EP2687697A2 - Mixing device for the aftertreatment of exhaust gases - Google Patents

Mixing device for the aftertreatment of exhaust gases Download PDFInfo

- Publication number

- EP2687697A2 EP2687697A2 EP13002561.2A EP13002561A EP2687697A2 EP 2687697 A2 EP2687697 A2 EP 2687697A2 EP 13002561 A EP13002561 A EP 13002561A EP 2687697 A2 EP2687697 A2 EP 2687697A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- exhaust gas

- inner tube

- mixing device

- mixing

- housing

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 239000007789 gas Substances 0.000 title claims abstract description 197

- 239000007788 liquid Substances 0.000 claims abstract description 35

- 239000000203 mixture Substances 0.000 claims abstract description 24

- 238000000034 method Methods 0.000 claims abstract description 6

- 230000007423 decrease Effects 0.000 claims description 23

- 230000002093 peripheral effect Effects 0.000 claims description 9

- 238000002485 combustion reaction Methods 0.000 claims description 6

- 239000007921 spray Substances 0.000 abstract description 27

- 238000002347 injection Methods 0.000 description 8

- 239000007924 injection Substances 0.000 description 8

- 239000003054 catalyst Substances 0.000 description 7

- XSQUKJJJFZCRTK-UHFFFAOYSA-N Urea Chemical compound NC(N)=O XSQUKJJJFZCRTK-UHFFFAOYSA-N 0.000 description 6

- 239000004202 carbamide Substances 0.000 description 6

- 230000000694 effects Effects 0.000 description 6

- 239000002245 particle Substances 0.000 description 6

- 239000011343 solid material Substances 0.000 description 6

- 239000000243 solution Substances 0.000 description 4

- 230000001419 dependent effect Effects 0.000 description 3

- 229930195733 hydrocarbon Natural products 0.000 description 3

- 150000002430 hydrocarbons Chemical class 0.000 description 3

- MWUXSHHQAYIFBG-UHFFFAOYSA-N nitrogen oxide Inorganic materials O=[N] MWUXSHHQAYIFBG-UHFFFAOYSA-N 0.000 description 3

- 230000008092 positive effect Effects 0.000 description 3

- QGZKDVFQNNGYKY-UHFFFAOYSA-N Ammonia Chemical compound N QGZKDVFQNNGYKY-UHFFFAOYSA-N 0.000 description 2

- 230000007062 hydrolysis Effects 0.000 description 2

- 238000006460 hydrolysis reaction Methods 0.000 description 2

- 238000004519 manufacturing process Methods 0.000 description 2

- 239000002243 precursor Substances 0.000 description 2

- 239000000126 substance Substances 0.000 description 2

- 238000011144 upstream manufacturing Methods 0.000 description 2

- 238000009736 wetting Methods 0.000 description 2

- 239000004215 Carbon black (E152) Substances 0.000 description 1

- 229910021529 ammonia Inorganic materials 0.000 description 1

- 230000015556 catabolic process Effects 0.000 description 1

- 238000010531 catalytic reduction reaction Methods 0.000 description 1

- 238000006243 chemical reaction Methods 0.000 description 1

- 239000003638 chemical reducing agent Substances 0.000 description 1

- 238000006731 degradation reaction Methods 0.000 description 1

- 238000011038 discontinuous diafiltration by volume reduction Methods 0.000 description 1

- -1 for example Chemical compound 0.000 description 1

- 239000000446 fuel Substances 0.000 description 1

- 238000010438 heat treatment Methods 0.000 description 1

- 230000003647 oxidation Effects 0.000 description 1

- 238000007254 oxidation reaction Methods 0.000 description 1

- 238000006722 reduction reaction Methods 0.000 description 1

- 230000008929 regeneration Effects 0.000 description 1

- 238000011069 regeneration method Methods 0.000 description 1

- 238000000926 separation method Methods 0.000 description 1

- 239000004071 soot Substances 0.000 description 1

- 238000003892 spreading Methods 0.000 description 1

- 238000003860 storage Methods 0.000 description 1

- 238000009827 uniform distribution Methods 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL COMBUSTION ENGINES

- F01N3/00—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust

- F01N3/08—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous

- F01N3/10—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous by thermal or catalytic conversion of noxious components of exhaust

- F01N3/18—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous by thermal or catalytic conversion of noxious components of exhaust characterised by methods of operation; Control

- F01N3/20—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous by thermal or catalytic conversion of noxious components of exhaust characterised by methods of operation; Control specially adapted for catalytic conversion ; Methods of operation or control of catalytic converters

- F01N3/2066—Selective catalytic reduction [SCR]

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F23/00—Mixing according to the phases to be mixed, e.g. dispersing or emulsifying

- B01F23/20—Mixing gases with liquids

- B01F23/21—Mixing gases with liquids by introducing liquids into gaseous media

- B01F23/213—Mixing gases with liquids by introducing liquids into gaseous media by spraying or atomising of the liquids

- B01F23/2132—Mixing gases with liquids by introducing liquids into gaseous media by spraying or atomising of the liquids using nozzles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F25/00—Flow mixers; Mixers for falling materials, e.g. solid particles

- B01F25/10—Mixing by creating a vortex flow, e.g. by tangential introduction of flow components

- B01F25/102—Mixing by creating a vortex flow, e.g. by tangential introduction of flow components wherein the vortex is created by two or more jets introduced tangentially in separate mixing chambers or consecutively in the same mixing chamber

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F25/00—Flow mixers; Mixers for falling materials, e.g. solid particles

- B01F25/30—Injector mixers

- B01F25/31—Injector mixers in conduits or tubes through which the main component flows

- B01F25/313—Injector mixers in conduits or tubes through which the main component flows wherein additional components are introduced in the centre of the conduit

- B01F25/3131—Injector mixers in conduits or tubes through which the main component flows wherein additional components are introduced in the centre of the conduit with additional mixing means other than injector mixers, e.g. screens, baffles or rotating elements

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL COMBUSTION ENGINES

- F01N3/00—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust

- F01N3/02—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for cooling, or for removing solid constituents of, exhaust

- F01N3/021—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for cooling, or for removing solid constituents of, exhaust by means of filters

- F01N3/023—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for cooling, or for removing solid constituents of, exhaust by means of filters using means for regenerating the filters, e.g. by burning trapped particles

- F01N3/025—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for cooling, or for removing solid constituents of, exhaust by means of filters using means for regenerating the filters, e.g. by burning trapped particles using fuel burner or by adding fuel to exhaust

- F01N3/0253—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for cooling, or for removing solid constituents of, exhaust by means of filters using means for regenerating the filters, e.g. by burning trapped particles using fuel burner or by adding fuel to exhaust adding fuel to exhaust gases

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL COMBUSTION ENGINES

- F01N3/00—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust

- F01N3/08—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous

- F01N3/10—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous by thermal or catalytic conversion of noxious components of exhaust

- F01N3/24—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous by thermal or catalytic conversion of noxious components of exhaust characterised by constructional aspects of converting apparatus

- F01N3/28—Construction of catalytic reactors

- F01N3/2892—Exhaust flow directors or the like, e.g. upstream of catalytic device

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL COMBUSTION ENGINES

- F01N3/00—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust

- F01N3/08—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous

- F01N3/10—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous by thermal or catalytic conversion of noxious components of exhaust

- F01N3/24—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous by thermal or catalytic conversion of noxious components of exhaust characterised by constructional aspects of converting apparatus

- F01N3/36—Arrangements for supply of additional fuel

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F25/00—Flow mixers; Mixers for falling materials, e.g. solid particles

- B01F2025/93—Arrangements, nature or configuration of flow guiding elements

- B01F2025/931—Flow guiding elements surrounding feed openings, e.g. jet nozzles

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL COMBUSTION ENGINES

- F01N2240/00—Combination or association of two or more different exhaust treating devices, or of at least one such device with an auxiliary device, not covered by indexing codes F01N2230/00 or F01N2250/00, one of the devices being

