suitable means such as bolts 73, and resilient fingers 74 clamped between the strip having lower free ends substantially in contact with the belts.

- each gate There are two series of fingers in each gate, the fingers of one series overlapping the fingers of the other series, whereby the gates are substantially air tight in rest position.

- a gate 75 comprising a pair of ale 7 6 having flanges 7 7 bolted to the strips of the gates 68 and 69 and depending spaced resilient fingers 78 clamped between the bars and having free ends substantially in contact with the belts.

- the fingers are preferably formed of soft, elastic material such as rubber whereby they may yield readily to the slight pressure of the tomatoes, and have frictional qualities so that they may tend to rub the wrappers from crimped condition and loosen them, and the tomatoes will not be bruised by contact therewith.

- the diagonal gates further serve to shift the tomatoes laterally of the belts and thus further disturb the wrappers, so that the air drawn downwardly between the belts may tend to pull the loosened edges of the wrappers away from the tomatoes and retain the wrappers in engagement with the belts until the tomatoes have been released therefrom.

- a resilient wrapper-engaging member 79 extends above the inclined path of the belts to engage tomatoes moving therealong, comprising a body 80 bolted to the supporting bars of the gates 69 and having resilient fingers 81 provided with transverse lugs 82 adapted to engage the loosened Wrappers and further dislodge them from the tomatoes.

- the tomatoes are freed from the wrappers during their travel through the housing and are delivered at the rear end of the housing toa transversely moving conveyor 83 having length substantially equal to the width of the housing and supported on shafts 84 and 85 journaled in an end member 86 of the housing, and a support 87 spaced therefrom.

- a helically out gear 88 loosely mounted on the shaft 85 at its end adjacent the machine is in mesh with a gear 89 on the shaft 25 and may be keyed to the shaft 85 by a clutch 9O operated by a foot lever 91 to effect operation of the transverse conveyor by the motor.

- the lever is retracted by a spring 92 to withestates:

- the upper and lower runs 98- and 99 of the belt widely spacedto term oppositely moving eonveyers; and positioned in: planes respectively above and hele'vv-the surface of the transverseconveyor, whereby operative standing at the latter may COIi-V6I1 iently transfer unwrapped ripe tomatoes deliv'ere'd thereto to the up er ran, and green tomatoes may fall macnthe end of the trans verse conveyor to the lower run.

- a divider 100' formed preferably of rela tively soft material such as canvas is sup ported above the center line of the upper run 98 by brackets 101 and 102 "edrespectively to the main housing and the wail, and- 'di-i' ides' the run into sections 1 03' and 104, to receive tomatoes of di-fierent sizes and blades 105- and 106 at the rear-end of the eeeveyor hing edly supported by brackets 10'? and 108 from the wall adjacent the two sections divertthe tomatoes into containers 1 09and 110.

- Sorting of ripe tomatoes into two lots according to size for transfer to the containers 109 and 110 is contemplated, and unripe tomatoes remaining on the conveyor will drop to the lower run of the belt and be moved toward the front end of the machine, and to any position desired forward thereof to which the conveyor may be extended.

- a deflecting blade 111 supported by the wall intercepts the unripe tomatoes and causes them to fall into a container 112.

- Incidental adjusting means may further be provided, for example belt tightening devices 118 and 119 supported by the housing.

- wrapped tomatoes are dumped from original shipping containers in which they have been transported, to the primary conveyor, and are moved thence onto the front ends of the spaced belts of the secondary conveyor.

- the resilient fingers yieldingly engage the wrappers and tend to loosen the same and disengage them from the tomatoes.

- the overlappin fingers; of the end gates seal the gates against passage of air currents therethr'ough except when tomatoes are i ng fingers, whereby 'air currents induced by the fan 19 are restricted to vertical inovement downwardly through: the open upper end of the housing, and when fingers are bent by passing tomatoes, air. currents may pass through the small temporary openings and assist in dislodging the wrappers.

- V The tomatoes tend to roll downwardly ever the inclined portions of the parallel space-d belts, the movement tending to fur ther" disturb the wrappers, which are thene-ngaged by the lugs on the depending fingers overlying the inclined portions.

- the operator and sorter may stop; the movement of the transverse conveyor tof per mit an accumulation of ripe tomatoesthereon while transferring; desired lots of toma toss to theupper run of the longitudinal conveyor. Operation of the spaced belts and primary conveyor may be stopped by shift ing the belt to the idling pulleys of the -n-1 otor and fan shafts, whereupon the longitudi- 105 n-al conveyor will be moved while no tomatoes are being moved through the machine, and the transverse conveyor isat rest.

