EP1741774A1 - Machine dishwashing compositions and their use - Google Patents

Machine dishwashing compositions and their use Download PDFInfo

- Publication number

- EP1741774A1 EP1741774A1 EP06116118A EP06116118A EP1741774A1 EP 1741774 A1 EP1741774 A1 EP 1741774A1 EP 06116118 A EP06116118 A EP 06116118A EP 06116118 A EP06116118 A EP 06116118A EP 1741774 A1 EP1741774 A1 EP 1741774A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- nonionic surfactant

- charge

- complex

- manganese

- composition according

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Classifications

-

- C—CHEMISTRY; METALLURGY

- C11—ANIMAL OR VEGETABLE OILS, FATS, FATTY SUBSTANCES OR WAXES; FATTY ACIDS THEREFROM; DETERGENTS; CANDLES

- C11D—DETERGENT COMPOSITIONS; USE OF SINGLE SUBSTANCES AS DETERGENTS; SOAP OR SOAP-MAKING; RESIN SOAPS; RECOVERY OF GLYCEROL

- C11D3/00—Other compounding ingredients of detergent compositions covered in group C11D1/00

- C11D3/39—Organic or inorganic per-compounds

- C11D3/3902—Organic or inorganic per-compounds combined with specific additives

- C11D3/3905—Bleach activators or bleach catalysts

- C11D3/3932—Inorganic compounds or complexes

-

- C—CHEMISTRY; METALLURGY

- C11—ANIMAL OR VEGETABLE OILS, FATS, FATTY SUBSTANCES OR WAXES; FATTY ACIDS THEREFROM; DETERGENTS; CANDLES

- C11D—DETERGENT COMPOSITIONS; USE OF SINGLE SUBSTANCES AS DETERGENTS; SOAP OR SOAP-MAKING; RESIN SOAPS; RECOVERY OF GLYCEROL

- C11D1/00—Detergent compositions based essentially on surface-active compounds; Use of these compounds as a detergent

- C11D1/66—Non-ionic compounds

- C11D1/72—Ethers of polyoxyalkylene glycols

-

- C—CHEMISTRY; METALLURGY

- C11—ANIMAL OR VEGETABLE OILS, FATS, FATTY SUBSTANCES OR WAXES; FATTY ACIDS THEREFROM; DETERGENTS; CANDLES

- C11D—DETERGENT COMPOSITIONS; USE OF SINGLE SUBSTANCES AS DETERGENTS; SOAP OR SOAP-MAKING; RESIN SOAPS; RECOVERY OF GLYCEROL

- C11D1/00—Detergent compositions based essentially on surface-active compounds; Use of these compounds as a detergent

- C11D1/66—Non-ionic compounds

Definitions

- This invention relates to detergent cleaning compositions especially adapted for use in automatic dishwashing machines.

- phosphate or phosphate-free compositions which contain an oxygen bleach and enzymes, especially amylolytic and proteolytic enzymes, such as amylases and proteases.

- the oxygen bleach is typically sodium perborate or sodium percarbonate which advantageously may be used in conjunction with an organic activator or bleach precursor, e.g. N, N, N', N'-tetraacetylethylene diamine (TAED), which upon dissolution will react to form an organic peroxyacid, e.g. peracetic acid, as the bleaching species.

- an organic activator or bleach precursor e.g. N, N, N', N'-tetraacetylethylene diamine (TAED)

- the starch removal properties of an automatic machine dishwashing composition containing a peroxygen bleach can be improved by incorporation of a dinuclear manganese complex.

- products of this kind ofter also contain nonionic surfactants. When the amount of nonionic surfactant is relatively high, particularly at or above 1% by weight of the composition, the manganese complex causes discolouration of the product.

- a first aspect of the present invention now provides an automatic machine dishwashing composition

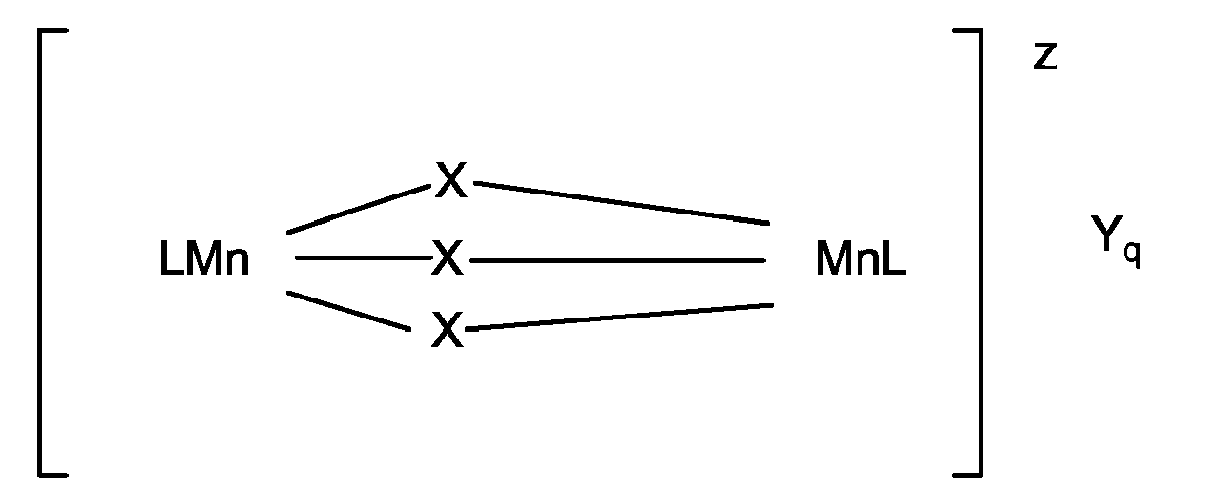

- a peroxygen bleach compound and a dinuclear manganese-complex having the general formula: wherein Mn is manganese which can individually be in the III or IV oxidation state; each x represents a coordinating or bridging species selected from the group consisting of H 2 O, O 2 2- , O 2- , OH - , HO 2 - , SH - , S 2- , >SO, Cl - , N 3- , SCN - , RCOO - , NH 2 - and NR 3 , with R being H, alkyl or aryl, (optionally substituted); L is a ligand which is an organic molecule containing a number of nitrogen atoms which coordinates via all or some of its nitrogen atoms to the manganese centres; z denotes the charge of the complex and is an integer which can

- a second aspect of the present invention provides use of one or more nonionic surfactant components (a) and (b) as defined in the first aspect of the present invention for reducing discolouration in a composition comprising a peroxygen bleach compound and a dinuclear manganese complex as defined in the first aspect of the present invention.

- the machine dishwashing composition is a mildly alkaline product having a solution pH below 12, e.g. from 8-12, preferably from 9-11.

- the solution pH as meant here is the pH as determined from a solution of 3g/l of the compositions in distilled water.

- Preferred manganese-complexes are those wherein x is either CH 3 COO - or O 2 or mixtures thereof, most preferably wherein the manganese is in the IV oxidation state and x is O 2- .

- Preferred ligands are those which coordinate via three nitrogen atoms to one of the manganese centres, preferably being of a macrocyclic nature. Particularly preferred ligands are:

- the type of counter-ion Y for charge neutrality is not critical for the activity of the complex and can be selected from, for example, any of the following counter-ions: chloride; sulphate; nitrate; methylsulphate; surfanctant anions, such as the long-chain alkylsulphates, alkylsulphonates, alkylbenzenesulphonates, tosylate, trifluoromethylsulphonate, perchlorate (ClO 4 - ), BPh 4 - , and PF 6 - ' though some counter-ions are more preferred than others for reasons of product property and safety.

- the preferred manganese complexes useable in the present invention are:

- compositions of the invention must contain at least 1%, preferably at least 2% by weight of nonionic surfactant. At least 50%, preferably at least 65%, optionally up to 90% or up t 100% by weight of the total nonionc surfactant must be selected from

- nonionic surfactants of group (a) are present in the composition of the invention.

- Preferred nonionic surfactants of group (a) include hydroxyalkyl glycolether surfactants having a melting point above 35°C, preferably above 40°C.

- a preferred class of such materials has from 6 to 20, preferably from 8 to 14 carbon atoms in the alkyl chain thereof and from 15 to 50, preferably from 20 to 40 glycol ether units.

- One such material is Dehypon 3697 GRAM, ex Cognis.

- nonionic surfactants of this group are high melting point polyalkoxylated alcohols, optionally with the -OH group endcapped such as with an alkyl group and typically having an average of 10 to 20 alkyl groups and more than 30 alkylene oxide groups, eg ethylene oxide and/or proplylene oxide groups.

- the nonionic surfactants used in group (b) can be any one or more nonionic surfactants such as mentioned anywhere in this specification.

- the granules with number average pore size less than 5 ⁇ m may be granules of suitable inorganic materials such as an alkali used carbonate, bicarbonate, sulphate or any mixtures thereof.

