EP0040117B1 - Polychromatic cathode ray tube and viewing device equipped with such a tube - Google Patents

Polychromatic cathode ray tube and viewing device equipped with such a tube Download PDFInfo

- Publication number

- EP0040117B1 EP0040117B1 EP81400605A EP81400605A EP0040117B1 EP 0040117 B1 EP0040117 B1 EP 0040117B1 EP 81400605 A EP81400605 A EP 81400605A EP 81400605 A EP81400605 A EP 81400605A EP 0040117 B1 EP0040117 B1 EP 0040117B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- cathode

- tube

- reserved

- gun

- control

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired

Links

- 238000010438 heat treatment Methods 0.000 claims description 21

- 238000012360 testing method Methods 0.000 claims description 9

- PLXMOAALOJOTIY-FPTXNFDTSA-N Aesculin Natural products OC[C@@H]1[C@@H](O)[C@H](O)[C@@H](O)[C@H](O)[C@H]1Oc2cc3C=CC(=O)Oc3cc2O PLXMOAALOJOTIY-FPTXNFDTSA-N 0.000 claims description 7

- 230000000903 blocking effect Effects 0.000 claims description 2

- 238000004519 manufacturing process Methods 0.000 description 3

- 239000003086 colorant Substances 0.000 description 2

- 238000001514 detection method Methods 0.000 description 2

- 238000010586 diagram Methods 0.000 description 2

- 238000000034 method Methods 0.000 description 2

- 230000001133 acceleration Effects 0.000 description 1

- 230000000712 assembly Effects 0.000 description 1

- 238000000429 assembly Methods 0.000 description 1

- 230000015556 catabolic process Effects 0.000 description 1

- 238000005520 cutting process Methods 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 238000010894 electron beam technology Methods 0.000 description 1

- 230000007257 malfunction Effects 0.000 description 1

- 239000000463 material Substances 0.000 description 1

- 238000005259 measurement Methods 0.000 description 1

- 238000012544 monitoring process Methods 0.000 description 1

- 238000009666 routine test Methods 0.000 description 1

- 238000011144 upstream manufacturing Methods 0.000 description 1

- 238000012795 verification Methods 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01J—ELECTRIC DISCHARGE TUBES OR DISCHARGE LAMPS

- H01J29/00—Details of cathode-ray tubes or of electron-beam tubes of the types covered by group H01J31/00

- H01J29/98—Circuit arrangements not adapted to a particular application of the tube and not otherwise provided for

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01J—ELECTRIC DISCHARGE TUBES OR DISCHARGE LAMPS

- H01J31/00—Cathode ray tubes; Electron beam tubes

- H01J31/08—Cathode ray tubes; Electron beam tubes having a screen on or from which an image or pattern is formed, picked up, converted, or stored

- H01J31/10—Image or pattern display tubes, i.e. having electrical input and optical output; Flying-spot tubes for scanning purposes

- H01J31/20—Image or pattern display tubes, i.e. having electrical input and optical output; Flying-spot tubes for scanning purposes for displaying images or patterns in two or more colours

Definitions

- the present invention relates to polychrome cathode ray tubes of the three-barrel type.

- Perforated mask cathode ray tubes (shadow mask according to the Anglo-Saxon name) fall into this category.

- These tubes are used, in particular in avionics to display on the dashboard navigation data or other useful for the pilot.

- one of the colors, red is reserved for viewing the alarms. This reserved color is not normally used to display the data except in combination with the other colors, with green for example to obtain yellow.

- the object of the invention is to remedy this drawback by modifying the structure of the tube so as to allow verification of the proper functioning of the barrel corresponding to the color reserved, the control then being able to be carried out according to routine test measurements used for check electronic circuits.

- a polychrome cathode ray tube with three guns, comprising a heating filament and a cathode by cannon, pins for the parallel supply of the filaments and a pin by cathode, and being characterized in that 'It is equipped with means for the external control of the heating of the filament of one of the three guns, called the reserved gun.