- A- nna-chine. forre'movingwrappersfrom tomatoes and the like comprising a housing, a conveyor supported by the housing, over-V lappi-ngresilient fingers supported by the housing transversely of the conveyor, and means; for actuating the conveyor; 7 2:- In amachine for removing wrappers from tomatoes and the like, a housing, a con- I veyor' movable in a path having horizontal and inclinedportions, a series of overlapping resilient fingerssupported by the hensingtransversely of said horizontal path, and a plurality of laterally spaced resilient fin; gerssu-pp rted by the housing longitudinally of the inclined p V 3; In a machine of the character described for removing, wrappers from tomatoes and the like, a housing,- a plurality of movable belts supported fromthe housing in parallel I and spacedrelationfor conveying wrapped tomatoes, a plurality of resilient fingers supported by the housing with their free ends adjacent the belts to engage the tomatoes while

- a frame In a machine for removing wrappers from tomatoes and the like, a frame, a closed chamber, a conveyor including a belt movable longitudinally of the frame, a series of resilient fingers supported by the frame above said conveyor to intercept wrapped tomatoes being moved by the conveyor, and means for inducing a flow of air downwardly between the moving tomatoes to hold the wrappers to the conveyor.

- a housing including a plurality of chambers, tomato conveying means including a plurality of movable belts, means for disengaging wrappers from the tomatoes including a series of resilient fingers supported by the housing and having free ends extending into the paths of the tomatoes to engage the wrappers, and means including conduits communicating with said chambers for moving air among the belts to separate the wrappers from the tomatoes.

- a conveyor including spaced parallel movable belts, means including resilient members engageable with the wrapped tomatoes while the same are being moved for dislodging the wrappers, and means for inducing a flow of air through the spacing between the belts to separate the wrappers from the tomatoes.

- a conveyor, wrapper-disengaging means, and wrapper-removing means comprising a plurality of conduits and means for moving air over the conveyor into said conduits and outwardly from the machine.

- a frame including a chamber having a closed top and a chamber having an open top, a series of parallel laterally spaced belts positioned in the chambers, a plurality of gates having slit edges positioned adjacent the belts for engaging wrapped tomatoes moved by the belts, an air conduit connected to the lower portions of the chambers below the belts, a fan in the conduit between the chamber, and a conduit connected to the top of the closed chamber for conducting the air therefrom.

- a frame including a plurality of chambers, a conveyor having a portion in each chamber, resilient strips positioned adjacent the conveyor for engaging the wrappers, air conduits connected to the several chambers, one having an inlet in one chamber and another having an outlet to atmosphere, and means including a fan housing having a plurality of compartments communicating with the conduits and a fan in each compartment for in ducing a flow of air from the inlet through the conduits to atmosphere.

- a frame including a plurality of chambers, selected chambers having closed tops, tomato conveying means including a series of parallel laterally spaced belts moving in paths having horizontal portions and inclined portions, wrapper disengaging means including a plurality of gates having slit edges positioned adjacent the belts for engaging wrapped tomatoes moved by the belts, selected gates extending diagonally of the belts for shifting the tomatoes, elastic strips having transverse ribs overlying the inclined portions of said paths for engaging the wrappers, air conduits connected to the several chambers, suction means for dislodging wrappers from tomatoes on the horizontal portions of the paths, and means for inducing flow of air upwardly from beneath the inclined portions of the belts for carrying away dislodged wrappers.

Description

April 12, 1932.

TOMATO: UNWRAPEiING MACHINE N. B. JANSSEN Filed Feb. 11, 1929 4 Sheets-Sheet 1 ATTORNEY April 1932- N. B. JANSSEN I 1,853,816

TOMiA'TO UNWRA'PPING MACHINE Filed Feb. 11, 1929 4 Sheets-Sheet 2 INVENTOR ATTORNEY TOMATO UNWRAPPING MACHINE Filed Feb. 11, 1929. 4 Sheets-Sheet 5 INVENTOR BY /V/22/ 5 Jansse/z ATTORNEY April- 12, 1932. N. B. JANSSEN TOMATO UNWRAPPING MACHINE 4 Sheets-Sheet 4 Filed Feb. 11, 1929 INVENTOR BY N/ie/s Z9. Jar/men.