- the inorganic granules themselves may be formed by spray drying or non-spray drying granulation, optionally with use of a small amount of a granulating aid such as a polymer or silicate in aqueous solution.

- a granulating aid such as a polymer or silicate in aqueous solution.

- the process conditions to achieve the required pore size are well known to those skilled in the art.

- the resultant particles can then be sprayed with an aqueous solution of the relevant nonionic(s) and dried, for example in a fluid bed drier.

- one or more other nonionics may be present in the amounts indicated by the foregoing.

- These may includes any alkoxylated nonionic surface-active agent wherein the alkoxy moiety is selected from the group consisting of ethylene oxide, propylene oxide and mixtures thereof, is preferably used to improve the detergency and to suppress excessive foaming due to some protein soil.

- nonionic surfactants for use in the invention are the low- to non-foaming ethoxylated strraightchain alcohols of the Plurafac® RA and LF series, supplied by the BASF, including Plurafac SLF 18B45; of the Lutensol® LF series, supplied by the BASF; of the Tritons DF series, supplied by the Rohm & Hass Company, and of the Synperonic® LF and NCA series, supplied by the ICI, Uniqema company.

- the peroxygen compound bleaches which can be utilized in the present invention include hydrogen peroxide, hydrogen peroxide-liberating compounds, hydrogen peroxide-generating compounds, as well as the organic and inorganic peroxyacids and watersoluble salts thereof, and mixtures thereof.

- the total amount of peroxygen bleach compound(s) is preferably from 5% to 25%, more preferably from 10% to 20% by weight of the composition.

- Hydrogen peroxide sources are well known in the art. They include the alkali metal peroxides, organic peroxide bleaching compounds such as urea peroxide, and inorganic persalt bleaching compounds, such as the alkali metal perborates, percarbonates, perphosphates and persulphates. Mixtures or two or more of such compounds may also be suitable. Particularly preferred is sodium percarbonate. However, sodium perborate, eg in the form sodium perborate monohydrate may also be used. Sodium perborate monohydrate is preferred to tetrahydrate because of its better storage stability while also dissolving very quickly in aqueous solutions. These bleaching agents may be utilied alone or in conjunction with a peroxyacid bleach precursor, such as TAED or any other bleach precursors known in the art, so long as it does not affect the starch-removing properties of the catalyst.

- a peroxyacid bleach precursor such as TAED or any other bleach precursors known in the art

- organic peroxyacids usable in this invention are those compounds known in the art having normally one or more peroxycarboxyl groups: in their molecular structure, e.g. 1,12 - diperoxydodecanedioic acid (DPDA) and phthaloylamido peroxycaproic acid (PAP).

- An inorganic peroxyacid salt usable herein is, for example, potassium monopersulphate.

- Compositions according to the present invention may also normally contain a detergency and water-softening builder.

- Builder materials may be selected from 1) calcium sequestrant materials, 2) precipitating materials, 3) calcium ion-exchange materials and 4) mixtures thereof.

- Examples of calcium sequestrant builder materials include alkali metal polyphospates, such as sodium tripoly phosphate;nitrilotriacetic acid, dipicolinic acid, chelidamic acid and their water-solubel salts; the alkali metal salts of ether polycarboxylates, such as carboxymethyloxy succinic acid, oxydisuccinic acid, mellitic acid; ethylene diamine tetraacetic acid; benzene polycarboxylic acids; citric acid; and polyacetal carboxylates as disclosed in US Patents 4,144,226 and 4,146,495 .

- alkali metal polyphospates such as sodium tripoly phosphate;nitrilotriacetic acid, dipicolinic acid, chelidamic acid and their water-solubel salts

- the alkali metal salts of ether polycarboxylates such as carboxymethyloxy succinic acid, oxydisuccinic acid, mellitic acid

- precipitating builder materials examples include sodium orthophosphate, sodium carbonate and sodium carbonate/calcite.

- Examples of calcium ion-exchange builder materials include the various types of water-insoluble crystalline or amorphous aluminosilicates, of which zeolites are the best-known representatives.

- Other useful materials are, for example, layered silicates, such as SKS®-6 ex Hoechst.

- compositions of the invention may contain any one of the organic or inorganic builder materials, such as sodium or potassium tripolyphosphate, sodium or potassium pyrophosphate, sodium or potassium orthophosphate, sodium carbonate or sodium carbonate/calcite mixtures, the sodium salt of nitrilotriacetic acid, sodium citrate, carboxymethyl malonate, carboxymethyloxy succinate and the water-insoluble crystalline or amorphous aluminosilicate builder materials, or mixtures thereof, although phosphates are less preferred.

- the organic or inorganic builder materials such as sodium or potassium tripolyphosphate, sodium or potassium pyrophosphate, sodium or potassium orthophosphate, sodium carbonate or sodium carbonate/calcite mixtures, the sodium salt of nitrilotriacetic acid, sodium citrate, carboxymethyl malonate, carboxymethyloxy succinate and the water-insoluble crystalline or amorphous aluminosilicate builder materials, or mixtures thereof, although phosphates are less preferred.

- compositions are, however, essentially free of phosphates and will contain, for example, alkali metal citrate, alkali carbonate, alkali metal carbonate/calcite, aluminosilicates (zeolites) or mixtures thereof as preferred builder materials.

- alkali metal is sodium or potassium, preferably sodium.

- the citrates are especially preferred.

- Suitable non-phosphate builders which may be used alone or in combination with any one or more other builders include methyl glycine diacetic acid (MGDA), eg sold as Trilon M, ex BASF, imino disuccinate (IDS) eg sold as Baypure CS, ex Lanxess and dipicolinic acid (DPA), eg available from Raschig.

- MGDA methyl glycine diacetic acid

- IDS imino disuccinate

- DPA dipicolinic acid

- alkali metal salts eg sodium salts

- inorganic detergency builders may have a dual role, eg the carbonates may also act as buffering agents (see below).

- the total amount of detergency builder for example comprising any one or more of any of the foregoing may for example be from 10% to 80%, preferably from 30% to 60% by weight of the total composition.

- An optional but highly desirable additive ingredient with multi-functional characteristics, particularly in non-phosphate compositions is from 1% to 10%, preferably about 5% by weight of a polymeric material having a molecular weight of from 1,000 to 2,000,000 and which can be a homo- or co-polymer of acrylic acid, maleic acid, or salt or anhydride thereof, vinyl pyrrolidone methyl- or ethyl-, vinyl ethers and other polymerizable vinyl monomers.

- polyacrylic acid or polyacrylate are polyacrylic acid or polyacrylate; polymaleic acid/acrylic acid copolymer; 70:30 acrylic acid/hydroxyethyl maleate copolymer; 1:1 styrene/maleic acid copolymer; isobutylene/maleic acid and diisobutylene/maleic acid copolymers; methyl- and ethyl-vinylether/maleic acid copolymers;ethylene/maleic acid copolymer; polyvinyl pyrrolidone; and vinyl pyrrolidone/maleic acid copolymer. These polymers are believed to function as co-builders, although under certain conditions they may also function as main builders.

- Buffering agents may be used in compositions according to the present invention in order to adjust and to maintain the alkalinity and pH at the desired level. These are for example, the alkali metal carbonates and bicarbonates, sometimes also borates, and silicates. If used, sodium silicates preferably have Na 2 O:SiO 2 ratios of from about 2:1 to 1:4. Another possible buffering agent is sodium disilicate having Na 2 O:SiO 2 ratio of about 1:1.8 to 1:2.5.

- the cleaning compositions in which the catalyst is used according to the invention may, as desired, contain an amylolytic enzyme, though conceivably a much smaller amount will now be sufficient.

- amylolytic enzymes for use in the present invention can be those derived from bacteria or fungi.

- Preferred amylolytic enzymes are those prepared and described in British Patent Specification No. 1 296 839 , cultivated from the strains of Bacillus licheniformis NClB 8061, NCIB 8059, ATCC 6334, ATCC 6598, ATCC 11 945, ATCC 8480 and ATCC 9945.

- Examples of such amylolytic enzumes are amylolytic enzymes produced and distributed under the trade name of Sp-95® or Termamyl® by Novo Industri A/S, Copenhagen, Denmark, as well as Termanyl and Duramyl, ex Novozymes and Properase and Purastar ex Genecor.

- amylolytic enzymes are generally presented as granules and may have enzyme activities of from about 2 to 10 Maltose units/milligram. Enzyme granules containing only minor proportions, e.g. less than 30%, particularly not more than 10% by weight of chloride to substantially nil, are preferably used in the compositions of the invention.

- amylolytic activity can be determined by the method as described by P.Bernfeld in "Method of Enzymology” Volume 1 (1955), page 149 .

- composition in which the catalyst is used according to the invention preferably also contains a proteolytic enzyme.

