JP2015221007A - Algae oil extraction method and algae oil extraction apparatus - Google Patents

Algae oil extraction method and algae oil extraction apparatus Download PDFInfo

- Publication number

- JP2015221007A JP2015221007A JP2014106424A JP2014106424A JP2015221007A JP 2015221007 A JP2015221007 A JP 2015221007A JP 2014106424 A JP2014106424 A JP 2014106424A JP 2014106424 A JP2014106424 A JP 2014106424A JP 2015221007 A JP2015221007 A JP 2015221007A

- Authority

- JP

- Japan

- Prior art keywords

- algae

- reaction chamber

- pressure

- temperature

- water vapor

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 241000195493 Cryptophyta Species 0.000 title claims abstract description 120

- 238000000605 extraction Methods 0.000 title claims abstract description 45

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims abstract description 53

- 238000001027 hydrothermal synthesis Methods 0.000 claims abstract description 29

- 239000012808 vapor phase Substances 0.000 claims abstract description 15

- 238000006243 chemical reaction Methods 0.000 claims description 64

- 238000000034 method Methods 0.000 claims description 30

- 238000010438 heat treatment Methods 0.000 claims description 25

- 238000007599 discharging Methods 0.000 claims description 7

- 238000003756 stirring Methods 0.000 claims description 4

- 238000001704 evaporation Methods 0.000 claims 2

- 230000003247 decreasing effect Effects 0.000 claims 1

- 239000012071 phase Substances 0.000 abstract description 7

- 239000000284 extract Substances 0.000 abstract description 5

- 239000003960 organic solvent Substances 0.000 abstract description 3

- 238000010297 mechanical methods and process Methods 0.000 abstract description 2

- 229920006395 saturated elastomer Polymers 0.000 abstract description 2

- 230000002542 deteriorative effect Effects 0.000 abstract 1

- 239000003921 oil Substances 0.000 description 53

- 210000004027 cell Anatomy 0.000 description 6

- 230000001276 controlling effect Effects 0.000 description 6

- 239000000203 mixture Substances 0.000 description 6

- 235000014113 dietary fatty acids Nutrition 0.000 description 5

- 229930195729 fatty acid Natural products 0.000 description 5

- 239000000194 fatty acid Substances 0.000 description 5

- 150000004665 fatty acids Chemical class 0.000 description 5

- 101100153168 Arabidopsis thaliana TIC21 gene Proteins 0.000 description 4

- 101100273813 Homo sapiens CDKN1A gene Proteins 0.000 description 4

- 108700038981 SUMO-1 Proteins 0.000 description 4

- 101100083337 Schizosaccharomyces pombe (strain 972 / ATCC 24843) pic1 gene Proteins 0.000 description 4

- 102100026940 Small ubiquitin-related modifier 1 Human genes 0.000 description 4

- 238000010586 diagram Methods 0.000 description 4

- 238000012545 processing Methods 0.000 description 4

- 230000001105 regulatory effect Effects 0.000 description 4

- 230000002093 peripheral effect Effects 0.000 description 3

- 239000002551 biofuel Substances 0.000 description 2

- 210000002421 cell wall Anatomy 0.000 description 2

- 238000013461 design Methods 0.000 description 2

- 230000007613 environmental effect Effects 0.000 description 2

- 239000003925 fat Substances 0.000 description 2

- 150000002632 lipids Chemical class 0.000 description 2

- 102000004169 proteins and genes Human genes 0.000 description 2

- 108090000623 proteins and genes Proteins 0.000 description 2

- 239000002994 raw material Substances 0.000 description 2

- 239000000126 substance Substances 0.000 description 2

- 101100274255 Arabidopsis thaliana CHER1 gene Proteins 0.000 description 1

- 102100024209 CD177 antigen Human genes 0.000 description 1

- 241000122141 Cryphonectria hypovirus 1 Species 0.000 description 1

- 108090000790 Enzymes Proteins 0.000 description 1

- 102000004190 Enzymes Human genes 0.000 description 1

- 101000980845 Homo sapiens CD177 antigen Proteins 0.000 description 1

- 101100256906 Saccharomyces cerevisiae (strain ATCC 204508 / S288c) SIC1 gene Proteins 0.000 description 1

- 230000002159 abnormal effect Effects 0.000 description 1

- 230000004075 alteration Effects 0.000 description 1

- 238000010923 batch production Methods 0.000 description 1

- 239000003225 biodiesel Substances 0.000 description 1

- 238000009529 body temperature measurement Methods 0.000 description 1

- 230000015556 catabolic process Effects 0.000 description 1

- 210000000170 cell membrane Anatomy 0.000 description 1

- 239000002131 composite material Substances 0.000 description 1

- 150000001875 compounds Chemical class 0.000 description 1

- 238000009833 condensation Methods 0.000 description 1

- 230000005494 condensation Effects 0.000 description 1

- 238000004925 denaturation Methods 0.000 description 1

- 230000036425 denaturation Effects 0.000 description 1

- 239000002158 endotoxin Substances 0.000 description 1

- 238000003912 environmental pollution Methods 0.000 description 1

- 238000002474 experimental method Methods 0.000 description 1

- 239000012530 fluid Substances 0.000 description 1

- 235000013305 food Nutrition 0.000 description 1

- 239000002803 fossil fuel Substances 0.000 description 1

- 150000004676 glycans Chemical class 0.000 description 1

- 230000002779 inactivation Effects 0.000 description 1

- 239000007791 liquid phase Substances 0.000 description 1

- 230000003287 optical effect Effects 0.000 description 1

- 230000029553 photosynthesis Effects 0.000 description 1

- 238000010672 photosynthesis Methods 0.000 description 1

- 229920001282 polysaccharide Polymers 0.000 description 1

- 239000005017 polysaccharide Substances 0.000 description 1

- 239000012429 reaction media Substances 0.000 description 1

- 238000011160 research Methods 0.000 description 1

- 230000000630 rising effect Effects 0.000 description 1

- 238000010792 warming Methods 0.000 description 1

Images

Abstract

Description

本発明は水蒸気を用いて藻類から油を抽出可能な環境負荷の少ない藻油抽出方法および藻油抽出装置に関する。 The present invention relates to an algae oil extraction method and an algae oil extraction apparatus with a low environmental load that can extract oil from algae using water vapor.

