JP4591860B2 - Hot water tap - Google Patents

Hot water tap Download PDFInfo

- Publication number

- JP4591860B2 JP4591860B2 JP2000075433A JP2000075433A JP4591860B2 JP 4591860 B2 JP4591860 B2 JP 4591860B2 JP 2000075433 A JP2000075433 A JP 2000075433A JP 2000075433 A JP2000075433 A JP 2000075433A JP 4591860 B2 JP4591860 B2 JP 4591860B2

- Authority

- JP

- Japan

- Prior art keywords

- valve body

- water

- hot water

- water inlet

- housing

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Description

【0001】

【発明の属する技術分野】

本発明は、自動温度調整機能を有する湯水混合栓に係り、特に感温素子により弁体の位置を適正化して混合水温度の安定を図るようにした装置構成に関する。

【0002】

【従来の技術】

従来の技術において、弁体の径方向の大きさに影響を与えている弁体及びハウジングの湯流路と水流路を遮断するシール部の構造は、例えば特開平8−75037に記載されているように、ハウジング及び弁体の周方向のほぼ同一面に、直径の異なる2個のOリングが中心を同じくして各々装着されている。図5に従来例による縦断面図を示す。ハウジング1においては、このハウジング1の外周壁上であって、ハウジング1の軸線方向に鉛直に設けられた溝18に収められたOリング19が、前記溝18の底周面および水栓本体30の内壁面17と当接して、ハウジング1内に流入する水流入口aと湯流入口bを遮断し、湯と水がハウジング1の外側で混合するのを防止している。

【0003】

一方、弁体4内に流入する水と湯を仕切る遮断構造は、弁体4の外壁上に、弁体の長さの軸方向の概略中心かつ軸線方向に鉛直に設けられた溝20に収められたOリング21が、この溝20の底周面と前記ハウジング1の内周面とに当接して弁体4内に流入する湯と水を遮断する構造となっている。

【0004】

すなわち、従来の技術における水流路と湯流路を遮断する目的で設けられたハウジング及び弁体の構造は、弁体4の長さの概略中心位置で弁体4の軸を中心とする鉛直周面上に、2個の異なるOリング20と21が配置されている。

【0005】

図4に従来の弁体とハウジングの構成を示した要部断面図を示す。ここで、弁体4回りにおけるハウジング1の外径寸法Aを構成する部品の要素で言えば、弁体4の外壁に設けられたOリング溝の内径寸法B、及びこのOリング溝20の深さ寸法C、及び弁体4の外径とハウジング1に設けられたOリング溝18との間の肉厚寸法D、及び該ハウジングのOリング溝18の深さ寸法Eの4つの要素から構成されている。

【0006】

【発明が解決しようとする課題】

一般的に自動温度調節機能を有し湯水の量を調節する弁体が中空円筒形状をした湯水混合栓においては、その吐出流量に影響する圧力損失の最も大きい箇所は、弁体と湯弁座および水弁座との間に設けられた円筒形状の隙間の総面積であることが多く、本件で取り上げた従来例もこれに該当する。ここで弁体と湯弁座および水弁座との間に設けられた、湯と水が弁体内に流入するための円筒形状の隙間の総面積を開口面積として、吐出流量との関係を以下概念的に図4を用いて説明する。図4では弁体4は水弁座2に着座されている状態である。開口面積とは、弁体の外径Fの円周長さと、弁体が湯水流入量を調節するために軸線方向に移動しうるストロークGとの積で表すものとする。ここで弁体の外径について言えば、弁体の軸線に垂直で弁体の両端面に設けられて弁体内に流入する湯及び水を遮断する約1mm幅の環形状から成るシート部22の外径と等しいものとする。

弁体の最大径Fの円周長さLは、下記の(1)式で表される。

【0007】

L=F×π ・・・・・・・(1)

【0008】

開口面積Sは前記数1に、弁体のストロークのGを乗じた、(2)式で表わされる

【0009】

S=L×G=F×π×G ・・・・・・・(2)

【0010】

開口面積S、すなわち弁体内に湯と水が流入しうる面積となる。すなわちこの面積が大きいほど、弁体の圧力損失が緩和されより多くの流量が弁体を通過し、湯水混合栓からの吐出流量の増加につながる。