ATTORNEY Patented Apr. 12, 1932 1,853,8ltt

NIELSIB; JANSSEN, OF KANSAS CITY, MISSOURI TOMATQUNWRAPPTNG Application filed February 11, 1929: se1-ia1.1 ro;;s3e;1ea

In accomplishingthese and other objects of my. invention, 1: have provided nnproved details of structure, the preferred forms of which are-illustrated 1n the. accompany-111gv drawings, WllGIBlIl Fig. 1 is a side elevation partly inisection and with part oftheside wallJbroken-away, of an unwrapping machine embodying my invention, and portions of conveying and re.--

packing elements;

Fig. .2 is-a planwiew of the machine and.

# portions of conveyors, one-of the: conveyors V being partly broken'aw-ay to discloseradow er. conveyor.v

Fig. 3 1s a vertlcal transverse SGCtlOIlsOIl the line .33, Flg. -1.

Fig. 4: isaa plan vievwof 'therear end. of a- 39 longitudinal conveyor and storageelements: and a cross sect1on-oa-wall'forsupporting.-

conveyors and diverting elements.

Fig. 5 is a section oft-transverse conveyor at'the. rearr end of-the machinevand-portions- H of parallel spaced belts 22 snmlar'to: thebelts 853 35 of the. machineadjacent.thereton Fig. 6 is-an enlarged perspective fragmentary longitudinal vie-w of the housing,-.con--.- veyorbelts, rollers, and flexible gates adapted to engage wrappedtomatoes moved by the belts.

Referring in detail to thedrawings:

l designates generally; a .frame includ-ing-. side walls-2 and 3', a front 'wal-l 4l,cross.1nem- H here 5 and reinforcing andsupporting; angles such as 6 and cornerposts/T. The sldesand front end wall. are. formed of'sheetymetal to form. enclosing; walls whereby the frame. may comprise a housing.

Running on. spaced'elongated. .rollersor move them rearwardly in the machine.

- pulleys 8 and?) journaledinlthe. side walls atthe front endof the housing and adj acentits top edge is. an integralprimary conveyor beltlO adaptedto receive wrappedtomatoesandmove the same rearwardly in the housing.

Located immediately behindthe primary 555. conveyorare belts l1 runningonroller shaftsl2land *13' journaledin the side walls. in horizontal plane slightly lower than the-primary conveyor and a roller shaft 14- down-. wardly offset from said plane. The shafts to support portions. 15 of the upper runs of the belts. in horizontalposition and portionsltl offthe runs in inclined position, to provide a secondary conveyor to receive tomatoes and The belts 11" are parall elTand spacedfto I provide openings An air conduit 18 communicates with the interior ofthe housing... below the horizontal portionsot'the beltsv anda tanv 19 mounted in a chamber 20fsup-- e.

ported by the housing and communicatingwith the conduit is adapted'to draw a current'of air downwardly between-the belts and; wrapped tomatoes supported thereby and through the openings-between the belts into the conduit and'through the chamber 26;

Locatedimmediately behindithe abovede scribed'secondary conveyor isanoth'er group,

11 and similarly movably supported on shafts 23', 24 and 25" forming a horizontal. conveyor portion 26' to receive tomatoes from the lower ends ofthe-inclined portions 16 of the belt :runsll, and-having alsovinclir tedl portions 27 similar to said inclined portions 16. v Y.

Condni'ts28 and29 are connectedinto the, housing, respectively below the horiz ontal path of'thelast named group of beltsto draw air downwardly therethrongh; and below the inclined. path to blow airu-pwardly the-re througl 1'-,.. and-I communicate with the a n..; chamber 20 similarly to the conduits lS-and- 21, the two setsof conduitshaving acommon inlet to the fan chamber and a common outlet 31 therefrom.

A fan housing 38 is preferably provided having a dividing wall 39 to form the chamber 20 communicating with the conduits 18, 28, 21 and 29, and a chamber 40 communicating with the conduits 34 and 35 and containing the fan 37 and having a discharge stack 41. The fans 19 and 37 are mounted on a common shaft 42 journaled in the fan housing 38.

The blasts delivered upwardly through the inclined paths assist the suction currents in moving wrappers that are disengaged from the tomatoes during the passage of the tomatoes rearwardly in the machine, as will be more particularly described.

The air currents are confined and rendered more effective by provision of walls43 and 44 having edges secured to the side walls of the housing and forming chambers 45 and 46 below the horizontal and inclined portions of the paths respectively.