- F01N2240/20—Combination or association of two or more different exhaust treating devices, or of at least one such device with an auxiliary device, not covered by indexing codes F01N2230/00 or F01N2250/00, one of the devices being a flow director or deflector

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL COMBUSTION ENGINES

- F01N2610/00—Adding substances to exhaust gases

- F01N2610/02—Adding substances to exhaust gases the substance being ammonia or urea

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL COMBUSTION ENGINES

- F01N2610/00—Adding substances to exhaust gases

- F01N2610/03—Adding substances to exhaust gases the substance being hydrocarbons, e.g. engine fuel

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL COMBUSTION ENGINES

- F01N2610/00—Adding substances to exhaust gases

- F01N2610/06—Adding substances to exhaust gases the substance being in the gaseous form

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL COMBUSTION ENGINES

- F01N3/00—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust

- F01N3/08—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous

- F01N3/10—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous by thermal or catalytic conversion of noxious components of exhaust

- F01N3/24—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous by thermal or catalytic conversion of noxious components of exhaust characterised by constructional aspects of converting apparatus

Definitions

- the invention relates to a mixing device for the aftertreatment of exhaust gases in an exhaust system of an internal combustion engine comprising a housing having an inlet opening having an inlet cross-section and an inner tube disposed within the housing with a mixing area formed in the interior of the inner tube, wherein at a front side of the housing a metering device for Supply of a liquid and / or a liquid-gas mixture is arranged.

- the inner tube on its lateral surface on access openings, through which the exhaust gases are introduced into the mixing area.

- the invention further relates to a method for mixing an exhaust gas with a liquid and / or a liquid-gas mixture using such a mixing device.

- a hydrolysis catalyst for reducing nitrogen oxides in an exhaust gas stream, in particular of a motor vehicle, is generally known.

- SCR selective catalytic reduction

- the exhaust gas stream is supplied with an immediately reducing substance, such as, for example, ammonia or a precursor, such as, for example, an aqueous urea solution which releases substances reducing the exhaust gas first.

- an immediately reducing substance such as, for example, ammonia or a precursor, such as, for example, an aqueous urea solution which releases substances reducing the exhaust gas first.

- the precursor is sprayed before the SCR catalyst in the exhaust stream.

- a so-called particulate filter is used regularly to minimize the emission of fines particles in a motor vehicle.

- the exhaust gas usually flows through the filter medium. This can lead to "blockage" of the particulate filter and consequently to an increase in the exhaust back pressure. This in turn has a negative effect on the engine performance and the fuel consumption of the internal combustion engine. Therefore, a particulate filter regeneration is usually carried out, which in particular by an active increase in the exhaust gas temperature of an exhaust gas stream, which then the particulate filter is supplied, is realized.

- hydrocarbons are added to the exhaust gas stream for heating the exhaust gas stream upstream of the particle filter.

- This mixture is then fed to a HC oxidation catalyst whose active component with the hydrocarbons by exothermic reaction generates a heated exhaust gas stream.

- This hot exhaust gas stream flows to the particle filter, where the carbonaceous soot particles stored in the particle filter are converted to CO, CO2, N2 and NO, whereby the particle filter is regenerated.

- the substance to be introduced into the exhaust gas which is generally liquid, is usually sprayed into the exhaust gas stream via a nozzle of a metering device.

- a uniform distribution of the liquid introduced into the exhaust gas is of essential importance.

- a mixing device of the type mentioned is, for example, in the DE 42 03 807 A1 disclosed.

- a device designed as a mixing device for the aftertreatment of exhaust gases in an exhaust system of an internal combustion engine is shown, which enables a mixing of exhaust gases with a urea solution before entering a hydrolysis catalyst.

- a conical baffle designed as an inner tube is arranged in a housing.

- the baffle has a plurality of holes as access openings in a mixing area formed within the baffle.

- a metering device designed as a pressure atomizing nozzle is arranged on the front side, via which a urea solution is supplied as a spray into the mixing region.

- the exhaust gas is introduced into the housing via an inlet opening and flows through the bores of the guide plate into the mixing area in which the exhaust gas is mixed with the spray.

- the disadvantage here, however, that act on the introduced spray in the circumferential direction through the introduced via the holes exhaust gas different strong forces, resulting in a deflection and thus to an asymmetrical spread of the spray. As a result, the spray is not homogeneously mixed with the urea.

- the invention is based on the first object to provide a mixing device which is as homogeneous as possible mixing a liquid and / or a liquid-gas mixture with the exhaust gas is guaranteed independently or only with little influence of an inflowing inflowing exhaust gas flow volume. Furthermore, the invention has the second object of providing a method for mixing a liquid and / or a liquid-gas mixture with the exhaust gas as homogeneously as possible.

- a mixing device for the aftertreatment of exhaust gases in an exhaust system of an internal combustion engine comprising a housing having an inlet opening having an inlet cross-section and an inner tube disposed within the housing with a mixing area formed in the interior of the inner tube, wherein at one end side of the housing a metering device for supplying a liquid and / or a liquid-gas mixture is arranged, and wherein the inner tube has on its lateral surface access openings through which the exhaust gases are introduced into the mixing region.

- the housing has a spiral-shaped housing section, wherein the spiral-shaped housing section extends at least along all access openings of the inner tube.

- the invention is based in a first step on the consideration that for a homogeneous mixing of the introduced in particular in the form of a spray liquid and / or the introduced liquid-gas mixture with the exhaust gas, a homogeneous spread of the spray in the mixing area is required.

- the invention is based on the consideration that for a homogeneous spreading of the spray on this circumferentially around the central main flow axis of the spray uniform flow forces must prevail. In other words, uniform flow and pressure conditions must be present in the circumferential direction. Therefore, the invention provides that the housing has a spiral-shaped housing section, which extends at least along all access openings of the inner tube.

- the spiral shape ensures that approximately equal flow and pressure conditions prevail on the outer lateral surface along the section of the inner tube provided with access openings, so that, in particular in the circumferential direction, a uniform supply of the exhaust gas over the Access openings in the mixing area and can form rotationally symmetric flow conditions in the mixing area.

- the inlet opening of the housing is used in particular for the supply of exhaust gas into the housing.

- the inner tube has as a main body in particular an elongated hollow body with a circular, oval, rectangular or polygonal cross section.

- Within the inner tube of the mixing region is formed, in which the exhaust gas is mixed with a supplied via the metering liquid and / or a liquid-gas mixture.

- the liquid contains in particular urea and / or hydrocarbon.

- the spiral-shaped housing section leads, in particular, the exhaust gas flowing in via the inlet opening towards the inner tube and in the circumferential direction along the inner tube. Due to the spiral shape occurs in this housing section in the circumferential direction a reduction in volume between the lateral surface of the inner tube and the housing wall and a spiral housing portion flowing through the exhaust stream is impressed by the spiral shape a certain twist.

- This spiral housing section extends at least along all the access openings, that is, all access openings of the inner tube are arranged within this housing section.

- the invention has the advantage that thereby a mixing device is provided, which ensures the most homogeneous possible mixing of a liquid and / or a liquid-gas mixture with the exhaust gas, or only with little influence of the inflowing exhaust gas volume flow.

- a mixing device is provided, which ensures the most homogeneous possible mixing of a liquid and / or a liquid-gas mixture with the exhaust gas, or only with little influence of the inflowing exhaust gas volume flow.

- a passage cross-section formed by the access openings advantageously decreases toward the axial end of the inner tube facing away from the metering device.

- the passage cross-section is the cross-sectional area which is available to the exhaust gas due to the inlet openings for entry into the mixing area.

- This passage cross-section can, for example, steadily decrease towards the end facing away from the metering device.

- the passage cross-section may, however, also decrease, in particular in regions, toward the end facing away from the metering device.

- the passage cross-section is greater in a region close to the dosing device than the passage cross-section in a dosing device-remote region.

- the individual areas are essentially the same size.