- subtilisins which are obtained from particular strains of B. subtilis and B.licheniformis, such as the commercially available subtilisins Maxatase® supplied by Gist-Brocades N.V., Delft, Holland, and Alcalase®, supplied by Novo Industri A/S, Copenhagen, Denmark.

- protease obtained from a strainof Bacillus having maximum activity throughout the pH range of 8-12, being commercially available from Novo Industri A/S under the registered trade names of Esperase® and Savinase®. The preparation of these and analogous enzymes is described in British Patent No. 1 243 784 .

- Another suitable protease useful herein is a fairly recent commercial product sold by Novo Industry A/S under the trade name "Durazym®" as described in WO-A-89/06279 .

- These enzymes are generally presented as granules, e.g. marumes, prills, T-granulates etc., and may have enzyme activities of from about 500 to 1700 glycine units/milligram.

- Enzyme granules containing only minor proportions, e.g. less than 30%, particularly not more than 10% by weight of chloride to substantially nil, are preferably used in the composition of the invention.

- these enzymes can each be present in a weight percentage amounts of from 0.2 to 5% by weight, such that, for amylolytic enzymes, the final composition will have amylolytic activity of from 10 2 to 10 6 Maltose units/kg, and, for proteolytic enzymes, the final composition will have proteolytic enzyme activity of from about 10 6 to 10 9 Glycine Units/kg.

- compositions according to the present invention may further contain any of the following additional ingredients.

- Stabilizing and anti-scaling agents include those belonging to the class of phosphonates sold under the trade name "Dequest®", such as ethylene diamine tetra-(methylene phosphonate), deithylene triamine penta-(methylene phosphonate) and ethylene hydroxyl diphosphonate.

- Dequest® such as ethylene diamine tetra-(methylene phosphonate), deithylene triamine penta-(methylene phosphonate) and ethylene hydroxyl diphosphonate.

- Another suitable class of anti-scaling agents are the low molecular weight polyacryalates, polymaleates and mixtures thereof or the copolymers thereof, having molecular weights of up to about 6000.

- a further suitable class of anti-scaling agents are polypeptides.

- Benzotriazide may be used as a silver protection agent.

- Zinc salts may be used as glass corrosion inhibitors and sulphonated polymers (eg Alcosperse 240) may be used as anti-scaling polymers.

- Clays such as hectorites and montmorillonites, may be included in the composition of the invention. These assist in reduction of spot formation on glassware, and may be present at from 0.5 to 10% by weight, preferably from 0.5 to 7% by weight. Particularly preferred is the addition of Laponite® clay at about 0.5 to 5% b weight, which is a synthetic hectorite. "Dequest” and “Laponite” are Trade Marks owned by, respectively, Monsanto and Laporte Industries.

- a filler may be required to complete the composition, though, in compacted powdered compositions it should preferably be avoided.

- a preferred filler is sodium sulphate.

- a typical composition according to the present invention may include from 0 to 80%, preferably from 5 to 60% by weight of a detergency and water-softening builder, from 0 to 80%, preferably 5 to 75% by weight of a buffering agent, from 1 to 40%, preferably from 2 to 20% by weight of a peroxygen compound bleach, and optionally an enzyme and fillers and may further comprise a dinuclear manganese complex as defined above, in an amount corresponding to an Mn-content of from 0.0001 to abut 1.0% by weight, preferably from 0.0005 to 0.5% by weight.

- compositions of the present invention may be in any suitable physical form, for example powdered and/or granular compositions or tablets. Tablets may be unitary or comprise two or more layers having differing compositions from each other, the tablet as a whole having the total constituents making-up the composition according to the present invention. Some or all of the dinuclear manganese complex may be in the same or in a different layer from a layer containing some or all of the nonionic surfactant, eg some or all of the nonionic surfactant component(s) (a) - (c) and/or any other non-ionic surfactant. Cavity tablets, eg with a spherical or ball component set into the cavity are also preferred. Again the manganese complex may in this way optionally be at least partially segregated from some or all of any or all of the nonionic surfactant component(s), whether components (a) - (c) or any other nonionic surfactant.

- Example 1 Two tablets were made, respectively designated "Comparative Example A” and “Example 1", the latter being in accordance with the present invention.

- the respective components were incorporated in powdered or granular form and dry-mixed before being compacted to form tablets.

Landscapes

- Chemical & Material Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Engineering & Computer Science (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Oil, Petroleum & Natural Gas (AREA)

- Wood Science & Technology (AREA)

- Organic Chemistry (AREA)

- Inorganic Chemistry (AREA)

- Detergent Compositions (AREA)

Abstract

wherein at least 50% by weight of the nonionic surfactant is selected from:

(a) at least one nonionic surfactant having a melting point greater than 35°C, preferably greater than 40°C;

(b) at least one nonionic surfactant in the form of a granule having pores with a number average pore size less than 5µm, the pores containing the nonionic surfactant;

and mixtures thereof.

Description

- This invention relates to detergent cleaning compositions especially adapted for use in automatic dishwashing machines.

- Automatic machine dishwashing products are nowadays, normally reduced phosphate or phosphate-free compositions which contain an oxygen bleach and enzymes, especially amylolytic and proteolytic enzymes, such as amylases and proteases. The oxygen bleach is typically sodium perborate or sodium percarbonate which advantageously may be used in conjunction with an organic activator or bleach precursor, e.g. N, N, N', N'-tetraacetylethylene diamine (TAED), which upon dissolution will react to form an organic peroxyacid, e.g. peracetic acid, as the bleaching species.

- As is known from

EP-A-0 530 870 , the starch removal properties of an automatic machine dishwashing composition containing a peroxygen bleach can be improved by incorporation of a dinuclear manganese complex. However, products of this kind ofter also contain nonionic surfactants. When the amount of nonionic surfactant is relatively high, particularly at or above 1% by weight of the composition, the manganese complex causes discolouration of the product. - We have now found that this problem can be overcome by special selection of the type of nonionic surfactant.

- A first aspect of the present invention now provides an automatic machine dishwashing composition comprising at least 1%, preferably at least 2% by weight of nonionic surfactant, a peroxygen bleach compound and a dinuclear manganese-complex having the general formula:

wherein at least 50% by weight of the nonionic surfactant is selected from: - (a) at least one nonionic surfactant having a melting point greater than 35°C, preferably greater than 40°C;

- (b) at least one nonionic surfactant in the form of a granule having pores with a number average pore size less than 5µm, the pores containing the nonionic surfactant;

- A second aspect of the present invention provides use of one or more nonionic surfactant components (a) and (b) as defined in the first aspect of the present invention for reducing discolouration in a composition comprising a peroxygen bleach compound and a dinuclear manganese complex as defined in the first aspect of the present invention.

- Preferably, the machine dishwashing composition is a mildly alkaline product having a solution pH below 12, e.g. from 8-12, preferably from 9-11.

- The solution pH as meant here is the pH as determined from a solution of 3g/l of the compositions in distilled water.

- Preferred manganese-complexes are those wherein x is either CH3COO- or O2 or mixtures thereof, most preferably wherein the manganese is in the IV oxidation state and x is O2-. Preferred ligands are those which coordinate via three nitrogen atoms to one of the manganese centres, preferably being of a macrocyclic nature. Particularly preferred ligands are:

- (1) 1,4,7-trimethyl-1,4,7-triazacyclononane, (Me-TACN); and

- (2) 1,2,4,7-tetramethyl-1,4,7-triazacyclononane, (Me-Me TACN).

- The type of counter-ion Y for charge neutrality is not critical for the activity of the complex and can be selected from, for example, any of the following counter-ions: chloride; sulphate; nitrate; methylsulphate; surfanctant anions, such as the long-chain alkylsulphates, alkylsulphonates, alkylbenzenesulphonates, tosylate, trifluoromethylsulphonate, perchlorate (ClO4 -), BPh4 -, and PF6 -' though some counter-ions are more preferred than others for reasons of product property and safety.

- Consequently, the preferred manganese complexes useable in the present invention are:

- (I) [(Me-TACN)MnIV(µ-0)3MnIV(Me-TACN)]2+(PF6 -)2

- (II) [(Me-MeTACN)MnIV(µ-0)3MnIV(Me-MeTACN)]2+(PF6 -)2

- (III) [(Me-TACN)MnIII(µ-0)(µ-OAc)2MnIII(Me-TACN)]2+(PF6 -)2

- (IV) [(Me-MeTACN)MnIII(µ-0)(µ-OAc)2MnIII(Me-MeTACN)]2+(PF6 -)2

- (I) [MnIV 2(µ-0)3(Me-TACN)2] (PF6)2

- (II) [MnIV 2(µ-0)3(Me-MeTACN)2] (PF6)2

- (III) [MnIII 2(µ-0) (µ-OAc)2(Me-TACN)2] (PF6)2

- (IV) [MnIII 2(µ-0) (µ-OAc)2(Me-TACN) 2](PF6)2

-

-

- It is of note that the manganese complexes are also disclosed in

EP-A-0458397 andEP-A-0458398 as unusually effective bleach and oxidation catalysts. In the further description of this invention they will also be simply referred to as the "catalyst". - These complexes are effective additives for starch removal in mechanical dishwashing compositions, even in the absence of amylolytic enzymes. Whereas amylolytic enzymes are not normally compatible with strong oxidizing and bleaching agents, a bleach system comprising a peroxide compound and the manganese complex bleach catalyst does not seem to attack amylolytic enzymes, so that both systems can be used together to provide a still further improvement of starch removal.