The machine is operated by a motor 47 mounted on a shelf 48 within the housing 1 having a driving shaft 49 journaled in the side wall 2 and provided with a pulley 5O keyed thereto and an idler pulley 51, both exterior of the housing. A belt 52 is adapted to run on the pulley and a pulley 53 on the fan shaft 42 to operate the fans, or on pulley 51 and an idler pulley 54 on the fan shaft for suspending operation of the shaft by the motor.

Motion is transmitted from the fan shaft 42 to the conveyors through a belt 55, reducing sets 56 and 57 mounted on parallel spaced shafts 58 journaled in the side walls 2 and 3, a belt 59 connecting the reducing sets, and a belt 60 running on a pulley 61 of the second set and a pulley 62 on the rear shaft 25 of the rearward conveyor.

The belts 22 transmit motion from the shaft 25 to the roller shafts 24 and 23. The rear pulley shaft 14 of the second conveyor is operated by a chain 63 through suitable sprockets from the shaft 23, and the belts 11 transmit motion from the roller shaft 14 to the roller shafts 13 and 12. The primary conveyor is operated at slower speed than the belts 11 and 22, by a chain 64 running on a sprocket 65 on the shaft 12 and a larger sprocket 66 on the shaft 9.

The roller shaft 8 of the primary conveyor is supported by a tightener 67 for adjusting the tension of the endless conveyor.

The two sets of spaced parallel conveying belts are similar and auxiliary elements associated with the same are alike so that only one group of such auxiliary elements will be described.

Depending into the path of the tomatoes and at right angles thereto are gates 68 and 69, one at each end of the horizontal portion of the path comprising metal strips 70 and 71 having end flanges 72 secured to the side walls of the housing by suitable means such as bolts 73, and resilient fingers 74 clamped between the strip having lower free ends substantially in contact with the belts.

There are two series of fingers in each gate, the fingers of one series overlapping the fingers of the other series, whereby the gates are substantially air tight in rest position.

Extending diagonally across the horizon-- tal portion of the upper run of each of the parallel belts is a gate 75 comprising a pair of ale 7 6 having flanges 7 7 bolted to the strips of the gates 68 and 69 and depending spaced resilient fingers 78 clamped between the bars and having free ends substantially in contact with the belts.

The fingers are preferably formed of soft, elastic material such as rubber whereby they may yield readily to the slight pressure of the tomatoes, and have frictional qualities so that they may tend to rub the wrappers from crimped condition and loosen them, and the tomatoes will not be bruised by contact therewith.

The diagonal gates further serve to shift the tomatoes laterally of the belts and thus further disturb the wrappers, so that the air drawn downwardly between the belts may tend to pull the loosened edges of the wrappers away from the tomatoes and retain the wrappers in engagement with the belts until the tomatoes have been released therefrom.

A resilient wrapper-engaging member 79 extends above the inclined path of the belts to engage tomatoes moving therealong, comprising a body 80 bolted to the supporting bars of the gates 69 and having resilient fingers 81 provided with transverse lugs 82 adapted to engage the loosened Wrappers and further dislodge them from the tomatoes.

The tomatoes are freed from the wrappers during their travel through the housing and are delivered at the rear end of the housing toa transversely moving conveyor 83 having length substantially equal to the width of the housing and supported on shafts 84 and 85 journaled in an end member 86 of the housing, and a support 87 spaced therefrom.

A helically out gear 88 loosely mounted on the shaft 85 at its end adjacent the machine is in mesh with a gear 89 on the shaft 25 and may be keyed to the shaft 85 by a clutch 9O operated by a foot lever 91 to effect operation of the transverse conveyor by the motor. The lever is retracted by a spring 92 to withestates:

' porting element for brackets and shafts presently described- Extendin between the machine and the wall is a wide Iengituuinat endless conveyor belt 93 supported on shafts 94 and 95- journaled hithe wall and brackets 96 fixed to the machinehousing, and; bearings 91 extending ia-terally' treaithe wall.

The upper and lower runs 98- and 99 of the belt widely spacedto term oppositely moving eonveyers; and positioned in: planes respectively above and hele'vv-the surface of the transverseconveyor, whereby operative standing at the latter may COIi-V6I1= iently transfer unwrapped ripe tomatoes deliv'ere'd thereto to the up er ran, and green tomatoes may fall freinthe end of the trans verse conveyor to the lower run.

A divider 100' formed preferably of rela tively soft material such as canvas is sup ported above the center line of the upper run 98 by brackets 101 and 102 "edrespectively to the main housing and the wail, and- 'di-i' ides' the run into sections 1 03' and 104, to receive tomatoes of di-fierent sizes and blades 105- and 106 at the rear-end of the eeeveyor hing edly supported by brackets 10'? and 108 from the wall adjacent the two sections divertthe tomatoes into containers 1 09and 110.