【0011】

この従来の構造では、湯水混合栓の本体を同一のままハウジングだけ取り替えて、より吐出流量の多いものにしようとした場合、すなわちハウジングの外径寸法が決まっている場合には、前述した弁体4の外壁に設けられたOリング溝の内径寸法B、及びこのOリング溝20の深さ寸法C、及び弁体4の外径とハウジング1に設けられたOリング溝18との間の肉厚寸法D、及び該ハウジングのOリング溝18の深さ寸法Eの4つの部品の構成要素が必要なため、前記開口面積を拡大するために弁体の外径Fを拡径して、吐水量を多くすることは構造的に困難であった。

【0012】

本発明の目的は、湯水混合栓本体に設けられた自動温度調節機能を有するハウジングの取り付け固定寸法を変えずに、すなわち従来のハウジングと外径寸法を変えることなく、湯水混合栓から吐出する流量をより多くできる自動温度調節機能を有するハウジングを提供することである。

【0013】

【課題を解決するための手段】

上記目的を達成するためになされた本発明は、筒状のハウジング部に、このハウジング部の周壁に、軸線方向に間隔をおいて設けた水流入口及び湯流入口と、前記水流入口と湯流入口との間で軸線方向に移動可能に組み込んだほぼ中空円筒状の弁体と、前記水流入口側で前記弁体の軸線方向の一端面に対向する水弁座と、前記湯流入口側で前記弁体の軸線方向の他端面に対向する湯弁座と、前記水弁座の下流側のハウジングの周壁に開けた混合水流出口と、前記水弁座から混合水流出口までの混合水流路中に組み込まれ前記弁体を前記湯弁座側に付勢する感温素子と、温度設定用の操作部に連接して前記弁体を前記水弁座側に付勢するばねとを備え、このハウジング部を湯水混合栓の本体にカートリッジ状に装着する湯水混合栓において、前記水流入口と前記湯流入口との間で前記ハウジングを軸線方向に垂直に分割し、分割された各々の端面を軸線方向に一定間隔を置いて対峙させ、該端面に挟まれた位置に前記弁体を配置すると共に、前記弁体の外周面に前記水流入口と前記湯流入口とを遮断するシール材を配置すると共に、分割した各ハウジングを前記弁体の内径部を通じて連結する連結部材を備えていることを特徴とした。

【0014】

これにより、ハウジング内に流入する湯と水を遮断するシール材と、弁体の外周面に接して弁体内に流入する湯と水を遮断するシール材とを同一部品としたため、従来例にある弁体に装着されたシール材に接するハウジングの周壁の肉厚Dが必要なくなり、必要でなくなった肉厚分を弁体の外周径に加えて拡径することが可能となる。

【0015】

これにより従来のハウジングの外径寸法を変えることなく、弁体の外径を大きくすることができ、前述したように湯と水が弁体内に流入する開口面積が大きくなり、湯水混合栓から吐出する流量を多くできる。

【0016】

さらに、前記シール材が前記弁体の外周面に装着されていることにより、ハウジングに流入する湯と水を遮断するシール材が弁体に装着されているため、弁体の外径そのものをハウジングの外径とほぼ同一の寸法まで大きくすることが可能で、これにより弁体の外径をさらに大きくすることができる。

【0017】

また、本発明は、前記分割された各々のハウジングが、前記温度設定用スピンドルと一体またはこれに連結された軸棒を介して連結されたことを特徴とした。これにより分割された各ハウジングを連結するための部材である軸棒が、ハウジングのほぼ中心軸線付近に位置するため、各々のハウジングが対峙して設けられてシール材が位置する環形状の場所には何ら影響することはない。

【0018】

【発明の実施の形態】

図1は本発明の実施例を示した湯水混合栓の構造を示す正面縦断面図である。図1において湯水混合栓の本体30の中に組み込まれる湯側ハウジング1aと水側ハウジング1bとから成るハウジング1の周壁には軸線方向に間隔をおいて水流入口a及び湯流入口bをそれぞれ開けると共に、これらの流入口a,bに連通する下流側には混合水流出口cを開けている。水流入口aはハウジング1の中の水室dに連通し、同様に湯流入口bと混合水流出口cはそれぞれ湯室e及び混合室fに連通し、この混合室fを経由して混合水が吐出端から吐出される。