- a region is formed by a defined peripheral surface of the inner tube, this peripheral surface resulting from the sum of the area of the solid material and the cross-sectional area of the access openings.

- the ratio of the area of the solid material to the cross-sectional area of the access openings in a dosing device-near area is smaller than the ratio of the area of the solid material to the cross-sectional area of the access openings in a dosing device remote area.

- the number of access openings expediently decreases at least in places towards the axial end of the inner tube facing away from the metering device.

- the decrease of the passage cross section formed by the access openings to the axial end of the inner tube facing away from the metering device can be realized in a relatively simple manner. This ensures, in particular in the case of an exhaust gas flowing into the housing from the axial direction, that the exhaust gas flowing into the inner pipe runs as homogeneously as possible into the mixing area along the entire section of the inner pipe provided with access openings flows.

- the distance between two adjacent access openings in the axial direction and / or in the circumferential direction increases towards the axial end of the inner tube facing away from the metering device.

- the number of access openings can thereby steadily decrease towards the end facing away from the metering device.

- the number of access openings may also decrease in some areas towards the end facing away from the metering device. In other words, the number of access openings in a dosing device remote area is smaller than the number of access openings in a dosing device nearer area.

- the cross-sectional area of the access openings advantageously decreases at least in regions toward the axial end facing away from the metering device.

- the cross-sectional area of the individual access openings can thereby steadily decrease towards the end facing away from the metering device.

- the cross-sectional area of the individual access openings may, however, also decrease in regions toward the end facing away from the metering device. That is, the cross-sectional area of the individual access openings in a dosing device-remote area is smaller than the cross-sectional area of the individual access openings in a dosing device-closer area.

- an exhaust gas inlet pipe extends at least partially into the housing, wherein the longitudinal central axis of the exhaust gas inlet pipe and the longitudinal center axis of the inner pipe are aligned substantially parallel to each other.

- the exhaust gas can be selectively supplied to a specific area within the housing.

- the exhaust gas inlet pipe extends in this case via the inlet opening into the housing, that is to say that the exhaust gas inlet pipe is guided through the inlet opening into the housing.

- the exhaust gas inlet pipe is designed in particular circular-cylindrical or conical.

- the outside diameter of the exhaust gas inlet pipe in the area of the inlet opening essentially corresponds to the diameter of the inlet opening.

- the exhaust gas inlet tube extends within the housing at least along the spiral-shaped housing section, wherein the Exhaust inlet pipe at the along the spiral-shaped housing portion extending peripheral surface has outlet openings.

- outlet openings are in particular arranged in full circumference on the peripheral surface of the exhaust gas inlet pipe and have, for example, a circular or slot-shaped geometry.

- an exhaust gas flow supplied in particular from an axial direction to the exhaust gas inlet pipe can be "deflected" in a radial direction as it leaves the exhaust gas inlet pipe through the outlet openings or it can be given at least one radial speed component.

- this contributes to the exhaust gas flowing as homogeneously as possible into the spiral-shaped housing section along the entire section of the exhaust gas inlet tube provided with outlet openings.

- the exhaust gas flowing into the exhaust gas inlet pipe can at least temporarily accumulate at the axial end of the exhaust gas inlet pipe facing away from the inlet opening and thus the exhaust gas volume flow from the outlet openings, which are located in this area, can be greater than the exhaust gas volume flow from the outlet openings of an area closer to the inlet opening, preferably takes the number of outlet openings to the axial end of the exhaust gas inlet pipe facing away from the inlet opening at least partially. This ensures that the exhaust gas flowing into the exhaust gas inlet pipe flows as homogeneously as possible into the spiral-shaped housing section along the entire section of the exhaust gas inlet pipe provided with outlet openings.

- the distance between two adjacent outlet openings in the axial direction and / or in the circumferential direction increases towards the axial end of the exhaust gas inlet tube facing away from the inlet opening.

- the number of outlet openings can decrease steadily towards the end facing away from the inlet opening.

- the number of outlet openings can also decrease in some areas towards the end facing away from the inlet opening.

- the number of outlet openings in a dosing device remote area is smaller than the number of access openings in a dosing device nearer area.

- the individual areas are essentially the same size.

- a region is formed by a defined peripheral surface of the exhaust gas inlet pipe, wherein this peripheral surface results from the sum of the area of the solid material and the cross-sectional area of the outlet openings.

- the ratio of the area of the solid material to the cross-sectional area of the outlet openings in a doser-near area is smaller than the ratio of the area of the solid material to the cross-sectional area of the outlet openings in a doser-remote area.

- the cross-sectional area of the individual outlet openings preferably decreases continuously towards the end facing away from the metering device.

- the cross-sectional area of the individual outlet openings may also decrease in regions toward the end facing away from the metering device. This means that the cross-sectional area of the individual outlet openings in a region remote from the doser is smaller than the cross-sectional area of the individual outlet openings in a doser-near region.

- the inner tube is circular-cylindrical or conical. Depending on the metering device used and the associated spread of the liquid and / or the liquid-gas mixture, these shapes continue to have a positive effect on a homogeneous spread of the liquid and / or the liquid-gas mixture in the mixing region.

- the diameter of the inner tube widens to the end facing away from the metering device.

- the access openings are advantageously provided with exhaust gas guide elements, which protrude from the main extension of the lateral surface.

- These exhaust gas guide elements serve, in particular, for the flow guidance of the exhaust gas and for preventing the escape of the liquid and / or the liquid-gas mixture from the mixing region.

- a swirl is impressed on the exhaust gas partial flows flowing through the inlet openings through the exhaust gas guide elements and / or the swirl movement generated by the spiral-shaped housing section is intensified.

- the geometry of the exhaust gas guide elements is to be matched to the respective individual case and, in particular, depends on the propagation characteristics of the introduced liquid and / or the introduced liquid-gas mixture in the mixing area and the occurring exhaust gas flow rates.

- the exhaust gas guide elements expediently extend at least into the mixing area.

- an exhaust gas guide may be provided which extends into the intermediate space between the lateral surface of the inner tube and housing wall.

- the exhaust-gas guide element or both exhaust-gas guide elements are preferably shaped in such a way that they "close off” the access opening in an opaque manner, as seen from the longitudinal central axis of the inner tube, that is to say that a beam (imaginary) extending radially outwards from the longitudinal center axis and perpendicular to this the access opening can penetrate as possible.

- the exhaust gas guide elements are integrally formed on the lateral surface of the inner tube. This allows a simple and inexpensive production.

- the projection of an opening axis of the exhaust gas guide element to an extending through the access opening of the exhaust gas guide central longitudinal plane of the inner tube with the longitudinal central axis of the inner tube an inclination angle of 5 ° to 90 °, preferably from 30 ° to 50 °, particularly preferably from 35 ° to 40 °.

- the central longitudinal plane extends through the center of the respective access opening on the one hand and through the longitudinal central axis of the inner tube on the other hand and extends along this longitudinal central axis.

- the inclination angle is the angle by which the exhaust gas guide element protrudes from the base casing surface of the inner tube, that is, out of the lateral surface without taking into account the exhaust gas guide elements.

- an opening axis of the exhaust gas guide element encloses an alignment angle of 0 ° to 90 °, preferably of 10 ° to 90 °, particularly preferably of 20 ° to 90 °, with a central longitudinal plane of the inner tube running through the inlet opening of the exhaust guide element.

- the central longitudinal plane runs to one through the center of each access opening and the other through the longitudinal central axis of the inner tube and extends along this longitudinal central axis.

- the orientation angle indicates that angle by which the access opening is "twisted out" from a course aligned in the direction of the longitudinal central axis of the inner tube.

- the exhaust gas elements With an alignment of the exhaust gas guide elements according to an orientation angle of less than 90 °, the exhaust gas elements cause a partial deflection of the exhaust gas partial flow toward the main injection direction.

- This achieves, in particular, that the exhaust gas flowing in from the spiral-shaped housing section is diverted through the inlet openings and the exhaust-gas guide elements arranged thereinto into partial exhaust streams which have a certain velocity component running in the main injection direction of the metering device, which in turn leads to a homogeneous mixing of liquid and / or liquid.

