US1663260A - Outboard-motor bracket - Google Patents

Outboard-motor bracket Download PDFInfo

- Publication number

- US1663260A US1663260A US729485A US72948524A US1663260A US 1663260 A US1663260 A US 1663260A US 729485 A US729485 A US 729485A US 72948524 A US72948524 A US 72948524A US 1663260 A US1663260 A US 1663260A

- Authority

- US

- United States

- Prior art keywords

- bracket

- canoe

- gunwale

- hull

- outboard

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B63—SHIPS OR OTHER WATERBORNE VESSELS; RELATED EQUIPMENT

- B63H—MARINE PROPULSION OR STEERING

- B63H20/00—Outboard propulsion units, e.g. outboard motors or Z-drives; Arrangements thereof on vessels

- B63H20/02—Mounting of propulsion units

- B63H20/06—Mounting of propulsion units on an intermediate support

Definitions

- This invention relates to improvements in outboard motor brackets.

- bracket for outboard motors, such bracket being adapted to facilitate the attachment of any standard outboard motor to such light-weight cra'tit as canoes or the like. It has heretofore been necessary to use comparatively cumbersome devices forattaching outboard motors to canoes i 1 a practical mannen, Canoes have so little inherent rigidity that it has frequently been thought necessary to support outboard motors therefrom by means of'brackets which are designed for attachment simultaneously to both gunwales of 'the canoe.

- bracket in effect, adds to the number of thwarts of the canoe and thus makes it more ditlicult for the operator of the canoe to move about therein. Furthermore many prior brackets have been usable only with specific outboard motors.

- the object of this invention to provide a bracket for outboard motors which may be attached to canoes or similar craft without being connected with more than one of the gunwales 0 and, without extending across the canoe, will nevertheless maintain such rigidity of support for the motor as to minimize vibration in the canoe and have ample strength.

- Figure 1 is a plan view of a spons'on canoe equipped with a bracket employing this invention.

- Figure 2 is a sectional view of a metallic casting of said bracket taken on the line indicated at section 22 in Figure 3.

- Figure 3 is an end elevation of the bracket, theside of the canoe being indicated in section on the line 3-3 of Figure 1.

- Figure 4 is a side elevation of the bracket as viewed on a line normal to the keel or longitudinal axis of the canoe.

- the canoe is designated in its entirety by the reference character 5 and will be noted to be provided in the usual manner with broad ribs 6. Being a sponson canoe it is provided with air chambers 7' along its sides.

- the body of the bracket comprises a cast ing 10 having a pair of spaced downwardly extending flanges 11 providing shoulders adapted to engage at spaced intervals the gunwales 12 of the canoe.

- the flanges 11 are carried on a substantially horizontal plate element 13 of the casting which is provided centrally with anupwardly bowed portion 14 generally oval in form as will be. noted in Figure 1. This bowed portion of the casting spans the space between the shoulders formed by flanges 11.

- the upwardly bowed portion 14 of the casting plate 13 extends. inwardly beyond the horizontal portions 15 of such plates and is carried downwardly as at 17 to provide an arm in which is threaded a screw 18 having a wing head 19 for its manipulation.

- a fitting 2O swiveled atthe end'of screw 18 carries an elongated clamping bar 21 which is preferably made of wood and of snflicient length to engage simultaneously a plurality of ribs of the canoe.

- This clamping bar cooperates with the shoulders provided by flanges 11 to engage the side of the canoe adjacent the gunwale for a very considerable portion of its length.

- the longitudinal extent-of bar 21 serves to make more rigid the portion of the canoe to which the bracket is applied.

- the arm 17 is of sufficient length to bring the clamping bar 21 well below the gunwales and thwarts so that in practically any standard make of canoe or similar light craft the clamping bar 21 will find a proper seat against the interior of the canoe

- flange 11 From the flange 11 similar flanges 24 and 25-extend about the perimeter of plate 13 in either direction and are integrally connected at their ends to the plate 26 which extends downwardly from the horizontal member 13 and is inclined with reference both to the clamping bar 21 and also with reference to the vertical.

- the plate 26 In addition to the bracing afforded to said plate by the flanges. 24 and 25, it is rigidificd by a triangular web 28 which'is substantially normal thereto, as is clearly indicated inthe drawings.