【0019】

ハウジング1の内部には、水流入口a側及び湯流入口b側にそれぞれ水弁座2及び湯弁座3を設ける。そして、これらの水弁座2と湯弁座3との間には、軸線方向に移動可能なほぼH状の縦断面を持つ温度調整用の弁体4を組み込む。この弁体4は、その軸線方向の両端を水弁座2及び湯弁座3との着座面とし、水側と湯側とを区画する隔壁4aに連絡口4bを開けたものである。そして、湯側ハウジング1aと水側ハウジング1bとに挟まれた位置であって弁体4の周りには環状のシール材5を組み込み、このシール材5を本体30の内壁に密着させて水側と湯側とを遮断している。

【0020】

ハウジング1の内部は、弁体4によって水室d及び湯室eに区画され、これらの下流に混合室fが形成される。そして、混合室fから水室dにかけて、一端が弁体4の隔壁4aに突き当たるスリーブ7を組み込む。このスリーブ7は水室dに臨む周壁にフィン状の部位7aによって水用の開口7bを開け、隔壁4aの連絡口4bと連通し、水室d及び湯室eと混合室fが連通し、弁体4の水弁座2及び湯弁座3に対する弁開度に応じた量比の水と湯が混合室fへ供給される。

【0021】

混合室fには水側ハウジング1bの内壁に一端が突き当たり他端をスリーブ7の端面に嵌め込んだ感温素子8を組み込む。この感温素子8は、混合室f内を通過する混合水の温度に感応して長さが変化し、吐出される混合水の温度が設定温度に保持されるように弁体4をシフトさせる機能を持つ。なお、感温素子8は形状記憶合金製に限らず、合成樹脂製の形状記憶素子を素材とするものや熱膨張・収縮性を持つワックスを封入した感温体であってもよい。

【0022】

弁体4の位置設定は、湯側ハウジング1aに挿入されたスピンドル9に連結されたハンドル11によって行う。ハンドル11の回転操作によりスピンドル9は連動回転し、この回転力を軸力に変換するためにネジ連結されたガイド20およびこれに当接するバイアススプリング10を介して弁体4に連結している。

【0023】

湯室eに組み込まれたバイアススプリング10は、感温素子8の伸長方向と反対方向に弁体4を付勢する。このバイアススプリング10は弁体4を水弁座2側に移動させる機能を持ち、混合温度に応じて弁体4を湯弁座3側に移動させる感温素子8に対して弁体4の位置をバランスさせる。

【0024】

図2は図1の構成部品を分解した斜視図である。湯側ハウジング1aの一端に設けられた開放部23よりスピンドル9を挿入して、スピンドル9と一体に形成されたスピンドル軸9aに、スピンドル9の回転力を軸力に変換するためガイド20、バイアススプリング10、及びワッシャ12を組み込む。次にシール材5を周囲に取付けて、このシール材5周囲に潤滑剤を塗布した弁体4をスピンドル軸9aに通し入れる。さらに感温素子8、ワッシャ13及びスリーブ7を組み込んだ水側ハウジング1bを、スピンドル軸9aに通し、水側ハウジング1bの端面より、スピンドル軸9aの溝部9bを貫通させて、この溝部9bに止め輪14を挿入固定して、湯側ハウジング1aと水側ハウジング1bを連結してハウジング1と成る。ここで、シール材5は、湯側ハウジング1aと水側ハウジング1bとが対峙する端面とに挟まれた構成となり、ハウジング1本来の水流入口aと湯流入口bとを遮断する機能、及び弁体4外周面においての水と湯を遮断する機能という二つの機能を持つ。

【0025】

図3は第二の発明による縦断面図であり、分割されたハウジング1a及び1bに挟まれる位置に弁体4を配置して、この弁体4の中心軸に鉛直でこの軸上に中心を有する環状の溝15を設け、この溝15の底周面に当接し、また本体30の内壁面17に当接し摺動する環形状のシール材16を配置したものである。このシール材16は弁体4内に流入する湯及び水を遮断する機能と、ハウジング1に流入する湯流入口bと水流入口aを遮断する機能をもつ。このように弁体4そのものを分割したハウジングの間に挟むことによって弁体4の外径をさらに大きくすることができ、第1の発明で述べた構成よりも通水面積を大きく確保でき圧力損失が小さくなり、さらに吐水量を増大させることができる。