- Gas Gemiches contributes to the exhaust.

- the metering device is arranged coaxially to the longitudinal central axis of the inner tube.

- the passage cross section formed by the access openings corresponds to 80% to 300% of the inlet cross section of the inlet opening, preferably 90% to 250%.

- Such a ratio of inlet cross section to passage cross section has a further positive effect on the homogeneous inflow of the exhaust gas into the mixing area.

- the lateral surface of the inner tube in addition to the access openings, in particular in the region of an axial end of the spiral-shaped housing section, an at least partially circumferential annular gap, which serves as a kind of "bypass" for the exhaust gas.

- a guide element can be arranged in the region of the annular gap which effects a deflection of an exhaust gas partial stream flowing through the annular gap at least partially in the main injection direction of the metering device.

- the inner tube is preferably arranged in the spiral housing section in such a way that in the circumferential direction between the inner tube and the housing wall there is always a distance dependent on the course of the spiral shape. As a result, there is always a gap between inner tube and housing wall in the circumferential direction and no "dead end" is formed, at which the incoming exhaust gas would accumulate. This further contributes positively to a homogeneous flow path through the spiral-shaped housing section.

- the second object is achieved by a method for mixing an exhaust gas with a liquid and / or a liquid-gas mixture using a mixing device as described above.

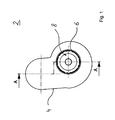

- FIG. 1 is a schematic representation of a mixing device 2 for the aftertreatment of exhaust gases in an exhaust system of an internal combustion engine shown.

- the mixing device 2 upstream of an SCR catalyst fluidically.

- the mixing device 2 comprises a housing 4 and a circular-cylindrical inner tube 6 arranged inside the housing 4.

- a mixing region 8 is formed in the interior of the inner tube 6.

- Fig. 2 shows in a schematic longitudinal sectional view along section line AA, the mixing device 2 from Fig. 1 ,

- the inner tube 6 arranged in the housing 4 can be seen with the mixing area 8 formed in its interior.

- a metering device 10 is attached to an end face of the housing 4.

- the metering device 10 is used to supply a liquid-gas mixture in the mixing region 8 via a nozzle 12 in the form of a spray 14.

- the liquid is a urea solution.

- the inner tube 6 has on its lateral surface 16 access openings 18, through which exhaust gases in the mixing region 8 can be introduced.

- the access openings 18 are provided with exhaust gas guide elements 20, which protrude from the main extension of the lateral surface 16. These exhaust gas guide elements 20 are used, in particular, for the flow guidance of the exhaust gas and, secondly, they prevent the escape of the spray 14 from the mixing region 8.

- the exhaust gas guide elements 20 are here formed integrally on the lateral surface 16 of the inner tube 6, which allows a simple and cost-effective production.

- the number of access openings 18 decreases steadily toward the axial end of the inner tube 6 facing away from the metering device 10.

- the distance between two adjacent access openings 18 increases in the axial direction and in the circumferential direction to the axial end of the inner tube 6 facing away from the metering device 10.

- a decrease in the passage cross section formed by the access openings 18 to the axial end of the inner tube 6 facing away from the metering device 10 is realized.

- Fig. 2 to recognize that the access openings 18 are "twisted out" about an aligned in the direction of the longitudinal center axis of the inner tube 6 course.

- the housing 4 comprises a spiral-shaped housing section 20 which extends along all access openings 18 of the inner tube 6, that is, all access openings 18 of the inner tube 6 are arranged within this spiral housing section 20.

- a circular-cylindrical exhaust gas inlet pipe 26 extends into the housing 4.

- the exhaust gas inlet pipe 26 is guided through the inlet opening 24 into the housing 4.

- the outer diameter of the exhaust gas inlet pipe 26 substantially corresponds to the diameter of the inlet opening 24.

- the longitudinal center axis of the exhaust gas inlet pipe 26 and the longitudinal center axis of the inner tube 6 are aligned parallel to each other and the exhaust gas inlet pipe 26 extends axially along the entire spiral housing portion 22.

- the outlet openings 28 are arranged completely on the peripheral surface 30 of the exhaust gas inlet pipe 26 and have a circular geometry.

- an exhaust gas feedstream 32 fed to the mixing device 2 initially flows via the exhaust gas inlet pipe 26 in the direction of the housing 4 and flows via the outlet openings 28 into the spiral housing section 22.

- the exhaust gas feedstream 32 thus exits the exhaust gas inlet pipe 26 through the outlet openings 28 is "deflected" from an axial direction in a radial direction or at least one radial velocity component is granted to it.

- the exhaust gas feedstream 32 is supplied relatively homogeneously to the spiral-shaped housing section 22 along the entire section of the exhaust gas inlet tube 26 provided with outlet openings 28.

- the spiral-shaped housing section 22 extends along all the outlet openings 28 and in particular along all the access openings 18 ensures that approximately the same flow and pressure conditions prevail on the lateral surface 16 of the inner tube 6 along the section provided with access openings 18.

- a uniform supply of partial exhaust gas streams takes place via the inlet openings 18 into the mixing area 8 and rotationally symmetrical flow conditions can form in the mixing area 8.

- the spray 14 can spread homogeneously in the mixing region 8, since there are approximately uniform flow and pressure conditions, in particular in the circumferential direction about the central main flow axis of the spray 14, which essentially corresponds to the longitudinal central axis of the inner tube 6 in such an arrangement. This ensures a homogeneous mixing of the spray 14 with the exhaust gas supplied via the inlet openings 18 in the form of exhaust partial streams.

- the exhaust gas inflow 32 which flows axially from the axial direction into the exhaust gas inlet pipe 26 and flows axially to the axial end facing away from the metering device 10, can at least temporarily accumulate in this end region of the exhaust gas inlet pipe 26, the exhaust gas volume flow flowing through the outlet openings 28 flows are in this area, at least temporarily greater than the exhaust gas volume flow, which flows through the outlet openings 28 of a dosing device nearer area.

- a partial deflection of the exhaust gas streams flowing through the inlet openings 18 toward the main injection direction of the spray 14 is caused by the illustrated orientation of the access openings 18 and thus in particular of the respective exhaust gas guide elements 20.

- the exhaust partial streams deflected in particular in the area close to the dosing device thus receive a certain velocity component running in the main injection direction of the dosing device 10. This contributes in addition to a homogeneous mixing of the spray 14 with the exhaust gas, since no or only a very small deflection of the spray 14 takes place, in particular in the area near the dosing device.

- Fig. 3 shows in a schematic cross-sectional view along section line BB of the mixing device Fig. 2 ,

- the arrangement of the inner tube 6 in the spiral-shaped housing section 22 can be seen. Due to the spiral shape in the circumferential direction caused by volume reduction of the gap between the inner tube 6 and housing wall, it is helped that prevail on the outer circumferential surface 8 of the inner tube 6 along the circumference approximately equal pressure and flow conditions, whereby a uniform possible supply of the exhaust gas in the mixing area 8 can take place.

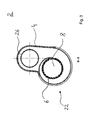

- Fig. 4 is shown in a schematic representation of a spiral housing portion 22 of an alternative embodiment.

- the inner tube 6 is arranged in the spiral-shaped housing section 22 such that in the circumferential direction between the inner tube 6 and the housing wall a distance s dependent on the course of the spiral shape is always formed.

- a distance s dependent on the course of the spiral shape is always formed.

- This further contributes positively to a homogeneous flow pattern through the spiral-shaped housing portion 22 at.

- r is the radius of curvature

- D is the diameter of the inner tube 6

- s is the distance of the lateral surface 8 of the inner tube 6 from the housing wall of the helical housing 22

- A is the cross-section of the inflow opening of the helical housing.

- Fig. 5 shows a schematic representation of an inner tube 6 in a further embodiment.

- the arranged on the lateral surface 16 of the inner tube 6 access openings 18 and the integrally formed at the inlet openings 18 exhaust gas guide elements 20 are shown.