- a wooden block 30 Bolted to the plate 26 and taking therefrom its angle is a wooden block 30 which is adapted to simulate the transom of a square sterned boat. It is for such boats that outboard motors are commonly made and it is obvious that by the provision of a block having mechanical characteristics similar to those of the transom of such a boat it will be made possible to accommodate on the bracket herein disclosed, any type or manufacture-of motor which is 'made to be fitted to such a standard boat.

- the block 30 is provided with recesses 31 which resemble the recesses frequently provided inboat transoms especially made for outboard motors.

- the block 30 is carried at such a distance from the hull of the canoe as to leave ample room for such sponson floats as are indicated at 7.

- the device is equally well adapted, of course, to be' fitted to a canoe without such floats.

- the position of the block is such that it will in its ordinary position at the side of the canoe be exactly at right angles to the longitudinal axis of the canoe so that a motor supported on the block will tend to exert its propulsive force in the direction of the canoe axis.

- a fitting 32 includes a plate adapted to be bolted to block 30 as best shown in Figure 3,

- the metal casting comprising the body of this device is made of aluminum and is consequently comparatively light. It will be noted that the device, is not large nor ditiicult to handle and that it does not interfere with the movements about the canoe structure in a way tending to make it 7 withstand the vibrations and propulsive et fort of the motor.

- the flanges 11 have sufiicient extent to engagethe gunwale without injury and the Wooden bar 21 is calculated to engage the canoe ribs Without marring their finish. Similarly, the swiveled cushion 40 adjusts itself automatically under pressure to a po.-

- a single clamping screw 18 which, after the bolt 34 has received its preliminary setting, may be used indefinitely for the purpose of comprising a fitting adapted to extend transversely across the gunwale of a canoe at the side thereof, relatively tixed means for engaging said gunwale exteriorly thereof, an adjustable clamping mechanism connected with said fitting and opposed to said relatively'tixed means whereby to be adapted to clampingly engage the side of a boat, and a transom member comprising a block socured to said fitting adjacent said means and having a tree margin with which the transom engaging dev ces of portable outboard motors are engageahle, said block being at such an angle with respect to said fitting as to be adapted to be approxinmtely normal to the heel of a boat when said fitting is applied to one of the

- a bracket adapted to extend transversely of the gunwale of a boat and provided with a portion adapted to rest upon said gunwale and with depending arms upon either side of such portion, a set screw in one of said arms, a clamping member carried by said screw, means connected with said-bracket for engaging the side of the boat opposite to said clamping member and a transom block connected with said bracket. to receive support therefrom at the side of the boat to which said bracket is connected, said block having a free margin adapted to receive and mount a portable outboard motor and being at such an angle with regard to said bracket as to be adapted to support said motor beside such a boat in a forward propelling direction.

- a bracket arranged for the operative support of a portable outboard motor provided with transom connections, of a pair of longitudinally spaced shoulders on said bracket adapted to engage one side of the hull of about at spaced points, a clamping bar elongated to extend substantially between said points and to engage the other side of such a boat hull intermediate said points, and means for manually adjusting said clamping bar with reference to such shoulders, whereby clampingly to engage a boat hull therebetween.

- a bracket casting providing fiat surfaces adapted to rest-upon the gunwale of a boatand adjacent shoulders adapted exteriorly to abut said gunwale, of an arm depending from said bracket and opposed to said shoulder, a screw advtcrior below the gunwale of the hull" of a her and justable through said arm, a clamping bar mounted on said screw and of a length substantially toextend between said shoulders, an extension of said bracket beyond said shoulders, and a transomblock mounted on F0 said extensionat-an' acute angle to a line connecting said shoulders, said block having I a free margin adapted to receive and sup-i j port a portable outboard motor and to snap pend such a motorbeside a boat to which;

- bracket is connected in a position to propel the boat forwardly.

- a bracket provided. with a portion adapted to rest on a gunwale ⁇ of a canoe hull and provided interiorly and extcriorly with relatively adjustable hull engaging members, of a transom element sup ported by said bracket at the side thereof in a position to project laterally from a hull with which such bracket is engaged, and afl cushion member adjustably connected with,- said bracket for engagement with the excanoe upon which said bracket is mounted.