【0026】

本発明で説明した分割されたハウジングが対峙して設けられた環状のスペースに配置するシール材は、必ずしも湯流路と水流路を完全に遮断する必要はなく、シール材が例えば樹脂製であってスリット溝が設けられていて多少の湯と水が逆流するものであっても良い。

【0027】

また、分割された各ハウジングを連結する軸棒は、必ずしも温度設定用スピンドルと一体でなくてもよく、例えばスピンドルに対して軸棒が、螺や樹脂爪などにより連結されていても良い。

【0028】

【発明の効果】

第一の発明により、ハウジングに流入する湯と水を遮断するシール材と、弁体に接して弁体内に流入する湯と水を遮断するシール材とを同一部品としたため、従来例にあるように弁体に装着されたシール材に接するハウジングそのものの周壁の肉厚が必要なくなり、必要でなくなった肉厚分を弁体の外周径に加えることが可能となり、従来のハウジングの外周寸法すなわち湯水混合栓本体への挿入固定に必要な寸法を変えることなく、弁体の外径を大きくすることが可能となる。よって弁体の外径が大きくなると、前述したように湯と水が弁体内に流入しうる通水面積が大きくなり、湯水混合栓から吐出する流量を多くできる。

【0029】

第二の発明により、ハウジングに流入する湯と水を遮断するシール材が弁体に装着されているため、弁体の外径をおよそハウジングの外径とほぼ同一の寸法まで大きくすることが可能で、これにより弁体の外径を第一の発明よりもさらに大きくすることができ吐水量が増やせる。

【0030】

第三の発明により、ハウジングのほぼ中心軸線付近に配置されたスピンドルに連結された軸棒を介して分割したハウジングを連結しているため、分割されたハウジングが対峙してシール材が位置する環形状の場所には何ら影響することはなく、本発明の第一項及び第二項の構成を満足させる。

【図面の簡単な説明】

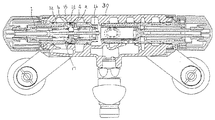

【図1】本発明の第一の発明の実施例を示した縦断面図。

【図2】図1の実施例の構成部品の分解斜視図。

【図3】第二の発明の実施例を示した縦断面図。

【図4】従来例による要部の断面図。

【図5】従来例を示した縦断面図。

【符号の説明】

a:水流入口

b:湯流入口

c:混合水流出口

d:水室

e:湯室

f:混合室

g:内壁ガイド

A:ハウジングの外径寸法

B:弁体のOリング溝の内径寸法

C:弁体のOリング溝の深さ寸法

D:ハウジングのOリング装着部の肉圧寸法

E:ハウジングのOリング溝の深さ寸法

F:弁体の外径

G:ストローク

1:ハウジング

1a:湯側ハウジング

1b:水側ハウジング

2:水弁座

3:湯弁座

4:弁体

4a:隔壁

4b:連絡口

5:シール材

7:スリーブ

7a:フィン状の部位

7b:水用の開口

8:感温素子

9:スピンドル

9a:スピンドル軸

9b:溝部

10:バイアススプリング

11:ハンドル

12:ワッシャ

13:ワッシャ

14:止め輪

15:弁体のOリング取り付け溝

16:シール材

17:本体内壁面

18:溝

19:Oリング

20:溝

21:Oリング

22:シート部

23:開放部

30:湯水混合栓本体[0001]

BACKGROUND OF THE INVENTION

The present invention relates to a hot and cold water mixing tap having an automatic temperature adjustment function, and more particularly to an apparatus configuration in which the position of a valve element is optimized by a temperature sensing element so as to stabilize the mixed water temperature.

[0002]

[Prior art]

In the prior art, the structure of a seal portion that shuts off the hot water flow path and the water flow path of the housing and the housing, which influences the size of the valve body in the radial direction, is described in, for example, Japanese Patent Laid-Open No. 8-75037. As described above, two O-rings having different diameters are mounted on substantially the same surface in the circumferential direction of the housing and the valve body, with the same center. FIG. 5 shows a longitudinal sectional view of a conventional example. In the housing 1, an O-

[0003]

On the other hand, the blocking structure for partitioning the water and hot water flowing into the

[0004]

That is, the structure of the housing and the valve body provided for the purpose of blocking the water flow path and the hot water flow path in the prior art has a vertical circumference centered on the axis of the

[0005]

FIG. 4 shows a cross-sectional view of the main part showing the configuration of a conventional valve body and housing. Here, in terms of the components constituting the outer diameter A of the housing 1 around the