近年、化石資源の枯渇、化石燃料に起因する地球温暖化・環境汚染等の環境負荷の低減等のために、植物等の生物資源を原料として製造されるバイオ燃料が注目されている。特に、バイオ燃料の原料として、食料に代わって、光合成により油脂類を蓄える藻類が注目されている。 In recent years, biofuels produced using bioresources such as plants as raw materials have attracted attention in order to deplete fossil resources and reduce environmental impacts such as global warming and environmental pollution caused by fossil fuels. In particular, algae that store fats and oils by photosynthesis instead of food are attracting attention as raw materials for biofuels.

藻類は、その細胞内に油脂類が蓄えられているので、その細胞壁を破壊した後に、有機溶剤等を用いて藻油を抽出する必要がある。特許文献1には、藻類からバイオディーゼル燃料を得るためのシステムが提案されており、その抽出セクションにおいては、超音波照射領域に藻類を通過させることで、藻類の内壁、外壁および油嚢を破壊する方法が採用されている。また、特許文献2には、藻類の細胞壁をボールミル、流動バレル装置を用いて機械的に破壊する方法が記載されている。

Since algae store fats and oils in the cells, it is necessary to extract the algae oil using an organic solvent or the like after breaking the cell wall.

一方、本発明者等は、基礎的研究例が殆ど無いソフト水熱プロセス(200℃以下の高温高圧の水および水蒸気)の化学特性を応用して、既存のオートクレーブでは不可能とされた高温耐性の蛋白質あるいは酵素、および細菌内毒素の不活性化が可能であることを見出している(特許文献3、4、5)。

On the other hand, the present inventors applied the chemical characteristics of a soft hydrothermal process (high-temperature and high-pressure water and steam below 200 ° C.) with almost no basic research examples, and made it impossible for existing autoclaves to achieve high-temperature resistance. It has been found that inactivation of proteins or enzymes and bacterial endotoxins can be achieved (

本発明者等は、ソフト水熱プロセスの化学特性に着目して、当該ソフト水熱プロセスを適用したところ、藻油を抽出可能なことを見出した。 The present inventors have found that algal oil can be extracted by applying the soft hydrothermal process, focusing on the chemical characteristics of the soft hydrothermal process.

本発明の課題は、かかるソフト水熱プロセスの新たな用途の発見に基づき、有機溶剤、超音波あるいは機械的方法を用いることなく、効率良く藻油を抽出可能な新たな藻油抽出方法を提案することにある。 The object of the present invention is to propose a new method for extracting algae oil that can efficiently extract algae oil without using organic solvents, ultrasonic waves or mechanical methods, based on the discovery of a new application of such a soft hydrothermal process. There is to do.

また、本発明の課題は、かかる新たな藻油抽出方法を用いて藻油を抽出するのに適した藻油抽出装置を提供することにある。 Moreover, the subject of this invention is providing the algal oil extraction apparatus suitable for extracting algal oil using this new algal oil extraction method.

上記の課題を解決するために、本発明の藻油抽出方法は、藻類から油を抽出するソフト水熱プロセスを含んでいる。ソフト水熱プロセスにおいては、反応室内に満杯とならない状態に入れた藻類を加圧熱水の状態とし、反応室内における藻類の上部空間に、蒸気飽和度が100%の飽和水蒸気の相と蒸気飽和度が100%を下回る乾燥水蒸気の相とが併存

する状態を形成することを特徴としている。

In order to solve the above problems, the method for extracting algae oil of the present invention includes a soft hydrothermal process for extracting oil from algae. In the soft hydrothermal process, the algae that are not filled in the reaction chamber are turned into pressurized hot water, and the saturated water vapor phase and steam saturation with 100% steam saturation are placed in the upper space of the algae in the reaction chamber. It is characterized by forming a state in which a phase of dry steam with a degree of less than 100% coexists.

本発明において用いる、高温高圧水蒸気を反応媒体とした化学反応である「ソフト水熱プロセス」の反応領域は、水蒸気温度が106℃〜184.1℃の範囲内の領域である。蒸気飽和度(%)は次式により表される。

{蒸気密度(kg/m3)/飽和水蒸気密度(kg/m3)}×100

The reaction region of the “soft hydrothermal process”, which is a chemical reaction using high-temperature and high-pressure steam as a reaction medium, used in the present invention is a region where the steam temperature is in the range of 106 ° C. to 184.1 ° C. Vapor saturation (%) is expressed by the following equation.

{Vapor density (kg / m 3 ) / Saturated water vapor density (kg / m 3 )} × 100

本発明の方法において、藻類を直接に加熱すると共に反応室の外側から藻類を間接的に加熱し、藻類の含水分を蒸発させて反応室内の上部空間から残留空気を反応室外に排出すると共に、当該上部空間からの水蒸気の排出を制御して当該上部空間の圧力を制御することで、藻類を加圧熱水の状態にすることができ、上部空間に、飽和水蒸気の相および乾燥水蒸気の相が併存する状態を形成することができる。 In the method of the present invention, the algae are directly heated and the algae are indirectly heated from the outside of the reaction chamber, the moisture content of the algae is evaporated, and the residual air is discharged from the upper space in the reaction chamber to the outside of the reaction chamber. By controlling the discharge of water vapor from the upper space and controlling the pressure of the upper space, the algae can be brought into a pressurized hot water state, and in the upper space, a saturated water vapor phase and a dry water vapor phase. Can co-exist.