- a bracket adapted to support an outboard motor wholly from one side of .a canoe, said bracket comprising canoe engaging elements at a plurality of horizontally and vertically spaced points exteriorly of said canoe, a transom member adapted detachably to *arry an outboard motor and a single cla'mph ing member adjustably connected with said elements and dapted to engage the interior of said canoe intermediate said elements.

- a bracket adapted for the support of an outboard motor and providedwithhorizontally and vertically spaced hull engaging elements an arm extending downwardly along said hull in laterally spaced relation to said ele ments and a single clamp adjustable with 3 reference to said arm in the directionof said elements and intermediate thereof.

- a universal bracket for the purposes described said bracket comprisin in combination a horizontal member shou dered for v i engagement with exterior portions of a gun- Wale, an arm connected with said member and extending across said-gunwale and outwardly therefrom, a clamp adjustable with respect to said arm in the direction of said shouldered portion of said member and a transom element connected with said member in laterally spaced relation to the shouldered portion thereof. whereby to afford clearance for an air chamber.

- a universal bracket for the purposes described comprising in combination a horizontal-member shouldered for engagement with exterior portions .ofa gunwale, an arm connected with said, memextending across said gunwale and downwardly therefrom, a clamp adjustable with respect to said arm in the direction of said shouldered portion of said member, atransom element connected with said memher in laterally spaced relation to the shouldered portion thereof whereby to afford clearance for an air chamber, and a cushion adjustably connected with said transom member and adapted for contact exterior-1y with the hull of a canoe beneath said 'gun- Wale. 1

- a universal bracket for the purposes described,-said bracket comprising clamping elements engageable interiorly and exteriorly with the hull of a canoe and interconnected with each other, means supported from said elements for carrying an outboard motor in operative relation to saidcanoe, a cushion, and an adjustable cushion-carrying member in swiveled connection With the cushion.

- a device of the character described including a casting having a substantially horizontal portion with depending flanges providing shoulders adapted for contact exteriorly with a gunwale, a convex portion intermediate such flanges and extending beyond such flanges and downwardly between said flanges in the form of an arm, a clamping bar adjustably supported from said arm and elongated to be substantially co-extensive with the distance between said flanges, a plate inclined with reference to said horizontal portion and connected therewith in a position laterally spaced outwardly from said flanges and extending above said horizontal portion whereby to receive detachably an outboard motor. 7

- a metallic casting shouldered at longitudinally spaced points for engagement with a gunwale and provided with an arm extending across saidgunwale and downwardly, a screw adjustable through said arm, a longitudinally elongated clamping bar carried by said screw, a transom element supported in an inclined position laterally of said gunwalc, a screw adjustable with respect to said transom element and a cushion swiveled to the end of said screw.

- a universal bracket comprising a casting having flat portions adjacent its ends adapted to be supported on the gunwale of a canoe, shoulders projecting downwardly from the planes of said flat portions and adapted to engage exteriorly said gunwale, a shell intermediate the ends of said bracket and integral with the fiat portions thereof, said shell being l'ormcd to provide integrally a depending arm spaced from said shoulders, a

- clamping device carried by said arm and operatively adjustable toward said shoulders, and a transom block mounted upon said bracket member beyond said shoulders from said arm and provided with a free margin to receive and support the transom engaging portion of a portable outboard motor.

Description

March 20, 1928; 6 1,663,260 v J.-A. MOULD' OUTBOARD MOTOR BRACKET Filed Aug. 1. 1924 ATTORNEYS.

- Patented Mar. 20, 1928.

UNITED STATES PATENT OFFICE.

JAMES A. MOULD, OF MILWAUKEE, WISCONSIN, A$SIG1\l()R T EVINR'U'DE MOTOR COM- PANY, OF MILWAUKEE, WISCONSIN.

OUTBOARD-MOTOR- BRACKET.

Application filed August 1, 1924. Serial No. 729,485.

This invention relates to improvements in outboard motor brackets.