- The compositions of the invention must contain at least 1%, preferably at least 2% by weight of nonionic surfactant. At least 50%, preferably at least 65%, optionally up to 90% or up t 100% by weight of the total nonionc surfactant must be selected from

- (a) at least one nonionic surfactant having a melting point greater than 35°C, preferably greater than 40°C;

- (b) at least one nonionic surfactant in the form of a granule having pores with a number average pore size less than 5µm, the pores containing the nonionic surfactant;

- Preferably, nonionic surfactants of group (a) are present in the composition of the invention. Preferred nonionic surfactants of group (a) include hydroxyalkyl glycolether surfactants having a melting point above 35°C, preferably above 40°C. A preferred class of such materials has from 6 to 20, preferably from 8 to 14 carbon atoms in the alkyl chain thereof and from 15 to 50, preferably from 20 to 40 glycol ether units. One such material is Dehypon 3697 GRAM, ex Cognis. Other suitable nonionic surfactants of this group are high melting point polyalkoxylated alcohols, optionally with the -OH group endcapped such as with an alkyl group and typically having an average of 10 to 20 alkyl groups and more than 30 alkylene oxide groups, eg ethylene oxide and/or proplylene oxide groups.

- The nonionic surfactants used in group (b) can be any one or more nonionic surfactants such as mentioned anywhere in this specification.

- The granules with number average pore size less than 5µm may be granules of suitable inorganic materials such as an alkali used carbonate, bicarbonate, sulphate or any mixtures thereof. Preferably, the inorganic granules themselves may be formed by spray drying or non-spray drying granulation, optionally with use of a small amount of a granulating aid such as a polymer or silicate in aqueous solution. The process conditions to achieve the required pore size are well known to those skilled in the art. The resultant particles can then be sprayed with an aqueous solution of the relevant nonionic(s) and dried, for example in a fluid bed drier.

- Optionally, one or more other nonionics may be present in the amounts indicated by the foregoing. These may includes any alkoxylated nonionic surface-active agent wherein the alkoxy moiety is selected from the group consisting of ethylene oxide, propylene oxide and mixtures thereof, is preferably used to improve the detergency and to suppress excessive foaming due to some protein soil.

- Examples of suitable nonionic surfactants for use in the invention are the low- to non-foaming ethoxylated strraightchain alcohols of the Plurafac® RA and LF series, supplied by the BASF, including Plurafac SLF 18B45; of the Lutensol® LF series, supplied by the BASF; of the Tritons DF series, supplied by the Rohm & Hass Company, and of the Synperonic® LF and NCA series, supplied by the ICI, Uniqema company.

- The peroxygen compound bleaches which can be utilized in the present invention include hydrogen peroxide, hydrogen peroxide-liberating compounds, hydrogen peroxide-generating compounds, as well as the organic and inorganic peroxyacids and watersoluble salts thereof, and mixtures thereof.

- The total amount of peroxygen bleach compound(s) is preferably from 5% to 25%, more preferably from 10% to 20% by weight of the composition.

- Hydrogen peroxide sources are well known in the art. They include the alkali metal peroxides, organic peroxide bleaching compounds such as urea peroxide, and inorganic persalt bleaching compounds, such as the alkali metal perborates, percarbonates, perphosphates and persulphates. Mixtures or two or more of such compounds may also be suitable. Particularly preferred is sodium percarbonate. However, sodium perborate, eg in the form sodium perborate monohydrate may also be used. Sodium perborate monohydrate is preferred to tetrahydrate because of its better storage stability while also dissolving very quickly in aqueous solutions. These bleaching agents may be utilied alone or in conjunction with a peroxyacid bleach precursor, such as TAED or any other bleach precursors known in the art, so long as it does not affect the starch-removing properties of the catalyst.

- The organic peroxyacids usable in this invention are those compounds known in the art having normally one or more peroxycarboxyl groups:

- Compositions according to the present invention may also normally contain a detergency and water-softening builder. Builder materials may be selected from 1) calcium sequestrant materials, 2) precipitating materials, 3) calcium ion-exchange materials and 4) mixtures thereof.

- Examples of calcium sequestrant builder materials include alkali metal polyphospates, such as sodium tripoly phosphate;nitrilotriacetic acid, dipicolinic acid, chelidamic acid and their water-solubel salts; the alkali metal salts of ether polycarboxylates, such as carboxymethyloxy succinic acid, oxydisuccinic acid, mellitic acid; ethylene diamine tetraacetic acid; benzene polycarboxylic acids; citric acid; and polyacetal carboxylates as disclosed in

US Patents 4,144,226 and4,146,495 . - Examples of precipitating builder materials include sodium orthophosphate, sodium carbonate and sodium carbonate/calcite.

- Examples of calcium ion-exchange builder materials include the various types of water-insoluble crystalline or amorphous aluminosilicates, of which zeolites are the best-known representatives. Other useful materials are, for example, layered silicates, such as SKS®-6 ex Hoechst.

- The compositions of the invention may contain any one of the organic or inorganic builder materials, such as sodium or potassium tripolyphosphate, sodium or potassium pyrophosphate, sodium or potassium orthophosphate, sodium carbonate or sodium carbonate/calcite mixtures, the sodium salt of nitrilotriacetic acid, sodium citrate, carboxymethyl malonate, carboxymethyloxy succinate and the water-insoluble crystalline or amorphous aluminosilicate builder materials, or mixtures thereof, although phosphates are less preferred.

- Preferred compositions are, however, essentially free of phosphates and will contain, for example, alkali metal citrate, alkali carbonate, alkali metal carbonate/calcite, aluminosilicates (zeolites) or mixtures thereof as preferred builder materials. In all of these, the alkali metal is sodium or potassium, preferably sodium. The citrates are especially preferred.

- Other suitable non-phosphate builders which may be used alone or in combination with any one or more other builders include methyl glycine diacetic acid (MGDA), eg sold as Trilon M, ex BASF, imino disuccinate (IDS) eg sold as Baypure CS, ex Lanxess and dipicolinic acid (DPA), eg available from Raschig. The alkali metal salts (eg sodium salts) of these are also useable.

- It should be noted that some of the foregoing inorganic detergency builders may have a dual role, eg the carbonates may also act as buffering agents (see below).

- The total amount of detergency builder, for example comprising any one or more of any of the foregoing may for example be from 10% to 80%, preferably from 30% to 60% by weight of the total composition.

- An optional but highly desirable additive ingredient with multi-functional characteristics, particularly in non-phosphate compositions is from 1% to 10%, preferably about 5% by weight of a polymeric material having a molecular weight of from 1,000 to 2,000,000 and which can be a homo- or co-polymer of acrylic acid, maleic acid, or salt or anhydride thereof, vinyl pyrrolidone methyl- or ethyl-, vinyl ethers and other polymerizable vinyl monomers. Preferred examples of such polymeric materials are polyacrylic acid or polyacrylate; polymaleic acid/acrylic acid copolymer; 70:30 acrylic acid/hydroxyethyl maleate copolymer; 1:1 styrene/maleic acid copolymer; isobutylene/maleic acid and diisobutylene/maleic acid copolymers; methyl- and ethyl-vinylether/maleic acid copolymers;ethylene/maleic acid copolymer; polyvinyl pyrrolidone; and vinyl pyrrolidone/maleic acid copolymer. These polymers are believed to function as co-builders, although under certain conditions they may also function as main builders.

- Buffering agents may be used in compositions according to the present invention in order to adjust and to maintain the alkalinity and pH at the desired level. These are for example, the alkali metal carbonates and bicarbonates, sometimes also borates, and silicates. If used, sodium silicates preferably have Na2O:SiO2 ratios of from about 2:1 to 1:4. Another possible buffering agent is sodium disilicate having Na2O:SiO2 ratio of about 1:1.8 to 1:2.5.

- Though not essential, the cleaning compositions in which the catalyst is used according to the invention may, as desired, contain an amylolytic enzyme, though conceivably a much smaller amount will now be sufficient.

- Reduction of the level of once an essential ingredient to even the possibility of omitting such an expensive enzyme ingredient, thereby resulting in improved performance, is one of the major advantages of the present invention, not only in terms technical benefit but also in terms of economy.