- These control means include, according to a first solution, a separate heating connection connecting one end of the filament in question to a control pin intended to be connected externally, through an auxiliary test circuit, to a source of heating current. This solution allows direct control by checking the passage of the heating current.

- control means allow indirect control of the heating by mounting an anode near the cathode of the barrel reserved to form with this cathode a diode, this anode being connected internally to the tube to a control pin, intended for be connected externally, through an annex test circuit (10), to a source establishing a DC voltage between said cathode and anode.

- a preferred embodiment consists in grouping these two assemblies on the same tube in order to combine the advantages and also benefit from a double control of the operation of the reserved barrel.

- the polychrome cathode-ray tube is arranged to allow the monitoring of the reserved gun, the autonomous operational commissioning of which is rare.

- the arrangements are based on the fact that two elements are to be checked, the heating filament and the cathode of the gun in question.

- the other upstream electrodes comprise the control grid or whenelt, also called grid G1, then the other screen, focusing, and acceleration grids; each of these electrodes is, according to current embodiments, common for the three guns. Consequently, a malfunction of a common electrode is detected directly by observation of the image displayed on the screen.

- the simplest but non-preferential mode is first exposed.

- an end connection 1 of the filament 2 of the reserved barrel is taken out separately to lead to an electrode outlet 3, constituted by a pin available on the base 4 of the tube if necessary.

- the filaments 2, 5 and 6 are normally connected in parallel internally to the tube, the connections leading to two heating pins 7-8 on which an AC or DC voltage is applied from an external power supply.

- pin 8 is common to the three filaments and pin 7 is common to filaments 5 and 6 which remain connected in parallel.

- the filament 2 is supplied separately between pins 8 and 3.

- the connection of filament 2 to the supply thus uses a connection 9 outside the tube instead of a connection to the pin internal to the tube according to the conventional assembly.

- This external connection 9 allows the test of the heating of the reserved barrel according to known methods, by controlling the passage of current for example.

- Block 10 symbolizes a test circuit. Note, the variant consisting in removing the two end connections of the filament 2 separately but which requires two additional output pins instead of one, a more delicate embodiment and which is not accompanied, moreover, by any advantage.

- a second version of arrangement of the tube makes it possible to locate the level control of the cathode 11 of the reserved barrel, that is to say at the level of the electronic emission.

- An additional electrode 12 forming an anode is inserted during manufacture and disposed near the cathode 11.

- the anode 12 is connected to an electrode outlet 13, constituted by a pin available if necessary.

- Vc DC voltage

- the assembly 11-12 constitutes a diode and the corresponding current detection is used to control the operation of the reserved barrel.

- the test can be carried out on the external link 15 connecting a direct source external to the anode 12.

- the cathodes of the tube are generally cylindrical in shape with the internal filament; the cylinder is closed at one end and covered at this end with a deposit of electron generating material under the effect of heating.

- the anode 12 can therefore be positioned between the end of the cathode 11 and the grid G1 so as to be opposite an emissive zone of the deposit.

- the anode must be designed to be small in size so as to close off the electron beam as little as possible.

- the inter-electrode space between the cathodes and the grid G1 is low and it follows from the difficulties of making and installing the anode 12 on an axial path.

- the deposit 20 is preferably extended on the cylindrical wall of the cathode 11 as shown in FIG. 2 to form a small area 21 opposite which the anode 12 is positioned. Zone 21 can also be the subject of a deposit separate from the terminal deposit 20.

- the version with anode is preferable to the first version because it also authorizes, indirectly however, the heating control and the detection of a possible break in this circuit.

- Fig. 3 shows such a solution applicable in particular to a tube with a shadow mask.

- the adjoining circuits consist of a circuit 30 generating the supply voltage U of the filaments, and video circuits 31, 32 and 33 respectively for the red, green and blue channels.