It is the primary object of this invention to produce a novel and simplified form of bracket for outboard motors, such bracket being adapted to facilitate the attachment of any standard outboard motor to such light-weight cra'tit as canoes or the like. It has heretofore been necessary to use comparatively cumbersome devices forattaching outboard motors to canoes i 1 a practical mannen, Canoes have so little inherent rigidity that it has frequently been thought necessary to support outboard motors therefrom by means of'brackets which are designed for attachment simultaneously to both gunwales of 'the canoe. Such a bracket, in effect, adds to the number of thwarts of the canoe and thus makes it more ditlicult for the operator of the canoe to move about therein. Furthermore many prior brackets have been usable only with specific outboard motors.

From the foregoing it willbe understood that it is, more specifically, the object of this invention to provide a bracket for outboard motors which may be attached to canoes or similar craft without being connected with more than one of the gunwales 0 and, without extending across the canoe, will nevertheless maintain such rigidity of support for the motor as to minimize vibration in the canoe and have ample strength.

Further objects of this invention are to provide a construction which will be as light and as strong as is possible, consistent with the objects before mentioned, to provide a device which will be simple, easyto manufacture, and of good appearance; and to provide a device which may be accommodated to various types of similar craft without-requiring any wide range of adjustment or modification for its attachment.

In the drawings:

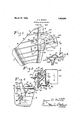

Figure 1 is a plan view of a spons'on canoe equipped with a bracket employing this invention.

Figure 2 is a sectional view of a metallic casting of said bracket taken on the line indicated at section 22 in Figure 3.

Figure 3 is an end elevation of the bracket, theside of the canoe being indicated in section on the line 3-3 of Figure 1.

Figure 4 is a side elevation of the bracket as viewed on a line normal to the keel or longitudinal axis of the canoe.

Like parts are identified by the same refer: ence characters throughout the several views.

The canoe is designated in its entirety by the reference character 5 and will be noted to be provided in the usual manner with broad ribs 6. Being a sponson canoe it is provided with air chambers 7' along its sides.

The body of the bracket comprises a cast ing 10 having a pair of spaced downwardly extending flanges 11 providing shoulders adapted to engage at spaced intervals the gunwales 12 of the canoe. The flanges 11 are carried on a substantially horizontal plate element 13 of the casting which is provided centrally with anupwardly bowed portion 14 generally oval in form as will be. noted in Figure 1. This bowed portion of the casting spans the space between the shoulders formed by flanges 11.

Projecting inwardly beyond flanges 11 the horizontal portions 15 of the plate 13 are arranged to rest upon the gunwale as is best shown in Figure 3. This provides a positive and stabilizing support for the entire structure.

The upwardly bowed portion 14 of the casting plate 13 extends. inwardly beyond the horizontal portions 15 of such plates and is carried downwardly as at 17 to provide an arm in which is threaded a screw 18 having a wing head 19 for its manipulation. A fitting 2O swiveled atthe end'of screw 18 carries an elongated clamping bar 21 which is preferably made of wood and of snflicient length to engage simultaneously a plurality of ribs of the canoe. This clamping bar cooperates with the shoulders provided by flanges 11 to engage the side of the canoe adjacent the gunwale for a very considerable portion of its length. The longitudinal extent-of bar 21 serves to make more rigid the portion of the canoe to which the bracket is applied. The arm 17 is of sufficient length to bring the clamping bar 21 well below the gunwales and thwarts so that in practically any standard make of canoe or similar light craft the clamping bar 21 will find a proper seat against the interior of the canoe hull.

From the flange 11 similar flanges 24 and 25-extend about the perimeter of plate 13 in either direction and are integrally connected at their ends to the plate 26 which extends downwardly from the horizontal member 13 and is inclined with reference both to the clamping bar 21 and also with reference to the vertical. In addition to the bracing afforded to said plate by the flanges. 24 and 25, it is rigidificd by a triangular web 28 which'is substantially normal thereto, as is clearly indicated inthe drawings.

Bolted to the plate 26 and taking therefrom its angle is a wooden block 30 which is adapted to simulate the transom of a square sterned boat. It is for such boats that outboard motors are commonly made and it is obvious that by the provision of a block having mechanical characteristics similar to those of the transom of such a boat it will be made possible to accommodate on the bracket herein disclosed, any type or manufacture-of motor which is 'made to be fitted to such a standard boat. For the purpose of receiving securely the clamping screws of an outboard motor-the block 30 is provided with recesses 31 which resemble the recesses frequently provided inboat transoms especially made for outboard motors. It will benoted that the block 30 is carried at such a distance from the hull of the canoe as to leave ample room for such sponson floats as are indicated at 7. The device is equally well adapted, of course, to be' fitted to a canoe without such floats.