- the access openings 18 and the exhaust gas guide elements 20 are "twisted out" from a course oriented in the direction of the longitudinal central axis of the inner tube 6 by an orientation angle ⁇ .

- the orientation angle ⁇ is enclosed between an opening axis 36 of an exhaust gas guide element 20 and a central longitudinal plane 38 of the inner tube 6 extending through the access opening 18 of the exhaust gas guide element 20.

- the central longitudinal plane 38 extends on the one hand through the center of the respective access opening 18 and on the other by the longitudinal central axis of the inner tube 6 and extends along this longitudinal central axis.

- the inlet openings 18 and in particular the exhaust gas elements 20 cause a certain deflection of the exhaust gas flowing through the access openings 18 exhaust partial flow back to the main injection direction of a metering device 10.

- the orientation angle ⁇ takes axially to the right that is, axially towards an end facing away from a metering device 10, toward.

- the size of the orientation angle ⁇ and in particular the increase axially to the right, is dependent in particular on the metering device 10 and nozzle 12 used in the individual case, as well as on the exhaust gas volume flows which flow through the access openings 18 into the mixing region 8 of the inner tube 6.

- Fig. 6 shows in a schematic longitudinal sectional view along section line EE an enlarged section of the inner tube Fig. 5 ,

- the arranged on the lateral surface 16 of the inner tube 6 access openings 18 and in particular the integrally formed at the inlet openings 18 exhaust gas guide elements 20 can be seen.

- an exhaust gas guide element 20 extends into a mixing region 8 and a further exhaust gas guide element 20 extends into a gap between the lateral surface 16 of the inner tube 6 and a housing wall of a housing 4, in which the inner tube 6 is arranged.

- the respective two exhaust gas guide elements 20 of an access opening 18 are shaped in such a way that they "close off” the access opening as opaque as possible, viewed radially from the longitudinal center axis of the inner tube 6. In this way, leakage of a metering device 10 into a mixing region 8 formed in the interior of the inner tube 6 is prevented particularly effectively.

- the illustrated exhaust elements 20 are in this case at an inclination angle ⁇ from the base surface of the inner tube 6, ie from the lateral surface 8 without consideration of the exhaust elements 20, from.

- FIG. 7 are in a schematic longitudinal sectional view of various embodiments of a Abgasleitelements 20 shown, which are arranged on access openings 18 of a lateral surface 16 of an inner tube 6, which is installed in a housing 4.

- V1 only one exhaust gas guide element 20 is arranged on an access opening 18, which extends into a gap between the lateral surface 16 and a housing wall of the housing 4.

- FIG. 2 shows an inlet opening 18, on which an exhaust gas guide element 20 is arranged, which extends into a mixing area 8 formed inside an inner tube 6.

- V3 is the same as in Fig. 6 illustrated embodiment.

- Fig. 8 shows a schematic longitudinal sectional view of a mixing device 2 in an alternative embodiment.

- the mixing device 2 substantially corresponds to in Fig. 1 to Fig. 3 shown mixing device.

- the distance between two axially adjacent outlet openings 28 of the exhaust gas inlet pipe 26 increases in the axial direction to the axial end of the exhaust gas inlet pipe 26 facing away from the inlet opening 24. Consequently, the number of outlet openings 28 to the inlet opening 24 facing away from the end down. This ensures that the exhaust gas inflow 32 flowing into the exhaust gas inlet pipe 26 flows as homogeneously as possible into the spiral-shaped housing section 22 along the entire section of the exhaust gas inlet pipe 26 provided with outlet openings 28.

- the lateral surface 16 of the inner tube 6 in the region close to the metering device has a circumferential annular gap which serves as a bypass channel 40 for the exhaust gas.

- a guide element 42 is arranged on and coaxially with the metering device 10 and protrudes axially into the mixing region 8 of the inner tube 6. The guide element 42 prevents the spray 14 from being exposed to the exhaust gas partial flow passing through the bypass passage 40 in the area close to the metering device. The guide element 42 further redirects this partial exhaust gas flow in the axial main injection direction.

- the guide element 42 is annular and preferably rotationally symmetrical and formed in its cross section on its outer surface to the dosing device 10 facing away from the end tapered.

- Fig. 9a - 9c show in schematic longitudinal sectional views of various embodiments of a guide element 42 and an inner tube 6 of an enlarged section C from Fig. 8 ,

- the differently configured access openings 18 can be seen.

- the guide elements 42 are designed differently, in particular with respect to their axial and / or radial extent.

- the axial extent of the metering device 10 facing away from the end portion 44 of in Fig. 9b shown guide element 42 is relatively large.

- contact or wetting of the metering device 10 facing away, radially inwardly end portion 44 of the guide element 42 can be realized with the spray 14.

- a slight and / or temporary wetting of the inner wall 46 of the guide element 42 is particularly advantageous in the exhaust gas flowed through state.

- the metering device 10 usually works temporarily. Thus, during the non-injection periods, a "degradation" of the liquid located on the inner wall 46 of the guide element 42 can be achieved.

- the effect is favored by the fact that the guide element 42 is thin-walled and / or is heated on the outside by the partial exhaust gas stream flowing through the bypass channel 40, so that the liquid located on the wall sections of the inner wall 46 also heats up. This heat facilitates the separation effect and splitting effect (secondary rupture) of the liquid droplets that lie on the inside of the guide element 42.

- the mixing function of the mixing device 2 is further promoted by the targeted slight temporary wall contact of the spray 14.

- the degree of temporary adhesion of the liquid On the interpretation of the axial extent of the guide element 42 and in particular its end portion 44 remote from the metering device 10 can be adjusted in a structurally simple and effective manner, the degree of temporary adhesion of the liquid.

- the metering device 10 and thus the spray angle and the density of the liquid is specified. These parameters affect the propagation characteristics of the spray 14 depending on the exhaust gas volumetric flow. If now a liquid with a different density and / or a metering device 10 with a different spray angle are installed, then it is sufficient if the mixing device 2 is adjusted by changing the axial extent of the guide element 42 and in particular of the metering device 10 facing away from end region 44 to to adjust the effect described above (secondary break).

Abstract

Description

Die Erfindung betrifft eine Mischvorrichtung zur Nachbehandlung von Abgasen in einer Abgasanlage einer Brennkraftmaschine, die ein Gehäuse mit einer einen Eintrittsquerschnitt aufweisenden Eintrittsöffnung und ein innerhalb des Gehäuses angeordnetes Innenrohr mit einem im Inneren des Innenrohres ausgebildeten Mischbereich umfasst, wobei an einer Stirnseite des Gehäuses eine Dosiereinrichtung zur Zuführung einer Flüssigkeit und/oder eines Flüssigkeit-Gas-Gemisches angeordnet ist. Dabei weist das Innenrohr an seiner Mantelfläche Zutrittsöffnungen auf, durch welche die Abgase in den Mischbereich einleitbar sind. Die Erfindung betrifft weiter ein Verfahren zum Mischen eines Abgases mit einer Flüssigkeit und/oder einem Flüssigkeit-Gas-Gemisches unter Verwendung einer derartigen Mischvorrichtung.The invention relates to a mixing device for the aftertreatment of exhaust gases in an exhaust system of an internal combustion engine comprising a housing having an inlet opening having an inlet cross-section and an inner tube disposed within the housing with a mixing area formed in the interior of the inner tube, wherein at a front side of the housing a metering device for Supply of a liquid and / or a liquid-gas mixture is arranged. In this case, the inner tube on its lateral surface on access openings, through which the exhaust gases are introduced into the mixing area. The invention further relates to a method for mixing an exhaust gas with a liquid and / or a liquid-gas mixture using such a mixing device.