- Each video circuit has an output of negative polarity connected to the control gate G1 and an output of positive polarity connected to the corresponding cathode KR, KV or KB.

- the blocking voltage between gate G1 and cathode can be for example -70 V and the common output connected to the reference ground potential.

- the respective video signals are transmitted by these circuits over the cathode connections.

- the video circuit of the red channel has a second output of positive polarity, for example at + 100 V, connected to the anode 12.

- the controls are obtained for example by means of current transformers 34, 35 placed on the external connections 9 of heating of the red cannon and supply of the anode 12.

- control circuits 10 The production of the control circuits 10 is based on known techniques, as well as the possible production of additional outputs 3 and / or 13 in the case where the pinout of the tube requires it, that is to say in the absence of an available pin .

Landscapes

- Manufacture Of Electron Tubes, Discharge Lamp Vessels, Lead-In Wires, And The Like (AREA)

- Video Image Reproduction Devices For Color Tv Systems (AREA)

- Indicating Measured Values (AREA)

Description

La présente invention concerne des tubes cathodiques polychrome du type à trois canons. Les tubes cathodiques à masque perforé (shadow-mask selon l'appellation anglo-saxonne) entrent dans cette catégorie.The present invention relates to polychrome cathode ray tubes of the three-barrel type. Perforated mask cathode ray tubes (shadow mask according to the Anglo-Saxon name) fall into this category.

Ces tubes sont utilisés, notamment en avionique pour visualiser sur la planche de bord des données de navigation ou autres utiles pour le pilote. De manière conventionnelle l'une des couleurs, le rouge, est réservée pour visualiser les alarmes. Cette couleur réservée n'est pas normalement utilisée pour visualiser les données sauf en combinaison avec les autres couleurs, avec le vert par exemple pour l'obtention du jaune.These tubes are used, in particular in avionics to display on the dashboard navigation data or other useful for the pilot. Conventionally, one of the colors, red, is reserved for viewing the alarms. This reserved color is not normally used to display the data except in combination with the other colors, with green for example to obtain yellow.

Un problème se pose alors dans le cadre de telles utilisations au niveau de la sécurité et de la fiabilité de l'équipement étant donné qu'en l'absence d'alarme cette teinte réservée n'est pas visualisée et qu'une panne éventuelle du circuit cathodique du tube générateur de cette couleur n'est guère décelable en pratique.A problem then arises in the context of such uses with regard to the safety and reliability of the equipment since, in the absence of an alarm, this reserved shade is not displayed and that a possible breakdown of the cathode circuit of the generator tube of this color is hardly detectable in practice.

Le but de l'invention est de remédier à cet inconvénient en modifiant la structure du tube de manière à autoriser la vérification du bon fonctionnement du canon correspondant à la couleur réservée, le contrôle pouvant alors s'effectuer selon des mesures de test routinières utilisées pour vérifier des circuits électroniques.The object of the invention is to remedy this drawback by modifying the structure of the tube so as to allow verification of the proper functioning of the barrel corresponding to the color reserved, the control then being able to be carried out according to routine test measurements used for check electronic circuits.