The position of the block is such that it will in its ordinary position at the side of the canoe be exactly at right angles to the longitudinal axis of the canoe so that a motor supported on the block will tend to exert its propulsive force in the direction of the canoe axis.

In'every canoe or like craft-there will be found some portion of the gunwa'le which will-be atsuch an angle with respect to the keel that block 30 will be at right angles to the keel. If the bracket is otherwise positioned, the block 30 may be at some angle other than 90 with respect to the keel, but slight deviations may be. taken care of by a corresponding manipulation of the tiller handle from its normal center line division, particularly if the outboard motor isof the type in which steering is accomplished by con trollin the direction of the propeller shaft.

Whi e the clamp made up of flanges 11 and the bar 21 would be adequate to secure the device to a canoe in such fashion as to negative the possibility of its accidental disconnection, nevertheless it is preferred to provide an additional co-operative canoe engaging element which rigidities and strengthens the canoe hull as well as tends 'to dampen vibrations therein.

- A fitting 32 includes a plate adapted to be bolted to block 30 as best shown in Figure 3,

and, in integral connection with said plate,

a threaded sleeve 33 within which a bolt thereon upon this swiveled connection with bolt 34.

The fact that the bar 21 is located somedistance below the flanges 11 results, when the thumb-screw 18 is turned up, in the production of a force tending to tilt the entire bracket about the gunwale as an axis. In such tilting movement the cushion 40 is brought into pressure contact with the outside of the canoe hull and by a preliminary adjustment of screw 34, it is possible so to adjust the position of the cushion that it will contact with the hull when the bracket is horizontal, substantially as indicated. This arrangement results in establishing contact with the hull at a plurality of widely spaced points, thereby dampening vibration and rigidifying the canoe as well as establishing an excellent engagement of the bracket with the canoe.

In practice the metal casting comprising the body of this device is made of aluminum and is consequently comparatively light. It will be noted that the device, is not large nor ditiicult to handle and that it does not interfere with the movements about the canoe structure in a way tending to make it 7 withstand the vibrations and propulsive et fort of the motor.

An important feature of this device is the arrangement whereby permanent attachment to any part of the canoe is unnecessary. The flanges 11 have sufiicient extent to engagethe gunwale without injury and the Wooden bar 21 is calculated to engage the canoe ribs Without marring their finish. Similarly, the swiveled cushion 40 adjusts itself automatically under pressure to a po.-

sition for floating contact with the canoe hull, and, being non-metallic and yieldable, it will not injure either the finish or structure of the craft. All of these several points of contact are established by the use of a single clamping screw 18 which, after the bolt 34 has received its preliminary setting, may be used indefinitely for the purpose of comprising a fitting adapted to extend transversely across the gunwale of a canoe at the side thereof, relatively tixed means for engaging said gunwale exteriorly thereof, an adjustable clamping mechanism connected with said fitting and opposed to said relatively'tixed means whereby to be adapted to clampingly engage the side of a boat, and a transom member comprising a block socured to said fitting adjacent said means and having a tree margin with which the transom engaging dev ces of portable outboard motors are engageahle, said block being at such an angle with respect to said fitting as to be adapted to be approxinmtely normal to the heel of a boat when said fitting is applied to one of the rcarwardly converging gunwales of such a. boat.

2. In a device of the character deseribedf the combination of a bracket adapted to extend transversely of the gunwale of a boat and provided with a portion adapted to rest upon said gunwale and with depending arms upon either side of such portion, a set screw in one of said arms, a clamping member carried by said screw, means connected with said-bracket for engaging the side of the boat opposite to said clamping member and a transom block connected with said bracket. to receive support therefrom at the side of the boat to which said bracket is connected, said block having a free margin adapted to receive and mount a portable outboard motor and being at such an angle with regard to said bracket as to be adapted to support said motor beside such a boat in a forward propelling direction.