Sorting of ripe tomatoes into two lots according to size for transfer to the containers 109 and 110 is contemplated, and unripe tomatoes remaining on the conveyor will drop to the lower run of the belt and be moved toward the front end of the machine, and to any position desired forward thereof to which the conveyor may be extended. A deflecting blade 111 supported by the wall intercepts the unripe tomatoes and causes them to fall into a container 112.

A chain 113 meshed with a sprocket 11 1 on the shaft 95 and with a reducing gear set 115 on a shaft 116 rotated through a belt 117 by the driving shaft 19 operates the conveyor belt 93 Incidental adjusting means may further be provided, for example belt tightening devices 118 and 119 supported by the housing.

In operating the machine, wrapped tomatoes are dumped from original shipping containers in which they have been transported, to the primary conveyor, and are moved thence onto the front ends of the spaced belts of the secondary conveyor. As the tomatoes pass the first gate, the resilient fingers yieldingly engage the wrappers and tend to loosen the same and disengage them from the tomatoes.

As the tomatoes are moved rearwardly, they come into contact with the resilient fingers of the diagonal gates, are shifted laterally,-

bending the: fingers pass through thegates'. A plurality of frictional effect-s are thus produced to loosen and disledgether' wrappers.- The: tomatoes then pass through the transverse gate at the" rear end of the horizontal path,-v where further disturbance of the Wrappers occurs.

The overlappin fingers; of the end gates seal the gates against passage of air currents therethr'ough except when tomatoes are i ng fingers, whereby 'air currents induced by the fan 19 are restricted to vertical inovement downwardly through: the open upper end of the housing, and when fingers are bent by passing tomatoes, air. currents may pass through the small temporary openings and assist in dislodging the wrappers. V The tomatoes tend to roll downwardly ever the inclined portions of the parallel space-d belts, the movement tending to fur ther" disturb the wrappers, which are thene-ngaged by the lugs on the depending fingers overlying the inclined portions. I Air currentsinduced by the suction and assisted by the fan 19, passing upwardly through the inclined pathof the tomatoes, assist in dislodging the wrappers and move the same" through the discharge conduits and deliver them through the stack. The irriwrapped tomatoes are delivered: to the trans verse conveyor. 7

The operator and sorter may stop; the movement of the transverse conveyor tof per mit an accumulation of ripe tomatoesthereon while transferring; desired lots of toma toss to theupper run of the longitudinal conveyor. Operation of the spaced belts and primary conveyor may be stopped by shift ing the belt to the idling pulleys of the -n-1 otor and fan shafts, whereupon the longitudi- 105 n-al conveyor will be moved while no tomatoes are being moved through the machine, and the transverse conveyor isat rest.

'What Lela-1 m and desire to secure by Letters Patent is: V

1. A- nna-chine. forre'movingwrappersfrom tomatoes and the like comprising a housing, a conveyor supported by the housing, over-V lappi-ngresilient fingers supported by the housing transversely of the conveyor, and means; for actuating the conveyor; 7 2:- In amachine for removing wrappers from tomatoes and the like, a housing, a con- I veyor' movable in a path having horizontal and inclinedportions, a series of overlapping resilient fingerssupported by the hensingtransversely of said horizontal path, and a plurality of laterally spaced resilient fin; gerssu-pp rted by the housing longitudinally of the inclined p V 3; In a machine of the character described for removing, wrappers from tomatoes and the like, a housing,- a plurality of movable belts supported fromthe housing in parallel I and spacedrelationfor conveying wrapped tomatoes, a plurality of resilient fingers supported by the housing with their free ends adjacent the belts to engage the tomatoes while being moved by the belts, and means for inducing a flow of air downwardly over the tomatoes through the spacing between the belts.

i. In a machine for removing wrappers from tomatoes and the like, a frame, a closed chamber, a conveyor including a belt movable longitudinally of the frame, a series of resilient fingers supported by the frame above said conveyor to intercept wrapped tomatoes being moved by the conveyor, and means for inducing a flow of air downwardly between the moving tomatoes to hold the wrappers to the conveyor.

5. In a machine of the character described for removing wrappers from tomatoes and the like, a housing including a plurality of chambers, tomato conveying means including a plurality of movable belts, means for disengaging wrappers from the tomatoes including a series of resilient fingers supported by the housing and having free ends extending into the paths of the tomatoes to engage the wrappers, and means including conduits communicating with said chambers for moving air among the belts to separate the wrappers from the tomatoes.