[0006]

[Problems to be solved by the invention]

In general, in a hot and cold water mixing tap that has an automatic temperature control function and a valve body that adjusts the amount of hot water and has a hollow cylindrical shape, the point of greatest pressure loss that affects the discharge flow rate is the valve body and the water valve seat. It is often the total area of a cylindrical gap provided between the water valve seat and the conventional example taken up in this case. Here, the total area of a cylindrical gap provided between the valve body and the hot water valve seat and the water valve seat for flowing hot water and water into the valve body is defined as the opening area, and the relationship with the discharge flow rate is as follows: The concept will be described with reference to FIG. In FIG. 4, the

The circumferential length L of the maximum diameter F of the valve body is expressed by the following equation (1).

[0007]

L = F × π (1)

[0008]

The opening area S is expressed by equation (2), which is obtained by multiplying the equation 1 by the stroke G of the valve disc.

S = L × G = F × π × G (2)

[0010]

The opening area S, that is, the area where hot water and water can flow into the valve body. That is, the larger the area, the more the pressure loss of the valve body is relaxed and a larger flow rate passes through the valve body, leading to an increase in the discharge flow rate from the hot and cold water mixing tap.

[0011]

In this conventional structure, when the main body of the hot and cold water mixing plug is replaced with the same housing and the discharge flow rate is increased, that is, when the outer diameter of the housing is determined, the above-described valve body is used. 4, an inner diameter dimension B of the O-ring groove provided on the

[0012]

An object of the present invention is to provide a flow rate to be discharged from a hot and cold water mixing tap without changing the mounting and fixing dimensions of the housing having an automatic temperature control function provided in the hot and cold water mixing tap body, that is, without changing the outer diameter of the conventional housing. It is an object to provide a housing having an automatic temperature control function capable of increasing the number of times.

[0013]

[Means for Solving the Problems]

In order to achieve the above object, the present invention provides a cylindrical housing part, a water inlet and a hot water inlet provided on the peripheral wall of the housing part at intervals in the axial direction, and the water inlet and the hot water flow. A substantially hollow cylindrical valve body which is incorporated so as to be movable in the axial direction between the inlet, a water valve seat facing one end surface in the axial direction of the valve body on the water inlet side, and on the hot water inlet side In the mixed water flow path from the water valve seat to the mixed water outlet, the hot water valve seat facing the other end surface in the axial direction of the valve body, the mixed water outlet opened in the peripheral wall of the housing on the downstream side of the water valve seat A temperature sensing element that urges the valve body toward the hot water valve seat side, and a spring that is connected to a temperature setting operation portion and biases the valve body toward the water valve seat side. In the hot and cold water mixer tap where the housing is attached to the main body of the hot and cold water mixer tap in the form of a cartridge, The housing is vertically divided in the axial direction between the water inlet and the hot water inlet, and the divided end faces are opposed to each other at regular intervals in the axial direction, and the valve is positioned between the end faces. And a connecting member for connecting the divided housings through the inner diameter portion of the valve body , and a sealing member for blocking the water inlet and the hot water inlet on the outer peripheral surface of the valve body. It was characterized by having.

[0014]

As a result, the sealing material that shuts off the hot water and water flowing into the housing and the sealing material that shuts off the hot water and water flowing into the valve body in contact with the outer peripheral surface of the valve body are the same parts, so that there is a conventional example. The wall thickness D of the peripheral wall of the housing in contact with the sealing material attached to the valve body is no longer necessary, and the unnecessary thickness can be increased in addition to the outer diameter of the valve body.

[0015]

As a result, the outer diameter of the valve body can be increased without changing the outer diameter of the conventional housing. As described above, the opening area through which hot water and water flow into the valve body is increased and discharged from the hot and cold water mixing tap. Can increase the flow rate.

[0016]

Furthermore, more particularly the sealing member is mounted on the outer peripheral surface of the valve body, the seal member for blocking the hot water flowing into the housing is mounted to the valve body, the outer diameter itself of the valve body it can be increased to almost the same dimension as the outer diameter of the housing, thereby increasing the outer diameter of the valve body further.

[0017]

Further, the present invention is characterized in that each of the divided housings is connected to the temperature setting spindle through a shaft bar that is integral with or connected to the temperature setting spindle. Since the shaft rod, which is a member for connecting the divided housings, is located in the vicinity of the central axis of the housing, each housing is provided opposite to each other in a ring-shaped place where the sealing material is located. Has no effect .