Der Einsatz eines Hydrolysekatalysators zur Reduzierung von Stickoxiden in einem Abgasstrom insbesondere eines Kraftfahrzeugs ist allgemein bekannt. Im Rahmen der beispielsweise mit einem SCR-Katalysator durchgeführten selektiven katalytischen Reduktion (SCR) wird dem Abgasstrom eine unmittelbar reduzierend wirkende Substanz, wie beispielsweise Ammoniak oder ein Vorprodukt, wie beispielsweise eine wässrige Harnstofflösung, das erst im Abgas reduzierende Substanzen freisetzt, zugeführt. Üblicherweise wird das Vorprodukt dabei vor dem SCR-Katalysator in den Abgasstrom eingesprüht.The use of a hydrolysis catalyst for reducing nitrogen oxides in an exhaust gas stream, in particular of a motor vehicle, is generally known. In the context of the selective catalytic reduction (SCR) carried out, for example, with an SCR catalyst, the exhaust gas stream is supplied with an immediately reducing substance, such as, for example, ammonia or a precursor, such as, for example, an aqueous urea solution which releases substances reducing the exhaust gas first. Usually, the precursor is sprayed before the SCR catalyst in the exhaust stream.

Darüber hinaus wird zur Minimierung des Ausstoßes von Feinstoffpartikeln in einem Kraftfahrzeug regelmäßig ein sogenannter Partikelfilter eingesetzt. Dabei strömt das Abgas üblicherweise durch das Filtermedium hindurch. Hierbei kann es zur "Verstopfung" des Partikelfilters und folglich zu einer Erhöhung des Abgasgegendrucks kommen. Dies wirkt sich wiederum negativ auf die Motorleistung und den Kraftstoffverbrauch der Brennkraftmaschine aus. Daher wird in der Regel eine Partikelfilterregeneration durchgeführt, welche insbesondere durch eine aktive Anhebung der Abgastemperatur eines Abgasstroms, welcher dann dem Partikelfilter zugeführt wird, realisiert wird. Üblicherweise werden hierbei zur Erwärmung des Abgasstroms stromauf des Partikelfilters dem Abgasstrom Kohlenwasserstoffe zugesetzt. Dieses Gemisch wird anschließend einem HC-Oxidationskatalysator zugeführt, dessen Aktivkomponente mit den Kohlenwasserstoffen durch exotherme Reaktion einen erhitzten Abgasstrom erzeugt. Dieser heiße Abgasstrom strömt zum Partikelfilter, wo die im Partikelfilter eingelagerten kohlenstoffhaltigen Russpartikel zu CO, CO2, N2 und NO umgesetzt werden, wodurch der Partikelfilter regeneriert wird.In addition, a so-called particulate filter is used regularly to minimize the emission of fines particles in a motor vehicle. In this case, the exhaust gas usually flows through the filter medium. This can lead to "blockage" of the particulate filter and consequently to an increase in the exhaust back pressure. This in turn has a negative effect on the engine performance and the fuel consumption of the internal combustion engine. Therefore, a particulate filter regeneration is usually carried out, which in particular by an active increase in the exhaust gas temperature of an exhaust gas stream, which then the particulate filter is supplied, is realized. Usually, hydrocarbons are added to the exhaust gas stream for heating the exhaust gas stream upstream of the particle filter. This mixture is then fed to a HC oxidation catalyst whose active component with the hydrocarbons by exothermic reaction generates a heated exhaust gas stream. This hot exhaust gas stream flows to the particle filter, where the carbonaceous soot particles stored in the particle filter are converted to CO, CO2, N2 and NO, whereby the particle filter is regenerated.

Hierbei wird die jeweils in das Abgas einzubringende, in der Regel flüssig vorliegende Substanz, üblicherweise über eine Düse einer Dosiervorrichtung in den Abgasstrom eingesprüht. Zur Erzielung eines möglichst hohen Wirkungsgrads ist dabei insbesondere eine gleichmäßige Verteilung der in das Abgas eingebrachten Flüssigkeit von wesentlicher Bedeutung.Here, the substance to be introduced into the exhaust gas, which is generally liquid, is usually sprayed into the exhaust gas stream via a nozzle of a metering device. In order to achieve the highest possible efficiency, in particular a uniform distribution of the liquid introduced into the exhaust gas is of essential importance.

Eine Mischvorrichtung der eingangs genannten Art ist beispielsweise in der

Der Erfindung liegt die erste Aufgabe zugrunde, eine Mischvorrichtung bereitzustellen, die ein möglichst homogenes Vermischen einer Flüssigkeit und/oder eines Flüssigkeit-Gas-Gemisches mit dem Abgas unabhängig oder nur unter geringem Einfluss eines zuströmenden zuströmenden Abgasvolumenstroms gewährleistet. Ferner liegt der Erfindung die zweite Aufgabe zugrunde, ein Verfahren zum möglichst homogenen Vermischen einer Flüssigkeit und/oder eines Flüssigkeit-Gas-Gemisches mit dem Abgas bereitzustellen.The invention is based on the first object to provide a mixing device which is as homogeneous as possible mixing a liquid and / or a liquid-gas mixture with the exhaust gas is guaranteed independently or only with little influence of an inflowing inflowing exhaust gas flow volume. Furthermore, the invention has the second object of providing a method for mixing a liquid and / or a liquid-gas mixture with the exhaust gas as homogeneously as possible.

Diese erste Aufgabe wird gelöst durch eine Mischvorrichtung zur Nachbehandlung von Abgasen in einer Abgasanlage einer Brennkraftmaschine, die ein Gehäuse mit einer einen Eintrittsquerschnitt aufweisenden Eintrittsöffnung und ein innerhalb des Gehäuses angeordnetes Innenrohr mit einem im Inneren des Innenrohres ausgebildeten Mischbereich umfasst, wobei an einer Stirnseite des Gehäuses eine Dosiereinrichtung zur Zuführung einer Flüssigkeit und/oder eines Flüssigkeit-Gas-Gemisches angeordnet ist, und wobei das Innenrohr an seiner Mantelfläche Zutrittsöffnungen aufweist, durch welche die Abgase in den Mischbereich einleitbar sind. Dabei weist das Gehäuse einen spiralförmigen Gehäuseabschnitt auf, wobei sich der spiralförmige Gehäuseabschnitt zumindest entlang sämtlicher Zutrittsöffnungen des Innenrohrs erstreckt.This first object is achieved by a mixing device for the aftertreatment of exhaust gases in an exhaust system of an internal combustion engine comprising a housing having an inlet opening having an inlet cross-section and an inner tube disposed within the housing with a mixing area formed in the interior of the inner tube, wherein at one end side of the housing a metering device for supplying a liquid and / or a liquid-gas mixture is arranged, and wherein the inner tube has on its lateral surface access openings through which the exhaust gases are introduced into the mixing region. In this case, the housing has a spiral-shaped housing section, wherein the spiral-shaped housing section extends at least along all access openings of the inner tube.

Die Erfindung geht dabei in einem ersten Schritt von der Überlegung aus, dass für ein homogenes Vermischen der insbesondere in Form eines Sprays eingebrachten Flüssigkeit und/oder des eingebrachten Flüssigkeit-Gas-Gemisches mit dem Abgas eine homogene Ausbreitung des Sprays in dem Mischbereich erforderlich ist. In einem zweiten Schritt geht die Erfindung von der Überlegung aus, dass für eine homogene Ausbreitung des Sprays auf dieses in Umfangsrichtung um die zentrale Hauptströmungsachse des Sprays gleichmäßige Strömungskräfte herrschen müssen. Mit anderen Worten müssen in Umfangsrichtung gleichmäßige Strömungs-und Druckverhältnisse vorliegen. Daher sieht die Erfindung vor, dass das Gehäuse einen spiralförmigen Gehäuseabschnitt aufweist, welcher sich zumindest entlang sämtlicher Zutrittsöffnungen des Innenrohrs erstreckt. Durch die Spiralform wird gewährleistet, dass an der außen liegenden Mantelfläche entlang des mit Zutrittsöffnungen versehenen Abschnitts des Innenrohrs annähernd gleiche Strömungs- und Druckverhältnisse herrschen, so dass insbesondere in Umfangsrichtung gesehen eine gleichmäßige Zuführung des Abgases über die Zutrittsöffnungen in den Mischbereich erfolgt und sich im Mischbereich rotationssymmetrische Strömungsverhältnisse ausbilden können.The invention is based in a first step on the consideration that for a homogeneous mixing of the introduced in particular in the form of a spray liquid and / or the introduced liquid-gas mixture with the exhaust gas, a homogeneous spread of the spray in the mixing area is required. In a second step, the invention is based on the consideration that for a homogeneous spreading of the spray on this circumferentially around the central main flow axis of the spray uniform flow forces must prevail. In other words, uniform flow and pressure conditions must be present in the circumferential direction. Therefore, the invention provides that the housing has a spiral-shaped housing section, which extends at least along all access openings of the inner tube. The spiral shape ensures that approximately equal flow and pressure conditions prevail on the outer lateral surface along the section of the inner tube provided with access openings, so that, in particular in the circumferential direction, a uniform supply of the exhaust gas over the Access openings in the mixing area and can form rotationally symmetric flow conditions in the mixing area.