- The amylolytic enzymes for use in the present invention can be those derived from bacteria or fungi. Preferred amylolytic enzymes are those prepared and described in

British Patent Specification No. 1 296 839 - The amylolytic activity can be determined by the method as described by P.Bernfeld in "Method of Enzymology" Volume 1 (1955), page 149.

- The composition in which the catalyst is used according to the invention preferably also contains a proteolytic enzyme.

- Examples of suitable proteolytic enzymes are the subtilisins which are obtained from particular strains of B. subtilis and B.licheniformis, such as the commercially available subtilisins Maxatase® supplied by Gist-Brocades N.V., Delft, Holland, and Alcalase®, supplied by Novo Industri A/S, Copenhagen, Denmark.

- Particularly suitable is a protease obtained from a strainof Bacillus having maximum activity throughout the pH range of 8-12, being commercially available from Novo Industri A/S under the registered trade names of Esperase® and Savinase®. The preparation of these and analogous enzymes is described in

British Patent No. 1 243 784 WO-A-89/06279 - Enzyme granules containing only minor proportions, e.g. less than 30%, particularly not more than 10% by weight of chloride to substantially nil, are preferably used in the composition of the invention.

- If used, these enzymes can each be present in a weight percentage amounts of from 0.2 to 5% by weight, such that, for amylolytic enzymes, the final composition will have amylolytic activity of from 102 to 106 Maltose units/kg, and, for proteolytic enzymes, the final composition will have proteolytic enzyme activity of from about 106 to 109 Glycine Units/kg.

- The compositions according to the present invention may further contain any of the following additional ingredients. Stabilizing and anti-scaling agents, crystal-growth inhibitors and threshold agents. Examples of suitable stabilizing and anti-scaling compounds are those belonging to the class of phosphonates sold under the trade name "Dequest®", such as ethylene diamine tetra-(methylene phosphonate), deithylene triamine penta-(methylene phosphonate) and ethylene hydroxyl diphosphonate. Another suitable class of anti-scaling agents are the low molecular weight polyacryalates, polymaleates and mixtures thereof or the copolymers thereof, having molecular weights of up to about 6000. A further suitable class of anti-scaling agents are polypeptides.

- Benzotriazide (BTA) may be used as a silver protection agent. Zinc salts may be used as glass corrosion inhibitors and sulphonated polymers (eg Alcosperse 240) may be used as anti-scaling polymers.

- Clays such as hectorites and montmorillonites, may be included in the composition of the invention. These assist in reduction of spot formation on glassware, and may be present at from 0.5 to 10% by weight, preferably from 0.5 to 7% by weight. Particularly preferred is the addition of Laponite® clay at about 0.5 to 5% b weight, which is a synthetic hectorite. "Dequest" and "Laponite" are Trade Marks owned by, respectively, Monsanto and Laporte Industries.

- Finally, the addition of a filler may be required to complete the composition, though, in compacted powdered compositions it should preferably be avoided. A preferred filler is sodium sulphate.

- A typical composition according to the present invention may include from 0 to 80%, preferably from 5 to 60% by weight of a detergency and water-softening builder, from 0 to 80%, preferably 5 to 75% by weight of a buffering agent, from 1 to 40%, preferably from 2 to 20% by weight of a peroxygen compound bleach, and optionally an enzyme and fillers and may further comprise a dinuclear manganese complex as defined above, in an amount corresponding to an Mn-content of from 0.0001 to abut 1.0% by weight, preferably from 0.0005 to 0.5% by weight.

- The invention will now be further illustrated by the following Examples.

- Compositions of the present invention may be in any suitable physical form, for example powdered and/or granular compositions or tablets. Tablets may be unitary or comprise two or more layers having differing compositions from each other, the tablet as a whole having the total constituents making-up the composition according to the present invention. Some or all of the dinuclear manganese complex may be in the same or in a different layer from a layer containing some or all of the nonionic surfactant, eg some or all of the nonionic surfactant component(s) (a) - (c) and/or any other non-ionic surfactant. Cavity tablets, eg with a spherical or ball component set into the cavity are also preferred. Again the manganese complex may in this way optionally be at least partially segregated from some or all of any or all of the nonionic surfactant component(s), whether components (a) - (c) or any other nonionic surfactant.

- Two tablets were made, respectively designated "Comparative Example A" and "Example 1", the latter being in accordance with the present invention. In each case, the respective components were incorporated in powdered or granular form and dry-mixed before being compacted to form tablets.

Table 1 Comparative example A Example 1 Tri Na Citrate 31.51 31.51 Na Carbonate 20.13 20.13 Na Sulphate 7.00 7.00 Na-silicate 9.96 9.96 Sodium acrylic/maleic copolymer 3.90 3.90 Polyacrylate granule 1.17 1.17 Styrene/Maleic anhydride copolymer 0.23 0.23 EP/PO nonionic* 4.00 1.26 Hydroxy Alkyl Polyglycolether nonionic** 2.74 Na Percarbonate 13.66 13.66 Manganese catalyst cogranule+ 1.22 1.22 Enzyme blend 2.68 2.68 Perfume 0.14 0.14 Dye solution 0.42 0.42 PEG 3.11 3.11 Glycerol 0.86 0.86 100.00 100.00 Total * m.pt. < 20°C

** m.pt. approx 60°C

+ complex of formula (I):(PF6)2 counter ion - After storage at 20°C and at 65% RH, for 2 weeks in a polypropylene bag, the tablets of Comparative Example A showed noticeable formation of brown spots whereas those of Example 1 showed substantially no discolouration.

Claims (11)

- An automatic machine dishwashing composition comprising at least 1%, preferably at least 2% by weight of nonionic surfactant, a peroxygen bleach compound and a dinuclear manganese-complex having the general formula:

wherein at least 50% by weight of the nonionic surfactant is selected from:(a) at least one nonionic surfactant having a melting point greater than 35°C, preferably greater than 40°C;(b) at least one nonionic surfactant in the form of a granule having pores with a number average pore size less than 5µm, the pores containing the nonionic surfactant;and mixtures thereof. - A composition according to claim 1, wherein at least 50% by weight of the non-ionic surfactant is at least one nonionic surfactant having a melting point greater than 35°C, preferably greater than 40°C.

- A composition according to claim 2, wherein the non-ionic surfactant having a melting point greater than 35°C is selected from one or more hydroxyalkyl polyglycolethers and optionally endcapped polyalkoxylated alcohols having at least 30 alkyleneoxy groups and mixtures thereof.

- A composition according to any preceding claim, comprising a nonionic surfactant in the form of a granule having pores with a number average pore size less than 5µm, the pores containing the nonionic surfactant; and mixtures thereof, wherein the granule is formed of one or more alkali metal carbonates, bicarbonates, sulphates and mixtures thereof.

- A composition according to any preceding claim, wherein the peroxygen bleach compound comprises an alkali metal percarbonate.

- A composition according to any preceding claim further comprising a bleach precursor or activator.

- A composition according to any preceding claim, the composition being substantially free of phosphate material.

- A composition according to any preceding claim, further comprising a citrate detergency builder.

- A composition according to any preceding claim, wherein the dinuclear manganese complex comprises a ligand selected from(1) 1,4,7-trimethyl-1,4,7-triazacyclononane, (Me-TACN); and(2) 1,2,4,7-tetramethyl-1,4,7-triazacyclononane, (Me-Me TACN).and mixtures thereof.

- A tablet comprising composition according to any preceding claim.