Suivant l'invention il est proposé de réaliser un tube cathodique polychrome à trois canons, comportant un filament de chauffage et une cathode par canon, des broches pour l'alimentation en parallèle des filaments et une broche par cathode, et étant caractérisé en ce qu'il est équipé de moyens pour le contrôle extérieur du chauffage du filament d'un des trois canons, dit canon réservé. Ces moyens de contrôle incluent, selon une première solution, une connexion séparée de chauffage reliant une extrémité du filament en question à une broche de contrôle destinée à être reliée extérieurement, à travers un circuit de test annexe, à une source de courant de chauffage. Cette solution permet un contrôle direct en vérifiant le passage du courant de chauffage. Suivant une seconde solution, les moyens de contrôle permettent un contrôle indirect du chauffage en montant une anode à proximité de la cathode du canon réservé pour former avec cette cathode une diode, cette anode étant connectée intérieurement au tube à une broche de contrôle, destinée à être reliée extérieurement, à travers un circuit de test annexe (10), à une source établissant une tension continue entre lesdites cathode et anode. Une réalisation préférentielle consiste à regrouper ces deux montages sur un même tube pour en cumuler les avantages et bénéficier aussi d'un double contrôle du fonctionnement du canon réservé.According to the invention, it is proposed to produce a polychrome cathode ray tube with three guns, comprising a heating filament and a cathode by cannon, pins for the parallel supply of the filaments and a pin by cathode, and being characterized in that 'It is equipped with means for the external control of the heating of the filament of one of the three guns, called the reserved gun. These control means include, according to a first solution, a separate heating connection connecting one end of the filament in question to a control pin intended to be connected externally, through an auxiliary test circuit, to a source of heating current. This solution allows direct control by checking the passage of the heating current. According to a second solution, the control means allow indirect control of the heating by mounting an anode near the cathode of the barrel reserved to form with this cathode a diode, this anode being connected internally to the tube to a control pin, intended for be connected externally, through an annex test circuit (10), to a source establishing a DC voltage between said cathode and anode. A preferred embodiment consists in grouping these two assemblies on the same tube in order to combine the advantages and also benefit from a double control of the operation of the reserved barrel.

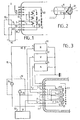

Les particularités et avantages de la présente invention apparaîtront dans la description qui suit donnée à titre d'exemple à l'aide des figures annexées qui représentent :

- Figure 1 un schéma simplifié d'un tube cathodique polychrome aménagé conformément à l'invention ;

- Figure 2 un schéma de détail relatif à une variante de réalisation du tube aménagé selon la Fig.1 ; et

- Figure 3 un schéma de réalisation du tube aménagé selon l'invention avec représentation de circuits d'alimentation extérieure et de circuits de contrôle.

- Figure 1 a simplified diagram of a polychrome cathode ray tube arranged in accordance with the invention;

- Figure 2 a detail diagram relating to an alternative embodiment of the tube arranged according to Fig.1; and

- Figure 3 an embodiment of the tube arranged according to the invention with representation of external supply circuits and control circuits.

Conformément à l'invention le tube cathodique polychrome est aménagé pour permettre la surveillance du canon réservé dont la mise en service opérationnelle autonome est rare. Les aménagements sont basés sur le fait que deux éléments sont à contrôler, le filament de chauffage et la cathode du canon considéré. Les autres électrodes en amont comportent la grille de commande ou whenelt, dite aussi grille G1, puis les autres grilles d'écran, de focalisation, et d'accélération ; chacune de ces électrodes est, selon les réalisations courantes, commune pour les trois canons. En conséquence, un mauvais fonctionnement d'une électrode commune est détecté directement par observation de l'image visualisée sur l'écran. Deux autres facteurs ont été pris en compte pour l'aménagement du tube, d'une part, la probabilité de panne la plus grande, qui est celle résultant du défaut de chauffage par coupure du circuit filament, et d'autre part, le nombre de broches disponibles sur le culot du tube qui est très limité et n'excède généralement pas une broche. En fonction de ces paramètres, plusieurs modes de réalisation sont envisagés dans ce qui suit.In accordance with the invention, the polychrome cathode-ray tube is arranged to allow the monitoring of the reserved gun, the autonomous operational commissioning of which is rare. The arrangements are based on the fact that two elements are to be checked, the heating filament and the cathode of the gun in question. The other upstream electrodes comprise the control grid or whenelt, also called grid G1, then the other screen, focusing, and acceleration grids; each of these electrodes is, according to current embodiments, common for the three guns. Consequently, a malfunction of a common electrode is detected directly by observation of the image displayed on the screen. Two other factors were taken into account for the arrangement of the tube, on the one hand, the highest probability of failure, which is that resulting from the failure of heating by cutting the filament circuit, and on the other hand, the number pins available on the tube base which is very limited and generally does not exceed one pin. Depending on these parameters, several embodiments are envisaged in the following.