[0018]

DETAILED DESCRIPTION OF THE INVENTION

FIG. 1 is a front longitudinal sectional view showing the structure of a hot and cold water mixing tap showing an embodiment of the present invention. In FIG. 1, a water inlet a and a hot water inlet b are opened on the peripheral wall of the housing 1 composed of a hot water side housing 1a and a water side housing 1b incorporated in the

[0019]

Inside the housing 1, a water valve seat 2 and a hot water valve seat 3 are provided on the water inlet a side and the hot water inlet b side, respectively. And between these water valve seats 2 and hot water valve seats 3, a temperature regulating

[0020]

The interior of the housing 1 is partitioned into a water chamber d and a hot water chamber e by a

[0021]

The mixing chamber f incorporates a temperature sensitive element 8 having one end abutting against the inner wall of the water-side housing 1b and the other end fitted into the end face of the

[0022]

The position of the

[0023]

The

[0024]

FIG. 2 is an exploded perspective view of the components shown in FIG. A spindle 9 is inserted from an open portion 23 provided at one end of the hot water side housing 1a, and a

[0025]

FIG. 3 is a longitudinal sectional view according to the second invention, in which a

[0026]

The sealing material disposed in the annular space provided with the divided housings opposed to each other described in the present invention does not necessarily need to completely block the hot water channel and the water channel, and the sealing material is made of, for example, resin. Further, a slit groove may be provided, and some hot water and water may flow backward.

[0027]

Further, the shaft rod that connects the divided housings does not necessarily have to be integrated with the temperature setting spindle. For example, the shaft rod may be connected to the spindle by a screw or a resin claw.

[0028]

【The invention's effect】

According to the first invention, the sealing material for blocking hot water and water flowing into the housing and the sealing material for blocking the hot water and water flowing into the valve body in contact with the valve body are the same parts, so that there is a conventional example. The thickness of the peripheral wall of the housing itself in contact with the sealing material attached to the valve body is no longer necessary, and the unnecessary thickness can be added to the outer diameter of the valve body. The outer diameter of the valve body can be increased without changing the dimensions necessary for insertion and fixation into the mixing plug body. Therefore, when the outer diameter of the valve body increases, the water flow area through which hot water and water can flow into the valve body increases as described above, and the flow rate discharged from the hot and cold water mixing tap can be increased.

[0029]

According to the second aspect of the invention, since the sealing member for blocking hot water and water flowing into the housing is mounted on the valve body, the outer diameter of the valve body can be increased to approximately the same size as the outer diameter of the housing. Thus, the outer diameter of the valve body can be made larger than that of the first invention, and the amount of water discharged can be increased.

[0030]

According to the third aspect of the invention, the divided housings are connected via the shaft rod connected to the spindle disposed substantially near the central axis of the housing, so that the divided housings face each other and the seal material is located. There is no influence on the location of the shape, and the configurations of the first and second terms of the present invention are satisfied.

[Brief description of the drawings]

FIG. 1 is a longitudinal sectional view showing an embodiment of the first invention of the present invention.

FIG. 2 is an exploded perspective view of components of the embodiment of FIG.

FIG. 3 is a longitudinal sectional view showing an embodiment of the second invention.

FIG. 4 is a cross-sectional view of a main part according to a conventional example.

FIG. 5 is a longitudinal sectional view showing a conventional example.

[Explanation of symbols]

a: water inlet b: hot water inlet c: mixed water outlet d: water chamber e: hot water chamber f: mixing chamber g: inner wall guide A: outer diameter B of the housing B: inner diameter C of the O-ring groove of the valve body C: Depth dimension D of O-ring groove of valve body D: Wall pressure dimension of O-ring mounting portion of housing E: Depth dimension of O-ring groove of housing F: Outer diameter G of valve body G: Stroke 1: Housing 1a: Hot water side Housing 1b: Water-side housing 2: Water valve seat 3: Hot water valve seat 4: Valve body 4a: Partition wall 4b: Connection port 5: Sealing material 7: Sleeve 7a: Fin-shaped portion 7b: Water opening 8: Temperature sensing Element 9: Spindle 9a: Spindle shaft 9b: Groove portion 10: Bias spring 11: Handle 12: Washer 13: Washer 14: Retaining ring 15: O-