本発明の方法におけるソフト水熱プロセスでは、密閉容器である反応室内において、藻類は加圧熱水の状態になる。液相である加圧熱水は高いイオン積、誘電率を備え、この状態の藻類においては、藻類の細胞のタンパク質および藻類の細胞外部の多糖類が加水分解され、藻類の細胞の中に閉じ込められている藻油の抽出が促進される。 In the soft hydrothermal process in the method of the present invention, the algae are in the state of pressurized hot water in the reaction chamber which is a sealed container. Pressurized hot water, which is a liquid phase, has a high ionic product and dielectric constant. In this state, the algal cell proteins and polysaccharides outside the algal cells are hydrolyzed and trapped in the algal cells. Extraction of the algae oil that is being promoted is promoted.

また、反応室内には、意図的に、処理対象の藻類が満杯とならないように入れてある。よって、反応室内には藻類の上側に上部空間ができる。藻類を直接に加熱することで、この上部空間に藻類の含水分が蒸発する。また、当該上部空間からの水蒸気の排出を調整することで当該上部空間の圧力を制御する(換言すると、流通式による圧力制御を行う)。これにより、上部空間には、飽和水蒸気の相が形成される。したがって、上部空間に形成される飽和水蒸気の抽出反応によっても藻油の抽出が期待できる。 In addition, the reaction chamber is intentionally placed so that the algae to be treated are not full. Therefore, an upper space is formed above the algae in the reaction chamber. By directly heating the algae, the water content of the algae evaporates in this upper space. Further, the pressure of the upper space is controlled by adjusting the discharge of water vapor from the upper space (in other words, pressure control by a flow type is performed). Thereby, a saturated water vapor phase is formed in the upper space. Therefore, extraction of algal oil can be expected also by extraction reaction of saturated water vapor formed in the upper space.

さらに、反応室の外側から、その内部の上部空間の飽和水蒸気温度以上となるように加熱することにより、反応室の上部空間における反応室内周面側の部分には、蒸気飽和度が100%を下回る乾燥水蒸気が形成される。したがって、この乾燥水蒸気の抽出反応によっても、藻油の抽出が期待できる。 Further, by heating from the outside of the reaction chamber so as to be equal to or higher than the saturated water vapor temperature of the upper space inside the reaction chamber, the steam saturation degree is 100% in the portion on the peripheral surface side of the reaction chamber in the upper space. Less dry water vapor is formed. Therefore, extraction of algal oil can also be expected by this dry steam extraction reaction.

このように、本発明の方法によれば、反応室内での藻類の直接加熱に加え、流通式による圧力制御および外部加熱を行うことで、反応室内の空間の蒸気飽和度を様々な藻油の最適抽出条件に制御できる。この結果、反応室内には、藻類で満たされた加圧熱水の部分と、上部空間の飽和水蒸気の部分および乾燥水蒸気の部分との3つの相状態が形成され、これらによる3つの化学的反応によって、藻油を効率良く抽出することが可能になる。 Thus, according to the method of the present invention, in addition to direct heating of the algae in the reaction chamber, by performing pressure control and external heating by a flow type, the steam saturation of the space in the reaction chamber can be adjusted for various algal oils. The optimal extraction conditions can be controlled. As a result, three phase states are formed in the reaction chamber, that is, a portion of pressurized hot water filled with algae, a portion of saturated water vapor in the upper space, and a portion of dry water vapor. This makes it possible to extract algal oil efficiently.

本発明者等の実験によれば、藻油抽出のためのソフト水熱プロセスにおける温度を、130℃〜184.1℃の範囲内にすれば望ましいことが確認された。また、ソフト水熱プロセスによる藻類の処理時間を、30分間から60分間の範囲内にすれば望ましいことが確認された。 According to the experiments by the present inventors, it was confirmed that it would be desirable if the temperature in the soft hydrothermal process for extracting algal oil was within the range of 130 ° C to 184.1 ° C. Moreover, it was confirmed that it is desirable that the treatment time of the algae by the soft hydrothermal process is within a range of 30 minutes to 60 minutes.

本発明の藻油抽出方法は、具体的には、処理対象の藻類を反応室に供給する供給プロセスと、反応室の室内温度および室内圧力を高めて、当該反応室内に加圧熱水の状態と、飽和水蒸気の相および乾燥水蒸気の相の併存状態とを形成可能にする昇温昇圧プロセスと、前記のソフト水熱プロセスと、反応室の室内温度を所定の温度に下げると共に室内圧力を大気圧に戻す降温降圧プロセスと、反応室から処理済の藻類を取り出す排出プロセスとを含む。昇温昇圧プロセスおよびソフト水熱プロセスでは、藻類を直接に加熱すると共に反応室の外側から藻類を間接的に加熱し、藻類の含水分を蒸発させて反応室内の上部空間から残留空気を反応室外に排出させると共に、当該上部空間からの水蒸気の排出を制御して当該上部空間の圧力を制御する。 Specifically, the method for extracting algal oil of the present invention includes a supply process for supplying algae to be treated to a reaction chamber, and the temperature and pressure of the reaction chamber are increased, and the state of pressurized hot water in the reaction chamber is increased. And a temperature-increasing process that makes it possible to form a saturated steam phase and a dry steam phase, and the soft hydrothermal process described above, and lowering the indoor temperature of the reaction chamber to a predetermined temperature and increasing the indoor pressure. And a temperature lowering / lowering process for returning to atmospheric pressure, and a discharge process for removing treated algae from the reaction chamber. In the temperature increase pressurization process and the soft hydrothermal process, the algae are directly heated and the algae are indirectly heated from the outside of the reaction chamber to evaporate the moisture content of the algae and to remove residual air from the upper space inside the reaction chamber. And the pressure of the upper space is controlled by controlling the discharge of water vapor from the upper space.