Le mode le plus simple mais non préférentiel est tout d'abord exposé. Selon cette première version une connexion d'extrémité 1 du filament 2 du canon réservé est sortie séparément pour aboutir à une sortie d'électrode 3, constituée par une broche disponible sur le culot 4 du tube le cas échéant. Les filaments 2, 5 et 6 sont normalement connectés en parallèle intérieurement au tube, les connexions aboutissant à deux broches de chauffage 7-8 sur lesquelles une tension U alternative ou continue est appliquée provenant d'une alimentation extérieure. Suivant l'aménagement représenté sur la Fig. 1, la broche 8 est commune aux trois filaments et la broche 7 est commune aux filaments 5 et 6 qui restent connectés en parallèle. Le filament 2 se trouve alimenté séparément entre les broches 8 et 3. La connexion du filament 2 vers l'alimentation utilise ainsi un raccordement 9 extérieur au tube au lieu d'une liaison à la broche interne au tube selon le montage conventionnel. Cette connexion extérieure 9 permet le test du chauffage du canon réservé selon des méthodes connues, par contrôle de passage du courant par exemple. Le bloc 10 symbolise un circuit de test. A noter, la variante consistant à sortir séparément les deux connexions d'extrémité du filament 2 mais qui nécessite deux broches de sortie supplémentaires au lieu d'une, une réalisation plus délicate et qui ne s'accompagne pas, par ailleurs, d'un quelconque avantage.The simplest but non-preferential mode is first exposed. According to this first version an end connection 1 of the

Une deuxième version d'aménagement du tube permet de situer le contrôle du niveau de la cathode 11 du canon réservé, c'est-à-dire au niveau de l'émission électronique. Une électrode supplémentaire 12 formant anode est insérée lors de la fabrication et disposée à proximité de la cathode 11. L'anode 12 est reliée à une sortie d'électrode 13, constituée par une broche disponible le cas échéant. Moyennant application d'une tension continue Vc entre cette broche 13 et celle 14 reliée à la cathode 11, l'ensemble 11-12 constitue une diode et la détection de courant correspondante est utilisée pour contrôler le fonctionnement du canon réservé. Comme il a été dit précédemment, le test peut s'effectuer sur la liaison extérieure 15 reliant une source continue extérieure à l'anode 12.A second version of arrangement of the tube makes it possible to locate the level control of the

Les cathodes du tube sont généralement de forme cylindrique avec le filament interne ; le cylindre est fermé à une extrémité et recouvert à cette extrémité d'un dépôt en matériau générateur d'électrons sous l'effet du chauffage. L'anode 12 peut donc être positionnée entre l'extrémité de la cathode 11 et la grille G1 pour être en vis-à-vis d'une zone émissive du dépôt. Toutefois, l'anode doit être conçue de faibles dimensions pour obturer le moins possible le faisceau d'électrons. En outre, il faut considérer que l'espace inter-électrodes entre les cathodes et la grille G1 est faible et il s'ensuit des difficultés de réalisation et d'implantation de l'anode 12 sur un trajet axial. Afin d'y remédier, le dépôt 20 est de préférence prolongé sur la paroi cylindrique de la cathode 11 comme représenté sur la Fig. 2 pour former une petite zone 21 en vis-à-vis de laquelle l'anode 12 est positionnée. La zone 21 peut également faire l'objet d'un dépôt séparé du dépôt terminal 20.The cathodes of the tube are generally cylindrical in shape with the internal filament; the cylinder is closed at one end and covered at this end with a deposit of electron generating material under the effect of heating. The

La version avec anode est préférable à la première version car elle autorise également, de façon indirecte toutefois, le contrôle du chauffage et le décèlement d'une coupure éventuelle de ce circuit.The version with anode is preferable to the first version because it also authorizes, indirectly however, the heating control and the detection of a possible break in this circuit.