3. In a device of the character described, the combination with a bracket arranged for the operative support of a portable outboard motor provided with transom connections, of a pair of longitudinally spaced shoulders on said bracket adapted to engage one side of the hull of about at spaced points, a clamping bar elongated to extend substantially between said points and to engage the other side of such a boat hull intermediate said points, and means for manually adjusting said clamping bar with reference to such shoulders, whereby clampingly to engage a boat hull therebetween.

4. In a device of the character described, the combination with a bracket casting providing fiat surfaces adapted to rest-upon the gunwale of a boatand adjacent shoulders adapted exteriorly to abut said gunwale, of an arm depending from said bracket and opposed to said shoulder, a screw advtcrior below the gunwale of the hull" of a her and justable through said arm, a clamping bar mounted on said screw and of a length substantially toextend between said shoulders, an extension of said bracket beyond said shoulders, and a transomblock mounted on F0 said extensionat-an' acute angle to a line connecting said shoulders, said block having I a free margin adapted to receive and sup-i j port a portable outboard motor and to snap pend such a motorbeside a boat to which;

such bracket is connected in a position to propel the boat forwardly.

5. In a device of the character described" the combination with a bracket provided. with a portion adapted to rest on a gunwale} of a canoe hull and provided interiorly and extcriorly with relatively adjustable hull engaging members, of a transom element sup ported by said bracket at the side thereof in a position to project laterally from a hull with which such bracket is engaged, and afl cushion member adjustably connected with,- said bracket for engagement with the excanoe upon which said bracket is mounted.

(3. A bracket adapted to support an outboard motor wholly from one side of .a canoe, said bracket comprising canoe engaging elements at a plurality of horizontally and vertically spaced points exteriorly of said canoe, a transom member adapted detachably to *arry an outboard motor and a single cla'mph ing member adjustably connected with said elements and dapted to engage the interior of said canoe intermediate said elements.

7. As a new article of manufacture, a bracket adapted for the support of an outboard motor and providedwithhorizontally and vertically spaced hull engaging elements an arm extending downwardly along said hull in laterally spaced relation to said ele ments and a single clamp adjustable with 3 reference to said arm in the directionof said elements and intermediate thereof. "1

8. A universal bracket for the purposes described, said bracket comprisin in combination a horizontal member shou dered for v i engagement with exterior portions of a gun- Wale, an arm connected with said member and extending across said-gunwale and outwardly therefrom, a clamp adjustable with respect to said arm in the direction of said shouldered portion of said member and a transom element connected with said member in laterally spaced relation to the shouldered portion thereof. whereby to afford clearance for an air chamber.

9. A universal bracket for the purposes described, said bracket comprising in combination a horizontal-member shouldered for engagement with exterior portions .ofa gunwale, an arm connected with said, memextending across said gunwale and downwardly therefrom, a clamp adjustable with respect to said arm in the direction of said shouldered portion of said member, atransom element connected with said memher in laterally spaced relation to the shouldered portion thereof whereby to afford clearance for an air chamber, and a cushion adjustably connected with said transom member and adapted for contact exterior-1y with the hull of a canoe beneath said 'gun- Wale. 1

10. A universal bracket for the purposes described,-said bracket comprising clamping elements engageable interiorly and exteriorly with the hull of a canoe and interconnected with each other, means supported from said elements for carrying an outboard motor in operative relation to saidcanoe, a cushion, and an adjustable cushion-carrying member in swiveled connection With the cushion.

a 11. A device of the character described, including a casting having a substantially horizontal portion with depending flanges providing shoulders adapted for contact exteriorly with a gunwale, a convex portion intermediate such flanges and extending beyond such flanges and downwardly between said flanges in the form of an arm, a clamping bar adjustably supported from said arm and elongated to be substantially co-extensive with the distance between said flanges, a plate inclined with reference to said horizontal portion and connected therewith in a position laterally spaced outwardly from said flanges and extending above said horizontal portion whereby to receive detachably an outboard motor. 7

12. In a device of the character described, a metallic casting shouldered at longitudinally spaced points for engagement with a gunwale and provided with an arm extending across saidgunwale and downwardly, a screw adjustable through said arm, a longitudinally elongated clamping bar carried by said screw, a transom element supported in an inclined position laterally of said gunwalc, a screw adjustable with respect to said transom element and a cushion swiveled to the end of said screw. I

13. As a new article of manufacture, a universal bracket comprising a casting having flat portions adjacent its ends adapted to be supported on the gunwale of a canoe, shoulders projecting downwardly from the planes of said flat portions and adapted to engage exteriorly said gunwale, a shell intermediate the ends of said bracket and integral with the fiat portions thereof, said shell being l'ormcd to provide integrally a depending arm spaced from said shoulders, a

clamping device carried by said arm and operatively adjustable toward said shoulders, and a transom block mounted upon said bracket member beyond said shoulders from said arm and provided with a free margin to receive and support the transom engaging portion of a portable outboard motor.