Die Eintrittsöffnung des Gehäuses dient insbesondere der Zufuhr von Abgas in das Gehäuse. Das Innenrohr weist als Grundkörper insbesondere einen länglichen Hohlkörper mit einem kreisrunden, ovalen, rechteckigen oder vieleckigen Querschnitt auf. Innerhalb des Innenrohres ist der Mischbereich ausgebildet, in dem das Abgas mit einer über die Dosiereinrichtung zugeführten Flüssigkeit und/oder einem Flüssigkeit-Gas-Gemisch vermischt wird. Die Flüssigkeit enthält insbesondere Harnstoff und/oder Kohlenwasserstoff.The inlet opening of the housing is used in particular for the supply of exhaust gas into the housing. The inner tube has as a main body in particular an elongated hollow body with a circular, oval, rectangular or polygonal cross section. Within the inner tube of the mixing region is formed, in which the exhaust gas is mixed with a supplied via the metering liquid and / or a liquid-gas mixture. The liquid contains in particular urea and / or hydrocarbon.

Der spiralförmige Gehäuseabschnitt führt insbesondere das über die Eintrittsöffnung zuströmende Abgas zu dem Innenrohr hin und in Umfangsrichtung entlang des Innenrohrs. Durch die Spiralform tritt in diesem Gehäuseabschnitt in Umfangsrichtung eine Volumenverkleinerung zwischen der Mantelfläche des Innenrohrs und der Gehäusewand auf und einem den spiralförmige Gehäuseabschnitt durchströmenden Abgasstrom wird durch die Spiralform ein gewisser Drall eingeprägt. Dieser spiralförmige Gehäuseabschnitt erstreckt sich dabei zumindest entlang sämtlicher Zutrittsöffnungen, das heißt, sämtliche Zutrittsöffnungen des Innenrohres sind innerhalb dieses Gehäuseabschnitts angeordnet.The spiral-shaped housing section leads, in particular, the exhaust gas flowing in via the inlet opening towards the inner tube and in the circumferential direction along the inner tube. Due to the spiral shape occurs in this housing section in the circumferential direction a reduction in volume between the lateral surface of the inner tube and the housing wall and a spiral housing portion flowing through the exhaust stream is impressed by the spiral shape a certain twist. This spiral housing section extends at least along all the access openings, that is, all access openings of the inner tube are arranged within this housing section.

Die Erfindung hat den Vorteil, dass dadurch eine Mischvorrichtung bereitgestellt wird, die ein möglichst homogenes Vermischen einer Flüssigkeit und/oder eines Flüssigkeit-Gas-Gemisches mit dem Abgas unabhängig oder nur unter geringem Einfluss des zuströmenden Abgasvolumenstroms gewährleistet. Durch den entlang der Zutrittsöffnungen verlaufenden spiralförmigen Gehäuseabschnitt stellen sich an der außen liegenden Mantelfläche annähernd gleiche Strömungs- und Druckverhältnisse ein, so dass insbesondere in Umfangsrichtung gesehen eine gleichmäßige Zuführung des Abgases über die Zutrittsöffnungen in den Mischbereich erfolgt und sich im Mischbereich rotationssymmetrische Strömungsverhältnisse ausbilden können.The invention has the advantage that thereby a mixing device is provided, which ensures the most homogeneous possible mixing of a liquid and / or a liquid-gas mixture with the exhaust gas, or only with little influence of the inflowing exhaust gas volume flow. As a result of the spiral-shaped housing section running along the access openings, approximately equal flow and pressure conditions are established on the outer lateral surface, so that a uniform supply of the exhaust gas to the mixing area occurs in particular in the circumferential direction and rotationally symmetrical flow conditions can form in the mixing area.

Ein aus axialer Richtung in das Gehäuse einströmendes Abgas, welches innerhalb des Gehäuses axial zu dem der Dosiereinrichtung abgewandten axialen Ende strömt, kann sich zumindest zeitweise in diesem Endbereich des Gehäuses anstauen, wodurch der Abgasvolumenstrom der durch die Zutrittsöffnungen, die sich in diesem Bereich befinden, größer wäre, als der Abgasvolumenstrom, welcher durch die Zutrittsöffnungen eines dosiereinrichtungsnäheren Bereichs strömt. Um dennoch möglichst gleich große Abgasvolumenströme zu erhalten, nimmt vorteilhafterweise ein durch die Zutrittsöffnungen gebildeter Durchtrittsquerschnitt zu dem der Dosiereinrichtung abgewandten axialen Ende des Innenrohrs hin ab. Dabei ist der Durchtrittsquerschnitt die Querschnittsfläche, die dem Abgas aufgrund der Zutrittsöffnungen zum Eintritt in den Mischbereich zur Verfügung steht. Dieser Durchtrittsquerschnitt kann zu dem der Dosiereinrichtung abgewandten Ende hin beispielsweise stetig abnehmen. Der Durchtrittsquerschnitt kann zu dem der Dosiereinrichtung abgewandten Ende hin aber auch insbesondere bereichsweise abnehmen. Mit anderen Worten ist der Durchtrittsquerschnitt in einem dosiereinrichtungsnahen Bereich größer, als der Durchtrittsquerschnitt in einem dosiereinrichtungsferneren Bereich. Dabei sind die einzelnen Bereiche untereinander im Wesentlichen gleich groß. Ein Bereich ist gebildet durch eine definierte Umfangsfläche des Innenrohrs, wobei sich diese Umfangsfläche aus der Summe von Fläche des Vollmaterials und der Querschnittsfläche der Zutrittsöffnungen ergibt. Das heißt, dass das Verhältnis der Fläche des Vollmaterials zur Querschnittsfläche der Zutrittsöffnungen in einem dosiereinrichtungsnahen Bereich kleiner ist, als das Verhältnis der Fläche des Vollmaterials zur Querschnittsfläche der Zutrittsöffnungen in einem dosiereinrichtungsferneren Bereich.An exhaust gas flowing from the axial direction into the housing, which flows axially to the axial end facing away from the metering device inside the housing, can at least temporarily accumulate in this end region of the housing, whereby the exhaust gas volume flow through the access openings located in this area, larger than the exhaust gas volume flow, which flows through the inlet openings of a dosing device nearer area. Nevertheless, in order to obtain as large as possible exhaust gas volume flows, a passage cross-section formed by the access openings advantageously decreases toward the axial end of the inner tube facing away from the metering device. In this case, the passage cross-section is the cross-sectional area which is available to the exhaust gas due to the inlet openings for entry into the mixing area. This passage cross-section can, for example, steadily decrease towards the end facing away from the metering device. The passage cross-section may, however, also decrease, in particular in regions, toward the end facing away from the metering device. In other words, the passage cross-section is greater in a region close to the dosing device than the passage cross-section in a dosing device-remote region. The individual areas are essentially the same size. A region is formed by a defined peripheral surface of the inner tube, this peripheral surface resulting from the sum of the area of the solid material and the cross-sectional area of the access openings. That is, the ratio of the area of the solid material to the cross-sectional area of the access openings in a dosing device-near area is smaller than the ratio of the area of the solid material to the cross-sectional area of the access openings in a dosing device remote area.