次に、本発明はソフト水熱プロセスを用いて藻類から油を抽出する藻油抽出装置であって、圧力容器からなる反応室と、反応室に処理対象の藻類を供給する藻類供給部と、反応室に供給した処理対象の藻類を加熱する加熱部と、反応室内の室内圧力を調整する圧力調節部と、反応室に供給された藻類を撹拌する撹拌部と、反応室から処理済の藻類を排出する藻類排出部とを有していることを特徴としている。 Next, the present invention is an algae oil extraction device for extracting oil from algae using a soft hydrothermal process, a reaction chamber composed of a pressure vessel, an algae supply unit for supplying algae to be treated to the reaction chamber, A heating unit for heating the algae to be treated supplied to the reaction chamber, a pressure adjusting unit for adjusting the indoor pressure in the reaction chamber, a stirring unit for stirring the algae supplied to the reaction chamber, and algae treated from the reaction chamber And an algae discharge part that discharges water.

さらに具体的には、藻類供給部は、処理対象の藻類を貯留する供給タンクと、供給タンクから藻類を反応室に供給する供給ポンプとを備えている。加熱部は、反応室内の藻類を加熱する内部ヒーターと、圧力室を外側から加熱する外部ヒーターと、反応室の温度を検出する温度計と、温度計による計測温度に基づき、内部ヒーターおよび外部ヒーターによる加熱状態を調節する温度指示調節計とを備えている。圧力調節部は、反応室から水蒸気を排出する排気管と、排気管に取り付けた圧力調整弁と、反応室の内部圧力を検出する圧力計と、圧力計による計測圧力に基づき、圧力調整弁を制御して室内圧力を調節する圧力指示調節計とを備えている。 More specifically, the algae supply unit includes a supply tank that stores the algae to be treated, and a supply pump that supplies the algae from the supply tank to the reaction chamber. The heating unit includes an internal heater for heating algae in the reaction chamber, an external heater for heating the pressure chamber from the outside, a thermometer for detecting the temperature of the reaction chamber, and an internal heater and an external heater based on the temperature measured by the thermometer. And a temperature indicating controller for adjusting the heating state. The pressure adjustment unit includes an exhaust pipe for discharging water vapor from the reaction chamber, a pressure adjustment valve attached to the exhaust pipe, a pressure gauge for detecting the internal pressure of the reaction chamber, and a pressure adjustment valve based on the pressure measured by the pressure gauge. A pressure indicating controller for controlling and adjusting the indoor pressure.

以下に、図面を参照して、本発明を適用した藻油抽出装置の実施の形態を説明する。 Embodiments of an algal oil extraction device to which the present invention is applied will be described below with reference to the drawings.

(装置構成)

図1(a)は、本発明のソフト水熱プロセスによる藻油抽出方法を用いて藻油を抽出する藻油抽出装置の平面図であり、図1(b)は藻油抽出装置を図1(a)の矢印bの方向から見た場合の側面図である。また、図2は藻油抽出装置の配管系統図である。

(Device configuration)

Fig.1 (a) is a top view of the algal oil extraction apparatus which extracts algal oil using the algal oil extraction method by the soft hydrothermal process of this invention, FIG.1 (b) shows an algal oil extraction apparatus in FIG. It is a side view at the time of seeing from the direction of arrow b of (a). FIG. 2 is a piping system diagram of the algal oil extraction device.

これらの図を参照して説明すると、藻油抽出装置1はバッチ式の装置であり、装置架台2を備え、装置架台2の上に各装置構成部が搭載されている。装置構成部には、各部の駆動制御を司る制御盤3、藻類にソフト水熱プロセスを施す縦置きの圧力容器からなるリアクタ(反応室)R1、リアクタR1に処理対象の藻類を供給する藻類供給部4、リアクタR1を加熱する加熱部5、リアクタR1内の圧力を調整する圧力調節部6、および、リアクタR1から処理済の藻類を排出する藻類排出部7が含まれている。

Referring to these drawings, the algal

藻類供給部4は、処理対象の藻類が投入される供給タンクT1と、供給タンクT1から藻類をリアクタR1に圧送する供給ポンプP1とを備えている。供給タンクT1からリアクタR1に藻類を供給する供給管11には、藻類の供給開始、供給停止の切り替えを行う手動弁HV1および供給電動弁MV1が配置されている。

The

縦置きのリアクタR1にはレベル計LG1が取り付けられている。供給される藻類の量を、異なる高さ位置に配置した複数個のレベルスイッチLS2〜LS5によって検出可能である。レベル計LG1に基づき供給電動弁MV1の開閉が制御される。 A level meter LG1 is attached to the vertical reactor R1. The amount of algae supplied can be detected by a plurality of level switches LS2 to LS5 arranged at different height positions. Based on the level meter LG1, the opening and closing of the electric supply valve MV1 is controlled.

リアクタR1を加熱する加熱部5は、図2に示すように、リアクタR1の内部の下側部

分に配置した複数、例えば3つの内部ヒーターH1〜H3と、リアクタR1の外周面に取り付けた複数、例えば8つの外部ヒーターH4〜H11とを備えている。内部ヒーターH1〜H3によって、リアクタR1内に供給された藻類が加熱され、外部ヒーターH4〜H11によってリアクタR1が外側から加熱される。

As shown in FIG. 2, the

リアクタR1の外周面における複数の部位には温度測定用の熱電対TE1〜TE6が配置されている。これらの熱電対TE1〜TE6による測定温度に基づき、温度指示調節計TICA1〜TICA4は内部ヒーターH1〜H3および外部ヒーターH4〜H11による加熱を調節してリアクタR1内が規定温度となるように調整する。 Thermocouples TE1 to TE6 for temperature measurement are arranged at a plurality of portions on the outer peripheral surface of the reactor R1. Based on the temperature measured by these thermocouples TE1 to TE6, the temperature indicating controllers TICA1 to TICA4 adjust the heating by the internal heaters H1 to H3 and the external heaters H4 to H11 so that the inside of the reactor R1 becomes a specified temperature. .