L'utilisation conjointe des deux versions représente la solution préférée, en réalisant si besoin est des sorties d'électrodes supplémentaires correspondant aux broches de sortie 3 et 13.The joint use of the two versions represents the preferred solution, producing if necessary additional electrode outputs corresponding to the

La Fig. 3 représente une telle solution applicable notamment à un tube à masque perforé. Les circuits attenants se composent d'un circuit 30 générateur de la tension U d'alimentation des filaments, et des circuits vidéo 31, 32 et 33 respectivement pour les canaux rouge, vert et bleu. Chaque circuit vidéo comporte une sortie de polarité négative connectée à la grille de commande G1 et une sortie de polarité positive connectée à la cathode correspondante KR, KV ou KB. La tension de blocage entre grille G1 et cathode peut être par exemple de - 70 V et la sortie commune reliée au potentiel masse de référence. Les signaux vidéo respectifs sont transmis par ces circuits sur les connexions de cathodes. Le circuit vidéo du canal rouge comporte une seconde sortie de polarité positive, par exemple à + 100 V, connectée à l'anode 12. Les contrôles sont obtenus par exemple au moyen de transformateurs de courant 34, 35 placés sur les connexions extérieures 9 de chauffage du canon rouge et 15 d'alimentation de l'anode 12.Fig. 3 shows such a solution applicable in particular to a tube with a shadow mask. The adjoining circuits consist of a circuit 30 generating the supply voltage U of the filaments, and

La réalisation des circuits de contrôle 10 relève de techniques connues, ainsi que la réalisation éventuelle de sorties complémentaires 3 et/ou 13 dans le cas où le brochage du tube l'exige c'est-à-dire en l'absence de broche disponible.The production of the

Claims (7)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR8010247 | 1980-05-08 | ||

| FR8010247A FR2484697A1 (en) | 1980-05-08 | 1980-05-08 | POLYCHROME CATHODIC TUBE AND VISUALIZATION DEVICE EQUIPPED WITH SUCH A TUBE |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0040117A1 EP0040117A1 (en) | 1981-11-18 |

| EP0040117B1 true EP0040117B1 (en) | 1984-06-13 |

Family

ID=9241743

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP81400605A Expired EP0040117B1 (en) | 1980-05-08 | 1981-04-15 | Polychromatic cathode ray tube and viewing device equipped with such a tube |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US4433292A (en) |

| EP (1) | EP0040117B1 (en) |

| JP (1) | JPS579040A (en) |

| DE (1) | DE3164120D1 (en) |

| FR (1) | FR2484697A1 (en) |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR940000383B1 (en) * | 1991-09-19 | 1994-01-19 | 주식회사 금성사 | Stray Emission Prevention Circuit of Cathode Ray Tube |

| US5736861A (en) * | 1995-08-07 | 1998-04-07 | Paul A. Keleher | Circuit breaker tester |

| US9625067B2 (en) | 2009-09-01 | 2017-04-18 | Sea Ng Corporation | Clamp suitable for increasing the fatigue life of the butt welds of a pipe pressure vessel which is subsequently bent |

| US20200237622A1 (en) * | 2017-10-16 | 2020-07-30 | Eric Campos | Chambered dispensing devices and methods |

| CN113329710B (en) * | 2019-01-17 | 2024-11-19 | 奥林巴斯株式会社 | Centralized control device, centralized control system, and control method for controlled equipment |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3623135A (en) * | 1969-09-16 | 1971-11-23 | Gen Electric | Electron gun assembly mounting |

| NL7107749A (en) * | 1971-06-05 | 1972-12-07 | ||

| FR2261507A1 (en) * | 1974-02-15 | 1975-09-12 | Normand Equip Ind | Petrol pump dispenser and pricing device - has calculator connected to pump counting circuits |

| US4066311A (en) * | 1977-02-22 | 1978-01-03 | Heath Company | Multiple gun cathode ray tube testing, cleaning, and rejuvenating apparatus |