Um eine Abnahme des Durchtrittsquerschnitts zu realisieren, nimmt die Anzahl der Zutrittsöffnungen zweckmäßigerweise zu dem der Dosiereinrichtung abgewandten axialen Ende des Innenrohrs hin zumindest bereichsweise ab. Dadurch kann auf verhältnismäßig einfache Weise die Abnahme des durch die Zutrittsöffnungen gebildeten Durchtrittsquerschnitts zu dem der Dosiereinrichtung abgewandten axialen Ende des Innenrohrs hin realisiert werden. Damit wird, insbesondere bei einem aus axialer Richtung in das Gehäuse einströmendem Abgas, erreicht, dass das in das Innenrohr strömende Abgas entlang des gesamten mit Zutrittsöffnungen versehenen Abschnitts des Innenrohrs möglichst homogen in den Mischbereich strömt. Hierfür nimmt der Abstand zweier benachbarter Zutrittsöffnungen in axialer Richtung und/oder in Umfangsrichtung zu dem der Dosiereinrichtung abgewandten axialen Ende des Innenrohrs hin zu. Die Anzahl der Zutrittsöffnungen kann dabei zu dem der Dosiereinrichtung abgewandten Ende hin stetig abnehmen. Die Anzahl der Zutrittsöffnungen kann zu dem der Dosiereinrichtung abgewandten Ende hin aber auch bereichsweise abnehmen. Mit anderen Worten ist dabei die Anzahl der Zutrittsöffnungen in einem dosiereinrichtungsfernen Bereich kleiner, als die Anzahl der Zutrittsöffnungen in einem dosiereinrichtungsnäheren Bereich.In order to realize a decrease in the passage cross-section, the number of access openings expediently decreases at least in places towards the axial end of the inner tube facing away from the metering device. As a result, the decrease of the passage cross section formed by the access openings to the axial end of the inner tube facing away from the metering device can be realized in a relatively simple manner. This ensures, in particular in the case of an exhaust gas flowing into the housing from the axial direction, that the exhaust gas flowing into the inner pipe runs as homogeneously as possible into the mixing area along the entire section of the inner pipe provided with access openings flows. For this purpose, the distance between two adjacent access openings in the axial direction and / or in the circumferential direction increases towards the axial end of the inner tube facing away from the metering device. The number of access openings can thereby steadily decrease towards the end facing away from the metering device. However, the number of access openings may also decrease in some areas towards the end facing away from the metering device. In other words, the number of access openings in a dosing device remote area is smaller than the number of access openings in a dosing device nearer area.

Um eine Abnahme des Durchtrittsquerschnitts zu realisieren, nimmt vorteilhafterweise die Querschnittsfläche der Zutrittsöffnungen zu dem der Dosiereinrichtung abgewandten axialen Ende hin zumindest bereichsweise ab. Die Querschnittsfläche der einzelnen Zutrittsöffnungen kann dabei zu dem der Dosiereinrichtung abgewandten Ende hin stetig abnehmen. Die Querschnittsfläche der einzelnen Zutrittsöffnungen kann zu dem der Dosiereinrichtung abgewandten Ende hin aber auch bereichsweise abnehmen. Das heißt, dass die Querschnittsfläche der einzelnen Zutrittsöffnungen in einem dosiereinrichtungsfernen Bereich kleiner ist, als die Querschnittsfläche der einzelnen Zutrittsöffnungen in einem dosiereinrichtungsnäheren Bereich.In order to realize a decrease in the passage cross-section, the cross-sectional area of the access openings advantageously decreases at least in regions toward the axial end facing away from the metering device. The cross-sectional area of the individual access openings can thereby steadily decrease towards the end facing away from the metering device. The cross-sectional area of the individual access openings may, however, also decrease in regions toward the end facing away from the metering device. That is, the cross-sectional area of the individual access openings in a dosing device-remote area is smaller than the cross-sectional area of the individual access openings in a dosing device-closer area.

In einer vorteilhaften Ausführungsform erstreckt sich ein Abgaseinlassrohr zumindest teilweise in das Gehäuse, wobei die Längsmittelsachse des Abgaseinlassrohres und die Längsmittelachse des Innenrohres im Wesentlichen parallel zueinander ausgerichtet sind. Über ein derartiges Abgaseinlassrohr kann das Abgas gezielt einem bestimmten Bereich innerhalb des Gehäuses zugeführt werden. Das Abgaseinlassrohr erstreckt sich hierbei über die Eintrittsöffnung in das Gehäuse, das heißt, dass das Abgaseinlassrohr durch die Eintrittsöffnung in das Gehäuse geführt ist. Dabei ist das Abgaseinlassrohr insbesondere kreiszylinderförmig oder konusförmig ausgebildet. Bei einer kreisrunden Eintrittsöffnung entspricht der Außendurchmesser des Abgaseinlassrohres im Bereich der Eintrittsöffnung im Wesentlichen dem Durchmesser der Eintrittsöffnung.In an advantageous embodiment, an exhaust gas inlet pipe extends at least partially into the housing, wherein the longitudinal central axis of the exhaust gas inlet pipe and the longitudinal center axis of the inner pipe are aligned substantially parallel to each other. About such an exhaust gas inlet pipe, the exhaust gas can be selectively supplied to a specific area within the housing. The exhaust gas inlet pipe extends in this case via the inlet opening into the housing, that is to say that the exhaust gas inlet pipe is guided through the inlet opening into the housing. In this case, the exhaust gas inlet pipe is designed in particular circular-cylindrical or conical. In the case of a circular inlet opening, the outside diameter of the exhaust gas inlet pipe in the area of the inlet opening essentially corresponds to the diameter of the inlet opening.

Vorteilhafterweise erstreckt sich das Abgaseinlassrohr innerhalb des Gehäuses zumindest entlang des spiralförmigen Gehäuseabschnitts, wobei das Abgaseinlassrohr an der sich entlang des spiralförmigen Gehäuseabschnitts erstreckenden Umfangsfläche Austrittsöffnungen aufweist. Durch diese Austrittsöffnungen kann ein dem Abgaseinlassrohr zugeführter Abgasstrom insbesondere in den spiralförmigen Gehäuseabschnitt strömen. Die Austrittsöffnungen sind insbesondere vollumfänglich an der Umfangsfläche des Abgaseinlassrohrs angeordnet und weisen beispielsweise eine kreis- oder schlitzförmige Geometrie auf. Dadurch kann auch ein insbesondere aus einer axialen Richtung dem Abgaseinlassrohr zugeführter Abgasstrom beim Austritt aus dem Abgaseinlassrohr durch die Austrittsöffnungen in eine radiale Richtung "umgelenkt" oder ihm zumindest eine radiale Geschwindigkeitskomponente erteilt werden. Ferner wird dadurch dazu beigetragen, dass das Abgas entlang des gesamten mit Austrittsöffnungen versehenen Abschnitts des Abgaseinlassrohrs möglichst homogen in den spiralförmigen Gehäuseabschnitt strömt.Advantageously, the exhaust gas inlet tube extends within the housing at least along the spiral-shaped housing section, wherein the Exhaust inlet pipe at the along the spiral-shaped housing portion extending peripheral surface has outlet openings. Through these outlet openings, an exhaust gas stream supplied to the exhaust gas inlet pipe can flow in particular into the spiral-shaped housing section. The outlet openings are in particular arranged in full circumference on the peripheral surface of the exhaust gas inlet pipe and have, for example, a circular or slot-shaped geometry. As a result, an exhaust gas flow supplied in particular from an axial direction to the exhaust gas inlet pipe can be "deflected" in a radial direction as it leaves the exhaust gas inlet pipe through the outlet openings or it can be given at least one radial speed component. Furthermore, this contributes to the exhaust gas flowing as homogeneously as possible into the spiral-shaped housing section along the entire section of the exhaust gas inlet tube provided with outlet openings.