Claims (2)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2000075433A JP4591860B2 (en) | 2000-03-17 | 2000-03-17 | Hot water tap |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2000075433A JP4591860B2 (en) | 2000-03-17 | 2000-03-17 | Hot water tap |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2001263511A JP2001263511A (en) | 2001-09-26 |

| JP2001263511A5 JP2001263511A5 (en) | 2007-04-26 |

| JP4591860B2 true JP4591860B2 (en) | 2010-12-01 |

Family

ID=18593329

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2000075433A Expired - Lifetime JP4591860B2 (en) | 2000-03-17 | 2000-03-17 | Hot water tap |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP4591860B2 (en) |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP4611102B2 (en) | 2005-04-28 | 2011-01-12 | 日本サーモスタット株式会社 | Hot and cold mixer tap |

| JP4979347B2 (en) * | 2006-10-31 | 2012-07-18 | 株式会社Lixil | Hot water mixing valve |

| CN103775681B (en) | 2013-04-27 | 2015-05-20 | 广州海鸥卫浴用品股份有限公司 | Jet shower device |

| CN103775678B (en) * | 2013-04-27 | 2014-12-10 | 广州海鸥卫浴用品股份有限公司 | Adjustable jet flow valve |

| CN110617347A (en) * | 2019-09-03 | 2019-12-27 | 潍坊百乐卫浴制品有限公司 | Split type thermostatic valve |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0875037A (en) * | 1994-08-31 | 1996-03-19 | Toto Ltd | Hot/cold water combination device |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS59188371U (en) * | 1983-05-31 | 1984-12-13 | 東陶機器株式会社 | thermostatic mixing valve |

| JPH049507Y2 (en) * | 1986-09-04 | 1992-03-10 | ||

| JPH02132176U (en) * | 1989-04-07 | 1990-11-02 | ||

| JP3791046B2 (en) * | 1996-05-07 | 2006-06-28 | 松下電器産業株式会社 | Seal structure and hot water mixing apparatus using the same |

-

2000

- 2000-03-17 JP JP2000075433A patent/JP4591860B2/en not_active Expired - Lifetime

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0875037A (en) * | 1994-08-31 | 1996-03-19 | Toto Ltd | Hot/cold water combination device |

Also Published As

| Publication number | Publication date |

|---|---|

| JP2001263511A (en) | 2001-09-26 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US5355906A (en) | Pressure balanced mixing valve | |

| US6557770B2 (en) | Thermostatic cartridge for mixer taps | |

| JP3447054B2 (en) | Mixing valve control unit | |

| US4381073A (en) | Thermostatically controlled cold and hot water mixer | |

| EP1590715B1 (en) | Thermostatic mixer with flow diverting means | |

| US5356074A (en) | Thermostatic mixing device | |

| US10378674B2 (en) | Hot and cold water mixing valve device | |

| KR0133684B1 (en) | Sanitary mixer tap with thermostat control | |

| US5988514A (en) | Apparatus for controlling fluid temperature | |

| KR100289292B1 (en) | Flow control ports for a thermostatic mixing faucet | |

| JP4591860B2 (en) | Hot water tap | |

| FI70993C (en) | TERMOSTATKRAN | |

| GB2139324A (en) | Fixture for thermostatically mixing hot and cold water | |

| JP4368049B2 (en) | Hot and cold mixer tap | |

| KR890000449B1 (en) | Fluid control valve | |

| JPH11108217A (en) | Pressure balancer between cold water and hot water | |

| JP3584973B2 (en) | Hot water mixing valve | |

| JP3410265B2 (en) | Hot water mixer tap | |

| JP2001254868A (en) | Water and hot water mixing device | |

| JP3131686B2 (en) | Switching valve seal structure | |

| JP2004251383A (en) | Combination faucet | |

| JP3360989B2 (en) | Hot water mixer tap | |

| JP2551657B2 (en) | Mixing valve | |

| JP4110659B2 (en) | Hot water mixing valve | |

| CA2251046A1 (en) | Pressure-equalizing control |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20070313 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20070313 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20100201 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20100412 |

|

| A521 | Written amendment |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20100607 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20100823 |

|

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20130924 Year of fee payment: 3 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 4591860 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20100905 |

|

| EXPY | Cancellation because of completion of term |