リアクタR1の内部には攪拌機MXIが配置されている。リアクタR1の内部に供給された藻類は、ソフト水熱プロセス時に藻類が撹拌される。攪拌機MXIの動作は、その駆動モータM3を駆動制御することによって行われる。 A stirrer MXI is arranged inside the reactor R1. The algae supplied into the reactor R1 are agitated during the soft hydrothermal process. The operation of the agitator MXI is performed by controlling the drive motor M3.

リアクタR1の圧力調節部6は、リアクタR1から水蒸気を排出する排気管12、13を備えている。これらの排気管12、13は復水器CD−1を介して、復水タンクT2に繋がっている。排気管13には圧力調整弁CV1が取り付けられており、圧力調整弁CV1は圧力指示調節計PIC1によって開閉量が制御される。圧力指示調節計PIC1は、圧力トランスミッタPT1によって検出されるリアクタR1の内圧が規定の内圧となるように、圧力調整弁CV1の開度を調整する。また、リアクタR1には安全弁SV1を介して大気開放され、内圧の異常な上昇が回避される。

The

リアクタR1から処理済の藻類を排出する藻類排出部7は、リアクタR1の底部に接続された排出管14と、排出管14を経由して処理済の藻類を次工程に送り出すための排出ポンプP2とを備えている。排出管14には排出電動弁MV2が取り付けられており、これを開閉することで、藻類の排出動作が制御される。

The

なお、図2の各符号の意味を以下に列記する。

GI1:開度指示計

GT1:開度発信器

GS1〜GS6:リミットスイッチ

LG1:レベル計

LS1〜LS5:レベルスイッチ

TICA1〜TICA4:温度指示調節計

TI1〜TI3:温度指示計

TE1〜TE6:熱電対

PIC1:圧力指示調節計

PT1:圧力トランスミッタ

PI1、PI4〜PI6:圧力計

PI2、PI3:連成計

ST1〜ST4:ストレーナ

GV1〜GV3:手動弁(圧力計用)

HV1〜HV9:手動弁

CHV1、CHV2:逆止弁

TCV1:温度調整弁

PRV1:減圧弁

SV1:安全弁

CV1:調節弁

MV1、MV2:電動弁

CD1:復水器

T1:供給タンク

T2:復水タンク

P1:供給ポンプ

P2:排出ポンプ

MX1:攪拌機

H1〜H3:内部ヒーター

H4〜H11:外部ヒーター

M1〜M3:モータ

SIC1、SIC2:インバータ

In addition, the meaning of each code | symbol of FIG. 2 is listed below.

GI1: Opening indicator GT1: Opening transmitters GS1 to GS6: Limit switches LG1: Level meters LS1 to LS5: Level switches TICA1 to TICA4: Temperature indicating controllers TI1 to TI3: Temperature indicators TE1 to TE6: Thermocouple PIC1 : Pressure indicating controller PT1: Pressure transmitter PI1, PI4 to PI6: Pressure gauge PI2, PI3: Compound meter ST1 to ST4: Strainer GV1 to GV3: Manual valve (for pressure gauge)

HV1 to HV9: Manual valves CHV1, CHV2: Check valve TCV1: Temperature adjustment valve PRV1: Pressure reducing valve SV1: Safety valve CV1: Control valve MV1, MV2: Electric valve CD1: Condenser T1: Supply tank T2: Condensation tank P1 : Supply pump P2: Discharge pump MX1: Stirrers H1 to H3: Internal heaters H4 to H11: External heaters M1 to M3: Motors SIC1, SIC2: Inverters

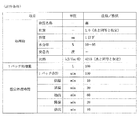

図3は、本例の藻油抽出装置1の設計条件例の一覧表を示す説明図であり、図4は藻油抽出装置1の機器仕様例の一覧表を示す説明図である。本例では、図3に示すように、1バッチ処理の想定処理時間が130分間に設定されている。処理時間の内訳は次の通りである。なお、これらの処理時間は処理条件(圧力、温度、設定時間)に応じて変化する。

FIG. 3 is an explanatory diagram showing a list of design condition examples of the algal

供給プロセス(図3の「供給」:処理対象の藻類をリアクタR1に供給する):10分間

昇温昇圧プロセス(図3の「昇温」:リアクタR1を密閉して内部温度および内部圧力を規定温度および規定圧力まで高めて、リアクタR1内の藻類を高飽和水蒸気の状態にする):30分間

ソフト水熱プロセス(図3の「抽出」):60分間

降温降圧プロセス(図3の「降温」:リアクタR1の内部温度を所定の温度に下げると共に内圧を大気圧に戻す):20分間

排出プロセス(図3の「排出」:リアクタR1から処理済の藻類を取り出す):10分間

Supply process ("supply" in FIG. 3: supply the algae to be treated to the reactor R1): 10 minutes Temperature rising pressurization process ("temperature increase" in FIG. 3: the reactor R1 is sealed to define the internal temperature and internal pressure Increase the temperature and the specified pressure to bring the algae in the reactor R1 into a highly saturated water vapor state): 30 minutes Soft hydrothermal process (“Extraction” in FIG. 3): 60 minutes : Reducing the internal temperature of the reactor R1 to a predetermined temperature and returning the internal pressure to the atmospheric pressure): 20 minutes Discharge process ("Discharge" in FIG. 3: Remove treated algae from the reactor R1): 10 minutes

(藻油抽出動作)

図5は、藻油抽出装置1を用いた藻油抽出動作を示すフローチャートである。この図を参照して、藻油の抽出動作を説明する。まず、ステップST1に示すように、処理対象の藻類を供給タンクT1に投入する。次に、ステップST2、ST3に示すように、処理対象の藻類を規定量だけリアクタR1に供給する(供給プロセス)。藻類が供給された後の状態は、図2に示すように、リアクタR1内に藻類が満杯に充填されずに、その上端部分に上部空間8が残る。

(Algal oil extraction operation)

FIG. 5 is a flowchart showing an algal oil extraction operation using the algal

藻類を供給し終えた後は、ステップST4、ST5に示すように、リアクタR1を内部および外側から加熱する。これにより、リアクタR1内の藻類が直接に加熱されて水蒸気が発生し、温度の上昇に伴って内圧が上昇する。圧力調整弁CV1を調整して排出される水蒸気量を制御することで、リアクタR1内の圧力を規定圧力まで上げると共に、内部温度を規定温度まで上げる(昇温昇圧プロセス)。 After supplying the algae, as shown in steps ST4 and ST5, the reactor R1 is heated from inside and outside. As a result, the algae in the reactor R1 are directly heated to generate water vapor, and the internal pressure increases as the temperature rises. By controlling the amount of water vapor discharged by adjusting the pressure regulating valve CV1, the pressure in the reactor R1 is increased to a specified pressure and the internal temperature is increased to a specified temperature (temperature increase pressurization process).