-

1980

- 1980-05-08 FR FR8010247A patent/FR2484697A1/en active Granted

-

1981

- 1981-04-15 EP EP81400605A patent/EP0040117B1/en not_active Expired

- 1981-04-15 DE DE8181400605T patent/DE3164120D1/en not_active Expired

- 1981-05-04 US US06/260,102 patent/US4433292A/en not_active Expired - Fee Related

- 1981-05-06 JP JP6709281A patent/JPS579040A/en active Pending

Also Published As

| Publication number | Publication date |

|---|---|

| JPS579040A (en) | 1982-01-18 |

| US4433292A (en) | 1984-02-21 |

| FR2484697A1 (en) | 1981-12-18 |

| FR2484697B1 (en) | 1982-06-11 |

| EP0040117A1 (en) | 1981-11-18 |

| DE3164120D1 (en) | 1984-07-19 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0040117B1 (en) | Polychromatic cathode ray tube and viewing device equipped with such a tube | |

| US4066311A (en) | Multiple gun cathode ray tube testing, cleaning, and rejuvenating apparatus | |

| FR2691567A1 (en) | Fluorescent display appts. for e.g. seven segment display - uses substrate carrying cathode, gate electrode and emitter covered with plate carrying anode and fluorescent material | |

| US4286148A (en) | Image intensifier tube with photocathode protective circuit | |

| EP0364346B1 (en) | Illumination box for an avionic display device | |

| US4571523A (en) | Fluorescent display device | |

| EP0567274A1 (en) | Hollow cathode discharge tube | |

| EP0044239B1 (en) | Microchannels image intensifier tube and image pick-up assembly comprising such a tube | |

| US4506191A (en) | Light source cathode ray tube | |

| KR100355504B1 (en) | Crt electron gun | |

| EP0678218B1 (en) | Method for visualising the intensity profile of a laser pulse | |

| CA1088989A (en) | Camera tube with auxiliary illumination | |

| JP2005158634A (en) | Display device | |

| US3986070A (en) | Pick-up tubes | |

| JPH03266342A (en) | Proximity type image intensifier | |

| JP2002334674A (en) | Fluorescent display tube and its drive method and drive circuit | |

| FR2517879A1 (en) | COLOR IMPURITY CORRECTION DEVICE FOR FLAT PANEL DISPLAY DEVICES | |

| US3459990A (en) | Voltage regulated direct view storage tube precollimation system | |

| JPH0383090A (en) | Structure for assembling display element | |

| US20050093423A1 (en) | Redundant flat lamp system | |

| US6486592B1 (en) | Integral night vision tube contact assembly and method of making | |

| KR910004353Y1 (en) | Noise protection structure of cathode ray tube | |

| GB1605140A (en) | Image intensifier devices | |

| KR20020056081A (en) | Cold cathode protection apparatus in the cathode ray tube | |

| US2734167A (en) | Testing device for cathode ray tubes |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): DE GB IT NL SE |

|

| 17P | Request for examination filed |

Effective date: 19811218 |

|

| ITF | It: translation for a ep patent filed | ||

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Designated state(s): DE GB IT NL SE |

|

| REF | Corresponds to: |

Ref document number: 3164120 Country of ref document: DE Date of ref document: 19840719 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19870430 Year of fee payment: 7 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19880416 |

|

| ITPR | It: changes in ownership of a european patent |

Owner name: OFFERTA DI LICENZA AL PUBBLICO |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: 746 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19881101 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee | ||

| ITTA | It: last paid annual fee | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19940321 Year of fee payment: 14 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19940326 Year of fee payment: 14 |

|

| EUG | Se: european patent has lapsed |

Ref document number: 81400605.2 Effective date: 19890726 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19950415 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19950415 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19960103 |