- Use of one or more nonionic surfactant components (a) and (b) :(a) at least one nonionic surfactant having a melting point greater than 35°C, preferably greater than 40°C;(b) at least one nonionic surfactant in the form of a granule having pores with a number average pore size less than 5µm, the pores containing the nonionic surfactant;and mixtures thereof;

for reducing discolouration in a composition comprising a peroxygen bleach compound and a dinuclear manganese complex having the general formula:

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP06116118A EP1741774B1 (en) | 2005-07-08 | 2006-06-27 | Machine dishwashing compositions and their use |

| PL06116118T PL1741774T3 (en) | 2005-07-08 | 2006-06-27 | Machine dishwashing compositions and their use |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP05076571 | 2005-07-08 | ||

| EP06116118A EP1741774B1 (en) | 2005-07-08 | 2006-06-27 | Machine dishwashing compositions and their use |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP1741774A1 true EP1741774A1 (en) | 2007-01-10 |

| EP1741774B1 EP1741774B1 (en) | 2008-08-06 |

Family

ID=35453526

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP06116118A Active EP1741774B1 (en) | 2005-07-08 | 2006-06-27 | Machine dishwashing compositions and their use |

Country Status (6)

| Country | Link |

|---|---|

| EP (1) | EP1741774B1 (en) |

| AT (1) | ATE403711T1 (en) |

| DE (1) | DE602006002075D1 (en) |

| ES (1) | ES2312089T3 (en) |

| PL (1) | PL1741774T3 (en) |

| PT (1) | PT1741774E (en) |

Cited By (38)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2008048537A1 (en) * | 2006-10-16 | 2008-04-24 | Danisco Us, Inc. Genencor Division | Non-phosphate dish detergents |

| EP1967577A1 (en) * | 2007-02-13 | 2008-09-10 | CHT R. BEITLICH GmbH | Catalysed peroxide bleach (catylasator bleach) |

| WO2010010003A3 (en) * | 2008-07-23 | 2010-07-29 | Cht R. Beitlich Gmbh | Catalysed peroxide bleach ("catalyst-bleach variant 3: all-in-one) |

| WO2010116139A1 (en) | 2009-04-09 | 2010-10-14 | Reckitt Benckiser N.V. | Detergent composition |

| WO2011027170A2 (en) | 2009-09-07 | 2011-03-10 | Reckitt Benckiser N.V. | Detergent composition |

| WO2011032868A1 (en) * | 2009-09-21 | 2011-03-24 | Henkel Ag & Co. Kgaa | Dishwasher detergent |

| WO2011042737A1 (en) | 2009-10-09 | 2011-04-14 | Reckitt Benckiser N.V. | Detergent composition |

| WO2011110849A1 (en) | 2010-03-09 | 2011-09-15 | Reckitt Benckiser N.V. | Detergent composition |

| WO2012066344A1 (en) | 2010-11-19 | 2012-05-24 | Reckitt Benckiser N.V. | Dyed coated bleach materials |

| WO2012066341A2 (en) | 2010-11-19 | 2012-05-24 | Reckitt Benckiser N.V. | Coated bleach materials |

| WO2012085534A1 (en) | 2010-12-21 | 2012-06-28 | Reckitt Benckiser N.V. | Bleach catalyst particle |

| WO2012123719A1 (en) | 2011-03-14 | 2012-09-20 | Reckitt Benckiser N.V. | Detergent composition with improved drying performance |

| WO2014060738A1 (en) * | 2012-10-15 | 2014-04-24 | Reckitt & Colman (Overseas) Limited | Ultrasonic method of cleaning |

| WO2015124384A1 (en) | 2014-02-20 | 2015-08-27 | Unilever N.V. | Machine dishwash composition |

| CN105164241A (en) * | 2013-05-02 | 2015-12-16 | 艺康美国股份有限公司 | Concentrated detergent composition for improved starch removal in dishwashing applications |

| US9249380B2 (en) | 2009-08-07 | 2016-02-02 | Robert McBride Ltd. | Dosage form detergent products |

| US9434915B2 (en) | 2008-11-11 | 2016-09-06 | Danisco Us Inc. | Compositions and methods comprising a subtilisin variant |

| WO2019233696A1 (en) | 2018-06-04 | 2019-12-12 | Reckitt Benckiser Finish B.V. | Composition |

| WO2020043844A1 (en) | 2018-08-31 | 2020-03-05 | Reckitt Benckiser Finish B.V. | Automatic dishwashing product |

| WO2020053132A1 (en) | 2018-09-14 | 2020-03-19 | Reckitt Benckiser Finish B.V. | Granulate for detergent composition |

| WO2020104320A1 (en) | 2018-11-19 | 2020-05-28 | Reckitt Benckiser Finish B.V. | Composition |

| WO2020152044A1 (en) | 2019-01-22 | 2020-07-30 | Reckitt Benckiser Finish B.V. | Method of forming an automatic dishwashing pouch, vacuum forming system and pouch |

| WO2020182656A2 (en) | 2019-03-11 | 2020-09-17 | Reckitt Benckiser Finish B.V. | Product |

| WO2021155135A1 (en) * | 2020-01-31 | 2021-08-05 | Ecolab Usa Inc. | Amylase synergy with oxygen bleach in warewash application |

| WO2021213807A1 (en) | 2020-04-23 | 2021-10-28 | Reckitt Benckiser Finish B.V. | Automatic dishwashing composition |

| WO2022002671A1 (en) | 2020-07-01 | 2022-01-06 | Reckitt Benckiser Finish B.V. | Method for making a gel or a gel-like detergent |

| WO2022002672A1 (en) | 2020-07-01 | 2022-01-06 | Reckitt Benckiser Finish B.V. | Use of a composition as anti-corrosion agent |

| US11266289B2 (en) | 2014-08-05 | 2022-03-08 | Reckitt Benckiser (Brands) Limited | Automatic washing machine and method |

| WO2022189536A1 (en) | 2021-03-12 | 2022-09-15 | Reckitt Benckiser Finish B.V. | Automatic dishwashing composition |

| WO2022253728A1 (en) | 2021-06-03 | 2022-12-08 | Reckitt Benckiser Finish B.V. | Detergent gel composition comprising a fatty alcohol ethoxylate |

| WO2023156427A1 (en) | 2022-02-15 | 2023-08-24 | Reckitt Benckiser Finish B.V. | Dishwashing detergent composition |

| WO2024002908A1 (en) | 2022-06-29 | 2024-01-04 | Reckitt Benckiser Finish B.V. | A dishwashing detergent composition, a water-soluble container, and an autodosing automatic dishwashing system |

| WO2024002848A1 (en) | 2022-06-29 | 2024-01-04 | Reckitt Benckiser Finish B.V. | Dishwashing, preferably an automatic dishwashing, detergent composition |

| WO2024126495A1 (en) | 2022-12-14 | 2024-06-20 | Reckitt Benckiser Finish B.V. | Solid unit dose detergent composition |

| WO2024231684A1 (en) | 2023-05-11 | 2024-11-14 | Innospec Limited | Use, method and dishwashing composition for preventing or reducing corrosion and/or staining of a metallic surface in a cleaning process |

| WO2025132975A1 (en) | 2023-12-20 | 2025-06-26 | Reckitt Benckiser Finish B.V. | Dishwashing composition |

| WO2025202640A1 (en) | 2024-03-26 | 2025-10-02 | Innospec Limited | Cleansing composition and article |

| WO2025202636A1 (en) | 2024-03-26 | 2025-10-02 | Innospec Limited | Cleansing composition and article |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0141470A2 (en) * | 1983-11-08 | 1985-05-15 | Unilever N.V. | Manganese adjuncts, their preparation and use |

| WO1994021775A1 (en) * | 1993-03-18 | 1994-09-29 | Unilever Plc | Detergent compositions |

| WO1995006711A1 (en) * | 1993-09-03 | 1995-03-09 | Unilever Plc | Bleach catalyst composition |

| US5622646A (en) * | 1994-04-07 | 1997-04-22 | The Procter & Gamble Company | Bleach compositions comprising metal-containing bleach catalysts and antioxidants |

-

2006

- 2006-06-27 PT PT06116118T patent/PT1741774E/en unknown

- 2006-06-27 EP EP06116118A patent/EP1741774B1/en active Active

- 2006-06-27 DE DE602006002075T patent/DE602006002075D1/en active Active

- 2006-06-27 ES ES06116118T patent/ES2312089T3/en active Active

- 2006-06-27 AT AT06116118T patent/ATE403711T1/en active

- 2006-06-27 PL PL06116118T patent/PL1741774T3/en unknown

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0141470A2 (en) * | 1983-11-08 | 1985-05-15 | Unilever N.V. | Manganese adjuncts, their preparation and use |

| WO1994021775A1 (en) * | 1993-03-18 | 1994-09-29 | Unilever Plc | Detergent compositions |

| WO1995006711A1 (en) * | 1993-09-03 | 1995-03-09 | Unilever Plc | Bleach catalyst composition |

| US5622646A (en) * | 1994-04-07 | 1997-04-22 | The Procter & Gamble Company | Bleach compositions comprising metal-containing bleach catalysts and antioxidants |