このように、藻類が直接に加熱されると共に、リアクタR1の外側から藻類が間接的に加熱される。藻類の含水分が蒸発して上部空間8から残留空気が排出される。また、上部空間8からの水蒸気の排出が制御されて、当該上部空間の圧力が制御される。この結果、リアクタR1の内部の藻類は加圧熱水の状態になり、上部空間には、飽和水蒸気の相および乾燥水蒸気の相が併存する複合状態が形成される。 Thus, the algae are directly heated and the algae are indirectly heated from the outside of the reactor R1. The water content of the algae evaporates and residual air is discharged from the upper space 8. Further, the discharge of water vapor from the upper space 8 is controlled, and the pressure of the upper space is controlled. As a result, the algae inside the reactor R1 are in a pressurized hot water state, and a composite state in which a saturated water vapor phase and a dry water vapor phase coexist is formed in the upper space.

この後は、ステップST6、ST7に示すように、この状態を規定時間(本例では60分間)に亘って維持する制御を行う(ソフト水熱プロセス)。この場合においても、藻類の直接加熱制御、リアクタR1の外部加熱制御、流通式による圧力制御が行われて、藻類が加圧熱水の状態に維持され、上部空間は、飽和水蒸気の相と乾燥水蒸気の相が併存する

状態に維持される。このように、各相の化学的反応特性が利用されて、藻類の細胞膜が破壊されて、内部から藻油が抽出されて分離する。このような各相の水蒸気の化学的反応特性を利用して藻油を抽出する技術は他に例のない斬新なものである。

Thereafter, as shown in steps ST6 and ST7, control is performed to maintain this state for a specified time (60 minutes in this example) (soft hydrothermal process). Also in this case, the direct heating control of the algae, the external heating control of the reactor R1, and the pressure control by the flow type are performed, the algae are maintained in the pressurized hot water state, and the upper space is dried with the saturated water vapor phase. A state in which a water vapor phase coexists is maintained. In this way, the chemical reaction characteristics of each phase are utilized, the algal cell membrane is destroyed, and the algal oil is extracted and separated from the inside. Such a technique for extracting algal oil by utilizing the chemical reaction characteristics of water vapor in each phase is unique and unique.

この後は、ステップST8、ST9に示すように、リアクタR1の温度および圧力を下げて、圧力を大気圧まで戻す(降温降圧プロセス)。そして、ステップST10に示すように、処理済の藻類をリアクタR1から排出して次工程に向けて送り出す(排出プロセス)。 Thereafter, as shown in steps ST8 and ST9, the temperature and pressure of the reactor R1 are lowered and the pressure is returned to the atmospheric pressure (temperature lowering pressure-lowering process). Then, as shown in step ST10, the processed algae are discharged from the reactor R1 and sent to the next step (discharge process).

(実施例)

本発明者等は、上記構成の藻油抽出装置1を用いて藻類の抽出処理を行った。処理条件は、ソフト水熱プロセスにおける温度を150℃とし、処理時間を60分間とした。

(Example)

The present inventors performed an algae extraction process using the algal

処理後の藻類を光学顕微鏡により確認したところ、処理後の藻類の細胞の形状が変化し、細胞内から脂質が溶出し、溶出した脂質が分散していることが確認された。 When the treated algae were confirmed by an optical microscope, it was confirmed that the shape of the cells of the treated algae changed, lipids eluted from the cells, and the eluted lipids were dispersed.

また、抽出した藻油の変性、変質の有無を確認するために、抽出した藻油の組成を処理前の藻油の組成と比較した。 Moreover, in order to confirm the presence or absence of denaturation and alteration of the extracted algae oil, the composition of the extracted algae oil was compared with the composition of the algae oil before the treatment.

図6は、抽出した(処理後の)藻油の脂肪酸組成と抽出前(処理前)の藻油の脂肪酸組成の分析結果を示すグラフである。このグラフに示すように、本例のソフト水熱プロセスによって抽出された藻油に変性、変質が生じていないことが確認された。なお、グラフにおける脂肪酸の命名法はIUPAC生化学命名法(Rule Lip. Appendix A, Appendix B)に従った表記である。 FIG. 6 is a graph showing the analysis results of the fatty acid composition of the extracted (after treatment) algal oil and the fatty acid composition of the algal oil before extraction (before treatment). As shown in this graph, it was confirmed that the algal oil extracted by the soft hydrothermal process of the present example was not modified or altered. The nomenclature of fatty acids in the graph is a notation according to the IUPAC biochemical nomenclature (Rule Lip. Appendix A, Appendix B).