JAMES A. MOULD.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US729485A US1663260A (en) | 1924-08-01 | 1924-08-01 | Outboard-motor bracket |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US729485A US1663260A (en) | 1924-08-01 | 1924-08-01 | Outboard-motor bracket |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| US1663260A true US1663260A (en) | 1928-03-20 |

Family

ID=24931253

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| US729485A Expired - Lifetime US1663260A (en) | 1924-08-01 | 1924-08-01 | Outboard-motor bracket |

Country Status (1)

| Country | Link |

|---|---|

| US (1) | US1663260A (en) |

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2470439A (en) * | 1947-03-03 | 1949-05-17 | Frederick E Kohler | Safety plate |

| US2475889A (en) * | 1948-02-16 | 1949-07-12 | Harry M Hafele | Motor mounting |

| US4041738A (en) * | 1976-05-10 | 1977-08-16 | Vann Stephen R | Locking device for outboard motor |

| US4616591A (en) * | 1985-04-18 | 1986-10-14 | Minor John M | Floatation, splashless canoe motor mount |

| US20170190405A1 (en) * | 2015-03-05 | 2017-07-06 | Phillip Reed | Side-mounted trolling motors and control systems |

-

1924

- 1924-08-01 US US729485A patent/US1663260A/en not_active Expired - Lifetime

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2470439A (en) * | 1947-03-03 | 1949-05-17 | Frederick E Kohler | Safety plate |

| US2475889A (en) * | 1948-02-16 | 1949-07-12 | Harry M Hafele | Motor mounting |

| US4041738A (en) * | 1976-05-10 | 1977-08-16 | Vann Stephen R | Locking device for outboard motor |

| US4616591A (en) * | 1985-04-18 | 1986-10-14 | Minor John M | Floatation, splashless canoe motor mount |

| US20170190405A1 (en) * | 2015-03-05 | 2017-07-06 | Phillip Reed | Side-mounted trolling motors and control systems |

| US10633069B2 (en) * | 2015-03-05 | 2020-04-28 | Phillip Reed | Side-mounted trolling motors and control systems |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US2832304A (en) | Stern-mounted hydrofoil device | |

| US3291088A (en) | Multi-purpose boat | |

| US3433195A (en) | Hydrofoil device for outboard motors | |

| US2886462A (en) | Boat attachment | |

| US3902443A (en) | Combination boat stabiliser and sail kit | |

| NO144769B (en) | DEVICE FOR INSTALLATION OF A ROD PROPELLER DEVICE ON A FLOATING VESSEL. | |

| US6305306B1 (en) | Watercraft stabilizer system | |

| US10940918B2 (en) | Watercraft with transom-mounted lifting fin | |

| US3094962A (en) | Hydro plane | |

| US1663260A (en) | Outboard-motor bracket | |

| US3062167A (en) | Trim attachment for power boats | |

| US4411214A (en) | Rowing scull | |

| JPH04212697A (en) | Stabilizer for ship | |

| US3604384A (en) | Boats | |

| US4516941A (en) | Rowing outrigger | |

| US7828614B2 (en) | Piggyback auxiliary motor bracket | |

| US3289226A (en) | Pontoon boat | |

| US3629885A (en) | Motor-mounting bracket | |

| US3696772A (en) | Boat stabilizer-sailing rig | |

| US3171382A (en) | Propeller mechanism for boats | |

| US1857347A (en) | Hydroplane ship | |

| US3001499A (en) | Rear mounted planing and stabilizing structure for power boats | |

| US2525933A (en) | Sail-equipped lifeboat having leeboards | |

| US3083679A (en) | Motor boat structure provided with a transverse vertical engine bed | |

| US1690435A (en) | Outboard-engine bracket |