Cited By (50)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2008048537A1 (en) * | 2006-10-16 | 2008-04-24 | Danisco Us, Inc. Genencor Division | Non-phosphate dish detergents |

| EP1967577A1 (en) * | 2007-02-13 | 2008-09-10 | CHT R. BEITLICH GmbH | Catalysed peroxide bleach (catylasator bleach) |

| WO2010010003A3 (en) * | 2008-07-23 | 2010-07-29 | Cht R. Beitlich Gmbh | Catalysed peroxide bleach ("catalyst-bleach variant 3: all-in-one) |

| US9434915B2 (en) | 2008-11-11 | 2016-09-06 | Danisco Us Inc. | Compositions and methods comprising a subtilisin variant |

| WO2010116139A1 (en) | 2009-04-09 | 2010-10-14 | Reckitt Benckiser N.V. | Detergent composition |

| US9249380B2 (en) | 2009-08-07 | 2016-02-02 | Robert McBride Ltd. | Dosage form detergent products |

| WO2011027170A2 (en) | 2009-09-07 | 2011-03-10 | Reckitt Benckiser N.V. | Detergent composition |

| WO2011032868A1 (en) * | 2009-09-21 | 2011-03-24 | Henkel Ag & Co. Kgaa | Dishwasher detergent |

| WO2011042737A1 (en) | 2009-10-09 | 2011-04-14 | Reckitt Benckiser N.V. | Detergent composition |

| EP3255132A1 (en) | 2009-10-09 | 2017-12-13 | Reckitt Benckiser Finish B.V. | Detergent composition |

| WO2011110850A1 (en) | 2010-03-09 | 2011-09-15 | Reckitt Benckiser N.V | Compression process for producing a bleach containing product |

| WO2011110849A1 (en) | 2010-03-09 | 2011-09-15 | Reckitt Benckiser N.V. | Detergent composition |

| WO2012066341A2 (en) | 2010-11-19 | 2012-05-24 | Reckitt Benckiser N.V. | Coated bleach materials |

| WO2012066344A1 (en) | 2010-11-19 | 2012-05-24 | Reckitt Benckiser N.V. | Dyed coated bleach materials |

| WO2012085534A1 (en) | 2010-12-21 | 2012-06-28 | Reckitt Benckiser N.V. | Bleach catalyst particle |

| WO2012123719A1 (en) | 2011-03-14 | 2012-09-20 | Reckitt Benckiser N.V. | Detergent composition with improved drying performance |

| US9157050B2 (en) | 2011-03-14 | 2015-10-13 | Reckitt Benckiser N.V. | Detergent composition with improved drying performance |

| US9617500B2 (en) | 2011-03-14 | 2017-04-11 | Reckitt Benckiser Finish B.V. | Detergent composition with improved drying performance |

| WO2014060738A1 (en) * | 2012-10-15 | 2014-04-24 | Reckitt & Colman (Overseas) Limited | Ultrasonic method of cleaning |

| CN109181903A (en) * | 2013-05-02 | 2019-01-11 | 艺康美国股份有限公司 | Concentrated cleaning compositions for the improved starch removal in dishwashing detergent is applied |

| US10253278B2 (en) | 2013-05-02 | 2019-04-09 | Ecolab Usa Inc. | Concentrated detergent composition for the improved removal of starch in warewashing applications |

| JP2016518496A (en) * | 2013-05-02 | 2016-06-23 | エコラボ ユーエスエー インコーポレイティド | Concentrated detergent composition for improved removal of starch in article cleaning applications |

| CN105164241A (en) * | 2013-05-02 | 2015-12-16 | 艺康美国股份有限公司 | Concentrated detergent composition for improved starch removal in dishwashing applications |

| US9969958B2 (en) | 2013-05-02 | 2018-05-15 | Ecolab Usa Inc. | Concentrated detergent composition for the improved removal of starch in warewashing applications |

| US10669510B2 (en) | 2013-05-02 | 2020-06-02 | Ecolab Usa Inc. | Concentrated detergent composition for the improved removal of starch in warewashing applications |

| WO2015124384A1 (en) | 2014-02-20 | 2015-08-27 | Unilever N.V. | Machine dishwash composition |

| EP3107987B1 (en) | 2014-02-20 | 2018-10-03 | Unilever N.V. | Machine dishwash composition |

| JP2017507209A (en) * | 2014-02-20 | 2017-03-16 | ユニリーバー・ナームローゼ・ベンノートシヤープ | Machine dishwashing composition |

| US11266289B2 (en) | 2014-08-05 | 2022-03-08 | Reckitt Benckiser (Brands) Limited | Automatic washing machine and method |

| WO2019233696A1 (en) | 2018-06-04 | 2019-12-12 | Reckitt Benckiser Finish B.V. | Composition |

| WO2020043844A1 (en) | 2018-08-31 | 2020-03-05 | Reckitt Benckiser Finish B.V. | Automatic dishwashing product |

| WO2020053132A1 (en) | 2018-09-14 | 2020-03-19 | Reckitt Benckiser Finish B.V. | Granulate for detergent composition |

| WO2020104320A1 (en) | 2018-11-19 | 2020-05-28 | Reckitt Benckiser Finish B.V. | Composition |

| WO2020152044A1 (en) | 2019-01-22 | 2020-07-30 | Reckitt Benckiser Finish B.V. | Method of forming an automatic dishwashing pouch, vacuum forming system and pouch |

| WO2020182656A2 (en) | 2019-03-11 | 2020-09-17 | Reckitt Benckiser Finish B.V. | Product |

| WO2021155135A1 (en) * | 2020-01-31 | 2021-08-05 | Ecolab Usa Inc. | Amylase synergy with oxygen bleach in warewash application |

| WO2021213807A1 (en) | 2020-04-23 | 2021-10-28 | Reckitt Benckiser Finish B.V. | Automatic dishwashing composition |

| WO2022002671A1 (en) | 2020-07-01 | 2022-01-06 | Reckitt Benckiser Finish B.V. | Method for making a gel or a gel-like detergent |

| WO2022002672A1 (en) | 2020-07-01 | 2022-01-06 | Reckitt Benckiser Finish B.V. | Use of a composition as anti-corrosion agent |

| WO2022189536A1 (en) | 2021-03-12 | 2022-09-15 | Reckitt Benckiser Finish B.V. | Automatic dishwashing composition |

| WO2022253728A1 (en) | 2021-06-03 | 2022-12-08 | Reckitt Benckiser Finish B.V. | Detergent gel composition comprising a fatty alcohol ethoxylate |

| GB2607585A (en) | 2021-06-03 | 2022-12-14 | Reckitt Benckiser Finish Bv | Detergent gel composition comprising a fatty alcohol ethoxylate |

| WO2023156427A1 (en) | 2022-02-15 | 2023-08-24 | Reckitt Benckiser Finish B.V. | Dishwashing detergent composition |

| WO2024002908A1 (en) | 2022-06-29 | 2024-01-04 | Reckitt Benckiser Finish B.V. | A dishwashing detergent composition, a water-soluble container, and an autodosing automatic dishwashing system |

| WO2024002848A1 (en) | 2022-06-29 | 2024-01-04 | Reckitt Benckiser Finish B.V. | Dishwashing, preferably an automatic dishwashing, detergent composition |

| WO2024126495A1 (en) | 2022-12-14 | 2024-06-20 | Reckitt Benckiser Finish B.V. | Solid unit dose detergent composition |

| WO2024231684A1 (en) | 2023-05-11 | 2024-11-14 | Innospec Limited | Use, method and dishwashing composition for preventing or reducing corrosion and/or staining of a metallic surface in a cleaning process |

| WO2025132975A1 (en) | 2023-12-20 | 2025-06-26 | Reckitt Benckiser Finish B.V. | Dishwashing composition |

| WO2025202640A1 (en) | 2024-03-26 | 2025-10-02 | Innospec Limited | Cleansing composition and article |

| WO2025202636A1 (en) | 2024-03-26 | 2025-10-02 | Innospec Limited | Cleansing composition and article |

Also Published As

| Publication number | Publication date |

|---|---|

| DE602006002075D1 (en) | 2008-09-18 |

| ES2312089T3 (en) | 2009-02-16 |

| ATE403711T1 (en) | 2008-08-15 |

| PT1741774E (en) | 2008-11-17 |

| PL1741774T3 (en) | 2009-01-30 |

| EP1741774B1 (en) | 2008-08-06 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1741774B1 (en) | Machine dishwashing compositions and their use | |

| EP0530870B1 (en) | Machine dishwashing composition | |

| EP2794836B1 (en) | Detergent composition comprising glutamic-n,n-diacetate, water and bleaching agent | |

| US8173587B2 (en) | Detergent composition | |

| AU632713B2 (en) | Detergent compositions | |

| EP0533239B1 (en) | Aqueous liquid cleaning compositions | |

| JPH05112799A (en) | Concentrated detergent powder composition | |

| US5719112A (en) | Dishwashing composition | |

| EP3013931B1 (en) | Composition comprising glutamic-n,n-diacetate (glda), water and enzyme | |

| WO1989004863A1 (en) | Machine dishwashing compositions | |

| US5527483A (en) | Nonaqueous gelled automatic dishwashing composition containing enzymes | |

| JP2611071B2 (en) | Detergent composition | |

| EP0395333A2 (en) | Detergent compositions | |

| JP2024520665A (en) | Detergent gel compositions containing fatty alcohol ethoxylates | |

| JPH0713238B2 (en) | Detergent composition for dishwasher | |

| JP2002541303A (en) | Bleach-containing detergent | |

| EP0313144A2 (en) | Non-phosphorus detergent bleach compositions | |

| AU2011225893A1 (en) | Detergent composition | |

| EP0266904A2 (en) | Machine dish washing composition containing dipicolinic acid | |