1 藻油抽出装置

2 装置架台

3 制御盤

4 藻類供給部

5 加熱部

6 圧力調節部

7 藻類排出部

8 上部空間

11 供給管

12、13 排気管

14 排出管

R1 リアクタ(反応室)

P1 供給ポンプ

MV1 供給電動弁

MV2 排出電磁弁

LG1 レベル計

LS2〜LS5 レベルスイッチ

H1〜H3 内部ヒーター

H4〜H11 外部ヒーター

TE1〜TE6 熱電対

TICA1〜TICA4 温度指示調節計

MXI 攪拌機

CD−1 復水器

CV1 圧力調整弁

T1 供給タンク

T2 復水タンク

PIC1 圧力指示調節計

DESCRIPTION OF

P1 supply pump MV1 supply motor operated valve MV2 discharge solenoid valve LG1 level meter LS2 to LS5 level switch H1 to H3 internal heater H4 to H11 external heater TE1 to TE6 thermocouple TICA1 to TICA4 temperature indicating controller MXI stirrer CD-1 condenser CV1 Pressure regulating valve T1 Supply tank T2 Condensate tank PIC1 Pressure indicating controller

Claims (7)

前記ソフト水熱プロセスにおいては、

反応室内に満杯とならない状態に入れた藻類を加圧熱水の状態とし、

前記反応室内における藻類の上部空間に、蒸気飽和度が100%の飽和水蒸気の相と蒸気飽和度が100%を下回る乾燥水蒸気の相とが併存する状態を形成することを特徴とする藻油抽出方法。 Including a soft hydrothermal process to extract oil from algae,

In the soft hydrothermal process,

Algae put in a state that does not become full in the reaction chamber is made into a state of pressurized hot water,

An algal oil extraction characterized by forming a state in which a saturated water vapor phase having a vapor saturation of 100% and a dry water vapor phase having a vapor saturation of less than 100% coexist in the upper space of the algae in the reaction chamber. Method.

前記藻類の含水分を蒸発させて前記反応室内の上部空間から残留空気を前記反応室外に排出させると共に、当該上部空間からの水蒸気の排出を制御して当該上部空間の圧力を制御して、

前記藻類を前記加圧熱水の状態にすると共に、前記上部空間に、前記飽和水蒸気の相および前記乾燥水蒸気の相が併存する状態を形成する請求項1に記載の藻油抽出方法。 Heating the algae directly and indirectly heating the algae from outside the reaction chamber;

While evaporating the water content of the algae and discharging residual air from the upper space in the reaction chamber to the outside of the reaction chamber, controlling the pressure of the upper space by controlling the discharge of water vapor from the upper space,

The algal oil extraction method according to claim 1, wherein the algae is brought into a state of the pressurized hot water, and a state in which the saturated water vapor phase and the dry water vapor phase coexist is formed in the upper space.

前記反応室の室内温度および室内圧力を高めて、当該反応室内に前記加圧熱水の状態と、前記飽和水蒸気の相および前記乾燥水蒸気の相の併存状態とを形成可能にする昇温昇圧プロセスと、

前記ソフト水熱プロセスと、

前記反応室の前記室内温度を所定の温度に下げると共に前記室内圧力を大気圧に戻す降温降圧プロセスと、

前記圧力室から処理済の前記藻類を取り出す排出プロセスと、

を含み、

前記昇温昇圧プロセスおよび前記ソフト水熱プロセスでは、

前記藻類を直接に加熱すると共に前記反応室の外側から前記藻類を間接的に加熱し、前記藻類の含水分を蒸発させて前記反応室内の上部空間から残留空気を前記反応室外に排出させると共に、当該上部空間からの水蒸気の排出を制御して当該上部空間の圧力を制御する請求項1、3または4に記載の藻油抽出方法。 A supply process for supplying algae to be treated to the reaction chamber;

A temperature-increasing process for increasing the room temperature and pressure in the reaction chamber so that the pressurized hot water state and the saturated water vapor phase and the dry water vapor phase coexist in the reaction chamber When,

The soft hydrothermal process;

A temperature lowering / decreasing process for lowering the room temperature of the reaction chamber to a predetermined temperature and returning the room pressure to atmospheric pressure;

A discharge process for removing the treated algae from the pressure chamber;

Including

In the temperature increase pressurization process and the soft hydrothermal process,

Heating the algae directly and indirectly heating the algae from the outside of the reaction chamber, evaporating the water content of the algae and discharging the residual air from the upper space in the reaction chamber to the outside of the reaction chamber; The algal oil extraction method according to claim 1, 3 or 4, wherein the pressure of the upper space is controlled by controlling the discharge of water vapor from the upper space.

圧力容器からなる反応室と、

前記反応室に処理対象の藻類を供給する藻類供給部と、

前記反応室に供給した処理対象の藻類を加熱する加熱部と、

前記反応室内の室内圧力を調整する圧力調節部と、

前記反応室に供給された藻類を撹拌する撹拌部と、

前記反応室から処理済の前記藻類を排出する藻類排出部と、

を有していることを特徴とする藻油抽出装置。 An algal oil extraction device for extracting oil from algae using the method according to claim 5,

A reaction chamber consisting of a pressure vessel;

An algae supply unit for supplying algae to be treated to the reaction chamber;

A heating unit for heating the algae to be treated supplied to the reaction chamber;

A pressure adjusting unit for adjusting the indoor pressure in the reaction chamber;

A stirring section for stirring the algae supplied to the reaction chamber;

Algae discharger for discharging the treated algae from the reaction chamber;

A device for extracting algal oil, comprising:

前記加熱部は、前記反応室内の藻類を加熱する内部ヒーターと、前記反応室を外側から加熱する外部ヒーターと、前記反応室の温度を検出する温度計と、前記温度計による計測

温度に基づき、前記内部ヒーターおよび前記外部ヒーターによる加熱状態を調節する温度指示調節計とを備えており、

前記圧力調節部は、前記反応室から水蒸気を排出する排気管と、前記排気管に取り付けた圧力調整弁と、前記反応室の内部圧力を検出する圧力計と、前記圧力計による計測圧力に基づき、前記圧力調整弁を制御して前記室内圧力を調節する圧力指示調節計とを備えている、

請求項6に記載の藻油抽出装置。 The algae supply unit includes a supply tank that stores the algae to be treated, and a supply pump that supplies the algae from the supply tank to the reaction chamber.