6'. In a machine of the character described for removing wrappers from tomatoes and the like, a conveyor including spaced parallel movable belts, means including resilient members engageable with the wrapped tomatoes while the same are being moved for dislodging the wrappers, and means for inducing a flow of air through the spacing between the belts to separate the wrappers from the tomatoes.

7. In a machine for removing wrappers from tomatoes and the like, a conveyor, wrapper-disengaging means, and wrapper-removing means comprising a plurality of conduits and means for moving air over the conveyor into said conduits and outwardly from the machine.

8. In a machine of the character described for removing wrappers from tomatoes, a frame including a chamber having a closed top and a chamber having an open top, a series of parallel laterally spaced belts positioned in the chambers, a plurality of gates having slit edges positioned adjacent the belts for engaging wrapped tomatoes moved by the belts, an air conduit connected to the lower portions of the chambers below the belts, a fan in the conduit between the chamber, and a conduit connected to the top of the closed chamber for conducting the air therefrom.

9. In a machine of the character described for removing wrappers from tomatoes, a: frame including a plurality of chambers, a conveyor having a portion in each chamber, resilient strips positioned adjacent the conveyor for engaging the wrappers, air conduits connected to the several chambers, one having an inlet in one chamber and another having an outlet to atmosphere, and means including a fan housing having a plurality of compartments communicating with the conduits and a fan in each compartment for in ducing a flow of air from the inlet through the conduits to atmosphere.

10. In a machine of the character described for removing wrappers from tomatoes, a frame including a plurality of chambers, selected chambers having closed tops, tomato conveying means including a series of parallel laterally spaced belts moving in paths having horizontal portions and inclined portions, wrapper disengaging means including a plurality of gates having slit edges positioned adjacent the belts for engaging wrapped tomatoes moved by the belts, selected gates extending diagonally of the belts for shifting the tomatoes, elastic strips having transverse ribs overlying the inclined portions of said paths for engaging the wrappers, air conduits connected to the several chambers, suction means for dislodging wrappers from tomatoes on the horizontal portions of the paths, and means for inducing flow of air upwardly from beneath the inclined portions of the belts for carrying away dislodged wrappers.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US339163A US1853816A (en) | 1929-02-11 | 1929-02-11 | Tomato unwrapping machine |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US339163A US1853816A (en) | 1929-02-11 | 1929-02-11 | Tomato unwrapping machine |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US1853816A true US1853816A (en) | 1932-04-12 |

Family

ID=23327786

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US339163A Expired - Lifetime US1853816A (en) | 1929-02-11 | 1929-02-11 | Tomato unwrapping machine |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US1853816A (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2586223A (en) * | 1948-06-28 | 1952-02-19 | Wayne A S Harmon | Produce unwrapping device |

-

1929

- 1929-02-11 US US339163A patent/US1853816A/en not_active Expired - Lifetime

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2586223A (en) * | 1948-06-28 | 1952-02-19 | Wayne A S Harmon | Produce unwrapping device |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US3901375A (en) | Package feeding and timing mechanism | |

| US3453800A (en) | Method and device for packaging pouches with soft contents in folding boxes | |

| US1945758A (en) | Fruit dumping method and apparatus | |

| US1853816A (en) | Tomato unwrapping machine | |

| US3932983A (en) | Tamper and confiner for product bucket | |

| US1428721A (en) | Conveyer | |

| US4179865A (en) | Pasta noodle packaging apparatus and method | |

| US2805533A (en) | Machines for sealing shipping cartons or the like | |

| US1791362A (en) | Walnut harvester | |

| US1350506A (en) | Nut-blancher | |

| US5664662A (en) | Vacuum combiner | |

| US2355500A (en) | Confection packaging machine | |

| US1468626A (en) | Wrapping machine | |

| US1774113A (en) | Sheet-feeding machine | |

| US2515166A (en) | Discharge hopper | |

| US3279634A (en) | Transfer apparatus | |

| US1273796A (en) | Device for removing cakes from carrier-sheets. | |

| US3200559A (en) | Fruit handling machine | |

| US2243879A (en) | Conveyer for pasteurizers | |

| US2648421A (en) | Unloading conveyer | |

| US1139492A (en) | Cotton-picker. | |

| US2078236A (en) | Can transporting device | |

| US2804982A (en) | Box dumper | |

| US2410147A (en) | Apparatus for grading fruits, vegetables, and other products according to size | |

| US1885494A (en) | Exhaust box |