| WO1994019445A1 (en) | Machine dishwashing composition | |

| EP1556471B1 (en) | Tablet of compacted particulate cleaning composition | |

| EP0772671B1 (en) | Method for preparing co-granules, co-granules thus obtained and use thereof as a component in detergent compositions | |

| CA2299831A1 (en) | Dishwasher detergent shaped bodies with specific geometry | |

| EP0319053A2 (en) | Improved phosphate-free detergent bleach compositions | |

| EP0987320A2 (en) | Detergent compositions |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC NL PL PT RO SE SI SK TR |

|

| AX | Request for extension of the european patent |

Extension state: AL BA HR MK YU |

|

| 17P | Request for examination filed |

Effective date: 20061214 |

|

| 17Q | First examination report despatched |

Effective date: 20070222 |

|

| AKX | Designation fees paid |

Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC NL PL PT RO SE SI SK TR |

|

| GRAP | Despatch of communication of intention to grant a patent |

Free format text: ORIGINAL CODE: EPIDOSNIGR1 |

|

| GRAS | Grant fee paid |

Free format text: ORIGINAL CODE: EPIDOSNIGR3 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC NL PL PT RO SE SI SK TR |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: FG4D |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: EP |

|

| REG | Reference to a national code |

Ref country code: IE Ref legal event code: FG4D |

|

| REF | Corresponds to: |

Ref document number: 602006002075 Country of ref document: DE Date of ref document: 20080918 Kind code of ref document: P |

|

| REG | Reference to a national code |

Ref country code: RO Ref legal event code: EPE |

|

| REG | Reference to a national code |

Ref country code: PT Ref legal event code: SC4A Free format text: AVAILABILITY OF NATIONAL TRANSLATION Effective date: 20081104 |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: TRGR |

|

| REG | Reference to a national code |

Ref country code: GR Ref legal event code: EP Ref document number: 20080403011 Country of ref document: GR |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080806 Ref country code: IS Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20081206 |

|

| REG | Reference to a national code |

Ref country code: PL Ref legal event code: T3 |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2312089 Country of ref document: ES Kind code of ref document: T3 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SI Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080806 Ref country code: LV Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080806 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080806 Ref country code: BG Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20081106 |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| PLBI | Opposition filed |

Free format text: ORIGINAL CODE: 0009260 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SK Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080806 Ref country code: CZ Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080806 |

|

| PLAX | Notice of opposition and request to file observation + time limit sent |

Free format text: ORIGINAL CODE: EPIDOSNOBS2 |

|

| 26 | Opposition filed |

Opponent name: HENKEL AG & CO. KGAA Effective date: 20090504 |

|

| 26 | Opposition filed |

Opponent name: THE PROCTER & GAMBLE COMMPANY Effective date: 20090506 Opponent name: RECKITT BENCKISER PLC I Effective date: 20090505 Opponent name: HENKEL AG & CO. KGAA Effective date: 20090504 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: EE Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080806 |

|

| NLR1 | Nl: opposition has been filed with the epo |

Opponent name: THE PROCTER & GAMBLE COMMPANY Opponent name: RECKITT BENCKISER PLC INTELLECTUAL PROPERTY DEPART Opponent name: HENKEL AG & CO. KGAA |

|

| PLAF | Information modified related to communication of a notice of opposition and request to file observations + time limit |

Free format text: ORIGINAL CODE: EPIDOSCOBS2 |

|

| PLAB | Opposition data, opponent's data or that of the opponent's representative modified |

Free format text: ORIGINAL CODE: 0009299OPPO |

|

| PLAF | Information modified related to communication of a notice of opposition and request to file observations + time limit |

Free format text: ORIGINAL CODE: EPIDOSCOBS2 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: MC Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090630 |

|

| PLAK | Information related to reply of patent proprietor to notice(s) of opposition modified |

Free format text: ORIGINAL CODE: EPIDOSCOBS3 |

|

| PLBB | Reply of patent proprietor to notice(s) of opposition received |

Free format text: ORIGINAL CODE: EPIDOSNOBS3 |

|

| PLAB | Opposition data, opponent's data or that of the opponent's representative modified |

Free format text: ORIGINAL CODE: 0009299OPPO |

|

| R26 | Opposition filed (corrected) |

Opponent name: THE PROCTER & GAMBLE COMMPANY Effective date: 20090506 Opponent name: RECKITT BENCKISER PLC I Effective date: 20090505 Opponent name: HENKEL AG & CO. KGAA Effective date: 20090504 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| RDAF | Communication despatched that patent is revoked |

Free format text: ORIGINAL CODE: EPIDOSNREV1 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090630 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090630 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100630 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20090627 Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20100630 |

|

| APBM | Appeal reference recorded |

Free format text: ORIGINAL CODE: EPIDOSNREFNO |

|

| APBP | Date of receipt of notice of appeal recorded |

Free format text: ORIGINAL CODE: EPIDOSNNOA2O |

|

| APAH | Appeal reference modified |

Free format text: ORIGINAL CODE: EPIDOSCREFNO |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: HU Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20090207 |

|

| APBQ | Date of receipt of statement of grounds of appeal recorded |

Free format text: ORIGINAL CODE: EPIDOSNNOA3O |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CY Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 20080806 |

|

| APBU | Appeal procedure closed |

Free format text: ORIGINAL CODE: EPIDOSNNOA9O |

|

| PLAB | Opposition data, opponent's data or that of the opponent's representative modified |

Free format text: ORIGINAL CODE: 0009299OPPO |

|

| R26 | Opposition filed (corrected) |

Opponent name: THE PROCTER & GAMBLE COMMPANY Effective date: 20090506 Opponent name: HENKEL AG & CO. KGAA Effective date: 20090504 Opponent name: RECKITT BENCKISER PLC INTELLECTUAL PROPERTY DEPART Effective date: 20090505 |

|

| PLCK | Communication despatched that opposition was rejected |

Free format text: ORIGINAL CODE: EPIDOSNREJ1 |

|

| PLBN | Opposition rejected |

Free format text: ORIGINAL CODE: 0009273 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: OPPOSITION REJECTED |

|

| 27O | Opposition rejected |

Effective date: 20130108 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R100 Ref document number: 602006002075 Country of ref document: DE Effective date: 20130108 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 11 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 12 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: PLFP Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GR Payment date: 20200611 Year of fee payment: 15 Ref country code: RO Payment date: 20200622 Year of fee payment: 15 Ref country code: IE Payment date: 20200624 Year of fee payment: 15 Ref country code: FI Payment date: 20200622 Year of fee payment: 15 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 20200625 Year of fee payment: 15 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20200619 Year of fee payment: 15 |

|

| REG | Reference to a national code |

Ref country code: NL Ref legal event code: PD Owner name: UNILEVER IP HOLDINGS B.V.; NL Free format text: DETAILS ASSIGNMENT: CHANGE OF OWNER(S), ASSIGNMENT; FORMER OWNER NAME: UNILEVER N.V. Effective date: 20210413 |

|

| REG | Reference to a national code |

Ref country code: BE Ref legal event code: PD Owner name: UNILEVER IP HOLDINGS B.V.; NL Free format text: DETAILS ASSIGNMENT: CHANGE OF OWNER(S), ASSIGNMENT; FORMER OWNER NAME: UNILEVER N.V. Effective date: 20210607 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R081 Ref document number: 602006002075 Country of ref document: DE Owner name: UNILEVER GLOBAL IP LIMITED, WIRRAL, GB Free format text: FORMER OWNER: UNILEVER N.V., ROTTERDAM, NL |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: PC2A Owner name: UNILEVER IP HOLDINGS B.V. Effective date: 20211117 |

|

| REG | Reference to a national code |

Ref country code: FI Ref legal event code: MAE |

|

| REG | Reference to a national code |

Ref country code: SE Ref legal event code: EUG |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: RO Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210627 Ref country code: FI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210627 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MM01 Ref document number: 403711 Country of ref document: AT Kind code of ref document: T Effective date: 20210627 |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: 732E Free format text: REGISTERED BETWEEN 20220203 AND 20220209 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210627 Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210627 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20210628 Ref country code: GR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20220105 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: PT Payment date: 20220617 Year of fee payment: 17 Ref country code: GB Payment date: 20220622 Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: TR Payment date: 20220624 Year of fee payment: 17 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20230620 Year of fee payment: 18 Ref country code: FR Payment date: 20230622 Year of fee payment: 18 Ref country code: DE Payment date: 20220914 Year of fee payment: 18 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: PL Payment date: 20230615 Year of fee payment: 18 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20230619 Year of fee payment: 18 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: IT Payment date: 20230621 Year of fee payment: 18 Ref country code: ES Payment date: 20230828 Year of fee payment: 18 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: PT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20231227 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20230627 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20230627 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R119 Ref document number: 602006002075 Country of ref document: DE |

|