The heating unit is based on an internal heater that heats the algae in the reaction chamber, an external heater that heats the reaction chamber from the outside, a thermometer that detects the temperature of the reaction chamber, and a temperature measured by the thermometer, A temperature indicating controller for adjusting a heating state by the internal heater and the external heater,

The pressure adjusting unit is based on an exhaust pipe that discharges water vapor from the reaction chamber, a pressure adjustment valve attached to the exhaust pipe, a pressure gauge that detects an internal pressure of the reaction chamber, and a pressure measured by the pressure gauge. A pressure indicating controller for controlling the pressure adjusting valve to adjust the indoor pressure.

The algal oil extraction apparatus according to claim 6.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2014106424A JP2015221007A (en) | 2014-05-22 | 2014-05-22 | Algae oil extraction method and algae oil extraction apparatus |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2014106424A JP2015221007A (en) | 2014-05-22 | 2014-05-22 | Algae oil extraction method and algae oil extraction apparatus |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| JP2015221007A true JP2015221007A (en) | 2015-12-10 |

| JP2015221007A5 JP2015221007A5 (en) | 2017-05-25 |

Family

ID=54784454

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2014106424A Pending JP2015221007A (en) | 2014-05-22 | 2014-05-22 | Algae oil extraction method and algae oil extraction apparatus |

Country Status (1)

| Country | Link |

|---|---|

| JP (1) | JP2015221007A (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN107619712A (en) * | 2017-09-30 | 2018-01-23 | 浙江树人学院(浙江树人大学) | A kind of method that ultrasonic assistant prepares pears seed oil |

| CN115491254A (en) * | 2022-10-08 | 2022-12-20 | 安徽省金鼎安全科技股份有限公司 | Method for extracting and refining carbon-fixing microalgae high-added-value organic matters |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2007054688A (en) * | 2005-08-22 | 2007-03-08 | Konoshima Chemical Co Ltd | Extraction method of organic substance and extractor of organic substance |

| US20110294175A1 (en) * | 2008-10-23 | 2011-12-01 | Eni S.P.A. | Integrated process for the production of bio-oil from micro-organisms |

-

2014

- 2014-05-22 JP JP2014106424A patent/JP2015221007A/en active Pending

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2007054688A (en) * | 2005-08-22 | 2007-03-08 | Konoshima Chemical Co Ltd | Extraction method of organic substance and extractor of organic substance |

| US20110294175A1 (en) * | 2008-10-23 | 2011-12-01 | Eni S.P.A. | Integrated process for the production of bio-oil from micro-organisms |

Non-Patent Citations (2)

| Title |

|---|

| AGUIRRE, ANA-MARIA; BASSI, AMARJEET: "Investigation of high pressure steaming (HPS) as a thermal treatment for lipid extraction from Chlor", BIORESOURCE TECHNOLOGY, vol. Vol.164, JPN6018011950, 6 May 2014 (2014-05-06), pages 136 - 142 * |

| 横山伸也: "微細藻類からの炭化水素の効率的回収", バイオインダストリー, vol. Vol.27, No.6,, JPN6018011948, 12 June 2010 (2010-06-12), pages Page.36-44 * |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN107619712A (en) * | 2017-09-30 | 2018-01-23 | 浙江树人学院(浙江树人大学) | A kind of method that ultrasonic assistant prepares pears seed oil |

| CN115491254A (en) * | 2022-10-08 | 2022-12-20 | 安徽省金鼎安全科技股份有限公司 | Method for extracting and refining carbon-fixing microalgae high-added-value organic matters |

| CN115491254B (en) * | 2022-10-08 | 2023-09-01 | 安徽省金鼎安全科技股份有限公司 | Extraction method for extracting high-added-value organic matters from carbon-fixed microalgae |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN106551614B (en) | The control method of cooking apparatus | |

| CN102333600B (en) | Cleaning equipment and cleaning method | |

| WO2018145332A1 (en) | Method and device for physical deacidification and deodorization of high acid-value, thermally unstable oil | |

| KR101773151B1 (en) | Method for supplying heat source for hydrothermal carbonization of organic waste | |

| CN103480632A (en) | Kitchen waste hydrothermal three-phase separation system | |

| JP2015221007A (en) | Algae oil extraction method and algae oil extraction apparatus | |

| CN201379407Y (en) | Vacuum pan | |

| CN204073623U (en) | Nitrogen charging device vacuum oil purifier | |

| US11071960B2 (en) | Reaction container | |

| CN104250854B (en) | A kind of method that crystal whisker of gypsum dry method turns shape | |

| EP3102798A1 (en) | A method and a system for driving a turbine | |

| RU2295681C2 (en) | Method and the device of the power-saving dehydration and the vacuum drying | |

| CN105502541A (en) | Acid recovery equipment and use method thereof | |

| CN107074602A (en) | The method of the continuous thermal hydrolysis of organic substance and the system for being suitable for carrying out methods described | |

| CN201978721U (en) | Energy-saving and rapid-heating device for ultrahigh pressure can | |

| Chemat et al. | Combined extraction techniques | |

| CN204235771U (en) | For the efficient crosslinking apparatus of PAP | |

| CN209857613U (en) | Drying system and drying device for transformer | |

| JP2006129765A (en) | Culture apparatus and method for sterilizing the same | |

| RU2650472C1 (en) | Food cooking line | |

| RU2706066C2 (en) | Method of seawater desalination using semiconductor thermoelectric cooling device with ultraviolet radiation at artificial reduction of atmospheric pressure | |

| JP4959604B2 (en) | Slurry production method and slurry production system | |

| RU2454911C1 (en) | Food cooking line | |

| CN213951116U (en) | Device for extracting spice by microwave irradiation induction | |

| CN106546067B (en) | Low-temperature integrated drying method for replacing bacterial cellulose gel film |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20170405 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20170405 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20180220 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20180403 |

|

| A02 | Decision of refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A02 Effective date: 20181204 |